Heat loss from added pole barn

I’ve been burning a central boiler 5036 for about 5 years now to heat my 1300 square foot home. I have an existing oil furnace that acts as a holding tank for hot water. I’ve only had to fill my boiler 1 time a day even in single digits. I recently added in a 2400 square foot pole barn with radiant in concrete pad. Spray foamed and insulated very well. Since then it seems to be draining the heat from my boiler. When the barn is calling for heat it’s dropping my boiler water sometimes as low as 130 degrees and I’m now filling my stove almost 3 times a day and that’s running the barn at 60 degrees. (I understand it’s a huge area but didn’t think it would be that hard on the stove) NOW my question is am I being Delusional about this and that’s just reality and also can I add an old water heater in the barn to act as a standby when called to help with the heat loss or any other options would be great. Thank you

Comments

-

A heat loss calculation for the barn would have, should have been your first step. You would need to do a heat loss calculation to size the heating plant properly.Do a heat loss calculation for the space you wish to heat. This will give you the information you need.

0 -

Pole barns are meant to be cheap outside storage, making it into anything efficient is near impossible. There are a lot of myths out there. One of them is somehow spray foam is magical and you will use no heat. R value is R value, doesn't matter what you use for insulation. Pole barns also tend to have large thermal bridges especially if metal structure.

Since the structure is there, there isn't all that much you can do, heat loss is what it is. Depending on how the heated slab was built, sometimes abandoning it and going for shop heaters can save a lot of cost. The shop heaters also only need to run when you are in there, so you won't have to keep the place warm all the time.

3 -

First off, is your forest eater an open to atmosphere system or closed?

Are the home and pole barn plumbed as one continuous loop or is the home set up as a separate heating loop or is there as second circulator for the pole barn?

Did you install a vapor barrier under the slab?

Did you insulate the slab and perimeter foundation of the pole barn??

What is the spacing of the of the pex in the concrete floor?

Did you keep the ends of the loops 6 inches away from the ends of the slab?

What is the ceiling height of the pole barn?

It all comes down to the amount of thermal mass you have. if you have a thin slab concrete slab you do not have a great deal of mass to store heat in. The heat transmitted through the pex to the slab will cool quickly because there is less and less heat delivered by your circulator or circulators that are pushing hot water to your home.

Short of filling your forest eater half full with standard fire brick to increase your thermal mass you will gain nothing.

Another option would be to change fuels by using a coal stoker boiler and filling the forest eater completely with standard fire brick and caping the stack to keep the heat in.

Alternate heating systems makes an outdoor coal stoker boiler that uses Pea Anthracite Coal for fuel

An electrician that works at a Montana coal mine eliminated his forest eater and placed an AHS S130 coal stoker boiler in its place building a shed to protect it and also store his coal out of the weather and he uses Montana mined Sub Bituminous Coal to heat his home and domestic hot water.

0 -

-

Not all pole barns are equal. I did radiant heat systems for a number of pole barn manufacturers in Missouri.

The key and challenging detail is the slab edge insulation, although the same issue as slab on grade framed homes.

We developed a Z flashing to cover the exposed edge of 2" foam used around the edge perimeter.

As some pole barns are built to the entry level price range, when using radiant there MUST be a good foam under slab detail used. 2" is the norm.

If the pole barn is insulated properly, the heatload should not be unlike a framed home.

I suspect in many areas pole barns are not held to the same building code requirements as homes. I've seen plenty insulated with just a 1" vinyl faced roll insulation in walls and roof, so very low R-value.

If you OWF is an open type you should have a heat exchanger between it and the backup boiler.

Are you adding corrosion inhibitors when you refill the OWF?

As noted, your wood and water consumption tells the story of the pole barns efficiency.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Adding water will do nothing for you. Simply put, the heat load is higher than the boiler can produce so either you need to make adjustments (insulation, air infiltration, underground lines, indoor piping, wood supply, or any combination thereof) or you need a bigger boiler.

0 -

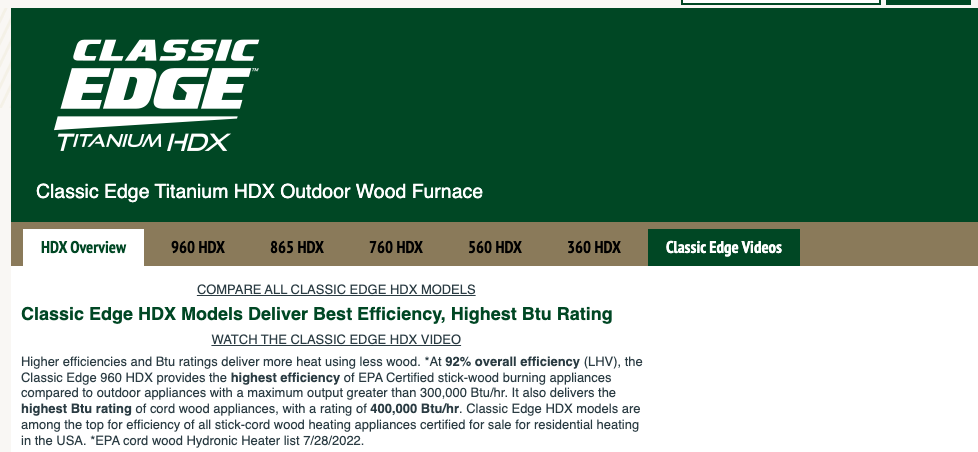

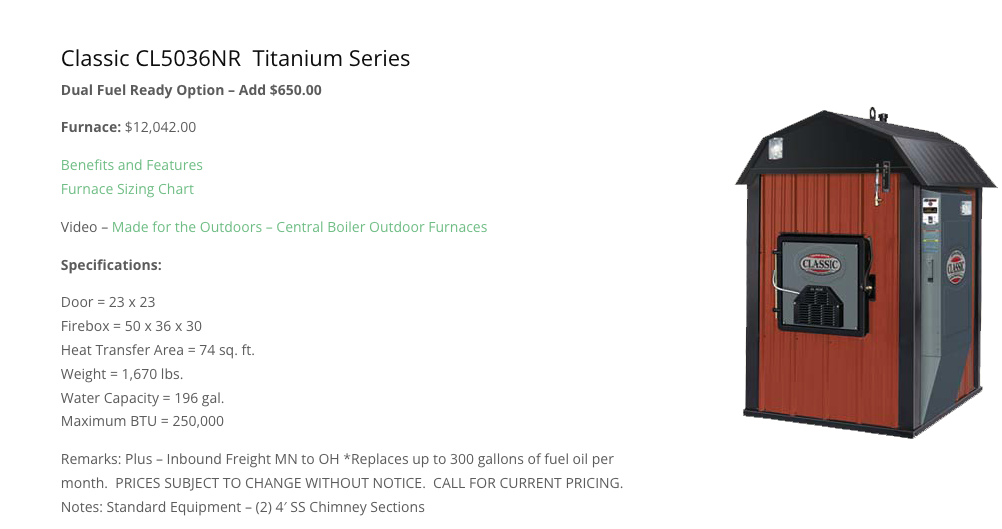

I looked online and couldn't find a BTU rating for that boiler, the best I could find is this page:

Which says it "Replaces up to 300 gallons of fuel oil per month." So that's 10 gallons per day. At 85% effiency a gallon of oil yields 96,000 BTU, ten gallons per day is 47,000 BTU/hr.

That doesn't seem like a lot of BTU for the amount of space you're heating.

You don't say how much wood you're burning, but on their website they have a calculator that shows a cord of red oak is equivalent to 139 gallons of oil. So burning at that top output would equate to a cord every 14 days, or every two weeks. If you're burning less than that your output is going to be less.

0 -

-

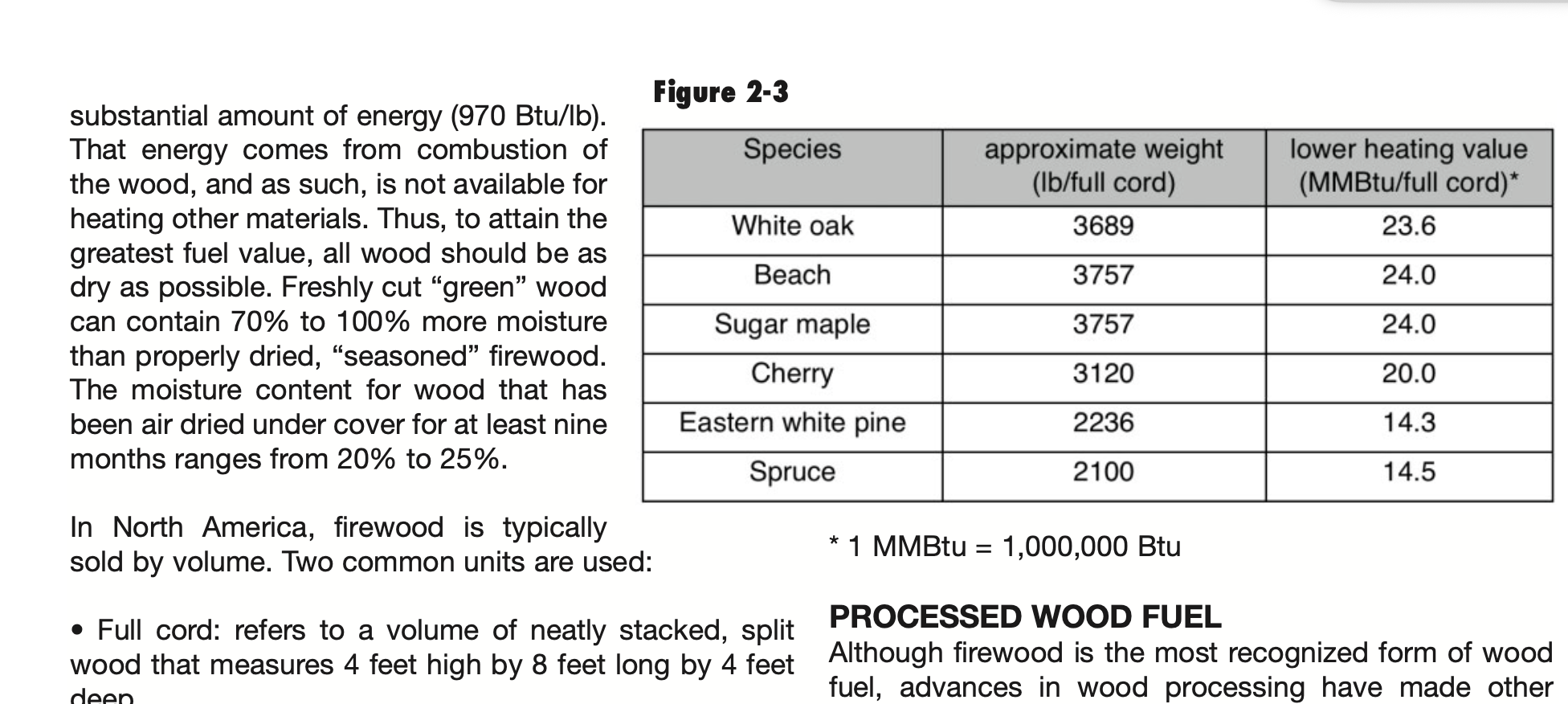

Missing from those OWF wood usage predictions are the quality of the wood, moisture content, and that it is burned at high, gasification temperatures.

So dry, aged hardwood would be the fuel for optimum performance.

Often wet, green, or too large of diameter wood is shoved in them. Unless wood is split down to 4 or 5" diameter the core will not air dry to a low moisture content

Studies years ago showed about 40 - 45% efficiencies in common OWF.

Some wood burners will swear that green or wet wood gives you more btus, than dried wood.

That is not quiet the case.

Diehard wood burners own and use a moisture meter to check the condition of their wood.

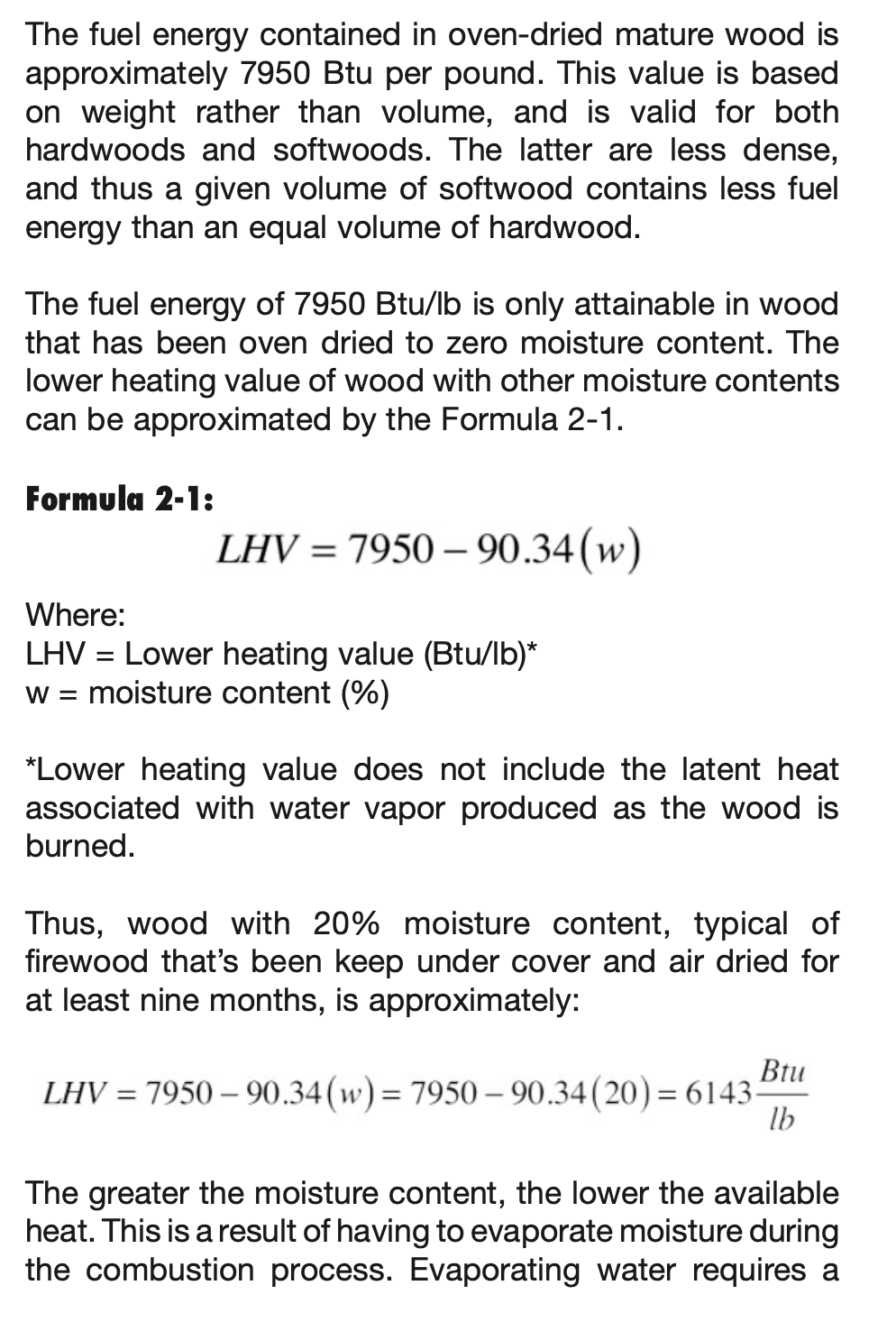

Some numbers, for crunching, here.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

Output number vary based on the version of the 5036.The HDX shows 400,000, the NR at 250,000

I wonder what size oil gun the offer for the dual fuel?

o

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I guess lining the floor and walls of the of the boiler with standard fire brick and using a fireplace coal grate and burning some Stove Anthracite Coal to get more heat is an option.

0 -

"So burning at that top output would equate to a cord every 14 days, or every two weeks."

A cord is 4,000 lbs, give or take. Feeding the firebox three times a day would be 42 feedings in 14 days, or about 100 lbs per feeding if you're doing a cord every two weeks. Sounds about right.

0 -

The 5036 is a non-gasification conventional turd with about 30% combustion efficiency using dry wood. They actually do a little better with wet/green wood due to the lack of heat exchanger. There is no such thing as an HDX (gasification) model of 5036. CB rates the BTU output at 250k/hr, but that's the first hour not continuous output. I have come to find in the real world with average 20-25% MC hardwood, continuous output of a 5036 is approximately 125-150k/hr which should cover this load, but something as simple as waterlogged underground lines can easily suck up 100k in a long run and this is an extremely common issue from folks who didn't want to spend the money on good underground lines such as Thermopex that comes from Central Boiler. The only way to know for sure is to start running some diagnostics (temp readings, head loss calcs, etc) to find out where the BTUs are going.

1 -

-

An infrared camera is a useful tool for finding heatloss in buildings, piping and trenches. Even the phone adapter type work well enough for finding heat loss.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements