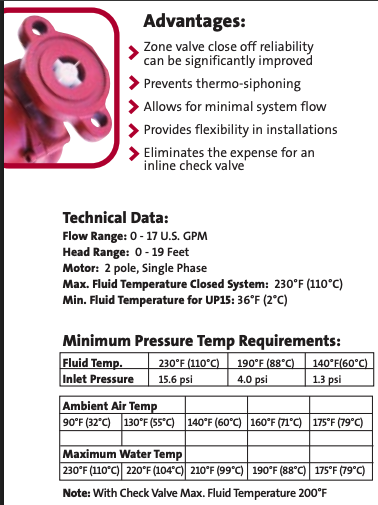

Expensive Check Valve

Comments

-

Caleffi, Taco, and Grundfos all playing together. Showing all the reps some love.

0 -

Is there also a check in the circ? If so, the ZV on the return could have some value if there are ghosts present. The hydronic type 👻

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I didn’t check the circ for a check : )

The owners of the house in the City called me there to find out why they weren’t getting heat to the zone to the left of the one with the pump. You can see there’s only a zone valve on the loop, no pump.

Other than the missing pump, the piping was OK, but the wiring was a disaster and I had to go home for a nap after trying to figure it out.8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab2 -

i wondered about that other Zv, thinking maybe a pump was mounted out at a manifold or something?

That pump has the IFC sticker on it, indicating the installer added the check

Are the checks loose in the box these days, or factory installed

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

brand new 15-58 on my shelf currently has the check pre-installed. Seems like they were shipping loose a few years ago though, can't remember exactly. Would be nice if they shipped loose so you could have a spare if you didn't need it on a job, they always seem to get destroyed when you take them out.

0 -

Pump getting hotter than water by 50 F.I destroyed the check valve. What's the risk of running my floor heat system without it?

0 -

They only way to remove them is to destroy them.

I'm going to add a pump to that loop and remove the Caleffi power heads, making sure the checks are installed. I think Grundfos sells checks by themselves.

@goodend If your pump is that hot, check the amp draw to make sure it matches the rating. If it's different, you may have to replace the cartridge (Taco?) or the motor and impeller.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0 -

The very first Grundfos checks were loose in the box, and came with a sticker indicating check installed. But they could be pushed in backwards, and they could spit out and get into the flange or piping!

The newest ones are larger diameter and I believe Grundfos pre- installs them. They can be removed with a needle nose pliers.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

If you remove the actuator the paddle inside the valve body will be floating, it's the spring tension in the motor that allows it to be manually locked open. Although flow should push it and keep it open, I have never tried it to confirm.

No harm in leaving the ZV in place, I think it is more reliable than a check in the pump body.

Reports from the field indicate 3- 5 years some of those IFC checks fail. This video shows how the checks rattle around at the pump discharge.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Nice setup and video, hr. Hard to see that check, but I believe you what it's doing.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0 -

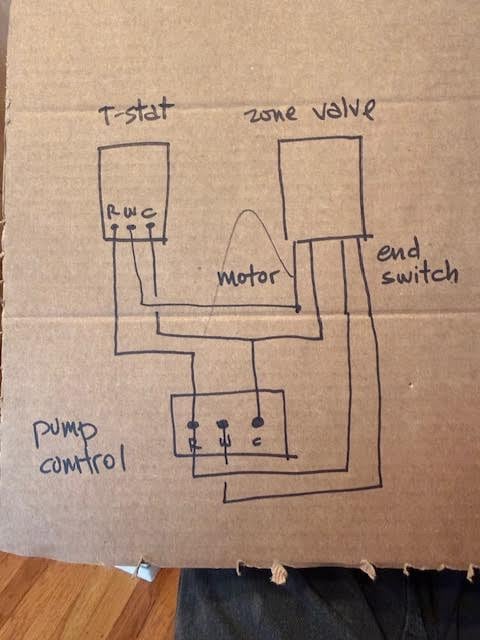

I added a pump to the zone that wasn't heating and installed a pump controller. And I left the existing zone valves operable at hr's suggestion that they provide a reliable check valve.

The hard part was the wiring: I only wanted the pump to come on after the zone valve was open. At first, I thought about adding a RIB (Relay In a Box), but then thought that I could do it with just the bare bones pump control and came up with this. Seems to work fine.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab1 -

That works.

I have seen 120V pumps wired through the end switch on a 120V zone valve also.I think officially you are supposed to add a electrical box for the multiple wire connections

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I thought about doing that with these 24 volt Caleffi zone valves, but the amp rating was too low. And the wires were too small, like 16 gauge.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements