riello f5 burner not firing

sputtered shut down would not restart

replaced filter, nozzle cleaned screen on pump … still would not fire .

checked power, fuel from tank … all good .

checked capacitor was supposed to be 12.4 micro farads mine tested at 9 …. therefore replaced. …. still would not fire … replaced control box still would not fire.

replaced fuel pump still would not fire. replaced electrodes still would not fire

replaced solenoid … still would fire, replaced nozzle again thought maybe I contaminated still not firing …

fan motor will run when jumping 5&6 …..could it still be the motor?

any help appreciated

Comments

-

Call a competent pro experienced with troubleshooting and setting up combustion on a Riello burner. Especially if you don't have the correct vacuum and pressure gauges (with adapters), and a combustion analyzer, and smoke tester-and know how to use them. When you replaced the pump, what was the existing pressure and did you set the same pressure on the new pump?

If you knew what you were doing you wouldn't have had to replace all those parts.

I've been fixing burners for over 35 years, I've never replaced all those parts on a Riello. Probably a dozen boxes, a few motors, 1 set of electrodes, a few motors, a few solenoids. Components rarely fail and are easy to check.

You probably haven't properly bled the system, have a vacuum leak or restriction, and/or don't have combustion set up properly.

If it ran when you jumped 5 & 6, it's not the motor.0 -

-

You have replaced so many parts it difficult to say what is going on.

Does it try to start and go on lockout?

Or it doesn't try to start at all?

0 -

tries to fire but does not .. initially before replacing capacitor fan motor would not run even if jumped across 5&6 …. now motor does run when jumped ….

0 -

You have to check/confirm with pressure gauge. As mentioned, you MUST get a competent tech experienced with Riello burners. It would’ve been a lot cheaper than replacing all those parts.

0 -

Since you changed the motor and the pump you probably missing either spark or fuel.

Maybe disconnect the nozzle line from the pump and see if you're getting oil and check for spark. The electrodes have to be set right.

AS @HydronicMike mentioned you're in this pretty deep. You really need a tech with the correct tools and a combustion analyzer

Your oil supplier must have a tech or know of one if your buying oil from a company with no service.

0 -

-

0

-

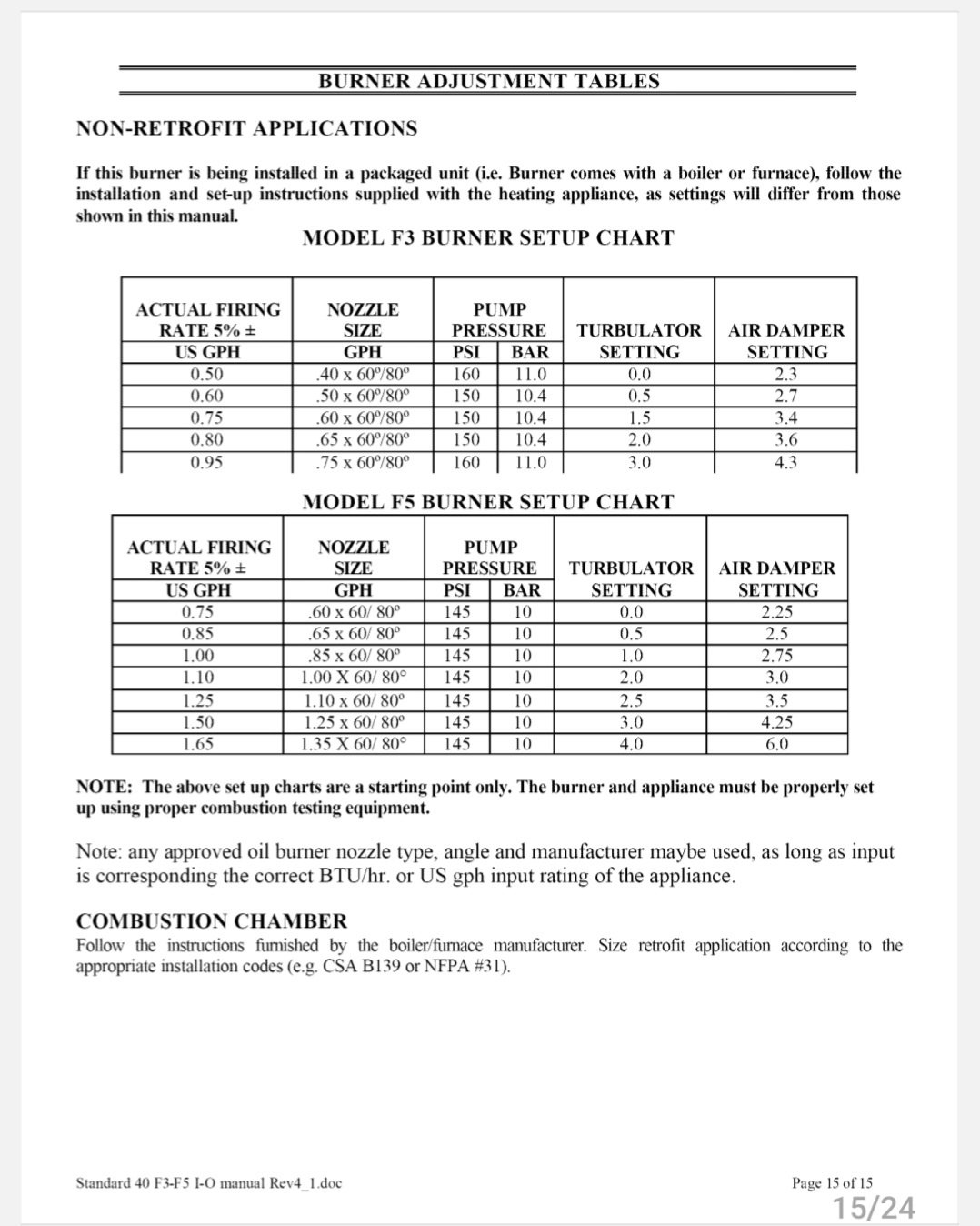

Pretty close to Riello retrofit specs.

Do you have Riello pressure and vacuum gauges? Is there atomization in the chamber? Have you looked down the air tube? Giant coke ball sitting in there?

0 -

Tries to start ? Just a flash then locks out ? Try a .75 60 W instead of the B . It could be the mix of the fuel oil .. Years ago we had a standard … I only use W now…

There was an error rendering this rich post.

0 -

-

I'm with rick. you won't go broke betting on fuel problem with riello. haven't experienced coupler failure myself but iirc the couple is a nylon D that could give up. but given all the parts replacement and depending how high the level of oil in your tank compared to the burner and whether the supply line goes overhead I also wouldn't be surprised if you have lost prime. maybe you don't mention and you have been bleeding clear on these retrials but are you checking for solid oil flow at the bleeder? I have had more trouble with the air on one riello than on hundreds of other burners in my experience. it did have an up and over oil line although it was well terminated with flare connections and the burner was about even with the bottom of the oil tank but I could never get that thing to prime and I could never identify a source of air. i put in a tee with valves in the oil line right before the boiler and I would run it out of a five gallon can and then I would partially crack the valve to the oil tank so it was still getting plenty of oil out of the can and it would start to draw on the tank line and then slowly over five mins I would close off the 5 gallon can and fully open the line from the tank. and then it would run a few months and air up again. my conclusion was, always two pipe riello. no problems since. maybe a tiger loop would have worked but I was so damn frustrated with this thing, i ran the second pipe and never (fingers crossed 5 years later) had another problem.

but could we catch a breath and go back to the beginning. you started with it sputtered but wouldn't light before you replaced anything iirc. i presume that the boiler had shut down and you mean it sputtered but wouldn't light when you reset it?

i'm a little confused that you later say the fan wouldn't run until you replaced the capacitor because if the fan wouldn't run that's the same motor that runs the pump and it shouldn't have sputtered (you might have heard buzzing of ignition but i wouldn't call that sputtered. or did the symptom change as you went through the various replacements and trials?0 -

-

I've been working on Riello burners since the Mectron series was common. I don't think I've ever had to replace the nylon coupling (Pump Drive Key). I don't gamble, other than slots once every few years maybe, but I'd bet the ranch that the coupling isn't the culprit. A professional might know if they happened to walk by the burner one day.

0 -

sputtering and subsequent shut down happened when the temperature dropped outside and burner was on for longer periods

fuel from tank checked… no blockage .275 gallon tank 3/4 full

line was removed from tank to burner blew out both ends also blew into the tank … no blockage

at this point motor wold not start even when jumping 5&6

checked electrical connections and specs with multimeter discovered that capacitor was out of range replaced after replacement would now start when jumping 5&6 . but when control box was in place solenoid would not open to disperse fuel….. replaced control box … now motor would start with control box in place ..solenoid would open tries to fire but does not ….fuel was coming through but not forcefully .

replaced pump…. now have fuel coming through pump at bleeder forcefully … no air

It appears to me from comments that I need to verify pressure and vacuum and quality of fuel.

thank you

0 -

figured out the problem. There pump was not fully bled of air

now works perfectly.

0 -

a costly lesson in riello. it is true that you need some training and instrumentation to take good care of these but it is a pretty logical process and I don't think it is at all wrong for the owner of one of these burners to want to understand and maintain their operation. for what you spent on parts you could probably have bought the instruments needed (maybe not quite get you a combustion meter but if you weren't changing the nozzle specs or air settings, plug and play on components shouldn't require a new combustion setting although it is always a good idea to insure the flame looks regular and does not exhibit excessive smoke and the ability to check this visually is not as readily available on many boilers as it once was)

you didn't actually need any instruments to bleed the air but sometimes you need an act of god. I should have lead with this which was buried in my post: "I have had more trouble with the air on one riello than on hundreds of other burners in my experience. "you never answered in what circumstances it stopped in the first place. maybe there was a bad part but maybe it just aired up to start with.

that is why i recommend running these two pipe unless the bottom of your oil tank is notably above the level of the burner and, in any event, if the oil line goes up in its pathway above the bottom of the tank requiring a lift at least at some if not all levels of oil in the tank to fill the line if you run out of oil or this can exacerbate the effects of a small air leak leading to the same result.1 -

It first started spitting shut then shut down. I followed steven lavimoniere diagnosis

discovered that capacitor was out of range not getting adequate spark. The burner was do for a rebuild anyway. It was manufactured in 2011. The total cost for all the parts I replaced was $300 for oem riello parts. Most of the burner guys I have spoken to locally only deal with becket or carlin. They were all telling me it was sludge in my tank and would charge $200 to blow out with a CO2 cartridge. I quickly discovered that was not the problem. by disconnecting the entire line and blowing out both ends with compressed air .

I also created a mechanism to blow out the bottom of the tank with an old general filter blowing compressed air through the small vent hole.

I never allow the oil level to drop below a 1/4 tank. The tank was replaced 5 yrs ago .

I went through the diagnosis and repair process step by step from easiest and less costly finally ending up with the pump….. .

It is now running beautiful ….no smoke fires up consistently. I will verify pump pressure when I get a riello namometer or find a oil technician who has one.

thanks for your help

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements