Question about where to set Pressurtrol cut out

Good morning, happy new year! I have a residential Weil-McLain natural gas single pipe steam boiler. I very much enjoy understanding how everything works and want to make everything work as efficiently as possible. I’m about half way though Dan’s book, We Got Steam heat, A Homeowners guide’.

A previous owner’s contractor has our gas boiler set at a 2.0 differential. .5 on cut in, 1.5 on cutout.

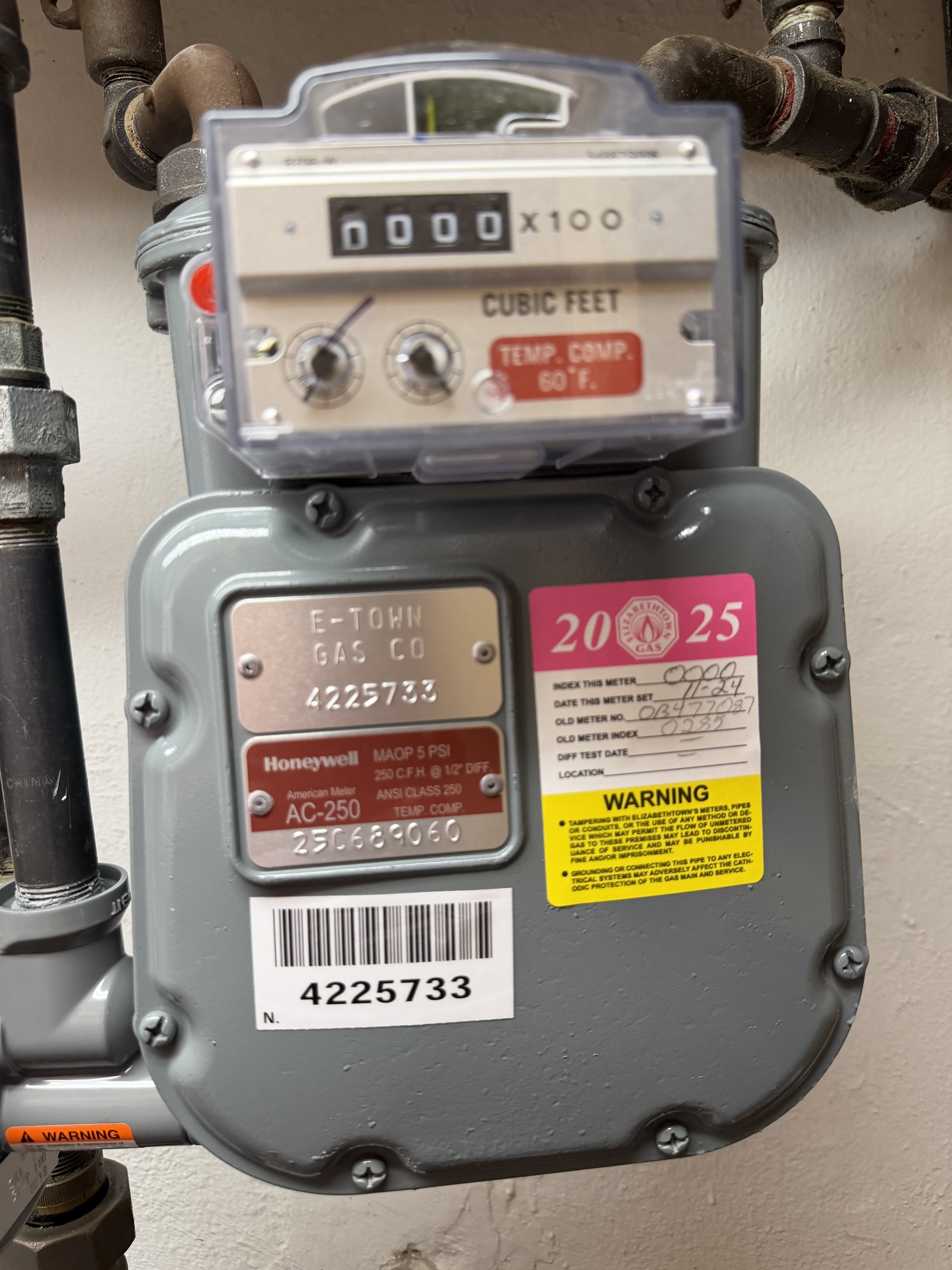

Small, history had some issues with the heat this winter but they all are resolved now, needed gas company to replace the meter and some other part which increased the gas pressure, before it was only 3.8, now it’s 6.5. Also, had to replace the control module on the boiler earlier this season too. Fyi, there’s a new last winter Gorton #2 main pipe vent as well. I have a mix of Gorton and Hoffman 1a adjustable vents throughout the house. The house is 3 floors but cast iron radiators just on 2 of the floors. 3rd floor has a mini split with a heat pump, it’s a finished 3rd floor but no one rarely goes up there so I keep the mini split set at 60 F.

With all that said, the boiler is running good and consistent and even heat throughout the house.

There’s no banging or hissing from the pipes or radiators but everything I’ve read so far in the ‘We got steam heat’ book, I should have my cutout set at 1.0 instead of 1.5. 1.0 will use less fuel and be gentler on the heating system.

What real world differences is there? So if I decrease it to 1.0, what changes should I expect? Longer heat cycles (probably only a few minutes longer)? And maybe even more even heat throughout the house? (I just want to understand more).

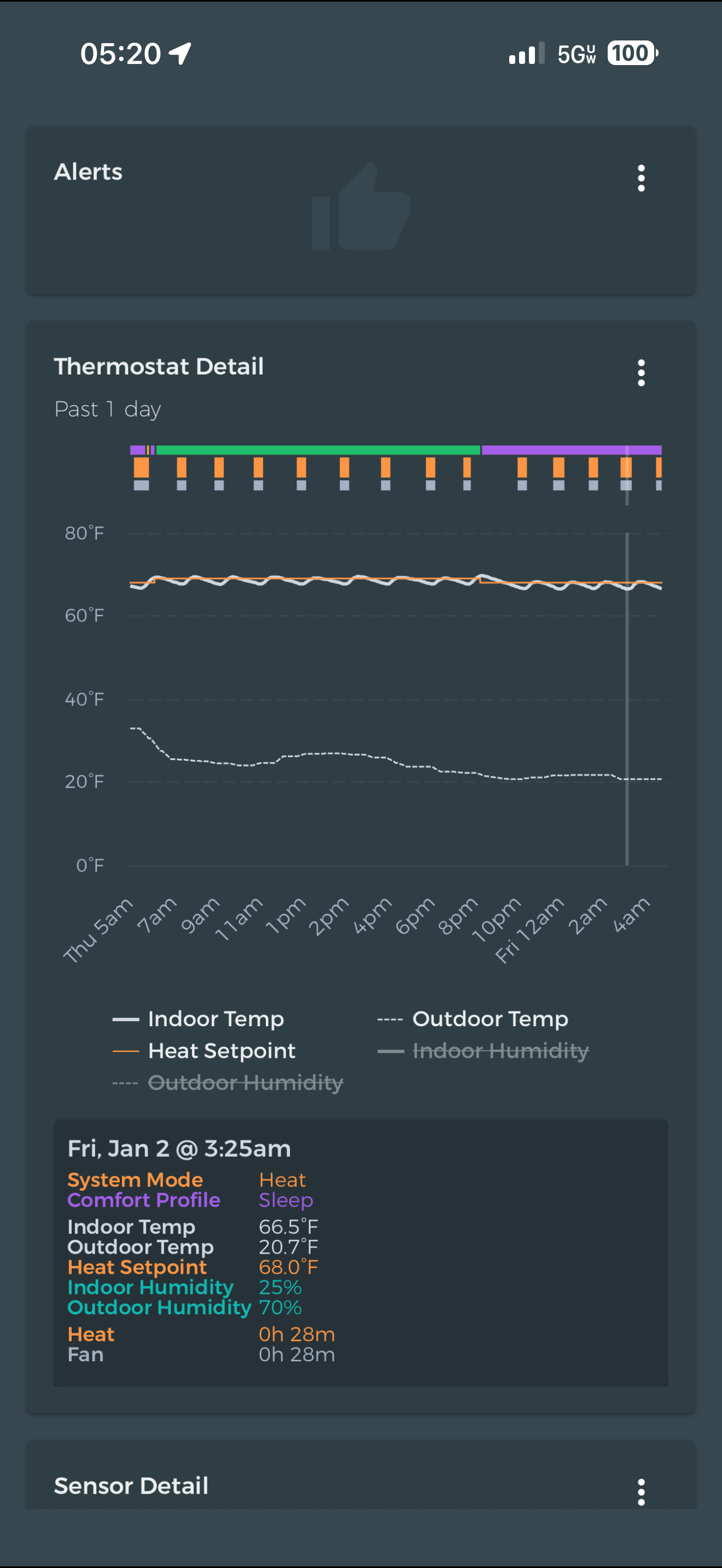

here’s a screenshot form beestat, most of my heat cycles are around 28 minutes or so.

thanks in advance!

Jonathan

Comments

-

" gas boiler set at a 2.0 differential. .5 on cut in, 1.5 on cutout. "

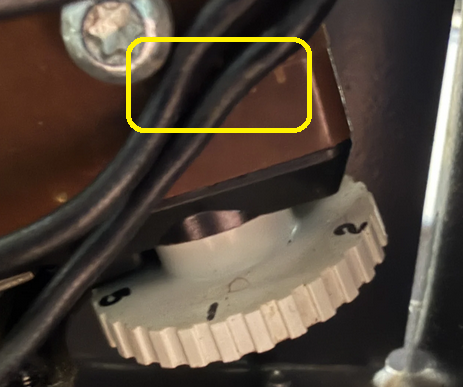

Looks to me like it is set at 1 for the differential, 0.5 on cut in for a cutout of 1.5 (additive), which is about the minimum and where you want it set at. The setting is the number straight out towards the front of the pressuretrol. If you look behind the black wires the ' Diff ' (Differential) index mark may be printed on the switch body.

If the Boiler's (Sq. Ft.) is well matched to the radiation EDR (Equivalent Direct Radiation) the system pressure may never come close to tripping the Pressuretrol.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

thanks 109_A, let me take another picture this afternoon when I’m home from the office with a better angle.

0 -

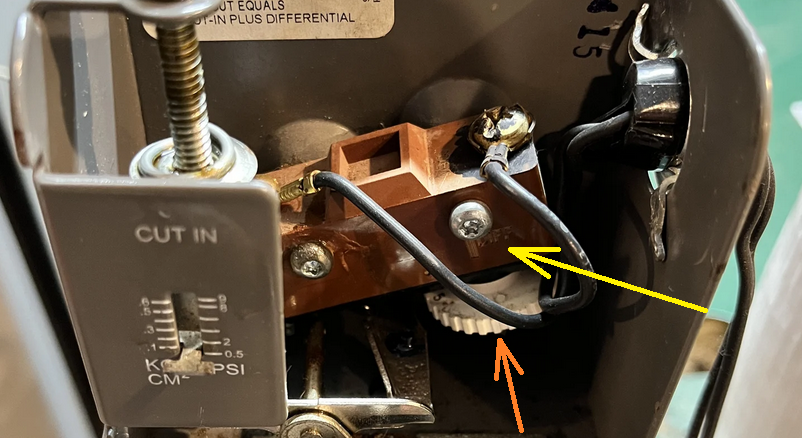

Yellow arrow is the typical label on the switch. The number at the Orange arrow is the actual setting. See the printed vertical line below the screw head.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

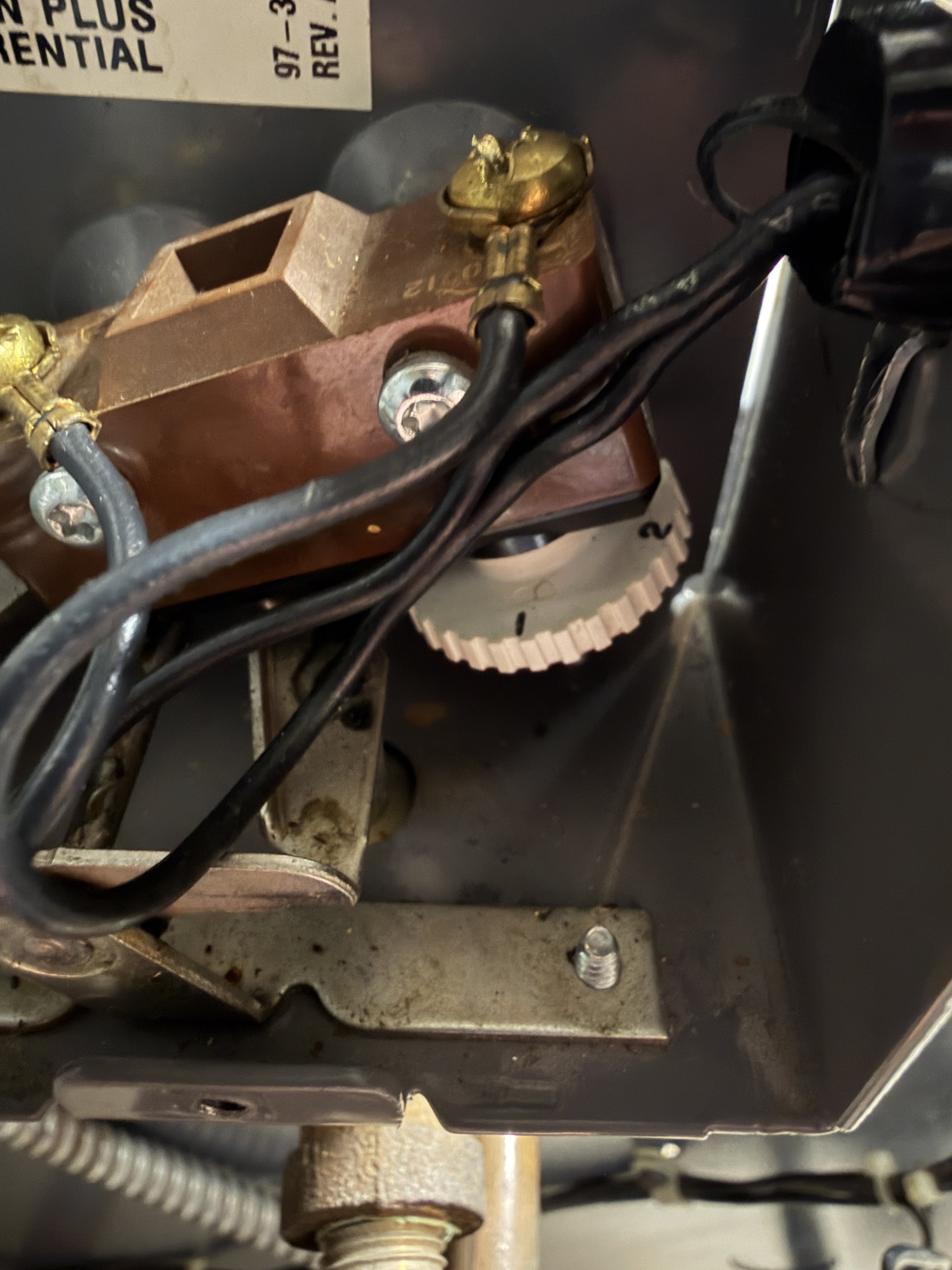

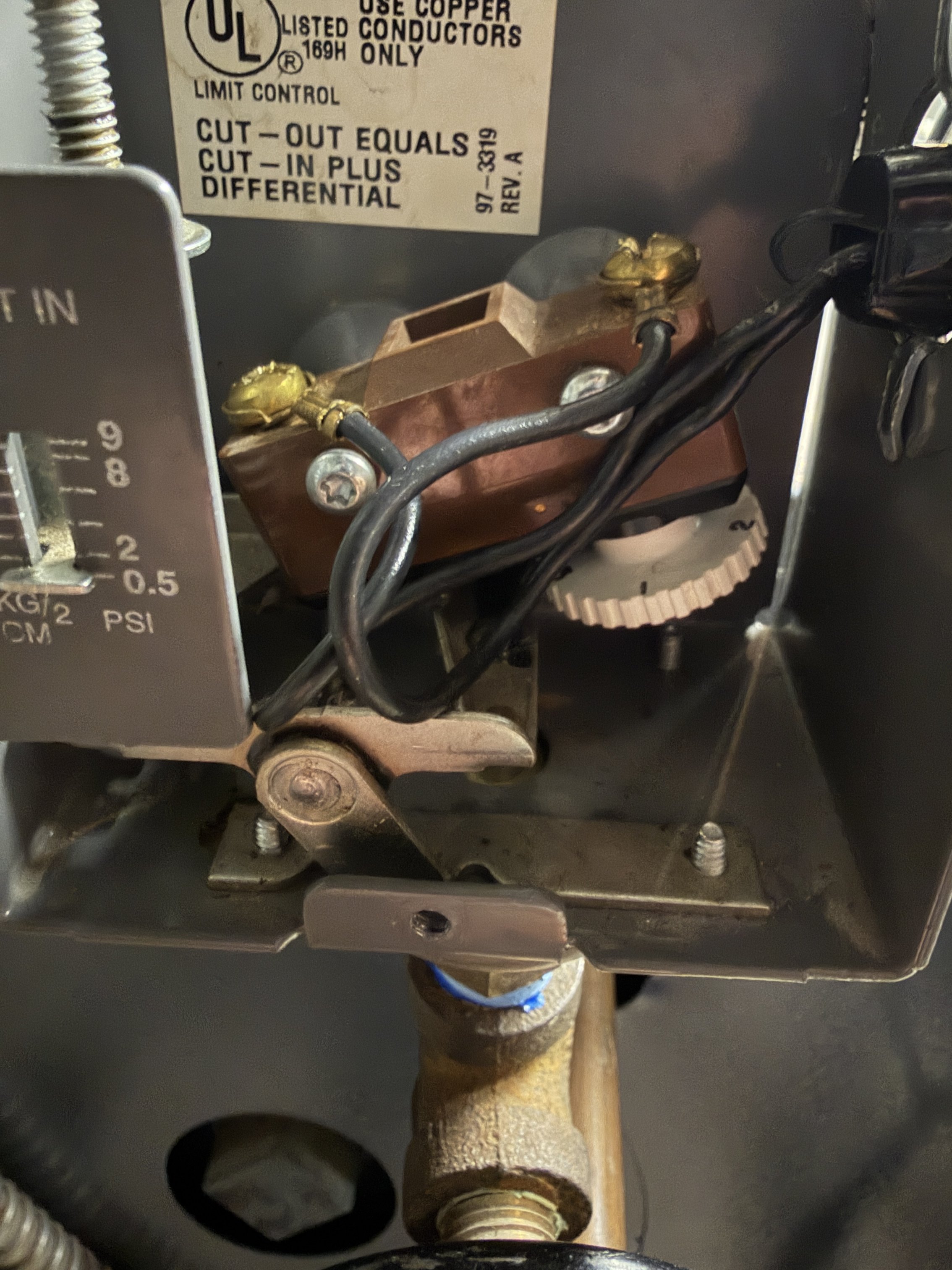

hi 109A_5, here’s pictures of my Pressurtrol I just took. Does it look to be at 1.5 or 1? Thank you!!!

0 -

-

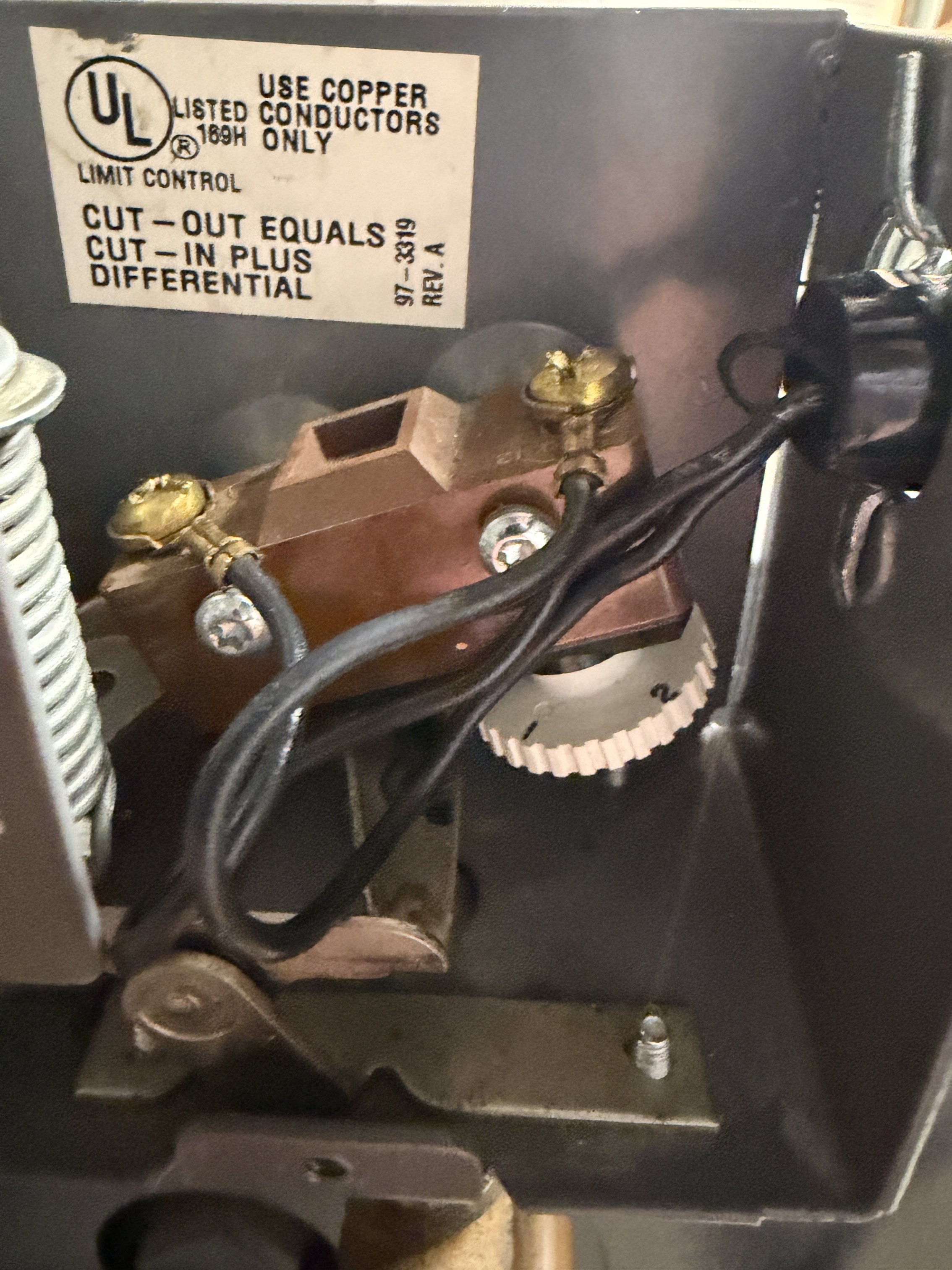

ok, thank you Jamie hall, I just changed it. Does this look good? Thank you!!!!

0 -

-

thanks 109A-5, let me take another look this evening and I’ll snap a pic too. Appreciate everyone’s time a lot!

0 -

You answered your own question. Its working good I wouldn't fiddle with it. 1/4 Psi or 1/2psi one way or the other won't change much.

1 -

thanks, but let me ask you a question, when I turned it down from 1.5 to 1.0, does it matter at all if the boiler is not even hitting that high to begin with? Sorry about these questions, just want to understand the reasons I’m doing everything and like to know intimately how and why everything works. Thanks!!!

0 -

Lower pressure is better, if the pressuretrol NEVER trips that is best.

As an example my boiler runs at never more than 2 inches of Water Column which is about 0.07 PSIG no where near 1.5 PSIG.

In an oversized boiler situation the pressuretroll limits the pressure by shutting off the burner. Also there really is no point to running the burner just to build pressure. And excessive pressure can damage things.

Also if the boiler happens to get way over filled with water (like up into the pipes) the pressuretrol will trip disabling the burner.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements