Viessmann Vitocal AWHP for hydronic baseboards or retrofit floor heating?

Comments

-

I like to also look at the mean minimum annual temperature, which is -20C. Somewhere between that and the 99% temperature (-15C) is where you want to land. Look at the available equipment and see what gets you there.

0 -

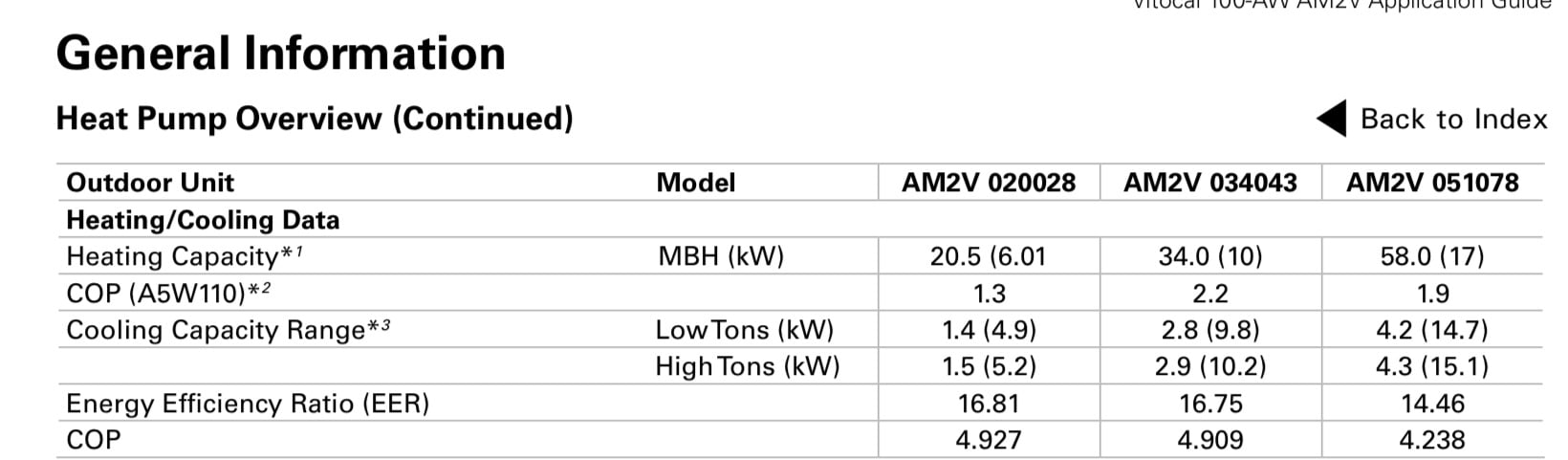

In that case it would be the bigger unit as the smaller one can only make 20k BTU at -20°C.

For moderate temps the big one is then way over capacity. I would guess their modulation allows them to run at only 10-20% and be efficient?

0 -

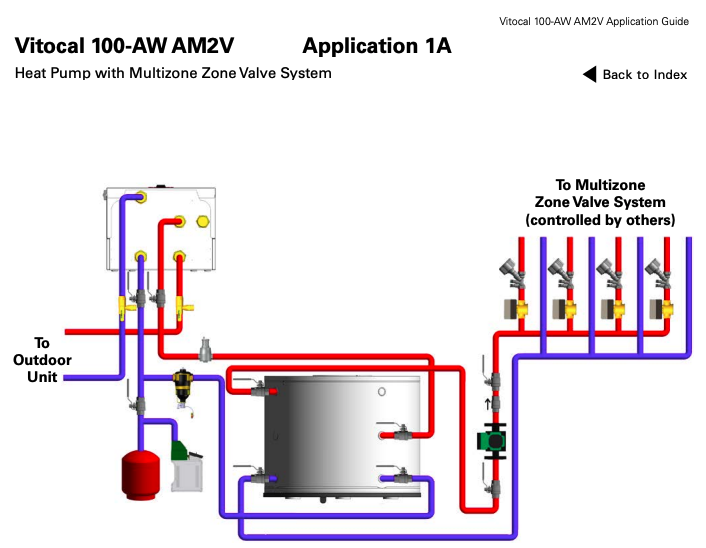

Not sure if its been posted yet, but here is Viessmann's application guide for that unit

0 -

I saw the guide, it has the buffer tank as a separator in every application. Though there is no application with only radiant infloor.

0 -

I wonder why they did not show a 2 pipe connection. You still get the separation and eliminate flowing across the top and bottom of the 4 port option?

And why the pipes crisscrossing the tank in the piping layout?

On mine I piped 2-pipe and put a flat plate HX so only the outdoor unit has glycol, not the entire system. They have a wiring connection PGC on the indoor unit for the HX pump to wire to.

One tank sensor runs the A2WHP, the second calls on the boiler, which is also controlled by the HP module.

\

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

As I said we are looking into ways to heat the basement and cool in the summer, I came across fan coils like this one:

Without much experience they seem exactly like what we want. They run with water temperature as low as 40°C with enough output for just two rooms and could cool in the summer. This way we could even install one on the main floor and use just one system all year round instead of a mini split with condenser.

Any thoughts on that?

0 -

Yes, the cooling load would not be high. I was hoping that the modulation of the unit can handle that.

0 -

the modulation is more about handling low load conditions without excessive cycling of the HP. The top end is the top end regardless of modulation.

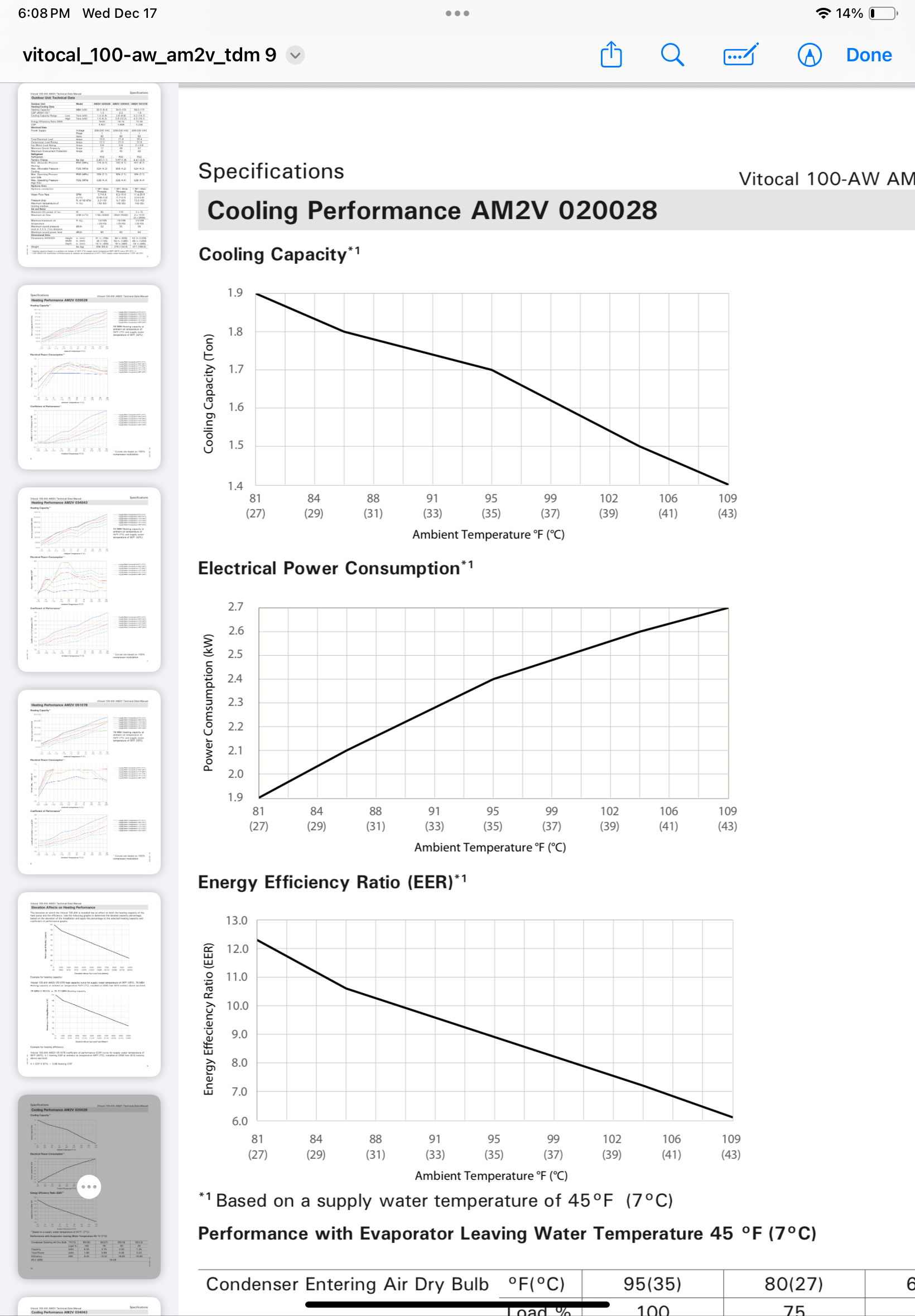

The spec sheet shows the cooling range

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Looks like a mini split is a way superior option.

0 -

As mentioned earlier, you generally don't want a buffer tank as it can lead to mixing which can give you a significant COP hit. When I did the calcs on mine, it looked like I needed one, but decided against installing it. The unit does cycle a bit (like 1 or 2 CPH) when it gets above 10C, but at that point the load is so low that any efficiency hit doesn't matter.

The one buffer configuarion that does work without any COP hit is a series connected two port volumizer. This essentially makes the system behave like a high mass setup with any chance of mixing.

There is very little drawback with over-sizing an AWHP, this lets it operate at lower modulation when you need the most amount of heat which increases COP.

I would not bother with indirect for DHW. I ran with this setup for a year but ended up putting a resistance element in that now runs on timer to recover during off peak. The issue is the recovery time when it drops bellow freezing especially in the deep freeze. Recovery could be 1h to 2h while you are not making any space heat when you need it the most. The COP of making DHW when it is -10C it is also low enough that not worth the extra complexity. Best option is a HPWH or resistance tank. Your extra efficiency dollars are better spent on drain water heat recovery.

I tried cooling with my AWHP but it cycles the unit a lot. It also creates a lot of issues with condensation on anything exposed. Kiss, if you have mini splits, use those for cooling.

0 -

I'll look and see under what condition the 6 KW resistance element kicks in. I have mine disabled, no need for it.

If it kicks in during a slow DHW recovery it would be much faster than a 4500W electric tank and a lot faster that a HPWH. It really depends on your DHW needs. The indirect is an expensive adder.

The Viessmann 100 is a nice tank for HPs, lots of coil surface and powered anode are features.

There is no one size fits all with A2WHP. Your specific system, temperature requirements, number of and size of zones, weather conditions, type of heat emitters, back up source, all need to be looked at closely.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Yeah, if what you're looking to do is heat and cool water and run it through a fan coil unit, there's not a lot to recommend that solution over a mini split.

0 -

Are mini splits throw aways when something like a compressor or module fails?

I've never installed or worked on one?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

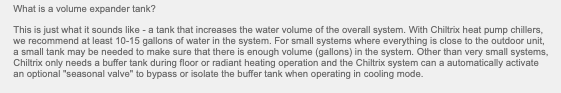

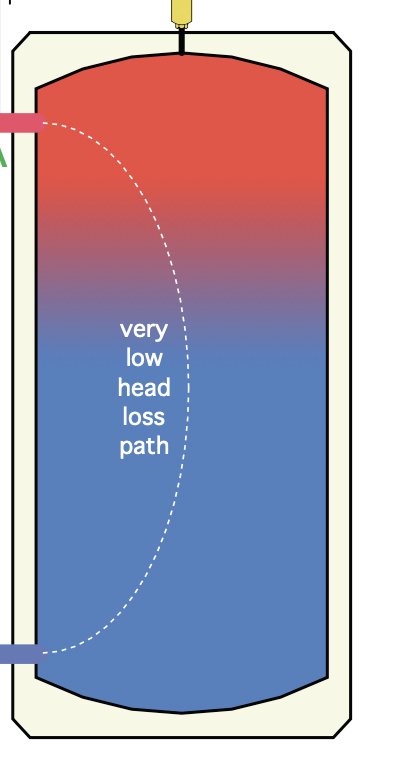

The one buffer configuarion that does work without any COP hit is a series connected two port volumizer. This essentially makes the system behave like a high mass setup with any chance of mixing.

Do you have a pic or sketch of a tank like this? Would it have a baffle in it like chilled water tanks typically do?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

All drawings I have seen show a simple tank with ports on top and bottom. Even if you are talking something like a 40gal buffer, which is very much on the large side, it will get fully cycled fairly quickly anyways, so don't think anything fancy is needed.

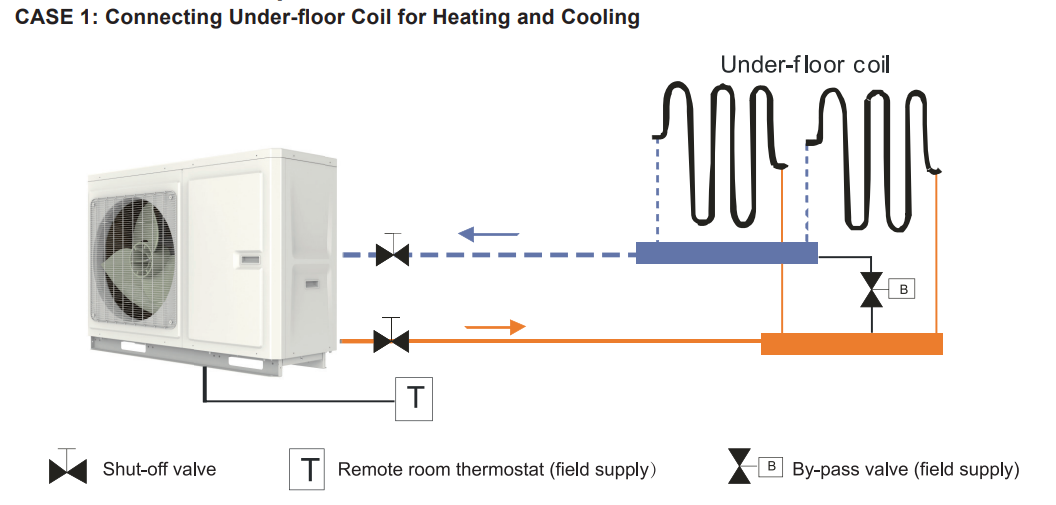

@Voodoo90 Also in terms of plumbing, the one that is the most efficient is direct to load with a differential bypass:

This is also the simplest and if your unit has a room sensor, you don't even need a thermostat. You can add a two port series buffer to the supply side if needed.

0 -

Would in a direct to load scenario the circulator pump of the indoor unit handle the entire circulation or where would the pump for the heating loop go?

Its very frustrating not being able to discuss these things directly with Viessmann, but through the contractor who tries to go the path of least resistance.

0 -

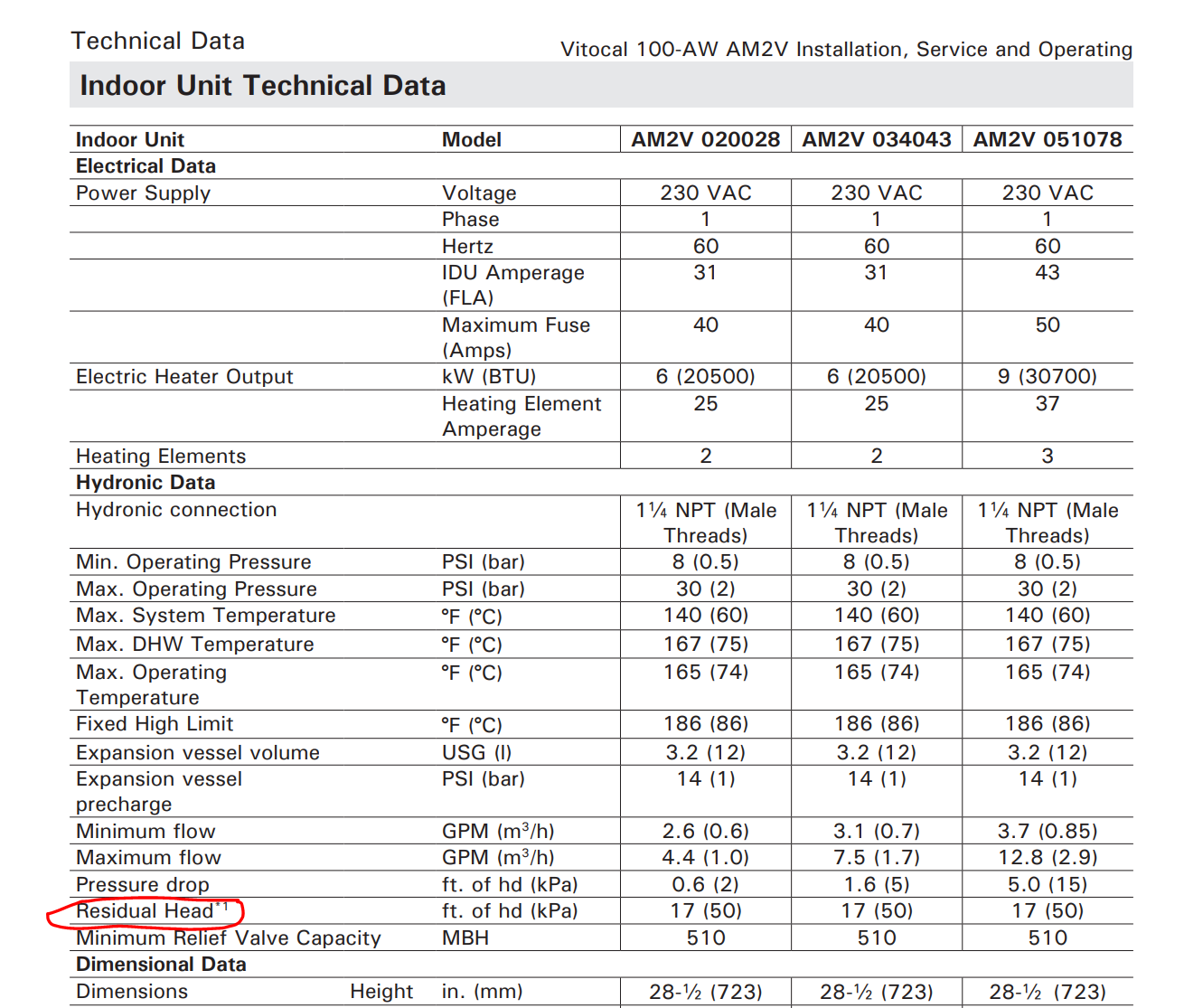

Yes. The pump inside the unit is all you need. You do have to do a bit of design as the head capacity is limited, from the data sheet, your emitters plus all the piping from manifolds need to be bellow 19' of head. I would design the emitters for about 10' of head to be safe which is pretty easy with floor heat

Depending on which size unit you go with, there is a minimum flow rate you need as well thus the need to for the differential bypass valve. Any areas you want extra toasty, you can put as always on which will reduce the amount of bypass when few zones are calling for heat.

When you draw it, it does look wrong as it is too simple. Some manufacturers don't show this option as it is easy to mess up if the emitter pressure drop is too high or not enough flow rate through the monoblock.

0 -

The pressure drop and the flor rate of the two in floor manifolds are pretty much set by the design, the output we need and the maximum floor temperature. The zones would ideally be always on with a water temperature what maintains the desired room temperature. There is only one thermostat or temperature sensor for the house.

0 -

If you have only one thermostat you don't need any zones so things get a lot simpler. You can go direct to load, no buffer, just using the circulator in the heat pump. The flow is always the same so you don't need the differential bypass valve.

My understanding is this is how houses are commonly plumbed in Europe, where air-to-water heat pumps are more common than in North America.

0 -

you will have a glycol derate also when you look at pump capacity. You will want at least 30% mix.

The circulator in the small Viessmann modulates between 3 and 6 gpm

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

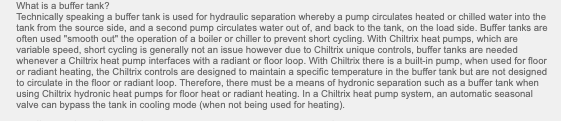

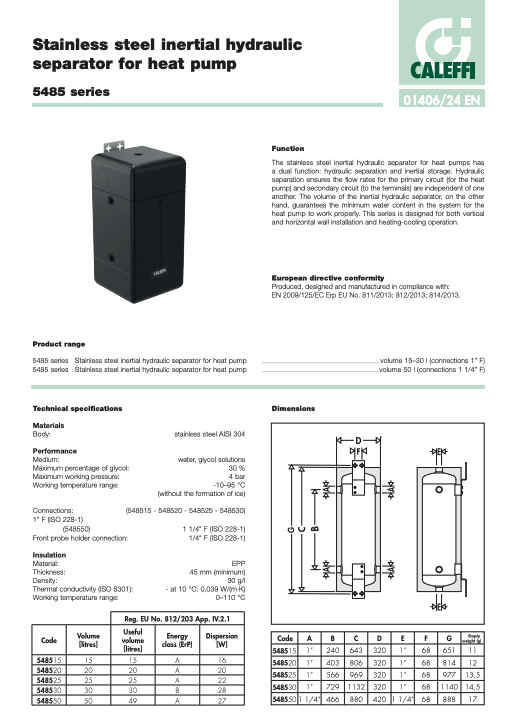

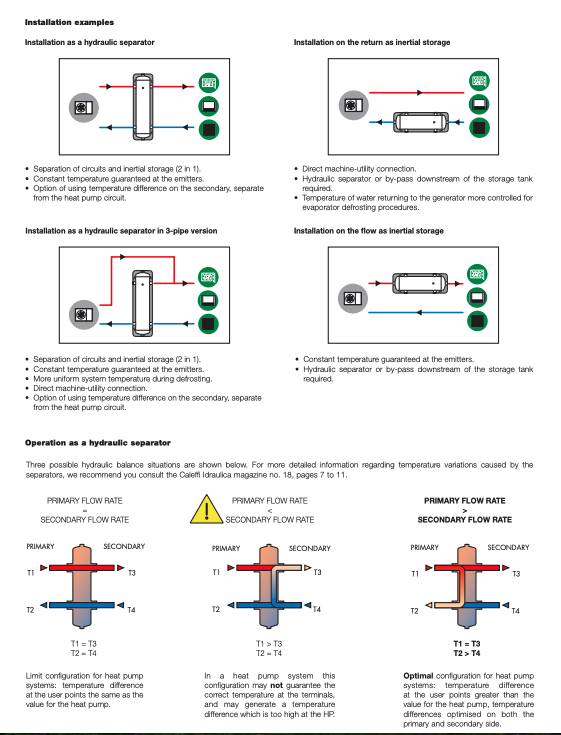

Chiltrix has a nice selection of buffer tanks for HP specific applications, here is their opinion on the application.

They do tank about volume expanders but no piping info. I don't see how piping in one side and out the other adds volume, water will just flow across from one port to the other

Chilled water tanks generally have a baffle inside that drives the water through the entire tank, for example.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

My understanding of what Chiltrix is saying there is that they expect the radiant zones to be controlled with a zone valve, so that when the zones are closed there needs to be an alternate path to allow flow.

The Chiltrix control philosophy — and I don't know if Veissmann is the same way — is that the emitters have to control their output to meet the demand for heat. When they do that, that in turn changes how much heat is being removed from the water flow. The heat pump monitors how much heat is being removed and modulates to try and match it. Even when there is no demand for heat there has to be some flow so that the heat pump can detect that there is no demand.

Outdoor sensing is easy because the heat pump is outdoors, so the default rough adjustment is to adjust the water temperature to meet the anticipated load. My understanding is that in Europe that is commonly done as the only control. If you wanted finer control you could have a room thermostat that controls a 3-way valve. When the thermostat is on flow goes through the radiant loops and when the thermostat is off the flow goes through a bypass pipe. When the bypass pipe is activated the heat pump will sense that the demand for heat is zero because the water because the water returns at the temperature it was sent at, and the heat pump shuts off.

1 -

they mention hydraulic separation, the hp from the radiant? I don’t see how that happens with a flow through volume expander tank?

Caleffi builds a 3 way diverting valve for that European market with bypass built in, it protects the hp flow as the 3 way valve changes position

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@hot_rod I was thinking for a simple tank with side ports. There is still some mixing but close enough.

@DCContrarian Pretty close. Overseas TRVs are near ubiquitous so it is direct to load with TRVs for local temperature control. The diff-bypass is needed on these as the TRVs modulate flow.

@Voodoo90 What is the overall flow rate and pressure drop of your as designed setup? If these are within the limit of the built in pump, you can connect direct connect. Looks like the 100-aw also has the option for room temperature sensing and control, so you don't need any extra controls.

0 -

@Kaos I will have to ask the engineer for the infloor about the exact values. The only option I would like to have is a floor temperature sensor that does not let the floor get hotter than 27°C. But there does not seem to be a wiring option for a sensor like that. But from what I have seen in the design we would not 27°C floor temperature at design load anyways.

Also, for a direct to load setup, how would the buffer tank sensor integrate into that as the buffer tank is mostly for return water mixed with overflow from the heatpumps in that case? More like a volumunizer.0 -

Volumizer, so in-line buffer tank. Cheap option is standard 20/40 gallon dual element water heater, remove the elements and use the 1" NPT element ports for connection. There is no need for any sensing, it just adds extra heat capacity to the loop to reduce cycling.

You don't need floor sensing with the right reset curve. If the supply temperature is not hot enough to cause the floor to overheat, there is no need to sense it.

0 -

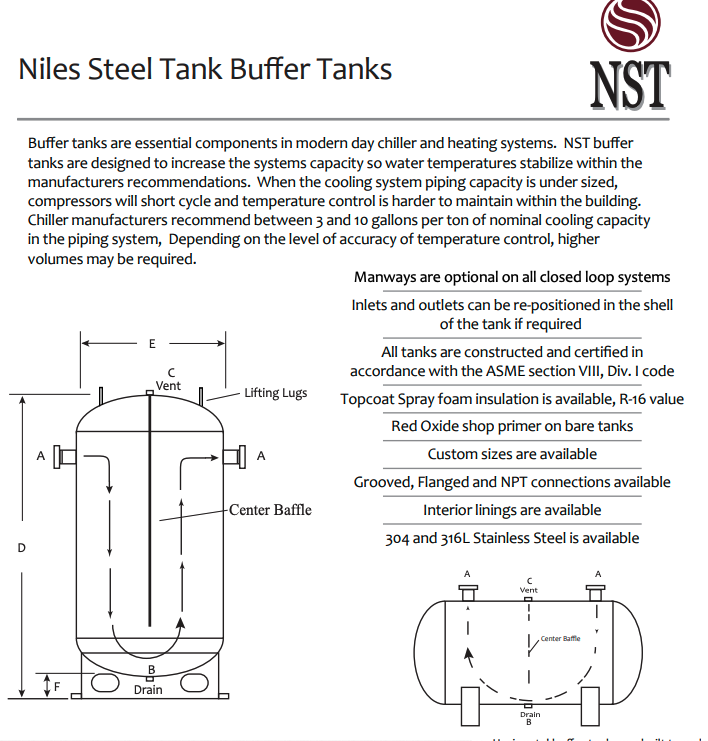

I agree a A2WHP is rarely a drop in replacement on a boiler supplying fin tube with a 180 design.

It is possible when building new to design and built with not to exceed 120SWT.

This radiant/ panel rad system in upstate NY. A single 40W circ on the distribution. Electric boiler backup has not been needed

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Generally what you find with an inline tank is flow will go from port to port and not enable the entire volume, I built a few clear plastic tanks to demonstrate this over the years, plastic aquarium tanks. Top to bottom connections on opposite sides would help.

So I would go with at least a 20 gallon tank to assure you are in fact adding volume. Or maybe a sparge tube at the bottom in connection.

The other benefits from a 3 pipe buffer is the hydraulic separation, if needed, at the cost of temperature blending.

Also some HPs use the buffer tank water for defrost. This is good as that heat was generated with higher COP then using resistance heater to defrost.

I know some mod cons show pump capacity available for direct piping, I don't see that info on the Vitocal, they use a small OEM Alpha for the circulation.

The pump sizing needs to take into account piping between indoor and outdoor unit and the % of glycol in that loop, the pressure drop of the HP.

I know one installation in CO where the loop from the outdoor to indoor 1-1/4" was quite long and limited the HP performance.

So calculate all this when you decide on a piping/ tank option.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Eventually I will contact Viessmann directly and ask them about these different options whether they are feasible or if the unit really just runs with the buffer tank in a 4 pipe setup.

0 -

The European market models are so much more refined and advanced in the ways they can be set up. I just wonder why they take a step back when introducing it to the market here.

0 -

I follow a UK hydronic chatroom to see how they pipe systems. Most often those are panel radiator systems, not so much radiant. So they deal with TRV controlled systems for the most part, small diameter copper tube distribution.

I think the UK and Germany are the largest A2WHP markets. So they are pioneering the various piping and installation methods.

Caleffi, Zilmet ad others in that market have developed small wall hung buffer tanks for HPs. We show the various piping options and considerations.

The Viessmann Vitocal manuals have improver a bunch since they introduces that product in the US. Maybe it indicates pump capacity available now?

The pump is right up against the cabinet so I cannot see the model number on mine.

Scott in Vancouver or Rich are the most knowledgable tech support people for this product that I have talked with

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Residual head from the spec sheet is the max head for all plumbing connected to the boiler pump, this includes air sep any piping to the outdoor unit. There is also a flow range, I would aim for the higher end as AWHP tend to run at lower delta T. My 5 ton unit runs at 10gpm.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements