How to pipe a Condensing boiler with heat exchanger for non O2 barrier pipe

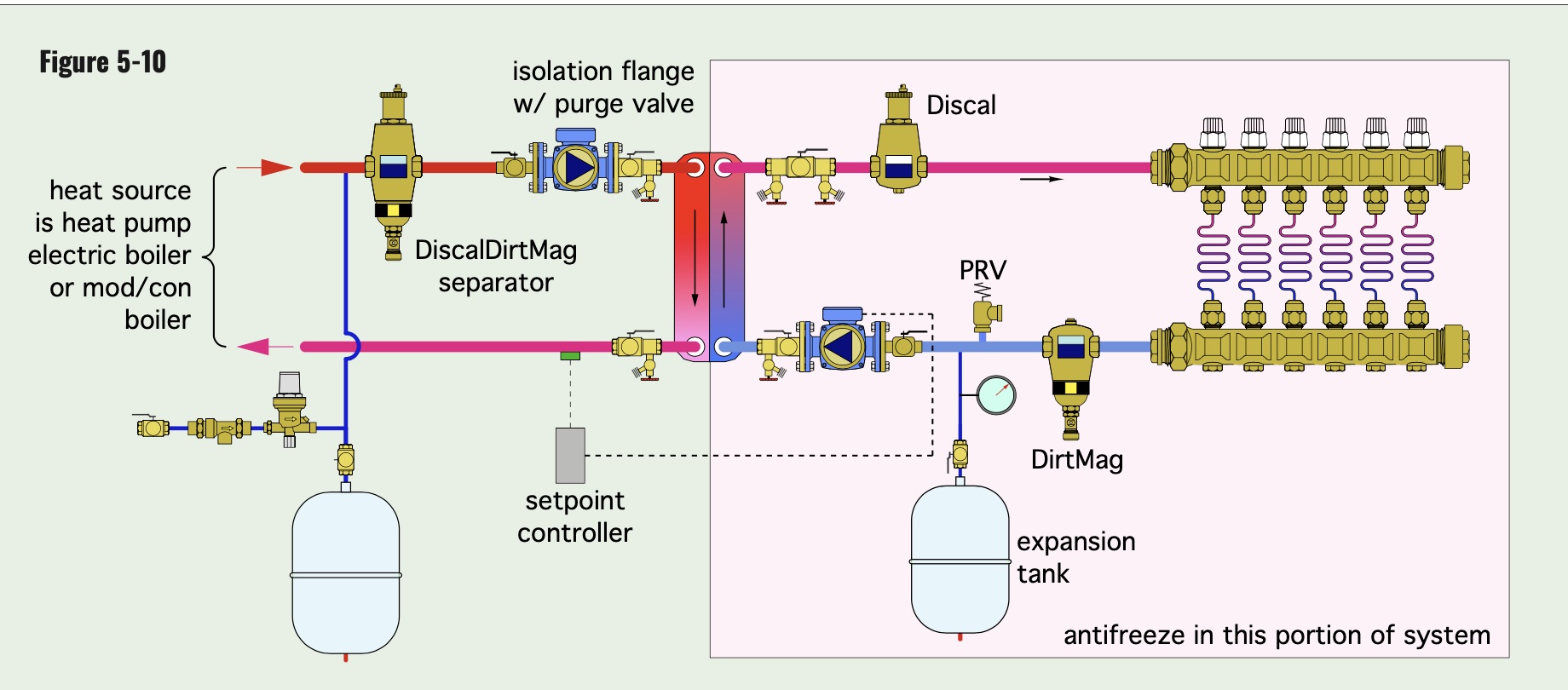

When using a heat exchanger with a condensing boiler to feed non-oxygen barrier pipe, how should it be plumbed? Option 1, come off the boiler, to a pump, then to closely spaced T’s and back to the boiler, with a separate loop coming from the closely spaced T’s, to a pump, and then through the 80 plate heat exchanger, with then another pump on the isolated side to feed the radiant tubing, or Option 2, come off the boiler, to the pump, through the heat exchanger and then back to the boiler, so basically plumbing it like the heat exchanger is a hydraulic separator?

Comments

-

It can be this simple. You need expansion and relief valves on both sides of the hx

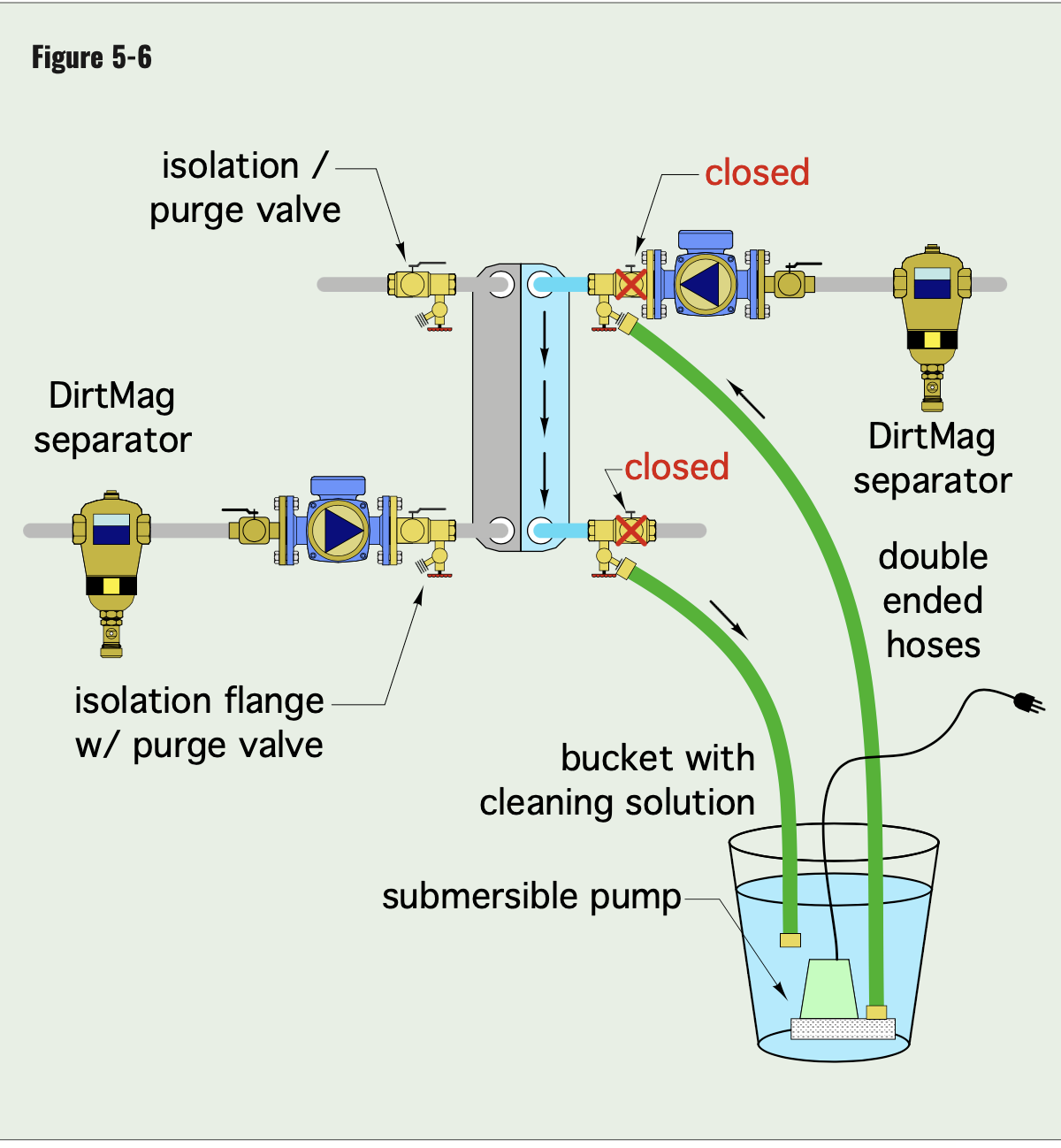

If the tube side needs glycol, conditioner, or occasional flushing, use some purge valves like the Webstone with hose connections. Counterflow through a FPHX.

A DirtMag for sure on the tube side of the HX.

Was the HX sized? Or is the 80 plate a guess?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

What is the Non- Barrier piping? Poly B, Onix? Regular pex?

One way is to use an All Stainless Steel Indirect water heater. Use the coil (1" coil at least) and have that as your boiler loop. Then use the hot and cold as your system loops. Use all brass, copper or stainless parts on that side for best results… a good inhibitor after cleaning/ flushing.

1 -

-

-

If the pumps are stainless and the expansion tank a lined type likw the the Amtrol Pro you could get all non ferrous piping.

Connecting Viessmann boilers to non barrier tube voids warranty, possibly others?

Temperature has a lot to do with O2 ingress. Higher temperature fin tube for example really pull in O2.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

I wonder how much water quality in different parts of the country affect that.

I had at least 4 customers who had PB tubing hooked up to their cast iron boiler, and with all iron parts, that had been in for at least 35 years that I know of , with no problems except leaky manifold connections. This was on a radiant system, and with 4way mixing valves, so I'm sure the low temperature of the system helped. I would have thought the pumps would be more prone to scaling up though, but didn't see it.

Rick

0 -

I agree it varies widely.

This sep was on a high temperature rubber tube system for 18 months and rusted through!

It was on it's 4 boiler in 20 some years of service.

I have seen other rubber tube systems with excellent water quality 10- 12 years after installation. No rhythm or reason for it??

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@hot_rod yes, the 80 plate was sized, I called Badger Pipe from Wisconsin as others have recommended them in various threads on here for heat exchangers, and that one’s the one they recommend. The boiler manufacturer states in the manual that any piping system that doesn’t have an oxygen barrier needs a heat exchanger. Thank you for your help as always.

@mattmia2 thank you, I assumed I just need to select a pump with enough head to handle the heat exchanger and the boiler, but wanted to verify.

0 -

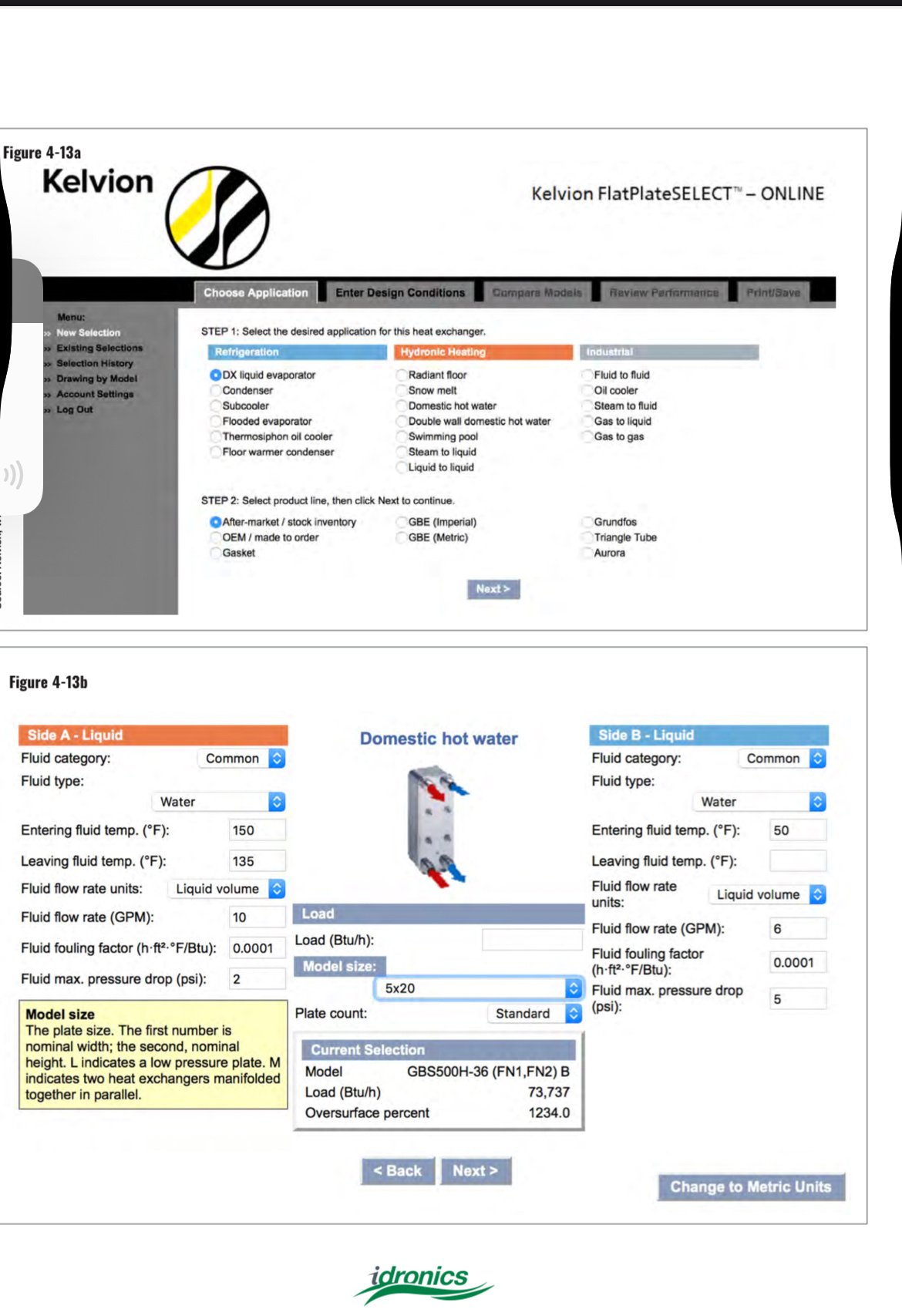

ideally you size a heat exchanger with a software like this. Most manufacturers have these calculators on their website

You need to input temperatures and flow on both sides.

80 plate sounds quite large?

This example for dhw production 50 degree in on the B side

It shows a 5x20 36 plate moving 73,000 btu/ h

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements