Steam In Return

I am having an issue with water hammer in a two pipe steam system. A month ago, we had a pin hole in our return pipe and had it replaced. Since then I’ve had water hammer in the return pipe and the return pipe is as hot as the steam main near the boiler. Leads me to believe steam is getting into the return pipe.

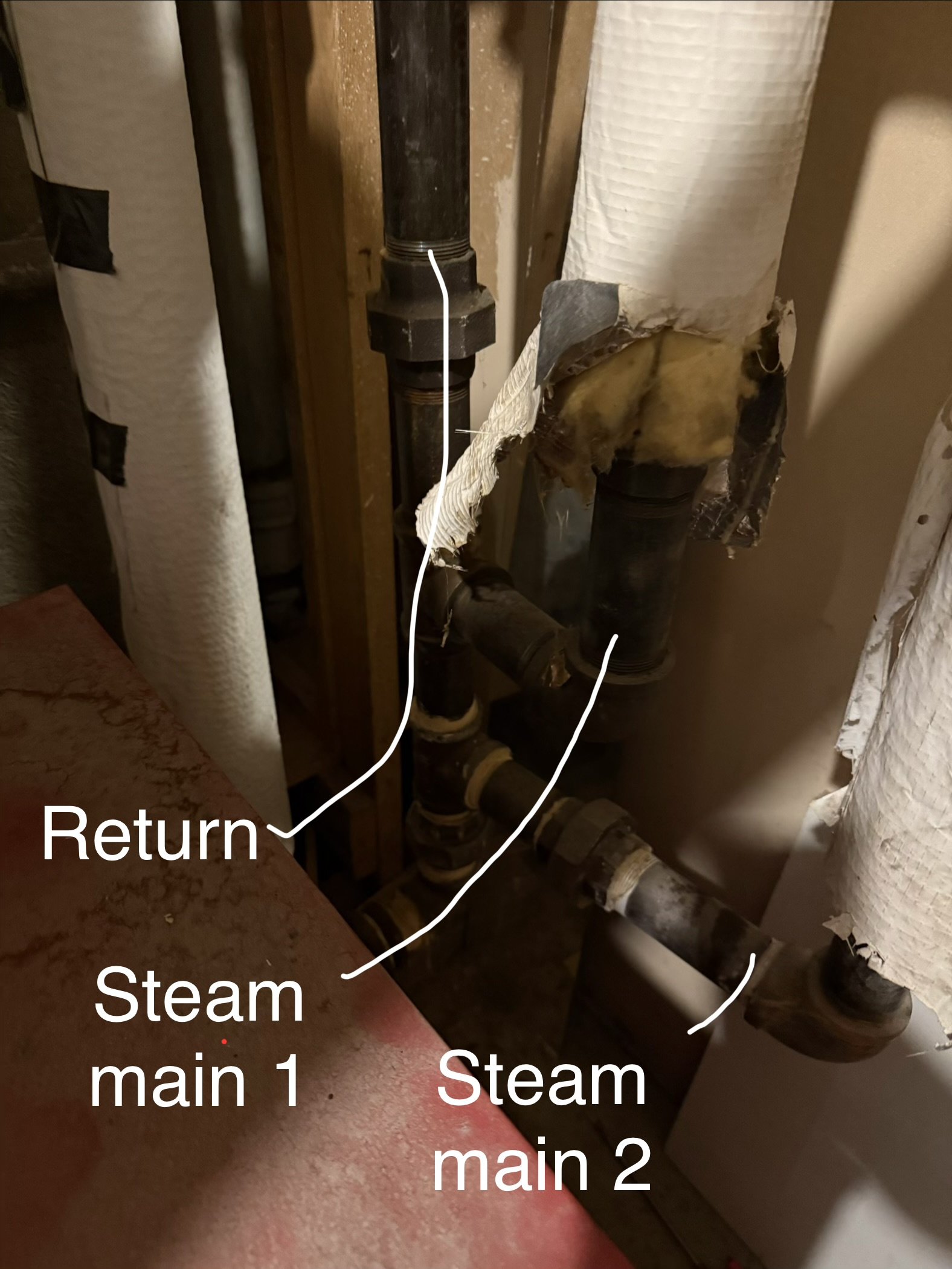

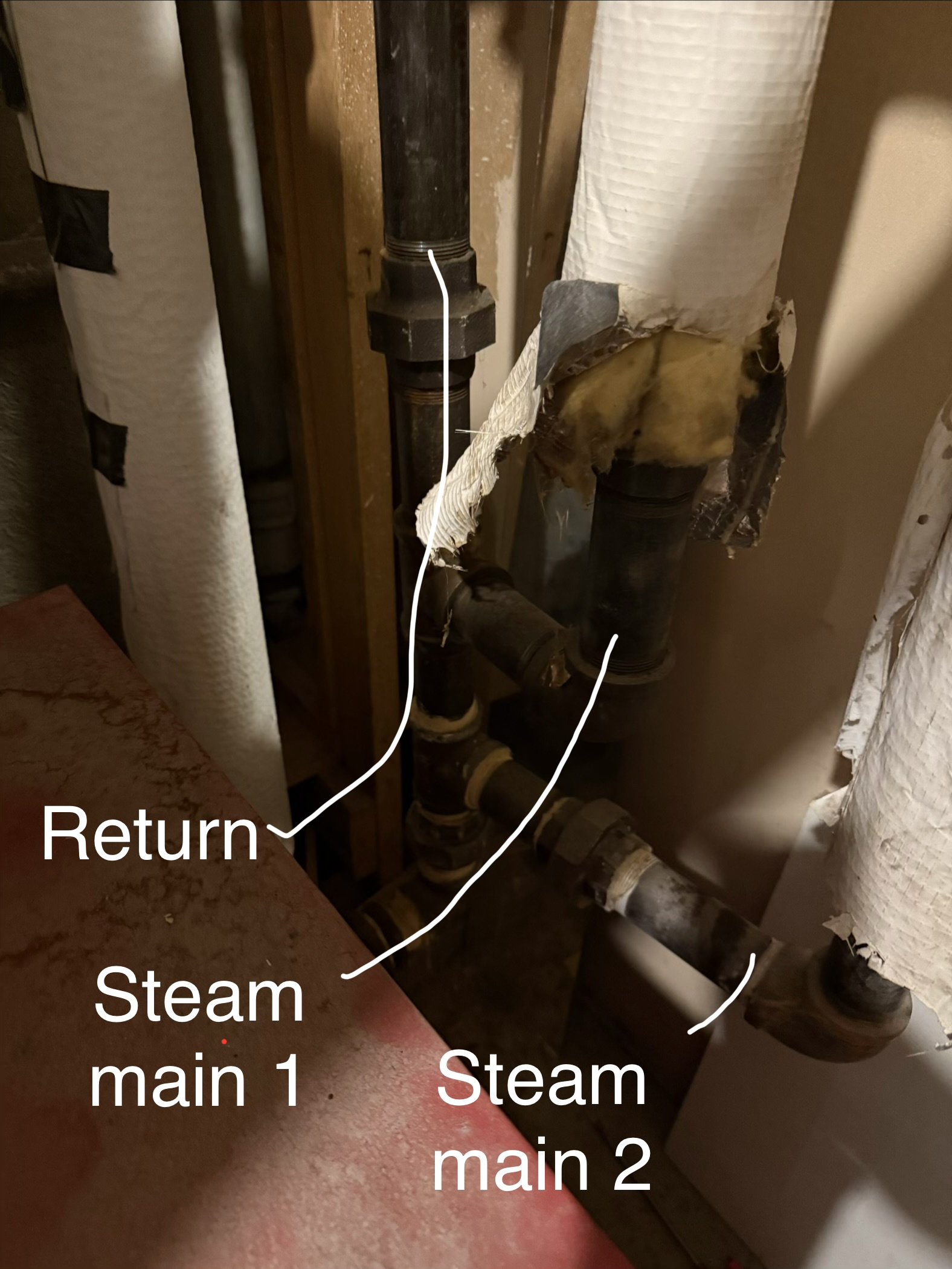

Here is the bear boiler piping:

I don’t see an F&T trap or anything to prevent steam from getting into the return. The return pipe plumbing seems odd to me as well.

We didn’t have hammer until a section of return pipe that developed a pin hole was replaced.

Having a technician come out next week and I’m hoping to get this issue identified so I can have it fixed.

Any insight is greatly appreciated.

Comments

-

The way that collection of fittings and pipes is put together is a bit odd — and there must be a good deal more piping. However, given what is shown, the pipe labeled "return" isn't one. It is directly connected to two pipes labeled "steam main" and is thus a steam main or, possible, a "steam main extension".

Can you provide a few more pictures showing a more general view of the boiler and the near boiler piping, and at least one radiator — both ends — and how the radiator steam runout and return lines are connected.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

Video tour of boiler piping:

0 -

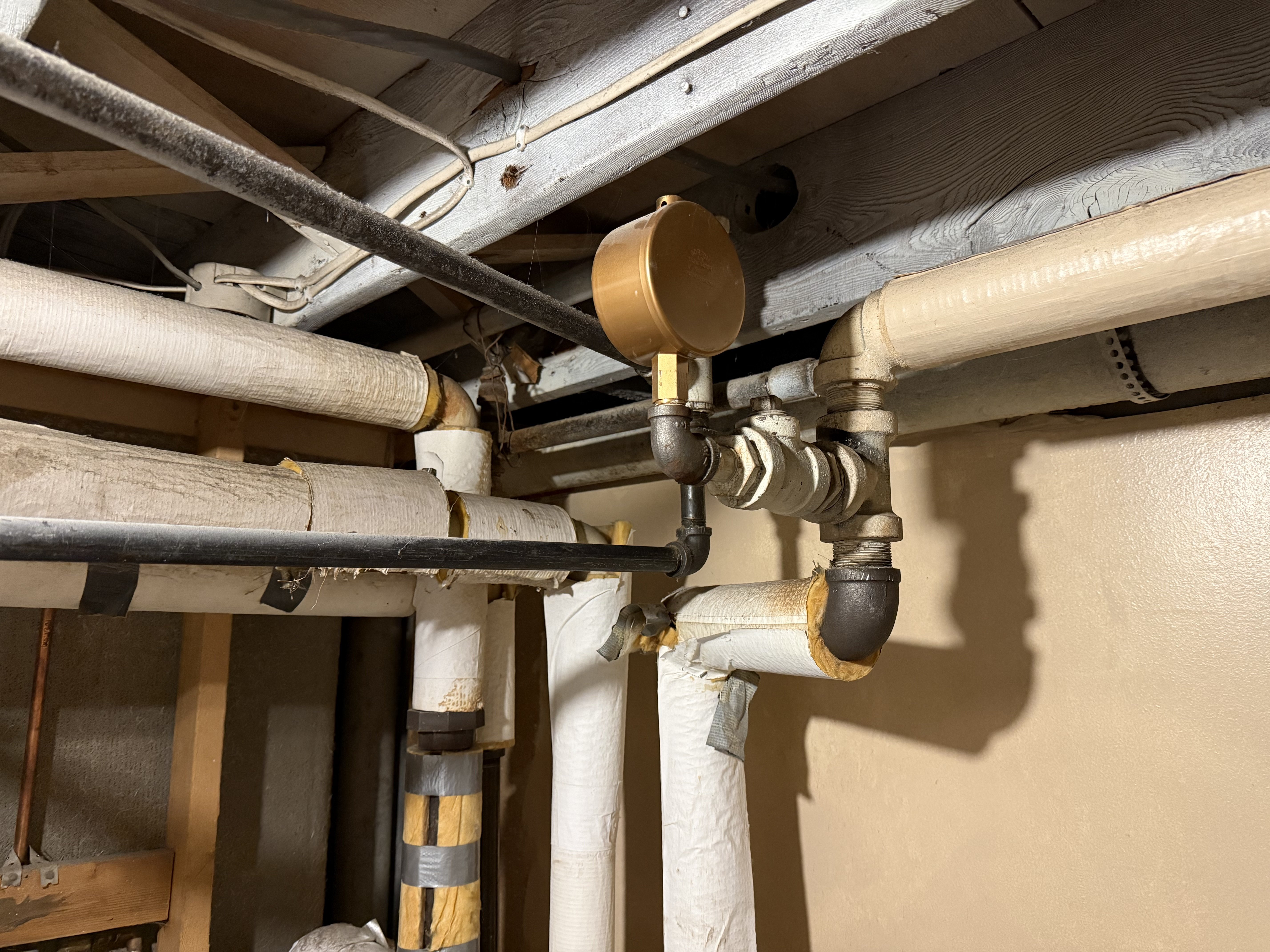

weird valve or petcock on top of return line tee above boiler.

Return line running beside a steam main leg.

0 -

Oh brother. From the look of the radiator and another odd fitting, I'm thinking this may have been, once upon a time in the dim past, a Paul system or some other vacuum assisted system. It isn't any more…

More to the point, however — and on a rather cursory look — you do have one steam riser, and a header, and one and only one steam takeoff from the header — that pipe about midway in the video which has the insulation more exposed (yellow checkerboard affair). The other lines you are pointing out are most likely all dry returns, and shouldn't any of them have steam in them.

Again, on a very cursory look, what may be the problem overall is that the water level in the boiler is lower than where those dry returns come into the boiler — which does allow steam into them.

Now. On that radiator, there is an inlet valve on one end, whicih should connect back to the checkerboard pipe. There is a trap at the other end, which should connect to a different pipe which should connect back to one of the three lines which you are referring to as steam mains.

Could you wander around the basement and identify which pipe all the radiator feed lines connect to, and then see how they trace back to that one lonely steam main — that checkerboard pipe? And then identify all the radiator return lines and trace back to one of those three return lines which you are identifying as steam mains?

The pipe or pipes which carry steam from the checkeboard pipe to the radiator inlets should NEVER be connected ANYWHERE to the pipe or pipes connecting to the radiator outlets, except possibly through what are called "crossover" traps — but we'll cross that bridge when we get to it.

I am suspicious of a problem with the water level in the boiler, or rather the accrual elevation of the boiler…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Thank you for the reply.

The two pipes that run around the basement are not connected to each other except directly above the boiler where the smaller lines come into a Tee then drop down into this assembly:

Steam main 1 and 2 are the ends of each of steam legs/mains that come off the boiler so I likely have wrong terminology in my labels.

I will get another video made up which gives a walk around of the piping in the basement.

0 -

Steam boiler pipe tour video:

0 -

Thank you! I think we are making headway here.

You have — quite correctly — identified the mains and the returns out in the wild so to speak.

That odd petcock thing on the returns where they join did, once upon a time, go to an extractor or maybe even a proper vacuum pump. Don't worry about it. What does need to happen is to have a good big vent or two installed there — probably two Gorton #2s would be appropriate. There will also need to be a vent — another Gorton #2 — on the end of the real steam main before it makes that drop.

Now to the problem of steam in those what we now recognize as returns. As you note, shouldn't be there. The pipe dropping from the end of the steam main is needed — it's the condensate drip from the steam main — BUT it should join those other pipes coming down well below the water line of the boiler, and I'm going to be that if you check you may find that in fact it joins above the water line. That is a much smaller boiler than was in there originally, and the old boiler's water line might easily have been a couple of feet higher.

What happens, I think, is that steam whizzes happily around the steam main — zips down that pipe and then zips right back up again into the return lines. Where it shouldn't be. The simplest and most reliable way to remedy that is going to be some repiping, but not much. Take the two lines which you idebtfued as stean naubs initially, join them together. Drop them all the way to the floor. Take the third line, which comes down from the steam main proper and also drop that to the floor, then join the lot of them together and bring them over to the Hartford Loop and return to the boiler.

You mentioned, by the way, something about an F&T trap. There is no need for such a nuisance…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

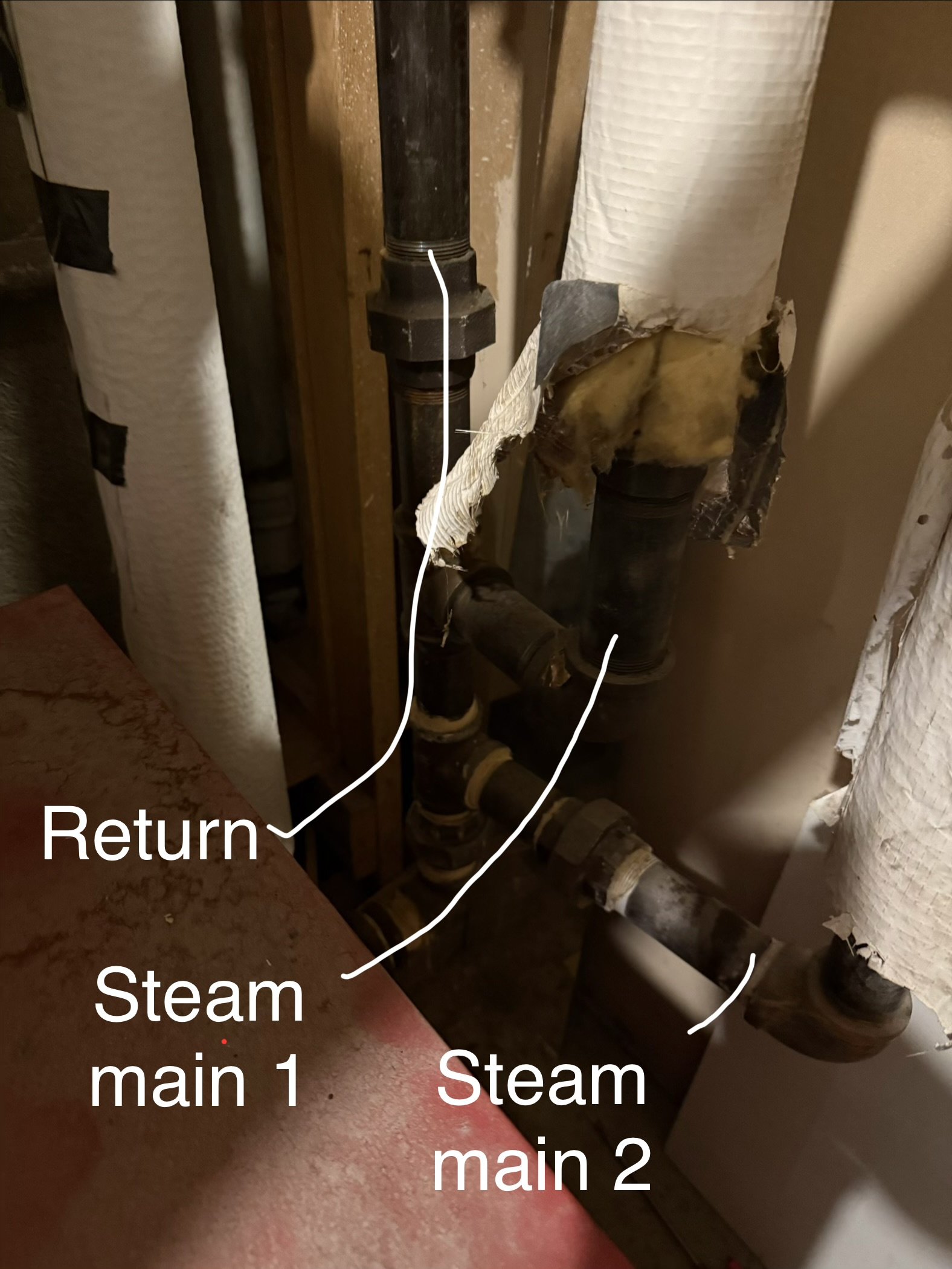

There is a vent on one of the steam mains here:

The other steam main/leg has a plug where a vent use to be I’d wager:

Going to have that plug replaced as I couldn’t get it off with a 36 inch wrench.

Thank you for your help!

0 -

Just spoke to the guy who helped install the current boiler and he confirmed that the old boiler was much larger and that they just tied into the existing piping.

Going to get the tech coming out next week updated so I can get an estimate for redoing the piping at the boiler next spring.

For the short term, if I fill the boiler just past the top mark on the boiler, the hammering stops.

I’m hoping to not have to scrap this system as it adds a lot of character to this house, but finding someone to work on it has been impossible until two months ago. Have to pay out the nose for trip charge as tech comes from 120 miles away, but it’s worth it to me.

0 -

That big vent on the steam main is a Gorton #2, so now you know what to get.

Is the plugged vent opening on the one steam main farther from the T where the two steam mains connect than the part with the Gorton?

Also, replace that petcock with a Gorton #2 as @Jamie Hall said. That's what vents air from the radiators, via the radiator traps.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

Oh no. You won't have to scrap it — just a few tweaks here and there will get you good! And your comment on what happens if you raise the boiler water level really makes me think we are on the right track here.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

The distance of the plugged vent on the other steam main is 2 inches further from the Tee or tie in than the current Gorton.

0 -

trivial. Of no cosequence.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Want to ensure I understand action plan for repiping at the boiler:

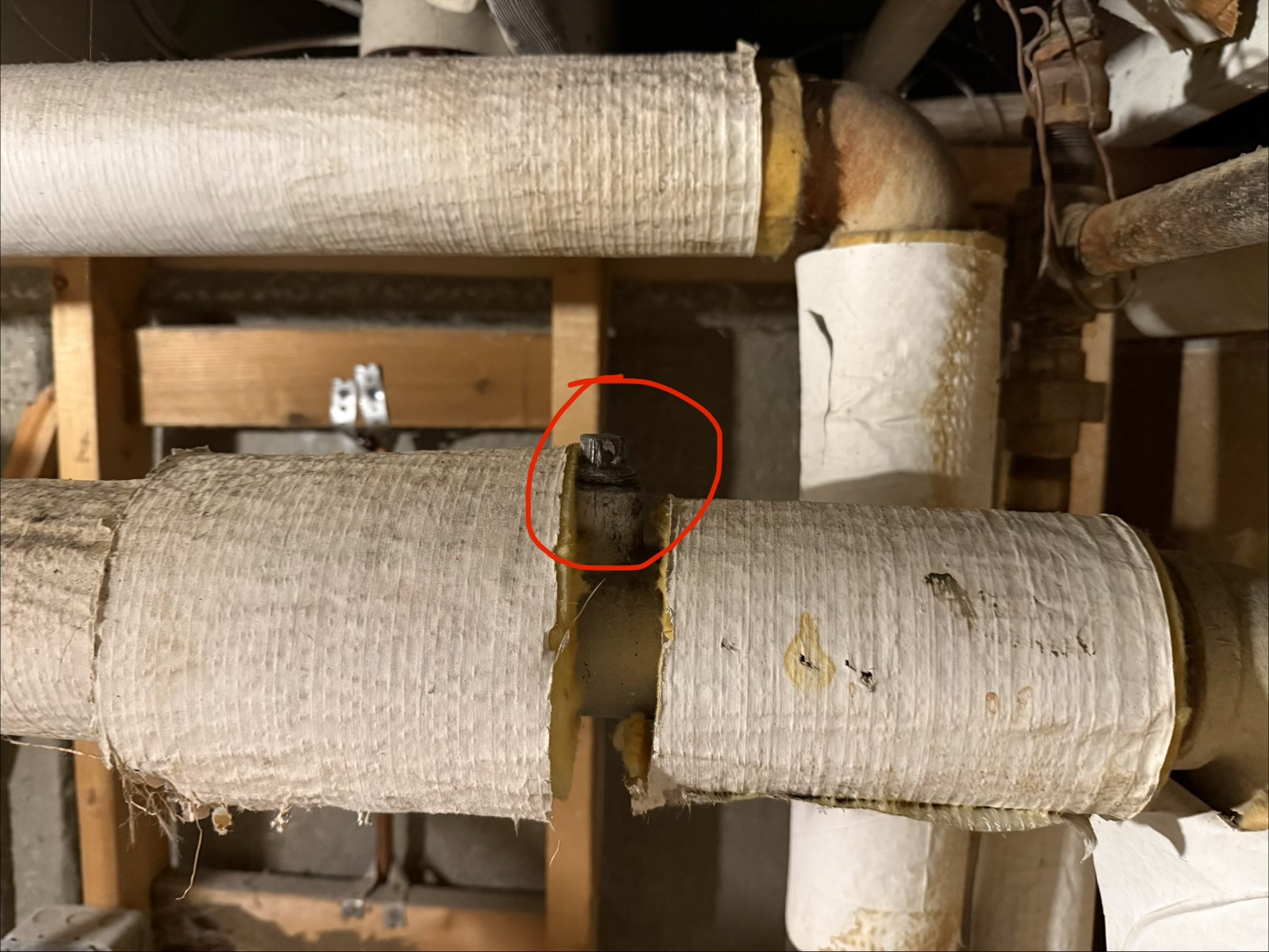

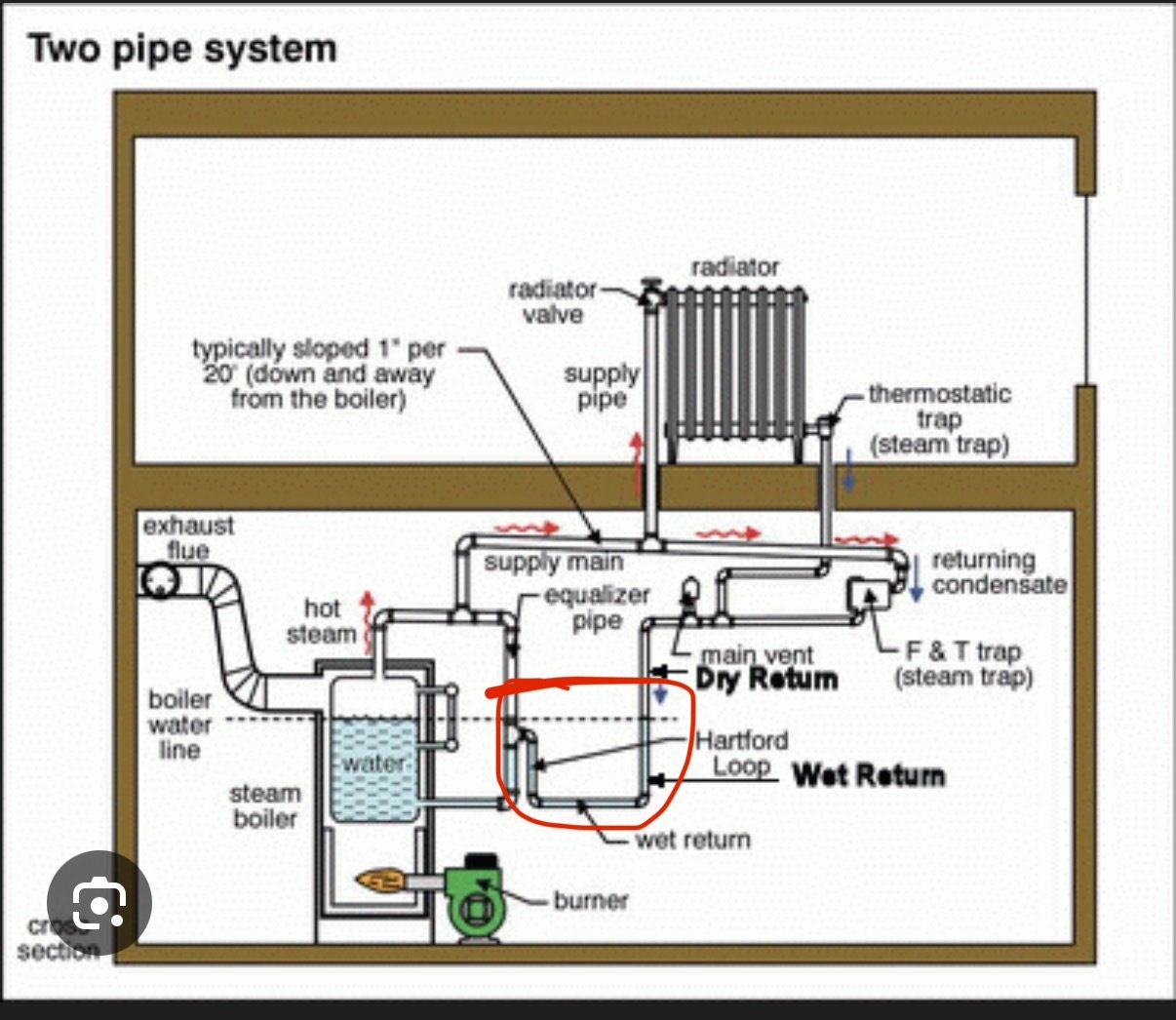

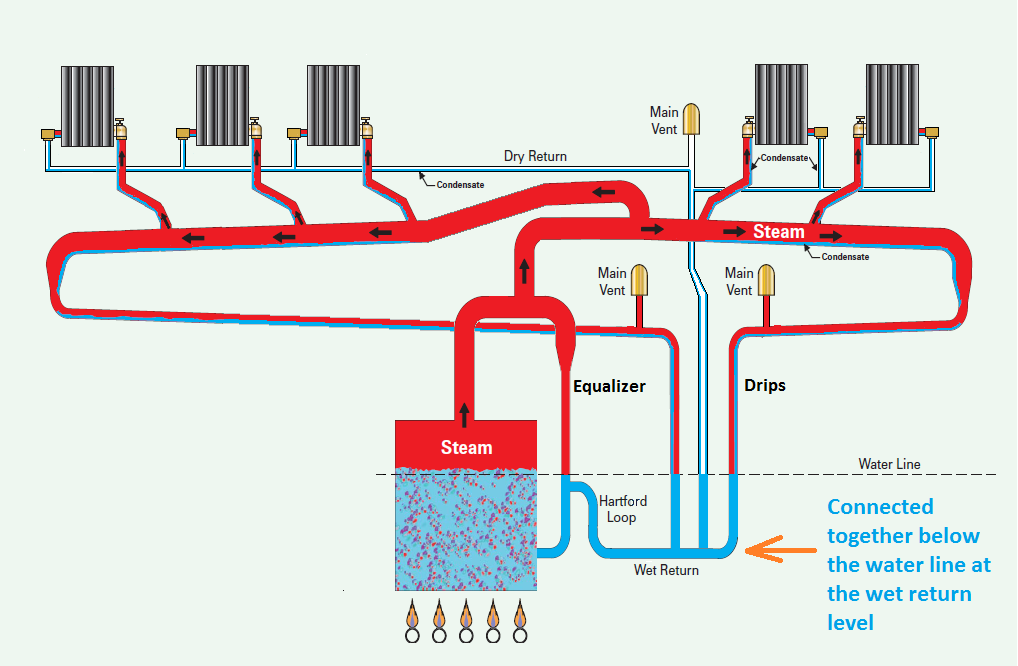

Steam main 1 and 2 are the end of each of the steam legs and need to be joined together and brought down to the floor and then back up into the boiler like in this diagram:

The red circled portion is where, on my system, currently ties into the boiler above the water line.

What should be done with the line labeled return in the first picture? Can it be left as is or does it need repiped as well? I’m thinking it could be tied into the two mains half way to the floor or is that wrong? Merging the return (the two smaller pipes that are connected to the traps on the radiators) with the two stream mains would still allow steam in return without something like an F&T trap?

Many thanks for all the input!

0 -

all of the connections from the mains to the return must be separate for each main and connect below the water line. they can connect to the same return as long as they drop below the water line first. the water prevents the steam from being able to get to the return. in fact the riser from the return likely remains filled with air so steam does not generally get down the riser since there is no place for that air to go because the water in the return is blocking it.

the connections from the dry returns to the wet returns may combine before they go below the water line.

higher differential pressure will push the steam from the mains through the water seal and in to the returns, that among other reasons is why controlling the pressure to a few oz/in^2 with a vaporstat is important.(also if you have radiators with vapor valves and no traps it keeps the steam from blowing through the radiators and in to the returns but you seem to have traps on your radiators).

if someone increased the pressuretrol/vaporstat settings that could cause this to be a new problem.

0 -

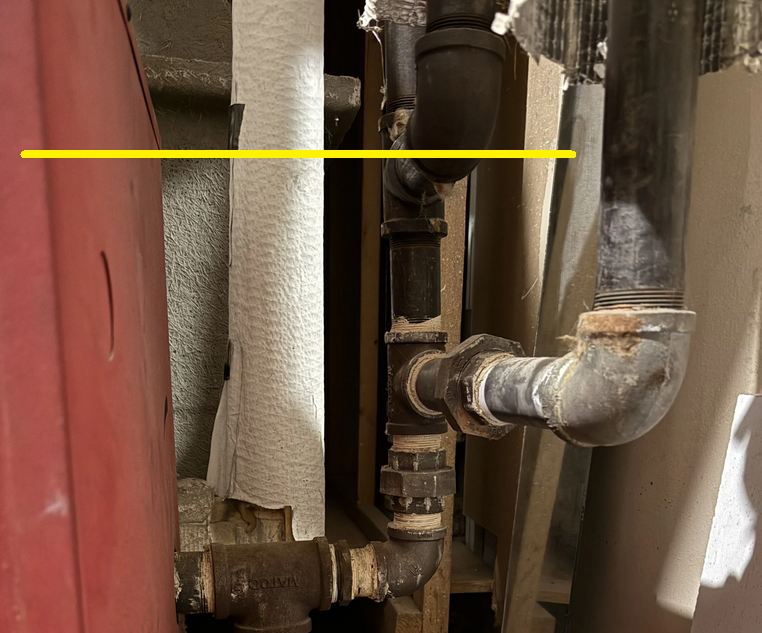

This is my largest issue, both steam mains connect to the return at the boiler above the water line of the boiler:

Red horizontal line is water line of the boiler, 1 and 2 are the ends of each steam leg. The previous boiler was larger and likely had a higher water line per some digging and talking with guy who helped install the current boiler.

I don’t believe the piping was correctly adjusted for the smaller boiler and lower water line.

0 -

whoever installed that boiler should have brought those down to near the floor before tying them together. if it is a vapor system there may be some differential pressure control device that is now missing as well although a vaporstat can usually make it work without it.

that isn't a correcting for the new boiler that is just steam piping 101. if there is something out in the system somewhere that was below the water line that no longer is, that is a failure to evaluate the system when replacing the boiler and a consequence of a boiler with a lower water line.

this piping was installed with the new boiler, anyone that knows steam knows they have to drop those below the water line before connecting them together.

0 -

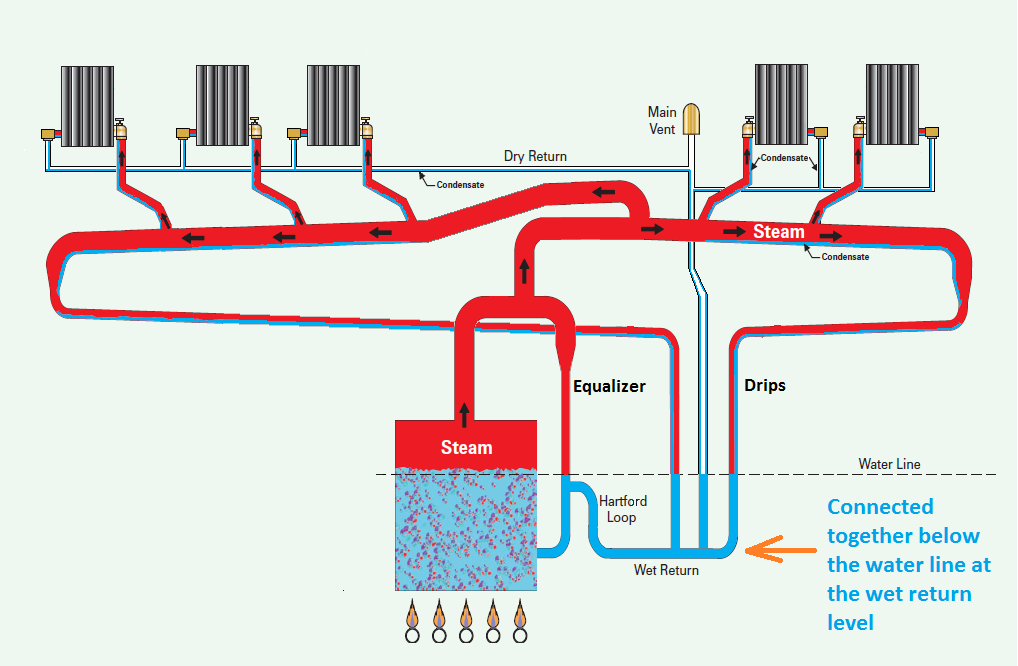

The way I see this system;

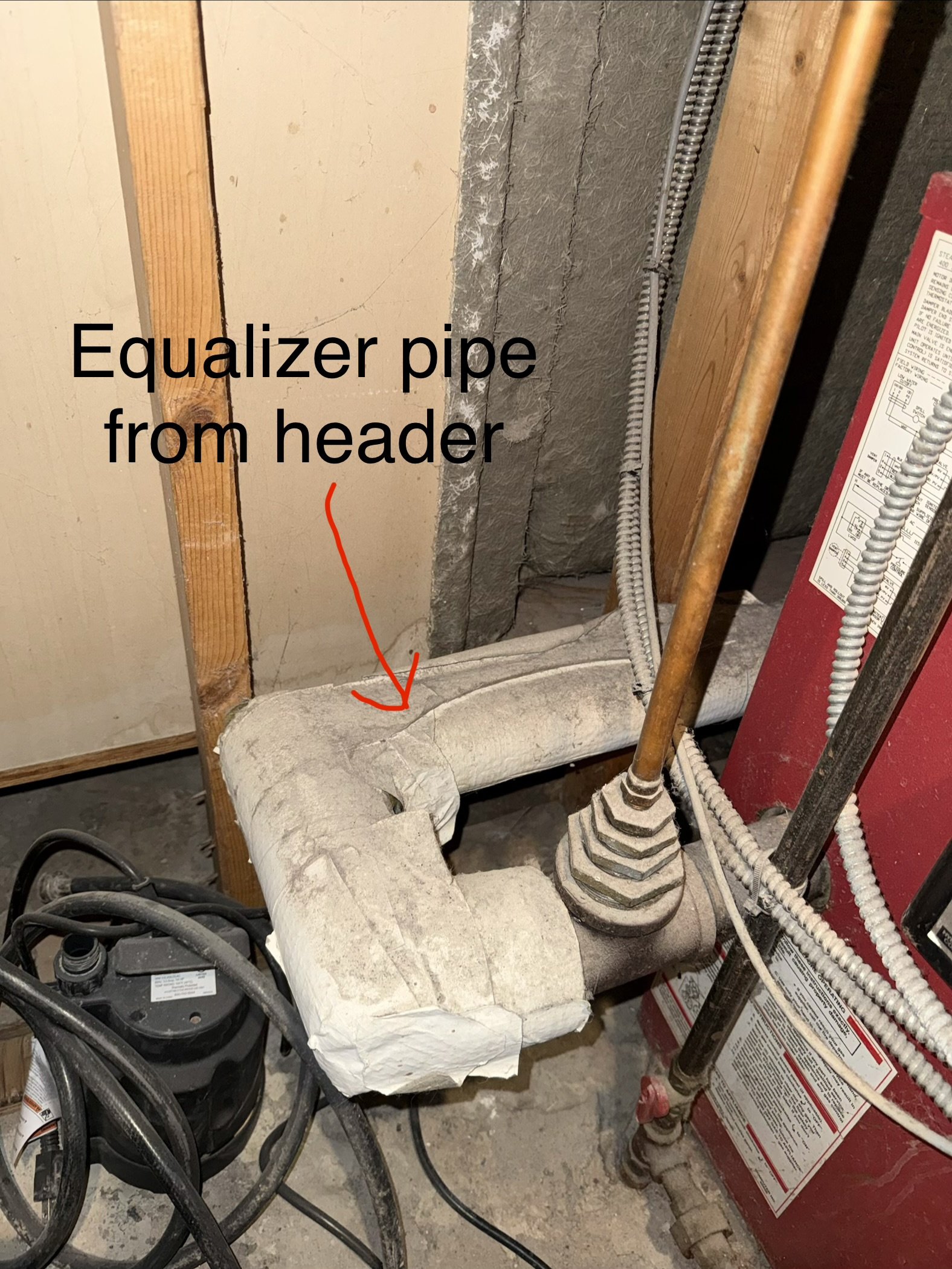

One boiler steam supply goes into the Header, one steam main leaves the Header. The Header then proceeds into the Equalizer, the bottom end of the Equalizer (not pictured well) goes into the bottom of the boiler. I see no Hartford loop.

The single main leaving the Header eventually splits. The far ends of the two branches both come back to the boiler and drop down onto two independent drips which are T'd into the into the dry return drip. The dry return continues down to the wet return.

The two dry returns are T'd together and become a single drip down to the very short wet return. I see no Hartford loop there either.

Where the three drips are tied together is probably too high. All independently should be to the bottom of the boiler joining together way below the water line to make the wet return. The very short wet return should then raise up and connect the the Equalizer at the proper height creating the Hartford loop.

IMO the Gorton #2 should be above the T'd connection of the two dry returns, not on the far end of one mains. This is so the air in the system (mains and radiators) is vented out of the radiators through the dry returns and out the Gorton #2. The Gorton #2 should be moved to the Red arrow, maybe add a 2nd Gorton #2 there if more venting is beneficial.

Presently venting the air out of the radiators (to let the steam in) is probably pretty poor. Depending on the boiler water height the venting may be blocked to parts of the system. Since the air can't get back to the only vent, assuming the valve above above the T'd connection of the two dry returns and others like it are closed.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

The valve above the T on the dry returns doesn’t pass any air even in the open position:

I have a spare Gorton #2 on hand I’ll be asking technician to swap as the fist work item.

Getting a game plan together to have the end of the two steam legs brought down to the floor, joined, then brought back up to the boiler, something like this:

0 -

this is 2 pipe. either the mains and returns both need vents or the mains need crossover traps that allow them to vent in to the returns. in some vapor systems the mains must be vented in to the returns but i don't think this is one of those systems.

0 -

another strange of this system; the equalizer comes off the header and goes back into the boiler on the opposite side of where the main and returns do:

The mains and return come back to the boiler on the opposite side of the boiler at the same height;

The pipe from the header (equalizer) can be seen wrapped in white, it goes behind the boiler and enters the boiler on the opposite side.

I understand, or at least see on paper, there is not Hartford loop on my system, sorry for the mixup in the video.

Looks like a lot more needs done to this system to make it be correctly piped…

0 -

I'm thinking your system should basically look like this, particularly the 3 Drips, Wet return, Hartford Loop, Equalizer and the Main Vent.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Since there are no crossover traps, this way (with 3 main vents) would probably vent the mains as fast as practical. Heat the pipe up with a torch to get that pipe plug out.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

the vents would be better at the ends of the mains. with them back by the boiler it is heating what is essentially a dry return that doesn't need to have steam in it.

0 -

Depending on the original system (which most of its interesting parts are probably long gone) this valve assembly may also be a check valve. It may not release air against atmospheric pressure. It may need a vacuum or a specific pressure differential at the threaded port to encourage any air flow. Also part of it may be missing, that nut may have been a lock nut for an adjustment of a piece that is now gone.

At this point you just want the best venting with the parts available today to run the system at best efficiency obtainable. Since you are burning fuel to push the air out of the system to get the steam to the radiators.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Put a #2 there as well.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

Agreed, however in this case it appears the main splits into two branches that wrap around the basement and the far end of at least one of the branches where the last radiator is on that branch is connected is very close to the boiler. The OP could verify this. My illustration does not show this characteristic well.

The illustration was mostly to show the 3 Drips, Wet Return and the Hartford loop connecting into the Equalizer and the boiler's water line.

Maybe the other branch has another main vent hidden where the steam main extension starts.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

made some headway with replacement of all radiator traps and control valve yesterday. In addition pigtail was cleaned and pressuretrol swapped to a model that allows for lower over all pressure:

System is happier but not done yet. Next week will have vents added to end of second steam leg as well as replacement of the petcock valve on the return with Gorton #2s.

After next weeks work a fresh assessment will be taken to determine if piping for the returns at the boiler will be need reworked.

Baby steps…

1 -

Unless the camera angle is a huge influence, to me the assessment is done the drip from Steam Main 1 is way too high, the drip from Steam Main 2 is maybe marginal. You might as well make it right and get it over with.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I think — I hope — that fixing that may be kind of next on the list. Depending on how things unscrew, there are several different ways it could be managed without much difficulty.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

The tech took measurements to get a supplies list. Vents are next visit and repipe if time allows. The drips from both steam legs as well as the return, 3 pipes in total, will be brought down to floor level, tied together then joined to the equalizer pipe just below the water level.

Thank you for all the help!

1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements