Firebox heat exchanger with a buffer tank

Hey there!

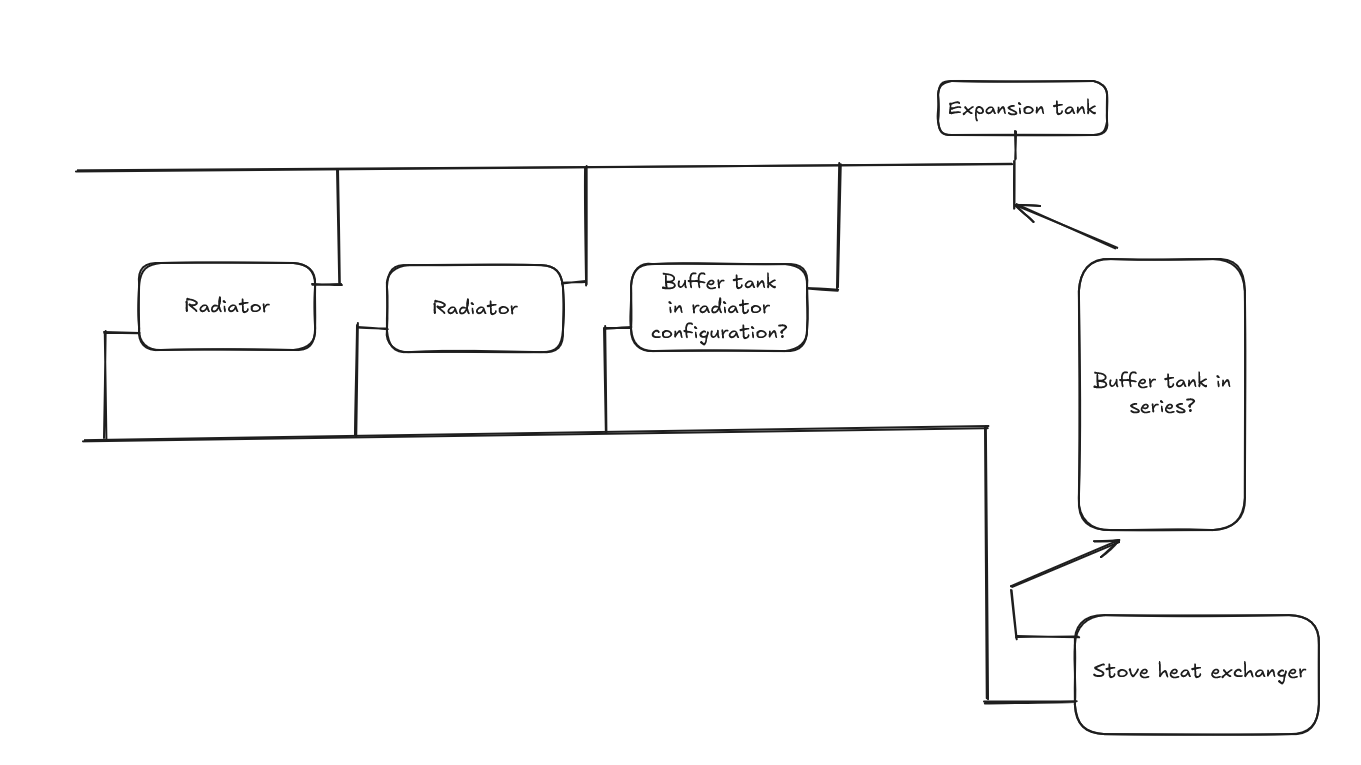

I'm trying to design a gravity fed heating system where I have a metal heat exchanger inside of a wood stove that is circulating water through cast iron radiators. The heat exchanger is kind of a DIY solution made from a series of welded pipes that is used very often here locally in eastern europe. In general it can be assumed to behave exactly like a classical heat exchanger with a cold inlet and hot outlet.

The big problem with such systems is that it's very hard to control the heat output initially when starting the fire, so there are moments when the exchanger receives a lot of heat. If the system is not big enough, this leads to water boiling in the expansion tank and in general dangerous temperatures in the system.

I have a small system for now that heats 3 rooms with somewhere around 60 sections in total. This amounts to around 20l of water in total, as the cast iron radiators are of new style and have reduced water capacity. I know for a fact that this amount of water is way too low for the system to not overheat.

From what I've read, the classical solution is to place a buffer tank in the system. The problem is that the amount of material I found online is extremely limited and but often there are 2 options mentioned:

- Placing the buffer tank in series to the hot outlet;

- Placing the buffer tank near the heat exchanger in a radiator configuration.

From what I understand placing it in series is the safest bet, as there will be a good amount of cold water to keep the water from boiling in the expansion tank initially. For me it's not entirely clear if such a configuration will allow for water to flow at all, as you have basically a big tank instead of a pipe. Assuming that water flow is not a problem, then another downside is that the radiators will only start to heat when the buffer tank will be hot.

The second option seems to be better, however I am afraid that the water will still rise to dangerous temperature initially.

For reference the plan for the buffer tank is to be around 80-100l, possibly more as to be on the safe side. I also want to clarify that the system will not contain any pumps now or in the future.

What do you think about this?

Comments

-

If the buffer is in series it will always be hot and not have a lot of "space" to absorb the over-heat.

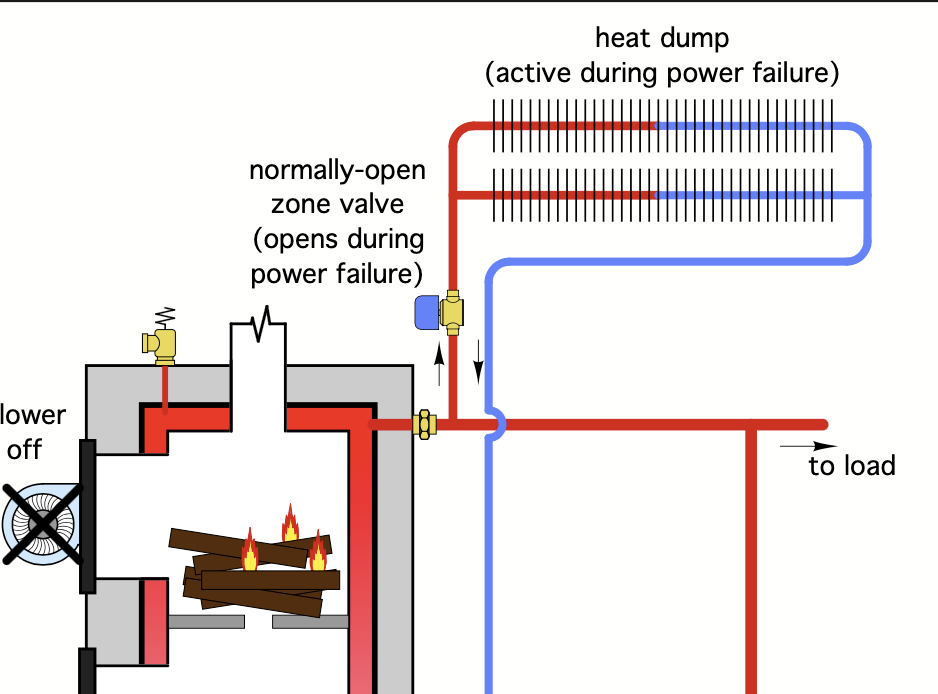

Another option that we use is a fin tube dump zone. These get used on large solar thermal arrays or wood fired equipment.

It would operate with an electric valve that opens if power fails of based on a thermostat. These are more often for power outage protection on pumped systems.

Or a 3 way thermostatic, non electric, option.

On solar systems the fin tube mounts behind the collectors and a 3 way valve diverts at a certain temperature.

A small fan coil works well also but requires power. On occasion a loop of pex tube is buried outside as a dump.

But you may as well try to capture and use the heat inside.

There is a formula that calculates firebox size to determine the btu size for a dump zone.

Without a pumped flow, the dump zone planning will be more involved. The tank mounted above the heater would allow it to it to thermo-siphon.

Is a DC pump and battery an option? That gives you better control options, a 20W solar panel to maintain a battery. Then you could put excessive energy into and out of the tank easily.

The very best method is build the fire to the load and not have to depend on a dump zone or protection. You need a full time fire tender for that :)

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

As a homeowner I am going from memory here to describe the bottom fed and the overhead gravity hot water heating methods.

How many floors does this home have?

You should pass on using the wood stove with a heat exchanger. A wood boiler or small coal stoker yes but not a wood stove.

The two proven methods of using a gravity hot water heating are either bottom fed or the overhead method.

With the bottom fed design the hot water radiators on the first floor utilize orifice discs to slow the water going into the first floor radiators allowing the hot water to reach the second and third floors first as the hot water would not travel as fast to the second or third floors if at all as water like electricity is lazy.

The first riser comes off the top of the boilers steam chest and either climbs to the highest point where the open to air expansion tank is and then the hot water flow drops to the radiators below it after it enters the open to air expansion tank or the riser is plumbed into the open to air expansion tank using a elbows and a Tee to connect with the open to air expansion tank to keep the tank warm at all times and the drop pipe connects to the radiators and the cooler water sinks from the radiators to the return riser back to the boiler.

The two risers should be piped very close to each other otherwise the water will not flow correctly to heat all the radiators.

The overhead method uses one riser for the hot water and the hot water leaves the open to air expansion tank and is piped to the radiators on the top floor and these radiators are piped so that the cooler water in them falls to the second floor radiators and heats the second floor and the cooler water in the second floor radiators drops to the first floor radiators and then that water drops to the cold water header that connects to the boiler sump to be reheated. The overhead method eliminates any need to bleed air from the radiators as any air in the radiators travels upward and into the open to air expansion tank and into the atmosphere.

I have seen drawings of overhead gravity hot water heating systems in England where they employ an oval livestock watering tank in the attic of a home to store the entire volume of hot water and pipe it to the radiators below the attic in this manner and replenish it as needed with a valve connected on the riser or cool water return pipe. The livestock tank was covered with wood planks or marine plywood.

Thoughts of a homeowner where it is 14 degrees Fahrenheit (-14.22 Celsius)

I think I have all the plumbing right.

1 -

Thanks for the answer. It makes complete sense about installing the buffer in series.

The idea behind having an emergency heat dump is also pretty clever (my attic is not isolated so it could be installed there), however my plan is to keep the solution as simple as possible and the budget to the minimum. Think of it as a temporary system that will be expanded (or even potentially rebuilt) to 4 more rooms in the near future.

Also, since I have cast iron radiators (that allow a pretty good flow), are there any benefits to going with a solution using a pump? I mean it's clear that you could get away with smaller pipes that are more neatly organized, but this is an old house that will be demolished in the next 10 years, so the looks are not a priority, it just needs to get the job done.

I wonder if perhaps having a bigger expansion tank with more water could make a difference?

It's a single floor. The stove heat exchanger is already installed, so using another technology is not an option.

I will most probably go with overhead method, as from what I've understood it provides a superior flow. I also have a relative that uses the same method and it works great for him, his system is at least 4x bigger than mine though.

The problem I am trying to solve as mentioned in my post is how do I avoid high pressure and water boiling in the overhead tank when the fire is at its hottest. I've seen this already happen on a few similar systems that are also this small, however I didn't confirm a solution from anyone on how to potentially fix it.

0 -

You will not have a solution UNLESS you have a massive open to atmosphere buffer tank. A steam cleaned surplus narrow gauge insulated vented railroad tank car would be ideal.

0 -

pressure in the water raises the boiling point. If you have a closed, pressurized system then you need an expansion tank

The larger the buffer tank the larger the expansion tank needs to beMy wood boiler had a 500 gallon tank and needed two 30 gallon expansion $$ tanks

The other option is an open system like most of the OWF. They just boil for temperature protection, no pressure means no expansion tank

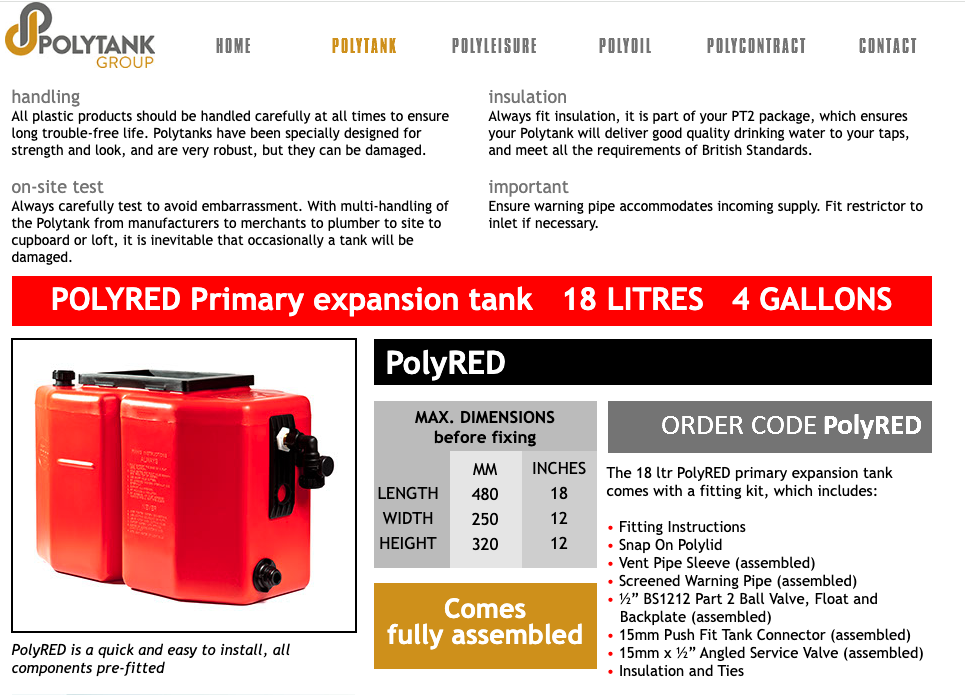

The attic tanks common in the UK are open to atmosphere

But corrosion is a huge deal with open systems and ferrous metals

I don’t see a tank in series adding any protection if the system runs to 200 F fire still burning, the tank doesn’t really act as a dump or over heat if it is the same temperature?

If anything the attic tanks may give you some over heat space and protection

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I don't plan on using a pressurized system and want to install an attic tank, I was assuming this is still called an expansion tank as it allows for expansion when water gets hot? Sorry for the confusion.

It does seem like a bigger capacity attic tank might do the trick. As for corrosion protection, I might get a stainless steel barrel, as those are widely available here.

0 -

Yes, it is still called an open to air expansion tank

Please keep in mind that you need marine plywood to cover the stock tank and under the tank and pressure treated lumber under the full sheet of marine plywood that is on the joist stringers.

You need to spread the weight of the stock watering tank over a wide area so you need to be sure to have enough dimensional lumber under the tank and heavy 1 inch marine plywood under the tank as well as on the tank lid.

A 55 gallon barrel will not be large enough to give you a buffer in an overhead open to air tank, a stock watering tank will. The galvanized stock tank will have a drain plug that you can use for the drop pipe to the radiators and a solder joint can be used to connect the hot water riser.

The problem you will have and continue to have is excess moisture in the attic. If you can have a drip pan soldered together with a drain hole that you can attach a hose to drain to a laundry sink all the better.

If you purchased an open to air expansion saddle tank and hang it from the roof trusses you could avoid moisture in your attic by having the drain line come into the living space rather than through the attic.

1 -

There are trade-offs with the buffer tank size. The larger the tank the more thermal lag you have on a cold start as the tank needs to warm.

But more tank capacity gives you more "no fire" run time.

The over-heat function seems to be the tank in the attic. If you plan on boiling that for protection you will need to continually add water.

Adding water continues to add scaling minerals to the system. And wasted energy

Those heat exchangers inside the firebox can be hard to control, especially when the fireplace is running for heat also. The basic concept for excessive hot water production is "use it or lose it" same with large thermal arrays in the summer.

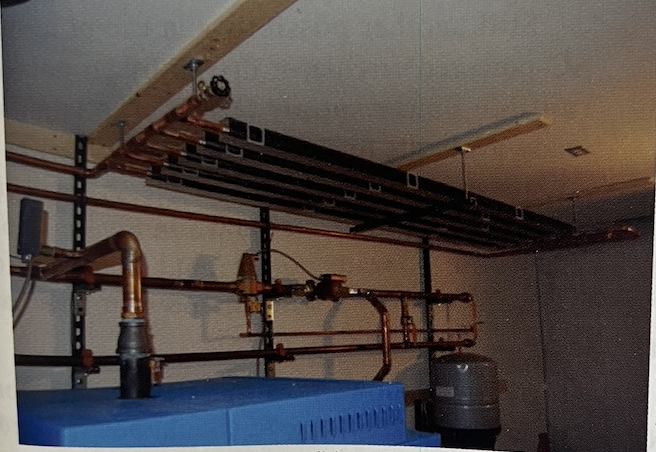

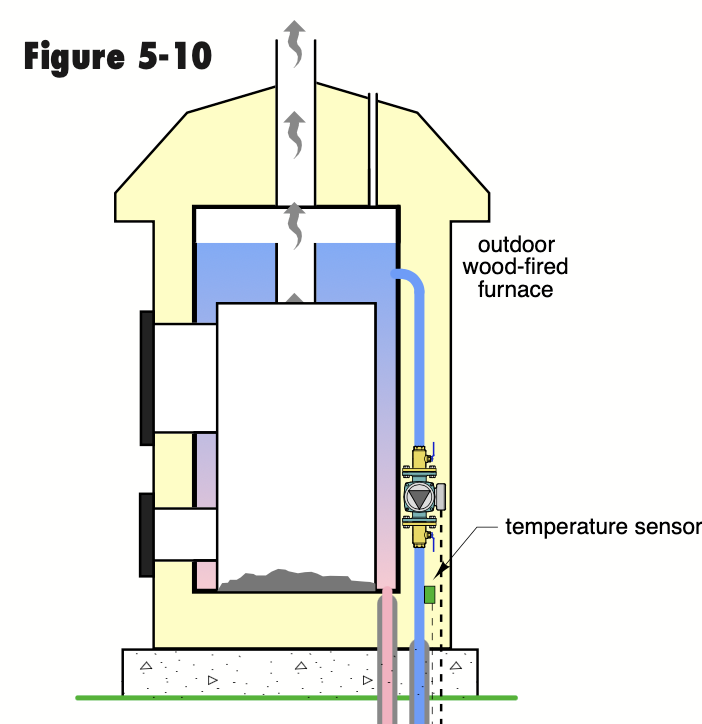

This is a common solid fueled beast used in the US. Large water content to buffer, open unpressurized, wood mess is outside.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

-

Thanks for the answers!

Thinking about it now, I forgot to mention that my attic is unheated (an not insulated) and the water there will most definitely freeze if the temperature drops in negatives. Most probably my only option for attic is to keep the container relatively small and insulate it well.

It seems that my only sensible option is to make the system capacity bigger by either adding a lot more radiators in the system or some kind of heat exchangers that can hold at least 100 liters or more, as the cast iron radiators I have don't hold that much compared to old style ones.

In any case I will try a few things out that make sense for me in my context and post here an update to let you know if it worked, as sadly a lot of equipment you mention is not widely available (or not at all) here, so I will have to DIY something out to keep it in the budget.

0 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements