Circulator Sizing

I have a large zone in my four zone system. This large zone includes the entire concrete floor of my finished walkout basement of approx 1,650 square feet. It is made up of four loops, all 7/8" ID and all in the 285-295' length and attached to a common header and fed by one circulator and a check valve ahead of the pump and a common return header.

This configuration worked well for 15 years until a boiler failure and subsequent replacement of the boiler, which ended up upsizing the piping feeding the zone from 3/4' to 1.25". Once that project was complete all the zones were bled of any air and 3 of the 4 worked fine but the one for the basement. We bleed it multiple times and no circulation.

I am being told that the pump is undersized and we need to installl a larger pump? The current pump is 20+ years old, so I am not opposed to replacing it, I just want it to be sized properly if I do so. The current pump is a B&G 1/25 HP, Max head 15', Max flow 22GPM and 2940 RPM. What are the thoughts on a bigger pump or is there another issue that we are possibly missing? Did upsizing cause the issue?

Because we rarely use the basement since all our children have their own homes now, its not a emergency, but I would like to get the zone back up and running.

Comments

-

the infloor loops (and really all of the zones) should be purged not just bled, offhand if I were asked about your scenario I would say airlock. all else the same upsizing the supply and return would not restrict flow, though there can be some downsides to a too large pipe size. Does the infloor zone work if your other 3 zone valves are closed? or still no flow?

2 -

Why would you need a bigger pump if the last one worked? I agree with @GGross. Try purging that one zone until you get water thru it.

0 -

That 7/8" tube will take a lot of flow to purge. The fill valve, even in fast fill mode, if you have one, would probably not give you enough flow. Connect a garden hose to the system and use the high flow that it provides.

Just keep an eye on pressure, stay below 27 pesi to avoid tripping any relief valves.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Can you elaborate on purging vs. bleeding.

I will have to try shutting down the other three zones and see.0 -

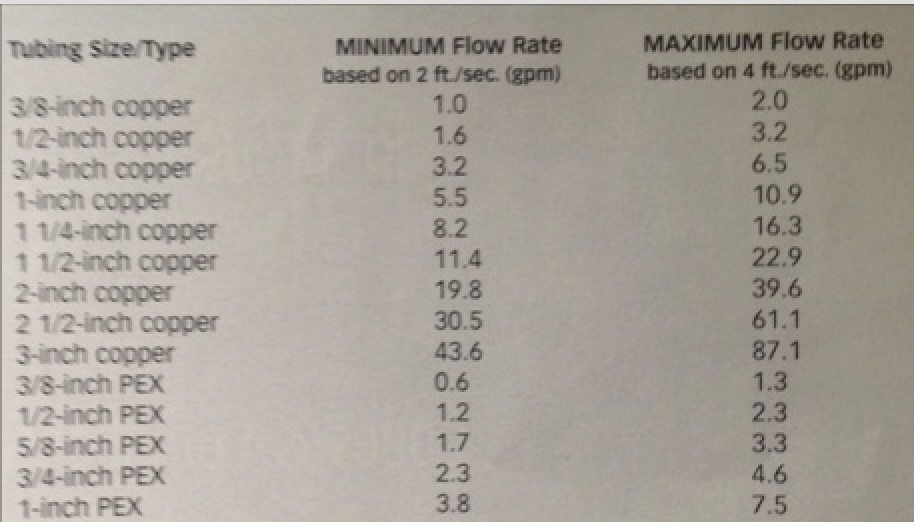

Purging, or power purge with a pump, to me, is pushing enough flow thtough the tube to remove air and any dirt ot debris. To move heavy particles you need about 5 fps velocity. I would consider that closer to 1" pex size, so you need about 8 gpm flow

\

Bleeding is more for removing a small air bubble trapped at a high point in a tank or radiator, for example

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

We were not using a external water source, so I will try purging and see if that takes care of te problem.

0 -

-

So purge each of the loops within the zone separately? In this case there is four loops making up the zone, each have valves to isolate.

0 -

That is the for certain method, loop by loop. If you have multiple short loops 3/8 or 1/2" you can often flow more than one loop at a time.

In either case the flow you have available makes a big difference. 1/2" fill valves set at 12 psi don't give a lot of flow. Fast fill position o the valve may get you 3- 5 gpm.

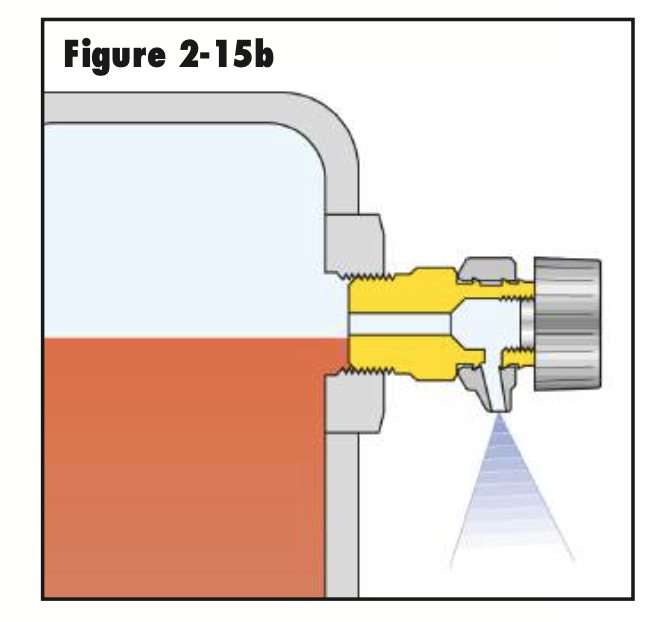

A 1/2 bypass around a fill valve at 45- 60 psi will get you 10 gpm or more. That would allow for more loops to be purged together.

The best indication is to put the purge hose in a 5 gallon bucket of water. Purge until all bubbles stop showing.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements