Alpine 105 Sage 2 Controller replaced

I've posted here before, but I've finally gotten around to replacing the Sage 2 controller on my Burnham Alpine 105 boiler. It is an indirect system used for DHW and 4 radiant zones. The boiler was using a Sage 2.1 controller that would throw a "hard lockout 25" error about once a week. I had purchased a replacement controller about 3 years ago and had it sitting on the shelf "just in case". Initially the error occurred every couple of months, but the frequency steadily increased and I'd finally had enough. After documenting all of the operating parameters I swapped the controllers today.

After the swap the boiler is running, but the system operation seems different to me. I can't say this with certainty, but it seems to be cycling more frequently and the running cycles seem longer.

Relevant setpoints are:

Central Heat: setpt 150; dIff above: +5; dIff below: -5

DHW: setpt 170; diff above +2; diff below: -7

Some detail:

Upon startup, the radiant immediately called for heat. The boiler temp was about 138 deg, and ran up to about 149 deg within the first 30 sec.

It then slowly slid back to about 146 deg by the 1 min mark.

It then slowly climbed to 150 deg at the 7 min mark and 155 deg at the 10min 30 sec mark before it dropped out of run mode.

Within 2 min it was at 145 and initiated another run cycle. By the time the purging, etc. was done it was at 138 deg and then ran for about 4-1/2 minutes. Two minutes after the cycle was complete another was initiated, again running for ~ 4-1/2 minutes.

Putting the initial cycle aside, when the radiant is calling for heat, it looks like the boiler will run for 4-1/2 min out of every 6-7 min. I don't have this documented, but I would have thought the previous operation (before changing the controller) was that it would run for maybe 90 sec every 10 minutes or so.

I've been through the operating parameters a couple of times and all looks the same as it did. The only difference I see is that on initial startup you have to select the boiler model. Initially "105B" was selected. The Sage 2.3 provided two options: 105-02 (selected), and 105-27.

Does the operation described above sound correct, or is there an incorrectly set operating parameter that I need to adjust?

Comments

-

Sounds like you are cycling way to often. That might have killed the old control. I don't know your system, but it sounds like you're trying to control the radiant temp with the boiler alone. where you may need a mixing valve if you don't have one.

0 -

Try setting the boiler circulator to medium ..

There was an error rendering this rich post.

0 -

The boiler should be modulating. Is the boiler turning down to its lowest firing rate?

0 -

Thank you for the input/comments. In response:

1. yes, there's a mixing valve. As best I can tell its working (green LED is on).

2. There are three circulators on the system - one for the DHW indirect tank, one for the boiler, and one for the radiant piping. All three are set at the LOW setting as they always have been. Which one should I move to MED? The one for the boiler?

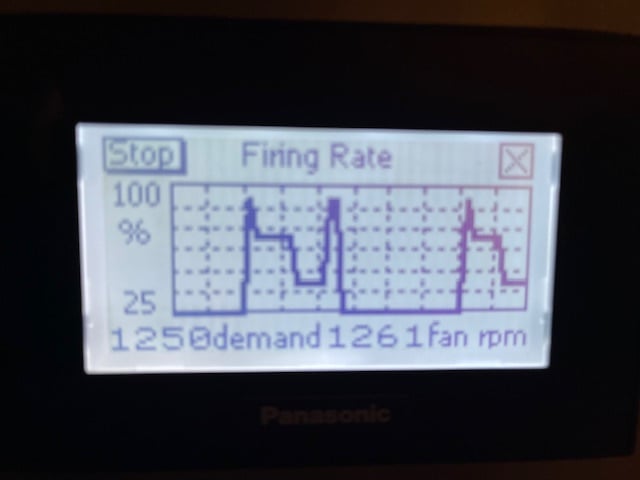

3. Re firing rate - not sure where to check and/or adjust this. From the status screen there's this graph:

From the status screen under detail there are two options - DHW and Central Heat. The values shown make not sense to me. They are:

DWH - Setpoint 170; Diff Above +72; DIff below -63

Central Heat - Setpoint 150; Diff Above +55; DIff below -45

0 -

looks like it is modulating some but possibly the controls could be set up better to smooth things out.

0 -

is there anything specific I should look at/adjust?

0 -

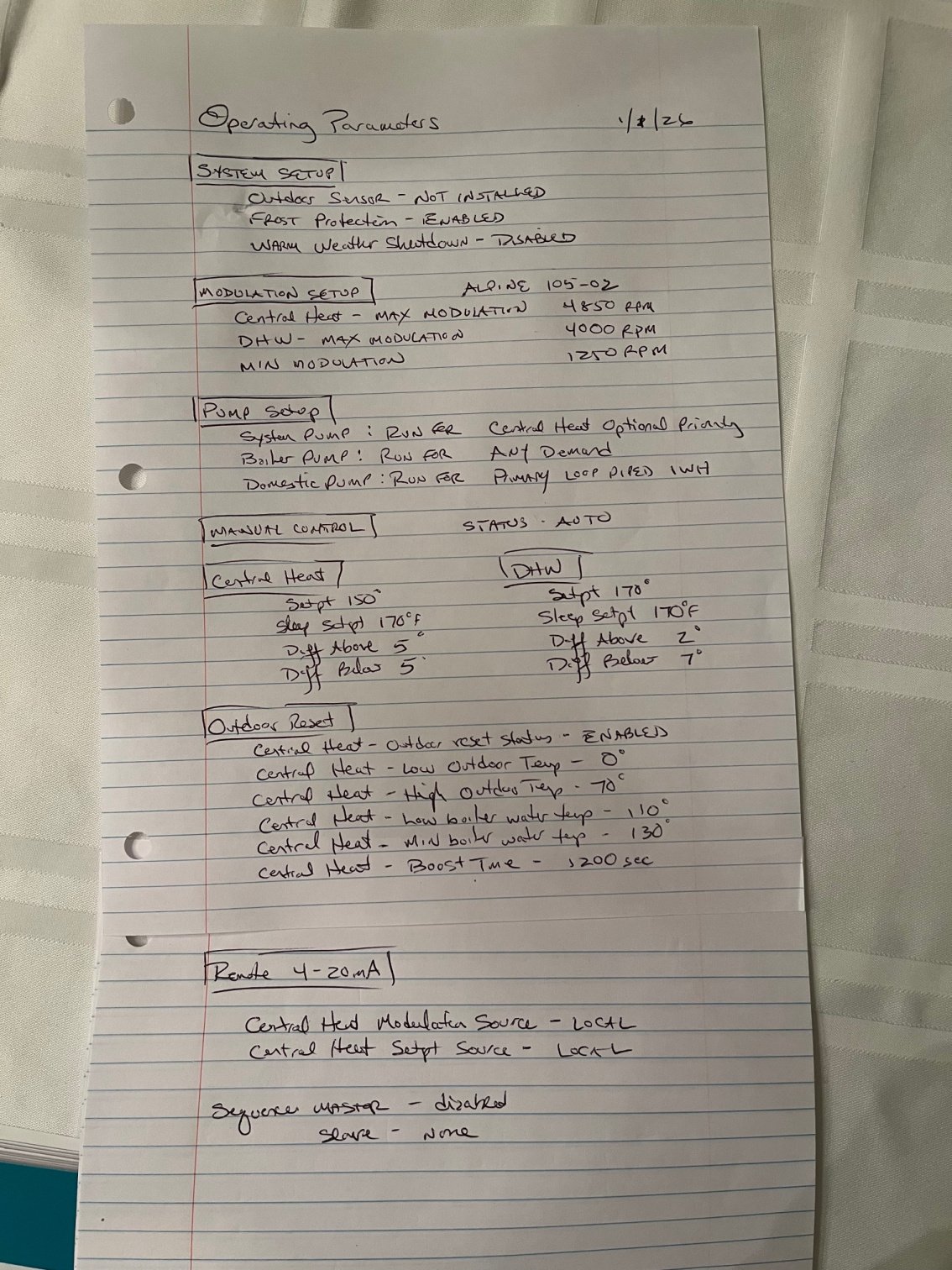

modulation settings:

Central Heat max: 4850 rpm

DHW max: 4000 rpm

Min: 1250 rpm

0 -

The circulator that loops though the boiler on the primary loop..It looks like it is set to low ..

There was an error rendering this rich post.

0 -

I’ll move the circulator speed from LOW to MED. What should I expect the result to be? Shorter runtimes when it cycles? What is the impact if I set it too high? How would I know?

0 -

Take more photos of the different setup and status screens available. Or even upload a video walking thru all the options. You can put the video on youtube and provide a link to it here.

0 -

Thank you for the suggestion of listing additional parameters or posting a video. I’ll see what I can do tomorrow.

One thought - it seems like the radiant is constantly calling for heat, as if the temperature in the tubing isn’t sufficient to heat the room. This is causing the boiler to be running almost constantly. The Central Heat set point is at 150 - as it’s always been. I was wondering if it made sense to raise the set point to the same as the DHW (170)?

0 -

How does the radiant call for heat? Do you have a thermostat in a room somewhere?

0 -

I would be looking on that radiant loop for an issue …. You have plenty of temperature for it. … Circulation , bad mixing valve or air ?

There was an error rendering this rich post.

0 -

There are four radiant zones controlled by three separate thermostats.

Note that the system hasn’t been opened nor have I changed anything with the exception of the Sage 2 board.

0 -

Are the thermostats satisfied, or are they constantly calling for heat? What is the temperature of the radiant tubing supply and returns?

0 -

This is a listing of the adjustable parameters:

0 -

The picture isn't high enough resolution. Not readable.

0 -

Better resolution file attached:

0 -

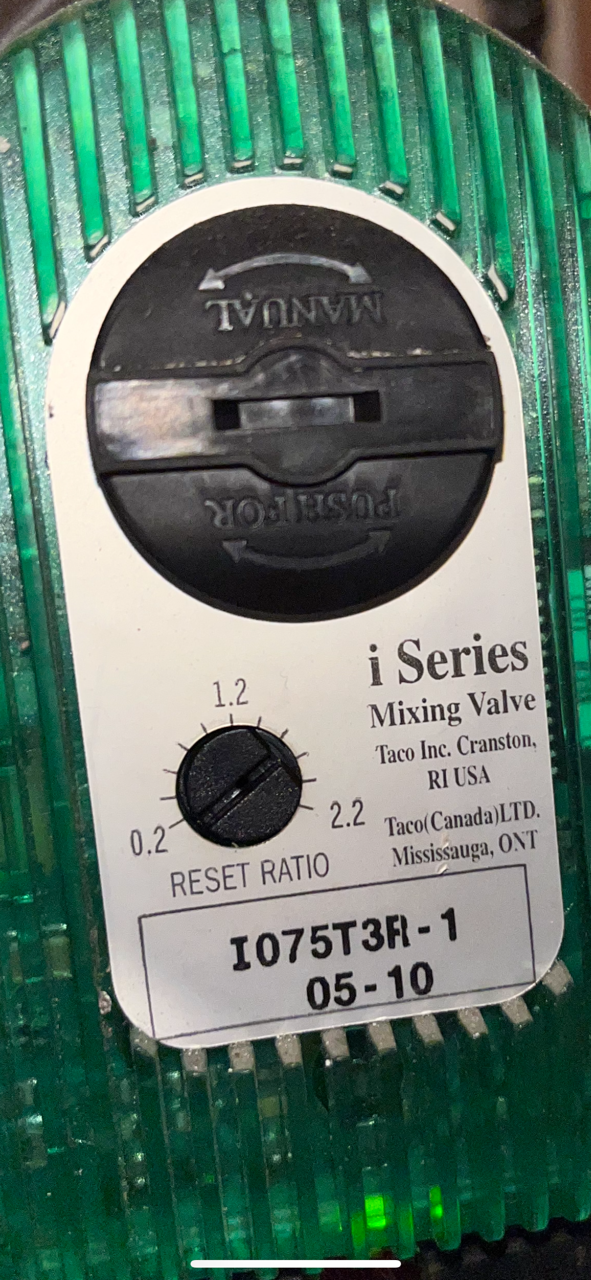

You said you have a mixing valve for the radiant? What temperature does it provide the radiant?

0 -

That seems like a really important question, but I have to say I have no idea. This is what the mixing valve looks like:

0 -

w/DIP switch settings…

0 -

Are there temperature gauges on the radiant manifolds? What do they say?

0 -

Oh, sorry. Forgot they were there 🤷🏻♂️.

Supply: 152

Return: 148

0 -

Where did you read those values? Take a picture of the temperature gauges.

0 -

If you go to the start of this thread you’ll see where I posted a picture of the system. The uponor manifold has round dial gauges on the left hand side. The manifold is below the gray expansion tank in the photo.

0 -

Yeah, I see that. I just wanted to confirm that is where you got those values. Good enough. (I'm not concerned with the supply and return temperatures from the boiler at this point.)

What kind of radiant do you have? The tubing runs under the subfloor?

0 -

yes. Pex under the subfloor. Two zones have hardwood floors (very inefficient). The other two are tiled bathrooms.

0 -

What temperature is it outside?

0 -

22 deg F when I took the readings.

0 -

Dip switches 1 and 2 can be used to enforce a maximum or minimum floor temperature. This is used to protect floors that are sensitive to excessive high temperatures. Or where it is desirable to maintain a minimum temperature to prevent cold floors.

Carry out this test. Flip dip switches 1 and 2 opposite to what you have pictured. Does the mix valve adjust the manifold supply temperature to approximately 110 degrees? This will take a little while as the heat is dissipated from the radiant loops.

0 -

How did the test go? Also, is there a sticker on the boiler with a model and serial number? Do you have a picture of that?

0 -

First, let me apologize for going radio silent. I unexpectedly had to travel for work and have been away. I just returned home late last night, and I’m leaving again on Friday.

I really appreciate people sticking with this thread and trying to help me.

I changed the position of the mixing valve dip switches this morning. I know it will take some time but I’ll check the manifold temps later today and report back. I’ll also post the boiler s/n shortly.

0 -

photo is a little blurry so I’m not posting it. Here’s the relevant info:

model ALP05F - 1LO2s/n 65188871

0 -

What size is the boiler? BTU output? Any dea of the heat load?

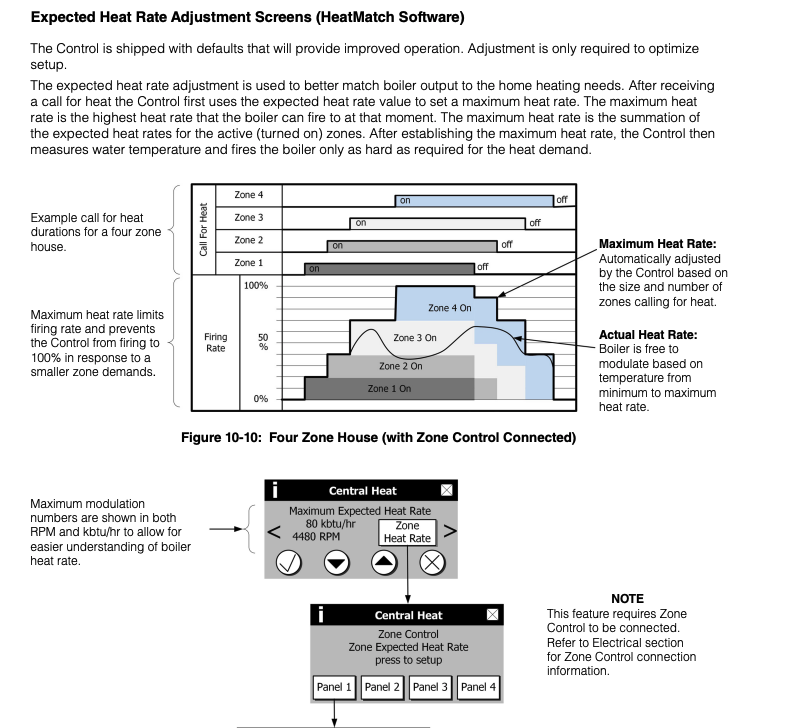

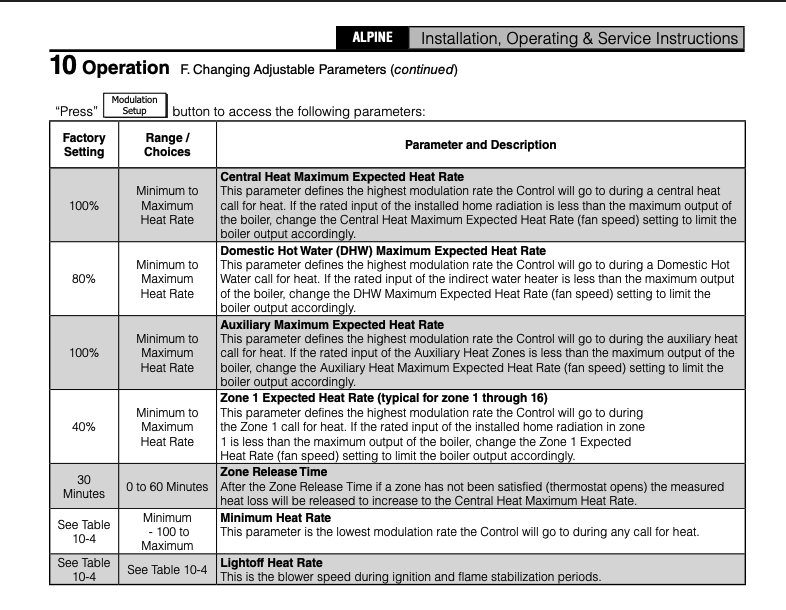

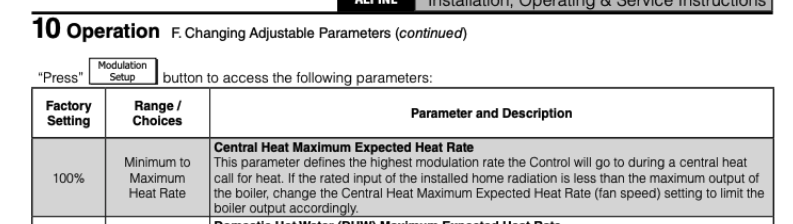

I like to use the modulation feature as explained in the manual. It helps prevent the boiler from ramping to high fire on every call, so it lengthens the boiler run cycles.

The boilers output is determined by the rpm that the fan runs, so the control basically sets or limits that rpm.

The manual does a good job of explaining the functions and adjustments.

There is also an anti cycling function which prevents the boiler from frequent on/ off cycles.

I would also use the outdoor resent function so the boiler never runs hotter than necessary.

This is for an Alpine with Sage control, look up the manual for your exact control at the website if you don't have the original manual.

'

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Mixing valve seems to be doing its job. Gauge temps dropped to about 70 deg (I thought 110 deg was min - ?). Regardless, should I adjust back?

Modulation is set w/min RPM 1250 and max 4850 rpm.

Boiler is an Alpine 105 - so 105 kBTU. Heat load is unknown.

0 -

So… I need a little additional input on the mixing valve.

I set dip sw 1&2 off on the mixing valve Came back 3-4 hrs later and both the supply and return were ~70 deg F and the boiler wasn’t running There was a radiant zone that I had left off so I kicked it on at the thermostat. Once the boiler fired I checked and saw no change on the radiant manifold temps

After 3-4 boiler cycles I thought I’d put the dip switches back, which I did When I looked down at the gauges they were now: 150 - 152 deg supply

138 - 140 deg return

Did the fact that I moved the dip switches immediately change the flow such that the manifold temps jumped? I didn’t check the temps after the boiler cycles, so maybe it was the cycling that brought the temp back up - ?I reset the dip switches off until I have some additional feedback

0 -

If you have 4 radiant zones and DHW, why do you have a mixing valve? Just set the boiler to the required radiant temperature. The lower the boiler operating temperature the higher the efficiency.

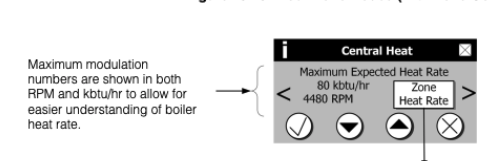

When you are at the modulation screen it also shows BTU/hr right above rpm

On this screen I would crank down the maximum heat rate as low as you can go and still maintain the home on a coldest day condition.

If you knew the heat load you would start there. If not, trial and error. Try 75% for starters. Factory setting is 100%. If you set it to 50%, you have a 52,000 btu/hr boiler.

This setting basically lowers the boilers highest output, attempting to match boiler output with the actual building load. But it still goes to 105,000 when DHW calls.

Are you comfortable getting into the control to fine tune settings to you home?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Put the dip switches back the way they were if you are done. I have to catch up and review your comments in a little bit.

0 -

I do not see a screen that shows the “max expected heat rate” or any BTU reading.

Re making adjustments - I’m a fairly technical person. Education in engineering. I’ve done some programming. I’m not a tech, so you have to go slow and explain everything!

Re comfort… that’s somewhat comical.

The house is almost 6000 sq ft and was built in 1907. Single pane windows. Cement stucco over wood framing. No insulation. Plaster walls. House is ALWAYS freezing. Furnace supplying forced air is two twinned 120,000 units. Radiant is intended to supplement the expanded kitchen’s small (8” dia) single forced air supply duct. Radiant was installed under subfloor/hardwood flooring. Did someone say “inefficient”? Gas bill came today ($800 for December). Just trying to make everything work as it should (and efficiently as possible!) but we gave up on the house ever being warm a long time ago. Two of the bathrooms with radiant are toasty though.0 -

That was an interesting test result. The instructions say dip switches 1 and 2 should enforce a maximum temperature of 110 degrees. It's important to understand how the mix valve works, and how to configure it. The boiler should really be configured with the mix valve in mind. Have you looked at the instructions for the mix valve?

@hot_rod posted some pages from the boiler manual. You should be aware that there exists an optional Sage Zone Control device. It is my understanding that zone by zone maximum heat rate parameters are not accessible unless using the boiler in conjunction with the Sage Zone Control. But you should be able to set a boiler maximum firing rate that caps the maximum output regardless of which zones are calling. Is there a "Modulation Setup" button on the screen anywhere?

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements