Unable to Achieve Desired Flow Rate in Radiator

Hey all I have a two zone hydronic radiator heating system with two Taco circulators and distribution manifolds for each zone. The boiler is a Ultimate PFO-4T that has been maintained and works well. The downstairs zone of the house is supplied by a pex manifold with individual flow meters for each zone as well as valves to adjust return flow. The manifold is downstream of a Taco 007e (new pump installed about two weeks ago) and has a main inlet connection of 1 inch. Each radiator has a 3/4 inch pex supply and return piping. There are five radiators on the first floor, four are larger cast iron three column radiators, and one is a Baseray baseboard approximately four feet long.

Each larger cast iron radiator is being supplied approximately 0.8 gpm per the flow meter on the distribution manifold. The baseboard flow rate is reading 0.6 gpm. I have opened the flow meter for each zone prior to the season and cleaned them all out and ensured they were free to move and not bound.

I am trying to raise flow to the baseboard radiator but have been unsuccessful. I have to basically turn off flow to two radiators to get the baseboard flow to increase. This does not see correct as the Taco 007e should have more than enough flow and discharge pressure per the spec sheet provided with the pump. The taco circulator is approximately six feet below the tallest radiator. The system is purged of air and running at 17psig of pressure per the gauge on the boiler.

Do I need a stronger pump or is something else the matter?

Comments

-

Is the baseboard loop on the last takeoff of the manifold ? Any parallel system should be piped reverse return , first one out the last one to return… Which will equalize the pressure drop across the manifold …

There was an error rendering this rich post.

0 -

Are there any Y strainers in the system?

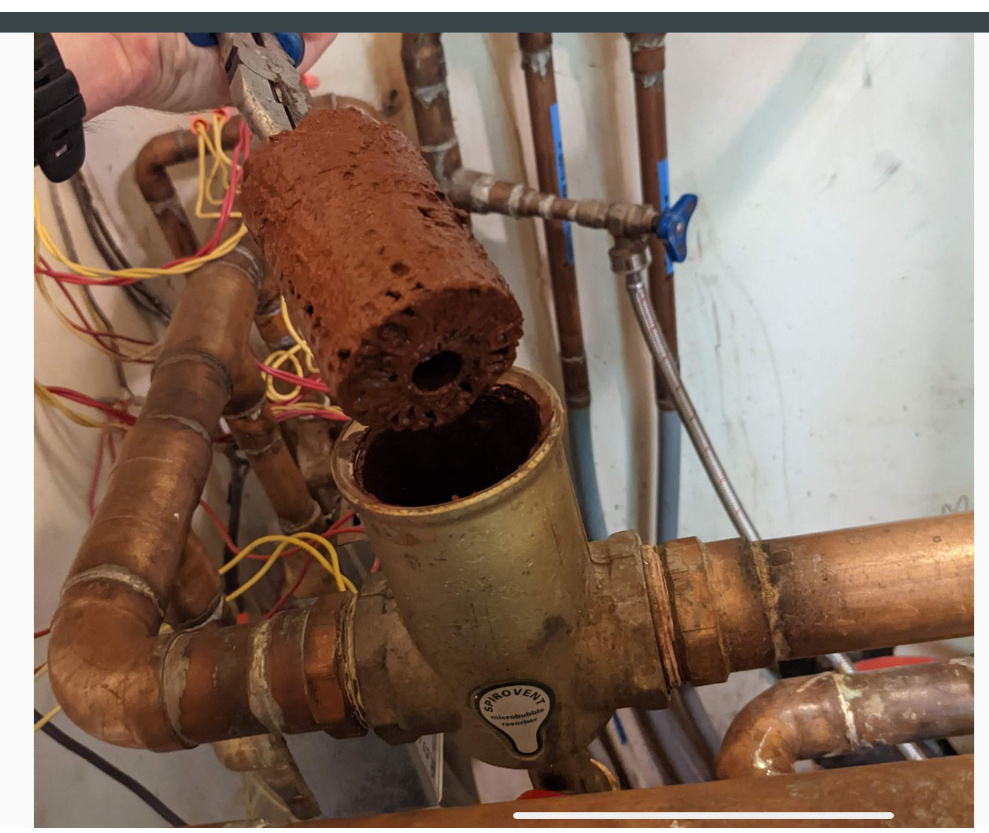

We have also seen air purgers sludge to the point of not allowing adequate flow.

It sounds like a flow restriction, maybe a partially closed iso valve?

Are there different flow modes in that circulator? I would force it tom the highest speed possible to check.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

The baseboard is connected to the next to last connection on the manifold. There are no strainers or air purgers in the line from the pump to the manifold. I have followed the piping from the manifold to the baseboard and it is all 3/4 inch pex and then swaps to 3/4 inch copper. It's a pretty straight shot from the manifold to the baseboard radiator. The baseray baseboard is in series with a small fin a tube baseboard that is also 3/4 inch copper piping with no valves or strainers.

0 -

Update: so I rebled the radiators on the first floor and closed all of the radiators except the baseboard and one other three column radiator and was unable to achieve more than 0.4gpm to the baseboard. I don't understand why I can't get more flow even with all of the other radiators isolated.

0 -

To your knowledge, has the system ever worked satisfactorily?

0 -

I believe the previous owner of the house thought it did but the room with the baseboard in it is very cold. I replaced the fin and tube 3/4 inch baseboard with a Baseray cast iron baseboard. When I first put the new pump in I was able to get more flow but not any more. I have bled the system, changed the boiler pressure, opened the breaker to the heater to reset the 007e circulator, and isolated different radiators to try and change DP across the baseboard.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements