Opinions on Cast Iron Radiator Automatic Bleeders

Opinions on Installing Automatic Air Bleeders on Cast Iron Radiators

I manage a smaller in-house HVAC/maintenance team that handles repairs, tune-ups, and light system upgrades across a variety of heating systems at our properties located in northern Minnesota.

Most of the properties we manage that have boilers are running fairly standard cast-iron boilers, largely Weil-McLain, Burnham, etc. and the majority of these buildings are turn of the century homes. Although the boilers themselves have been updated throughout the years, many of the heating systems themselves are approaching 80–100 years old, with original or near-original cast-iron radiators.

Over the last few seasons, we’ve had several owners ask if there’s a way to reduce service calls that are strictly for bleeding radiators when tenants report cold or partially heating radiators. With the volume of properties we manage, I do agree these trips add up quickly.

One idea we’ve been exploring is offering an upgrade option where we:

- Install automatic fill valves on systems that don’t currently have them, and

- Add automatic air bleeders directly at the cast-iron radiators, where feasible.

Examples of the types of vents we’re looking at:

- Watts 1/8" FV4 auto air vent

- Caleffi 1/8" automatic hygroscopic air vent

The goal would be to reduce manual bleeding needs while still keeping the systems stable and reliable, especially in older buildings where air issues are fairly common at the start of the heating season.

Before rolling this out as a recommendation to owners, I wanted to get feedback from those with more long-term experience:

- Have you had success (or problems) installing automatic air vents directly on cast-iron radiators?

- Any concerns with leakage, longevity, or tenant tampering in occupied units?

- Do you prefer certain styles or manufacturers over others for radiator-level air venting?

- In older systems like these, do you see any downsides compared to sticking with manual vents only?

Appreciate any insight, lessons learned, or things to watch out for. Thanks in advance!

Comments

-

Even with large cast radiators, at some point all the air should be eliminated and should not need ongoing or frequent radiator bleeding?

What type of air elimination do the systems have at the boiler? The majority of the air elimination happens at the highest temperature point in the system, at the boiler.

In some cases systems can pull air in through auto vents if the pump/ expansion tank relationship is not ideal, maybe take a look at near boiler piping at the chronic air problem jobs.

Any brand of hydroscopic vent will need occasional replacement. We suggest every 3 years on the Caleffi. It really depends on how many wet dry cycles the see, dirt in the system, etc.

Caleffi, probably others have a manual off position should a leak develop the tenants should know how to turn them off.

A float type auto vent is an option, not a great looking solution, and more prone to damage mounted high on a radiator.

With the additional accessories a float type gives you two shutoff mechanisms, the internal float and a hydroscopic cap. Plus an added "anti siphon" check to prevent air from going backwards into the vent.

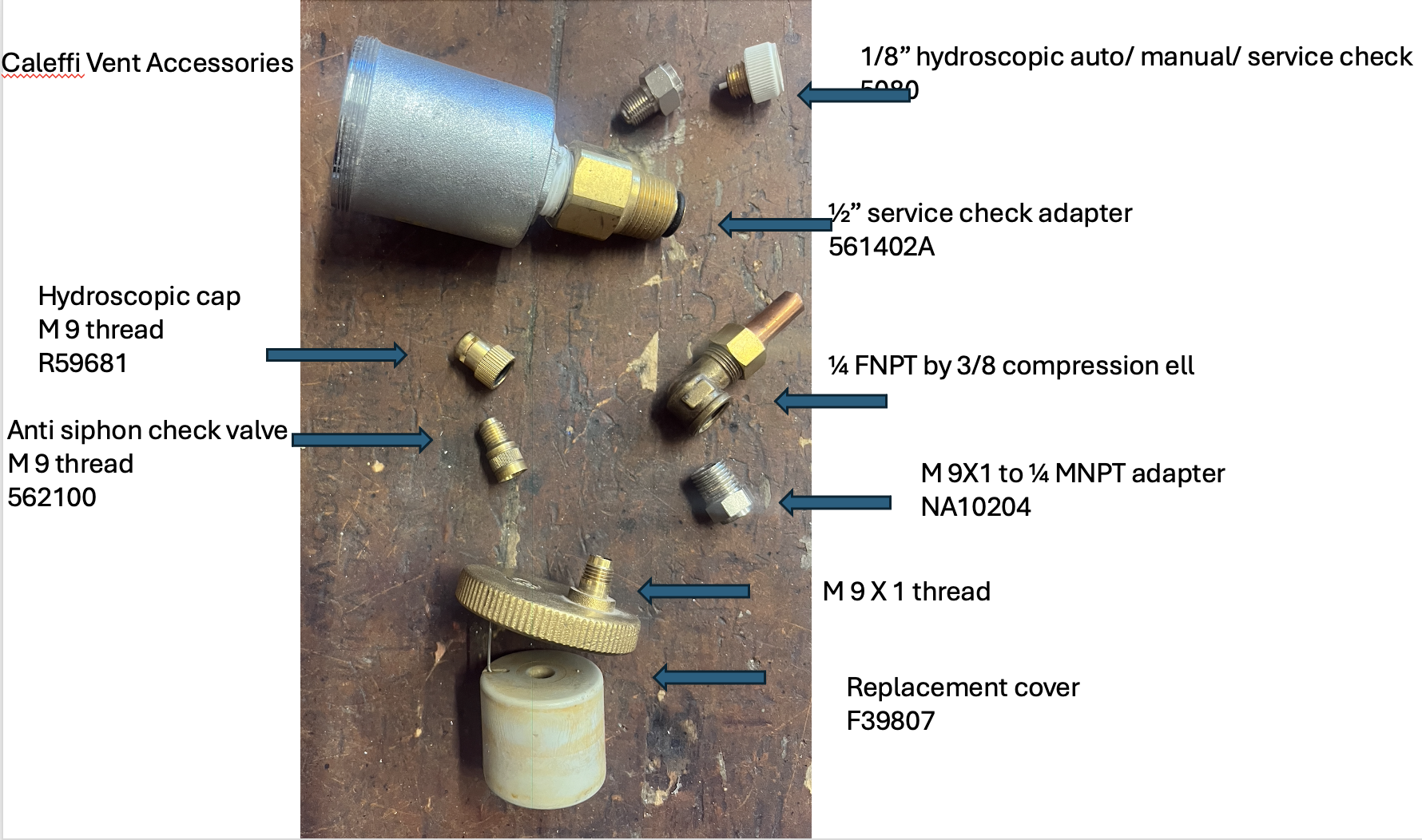

This pic from top shows an 1/8 hydroscopic auto/ manual/ and built in service check

A service check on on the plated auto vent body.

The anti siphon adapter, hydroscopic cap.

To the right the chrome thread adapter to put a NPT thread and discharge tube on the vent.

So you have a few options to select from.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I am not a heating pro, but I maintain the heating system in our 1924 4-unit building in Boston. It's a gravity conversion hot water system with original cast iron rads and two Weil Mclain WGO-5 cast iron boilers.

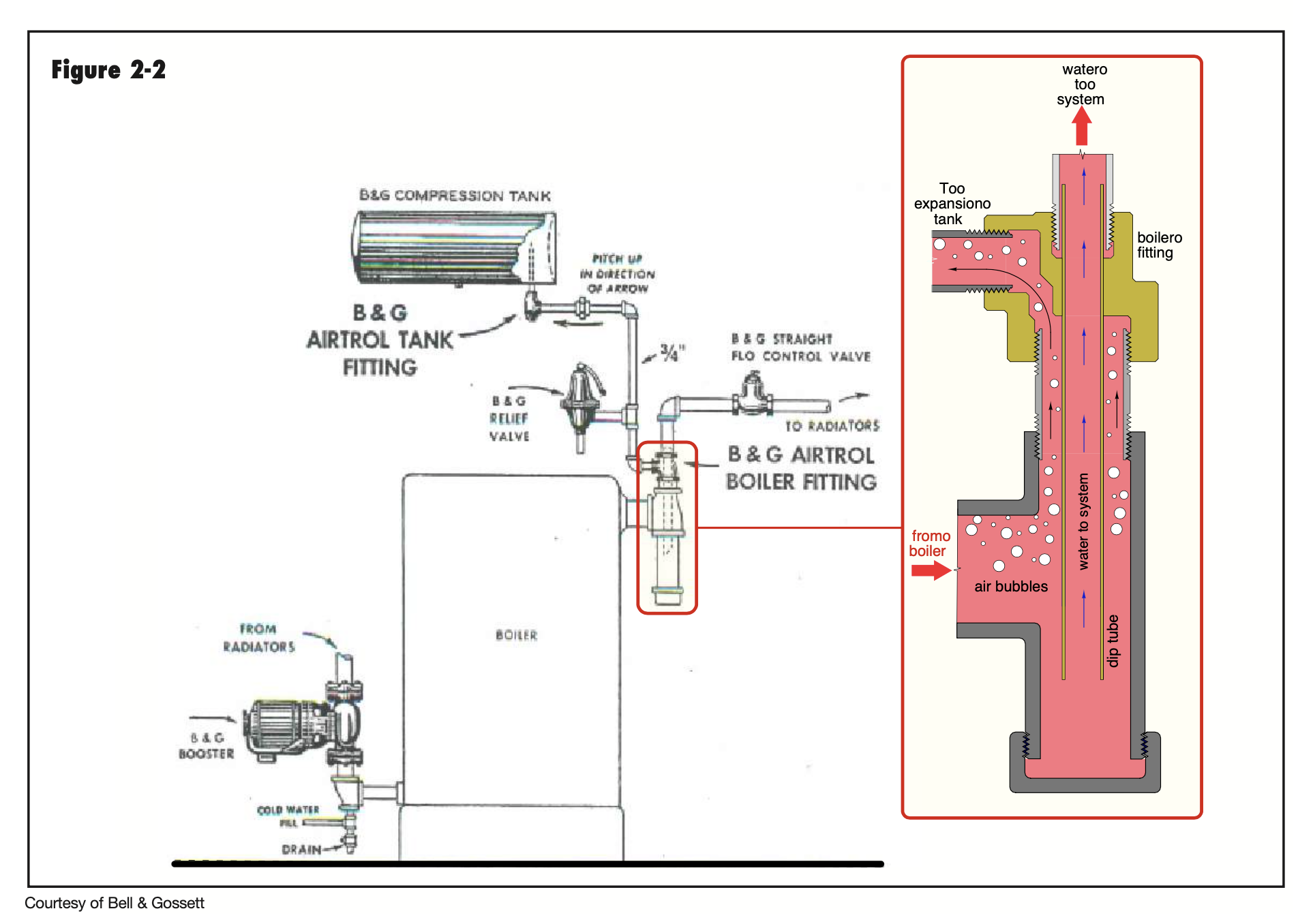

When I moved in here 18 years ago, air in the rads was a constant headache. With the help of the pros here on HH, I learned that the main reason for constant air problems (despite annual bleeding) was that our HVAC company was draining and refilling our old steel compression-type expansion tank once per year. That added 15+ gallons of fresh air-laden water every year, which then ended up in our rads. And even without the annual addition of water, the compressed air in the tank was dissolving back into the existing water. My first attempt to fix this was adding an Aitrol tank fitting to the compression tank. The Airtrol prevents migration of air-laden water down into the boiler, but I was concerned that our boiler service guys would not know how to use it properly and would still be draining/refilling the tank.

I ultimately solved that problem by removing the old compression tank and installing an SX-40V diaphragm tank serving both boilers. I also learned that we had no air elimination devices. Our Weil Mclains have built in air separation ports, so when I added the SX-40V, I added the Caleffi automatic vents that @hot_rod mentioned, one on each boiler's air separation port. After that, no more air in radiators.

So while a little more expensive and time-consuming than putting vents on radiators, you might want to advise your customers that the ultimate solution to air problems in old heating systems is (1) replacing old compression tanks with diaphragm tanks, and (2) adding air elimination devices at/near the boilers, especially if they are Weil Mclain or other brands that have built-in air separation ports that are already there waiting to be used.

This strategy should be especially attractive to owners of multi-unit buildings, because any air vent on a radiator will eventually leak or otherwise need replacing, requiring access inside the unit. By putting the air elimination device(s) on/near the boiler(s) instead, the building owners will never get a no-heat call from a tenant requiring access to the unit to replace a leaking/non-functioning vent.

3 -

proper air elimination/management happens at the boiler. If you are bleeding radiators after the initial fill of the system you have problems with how your air management at the boiler is set up.

If you put auto vents in apartments you will have leaks that no one is reporting because auto air vents will all eventually leak.

0 -

I would argue that getting the pump, expansion tank, and auto fill order right at the boiler would cost less than adding auto vents in each unit and certainly less than maintaining them. Either arrange it to vent the air with a bladder type tank or to send the air back in to the compression tank on a system with a compression tank. Read "pumping away", it is how you solve problems with air in emitters.

1 -

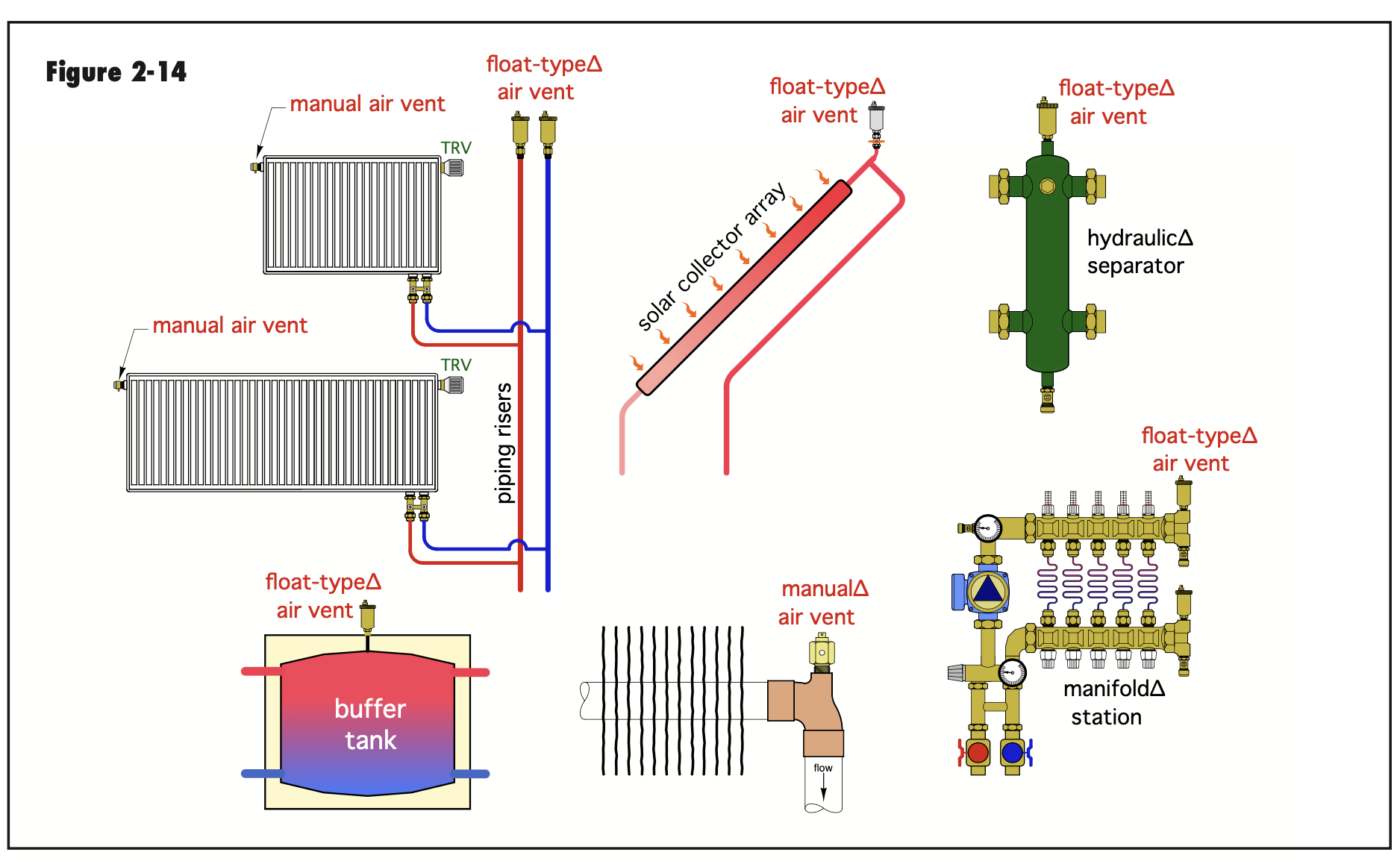

The vents at cast radiators, for example are considered high point vents. Typically useful at first fill. Over extended periods on off cycles air will rise to high points, the radiators are high point areas. So any type of vent there is a compliment to the purger back at the boiler.

Vents on radiators can be the only option if the purger at the boiler is: non existent, improperly applied, plugger, or low quality.

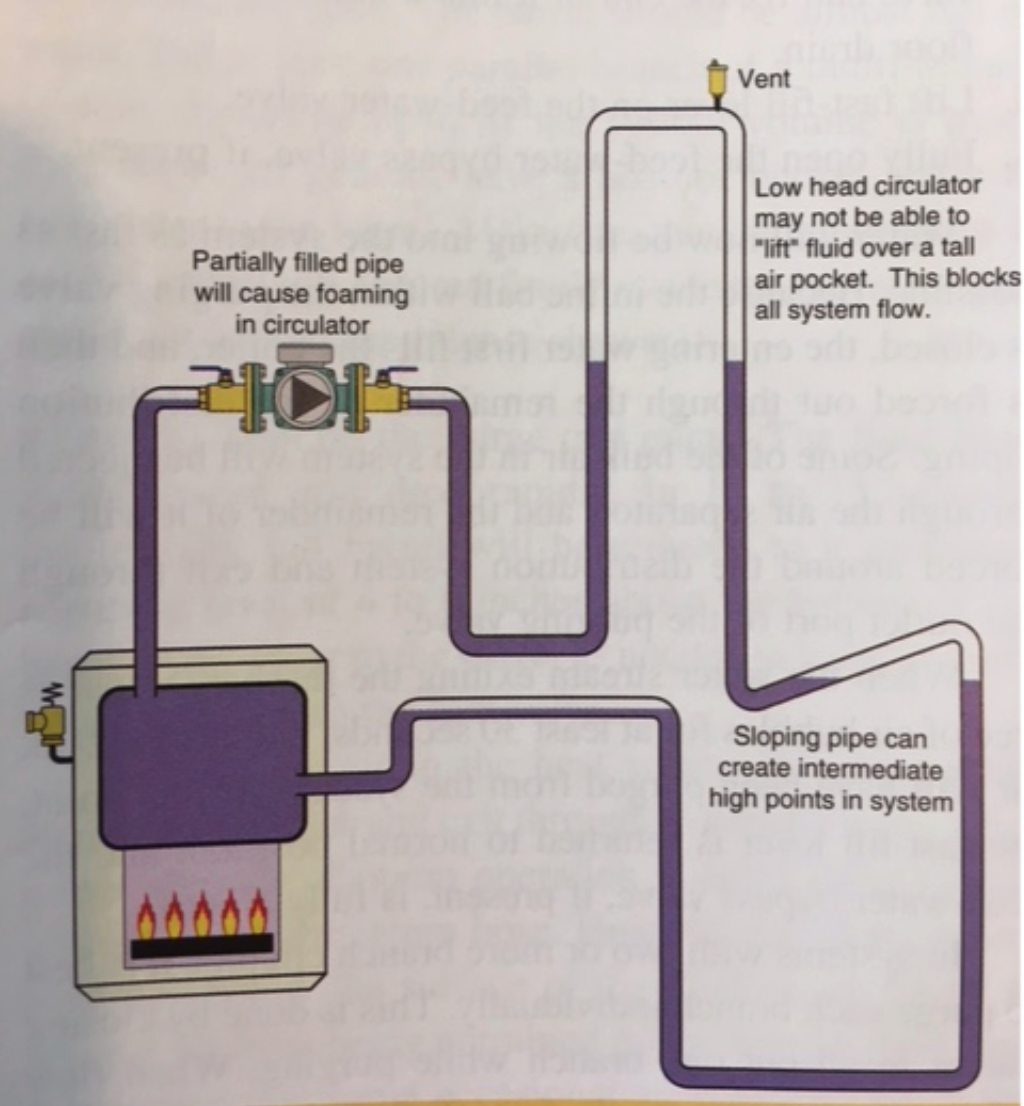

Piping and flow velocity has a lot to do with air removal. Slow velocity under 2 fps doesn't allow air to be pushed along with the water flow, so especially on down flow in vertical piping, you need around 3-4 fps to push the bubbles.

Variable speed pumping and large pipe diameter gravity conversions present even more air removal challenges. You need a lot of flow in a 2" pipe to shove air down the road.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

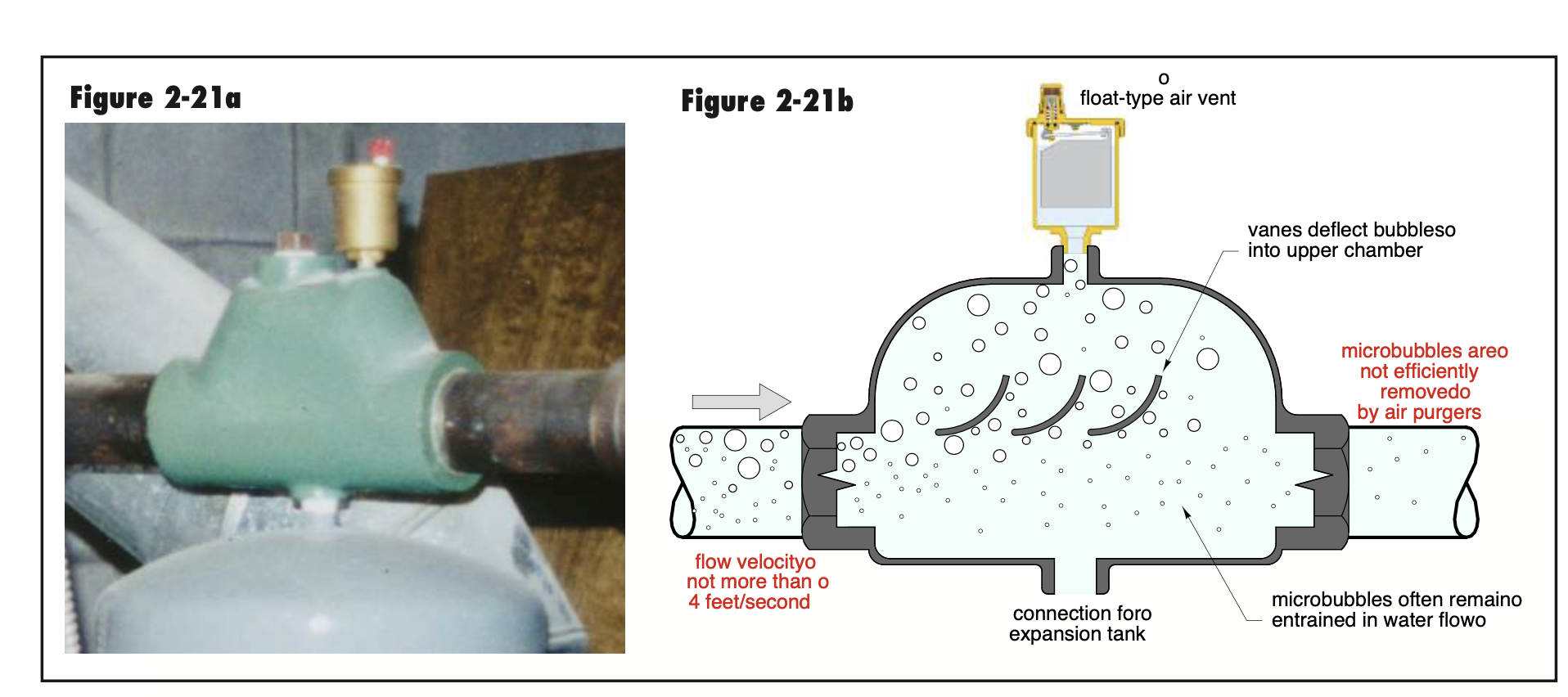

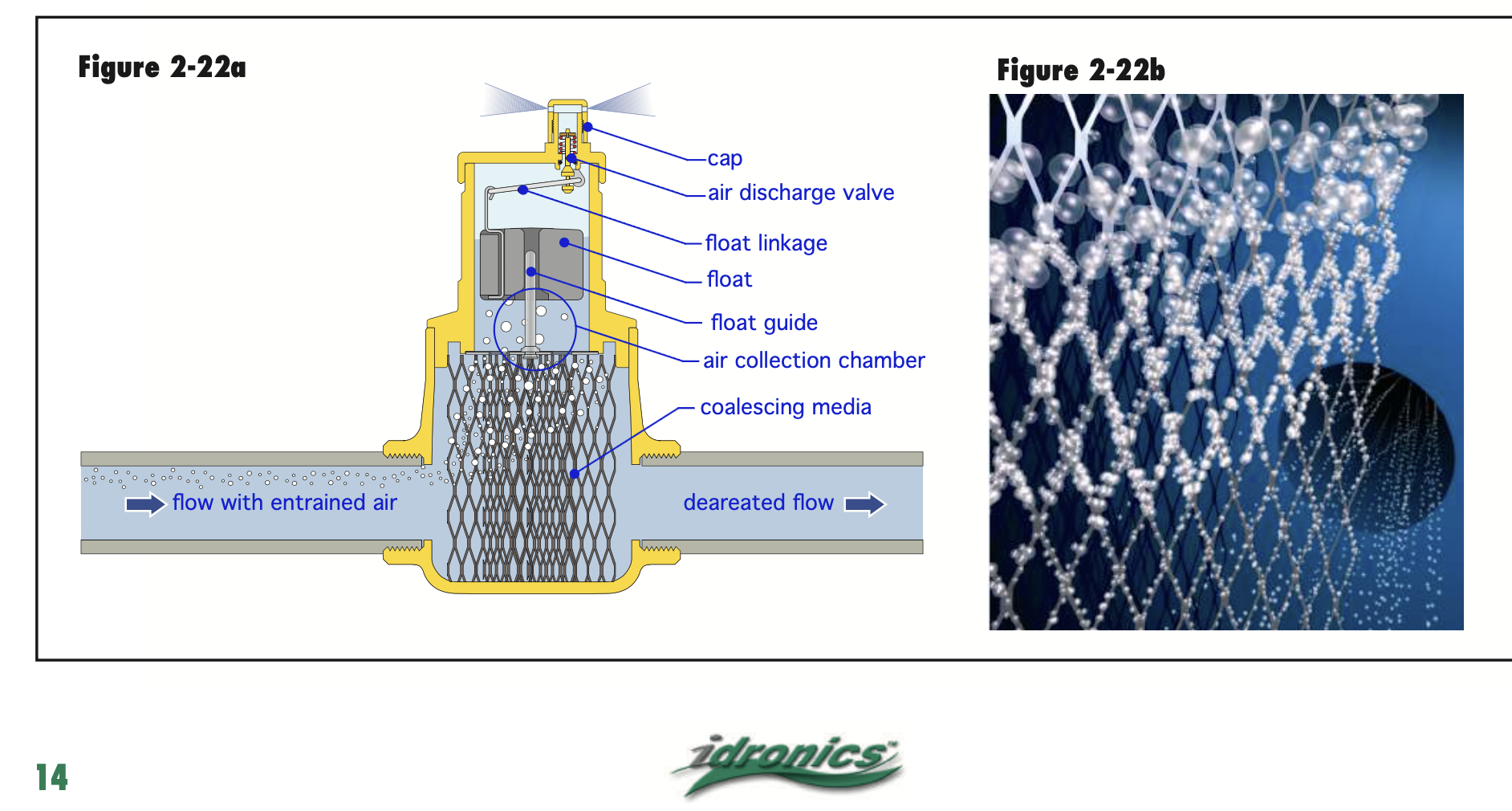

The mechanics at work with the various air removal devices.

With a compression tank you should have the Airtrol fitting for best result. The boiler it self is doing most of the air separation, the fitting assures it goes into the tank, and stays there. Some boilers had sectiond designed as air removal function.

The scoop or ramp "camelbacks" depend a lot on slowing the flow.it a wide spot creating a low velocity zone. So you want enough flow to get air to it, but not too much that air blows right through. The vanes inside and buoyancy of the bubble is at play also. A section of straight pipe upstream allows the bubbles to start to rise to the top of the pipe for a better removal opportunity in the "ramp"

I've done numerous glass pipe demos with this type of purger, they struggle to grab the microbubbles. The bubbles often smaller than the eye can see.

With microbubble type air purgers flow velocity doesn't have a lot of effect. It is still a low velocity chamber like a camelback, but the media stops and traps the bubbles. Microbubble resorbers were developed mainly to eliminate the smallest bubbles within 10- 20 passes through the device. Critical on glycol systems and high efficiency low water content boilers

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

This book will explain what you may need to do. It can be purchased at this sight. When I taught Voc. Ed. years ago, it was a go to for much if not all heating system air issues.

0 -

I have to ask, how many of these homes have gravity hot water heating with two risers and open to air expansion tanks in the attics or top floors?

How many of these homes have no compression tanks or expansion tanks? If neither are used the radiators are the air management system wherein they have an air charge in them to create the point of no pressure change to create circulation.

How many of these homes have circulators with steel compression tanks over their boilers? Removing them is a huge blunder.

Over time automatic air vents leak and have to be replaced.

As Matt has stated the excellent book pumping away shows how this is done. It is how my systyem was installed and I have no issues with air in my system and I do not have to crawl around bleeding baseboard.

As Mr. Holohan has said "if all you get is water it ain't an air problem.

0 -

@leonz Can plain steel compression tanks be made to work so they don't contribute to air problems? Yes they can, as we both have done, with an Airtrol tank fitting that is correctly plumbed with 3/4" pipe and sufficient pitch.

Do most heating pros these days (with many of the older guys retiring) understand how Airtrols work, how to plumb them properly and use them? No, they don't. And that's the main problem. An incorrectly installed Airtrol is useless, and how many photos have we seen of Airtrols with incorrectly sized or pitched pipes?

What the new generation of heating pros do understand is diaphragm tanks and air eliminators, so for better or worse, we live in a world in where that's the dominant paradigm.

0 -

-

-

-

I agree with you jesmed,

that is why I am working steadily on getting our counties great white fathers to use them for their new office building by proving how much better this type of air management system is when using a large hot water buffer tank in the above ground walk in basement and cast panel radiators to store hot water to create the greatest amount of stored heat energy that will require the smallest amount of energy to reheat it even by using one circulator to feed a nurse tank on the top floor that will feed all the radiation on all three floors from overhead as it is a new building.

0 -

Have you tried simply turning the thermostats up in the apartments for 24-48 hours to purge the perceived air problems??????????????????????????

0 -

Like I said, simply turning the house thermostat all the way up would do this as well.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements