Radiant slab operation, as the slab warms

I got to thinking about the conditions a slab goes through as it warms.

Take a 1500 square foot shop, 4" thickness: 27 btu/ sq ft calculated load, 40,500 boiler input needed.

A boiler after the efficiency derate and 30% PG derate, of 42,000 btu/hr would be a close match, possibly a 60K in boiler.

1500 sq ft, 4" thick pour is around 18 cubic yards of concrete

18 yards X 4000lbs/ yard= 72,000 lbs

Heat capacity of concrete, varies a bit depending on the mix 29.4 btu/ cu'/ degreeF

To take a slab from a starting temperature of 50°- 80° a 30∆,

440,550 BTUs are needed. divide that by the 42K boiler you need 10.4 hours to warm the slab.

However you also need to know that while the slab heats you have down loss, edge loss and up loss to the load of the space. Those numbers are not as easy to pin down, as wind, ambient outdoor, solar gains, doors opening and closing, internal gains etc are a moving target.

If you start with 477 X 3 gpm X 30 delta within minutes these numbers are changing.

the 477 changes with glycol warming, 3 gpm changes as the fluid thins, and the delta is moving as the space warms

So while the formula 477 X 3 X 30∆ indicates 42,930 being delivered that is at one specific condition, lasting maybe only minutes.

The only way to know would to be monitor ∆ S&R at the manifold and flowrate, a BTU meter for example.

This also shows the wait time involved can vary quite a bit.

Suppose you start with the slab at 20° or 0° these numbers change considerably, slab thickness and the delta of a slab going from 10° to 80° for example.

Anything missing?

trainer for Caleffi NA

Living the hydronic dream

Comments

-

10.4 hrs to heat up slab. How long for the whole house to get to 68F if all starting at 50F? I think in reality all those heat losses add up. The slab and house will be able to extract heat faster when cold if the boiler will let it. Trying to think of the math involved is headache inducing. I'll plan for a full 24hrs to get the house up to usual temp. I don't see any holes in your math.

0 -

Now that's my kind of math, @hot_rod ! That sort of thinking is just fun.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

I appreciate the analysis.

Let me offer a slightly different take. When the slab is at steady temperature, the heat flow in and the heat flow out is balanced. The heat flow in is what the boiler provides. The heat flow out can be divided into useful heat, which heats the occupied space, and unusable heat which goes somewhere else.

To get the 27 BTU/sf calculated load, the surface of the slab has to be 13.5F above room temperature. Let's say we've achieved steady state, the room is at 66.5F, the surface of the slab is at 80F. There is 40,500 BTU/hr going into the room, and some unknown amount going into unusable heat.

Then let's turn the clock back to when the heat was turned on. The room was at 50F, the slab was at 50F and heat flow into the slab was zero. So unusable heat was zero. When you first turn the heat on, the slab temperature doesn't change right away, so the heat going into the room is still zero, the unusable heat is still zero, and all of the heat supplied goes into warming the slab.

But as the slab warms, it starts releasing heat into the room as well as losing unusable heat. So if you apply a constant amount of heat, the warmer the slab is, the slower it warms. In fact, if the amount of heat is exactly equal to the heating load, the slab never reaches the design temperature — the closer it gets, the more the heat gain slows.

That's complication one.

Complication two is that the building itself has heat capacity. To get to the final steady state, not only do you have to warm the slab, but you have to warm the building too. If the building is starting at 50F like the slab, as soon as the slab warms at all heat is going to start flowing from the slab into the inside air, and from the air into the building and its contents. So even at the lowest temperatures you don't get the full heat load going into the slab.

If you wanted to fully model this you'd have to model the unusable heat with regard to slab temperature, and you'd have to estimate the heat capacity of the building and model the temperature of the building. You could do this with a spreadsheet with a row for each of a series of time intervals. In each time interval:

- The ending temperature of the slab is equal to the starting temperature of the slab plus net heat flow into the slab divided by the heat capacity of the slab.

- Net heat flow into the slab is equal to heat provided by the boiler less heat used warming the room and unusable heat.

- Heat used warming the room is equal to (starting) slab temperature minus (starting) room temperature times a constant (2 BTU/hr/sf)

- Unusable heat is equal to slab temperature minus ground temperature times a constant

- Ending temperature of the room is equal to the starting temperature of the room plus net heat flow into the room divided by the heat capacity of the room.

- Net heat flow into the room is heat used warming the room less room heat loss

- Room heat loss is (starting) room temperature minus outdoor temperature times a constant

Items in bold are calculated values for each time interval, items in italics are constants that you have to estimate.

If you put all that into a spreadsheet, what you'll see is that heating the slab actually takes quite a bit longer. What you also see is that the higher the heat provided by the boiler, the faster the slab responds and the faster the room warms up.

The ideal configuration is something where you have both an outdoor sensor and a slab sensor. When the slab is warm, use the outdoor sensor to guide outdoor reset to keep the boiler output near the heating load. When the slab is cold, put full output into the slab until it warms up.

2 -

the ground below and the edge around is “load” so we put r-value numbers to insulation addressing it. Just as we do the wall insulation. So the “unusable amount” to me is just load, it is calculated into the load. It’s not a separate component.

Complications could be the ground is warmer than ambient so those down and out loads are very transient and different also. I don’t know the load calcs ask for ground temperature and conductivity of the soil for example. Or the frost depth since there are footings and foundation stem walls involved. The slab edge sees ambient temperature conditions, the ground below probably not so cold.

Robert Bean used to have ir scans and FEA analysis of those earth losses. Examples of how insulation lying flat around the perimeter changed those foundation losses also.

I think the ASHRAE TC tech committees dug deep into these questions.

I agree steady state would be the building load is met, energy input matches energy loss, which includes up, down and sideways loss or load.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

The lag seems pretty annoying.

0 -

And completely unavoidable. Physics may be a b***h, but thermodynamics is worse. And it illustrates why one makes every effort to bring a radiant system — particularly a slab — to a constant temperature and leave it there. Use some other heating method to make short term changes.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

I agree with part of what your saying — a heated slab by itself is going to be disappointing if what you're after is a heating system that can keep a room at a steady temperature regardless of heating load. You need something else that can react faster to changes in load.

But I disagree with the idea that a constant temperature is the optimum control strategy for a heated slab. If the room temperature is constant, the heat output from a constant temperature slab is constant too. And unless you set it for a very low output that's not going to be conducive to keeping a steady indoor temperature. Vary the temperature of the slab according to the expected load, but keep in mind that the reaction time is going to be slow, so have something else that can react faster.

0 -

@hot_rod : "the ground below and the edge around is “load” so we put r-value numbers to insulation addressing it. Just as we do the wall insulation. So the “unusable amount” to me is just load, it is calculated into the load. It’s not a separate component."

When you're doing a Manual J, all you care about is maximum load and having enough capacity to meet it, so load is load.

In this simulation, the "unusable heat" load behaves differently from the heating load — the heating load is assumed to be proportional to the difference between the outside temperature and the interior temperature, and the unusable heat load is driven by the slab temperature and the ground temperature. They're not the same, and they're not going to move together, so they need to be modeled separately.

0 -

Ideally the controller would be aware of future outdoor temps, future scheduled occupant requested indoor temps, and second stage heat from radiators or air. Expensive.

0 -

but outdoor temperature changes don’t necessarily mean the swt needs to ramp, indoor may not be dropping. the internal gains may be contributing enough heat to cover the loads for a time

In some cases inside gains can over-heat the space, a large sudden occupancy for example you see this when you attend seminars sometimes

Do the indoor feedback component can have some value Ecobee trued that predicted weather input fir a but.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@DCContrarian you are right, of course — the heat output from the slab, and hence its running temperature, does need to change depending on the load. Or, perhaps more practically, on the base load. This is why — in my humble (?) opinion, a well-tuned outdoor reset should be coupled with the slab heat. Those changes are on a time scale which a slab — unless it is exceptionally massive — can manage. What a radiant slab can't do well is negotiate relatively short changes in load, such as occupancy or — particularly solar or wind/infiltration loadings — never mind occupant demand (as distinct from loading) — Aunt Martha, who likes things at 85, comes to visit for tea. That's where you need — again in my humble opinion — some other form of heat (panel radiators?) which can respond very quickly but isn't intended to handle the base load.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

The Law of Conservation of Energy

If energy can neither be created or destroyed, I suppose it is all useable, or recyclable energy. So I guess the term energy loss isn’t exactly accurate?

If the energy that goes down warms the subsoil, that lessens the downward loss that the slab experiences, which lowers the upward load.

I’ve just never heard it called “unusable amount”Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

@hot_rod : "In some cases inside gains can over-heat the space, a large sudden occupancy for example you see this when you attend seminars sometimes."

On a cold, sunny winter day the solar gain can be substantial. Then the sun goes down or even just behind a cloud and all of a sudden your heating load doubles.

0 -

@hot_rod : "I’ve just never heard it called 'unusable amount'."

Yeah, I made that up. Trying to find a way to differentiate between heat lost from the conditioned space and heat lost before it even makes it to the heated space.

1 -

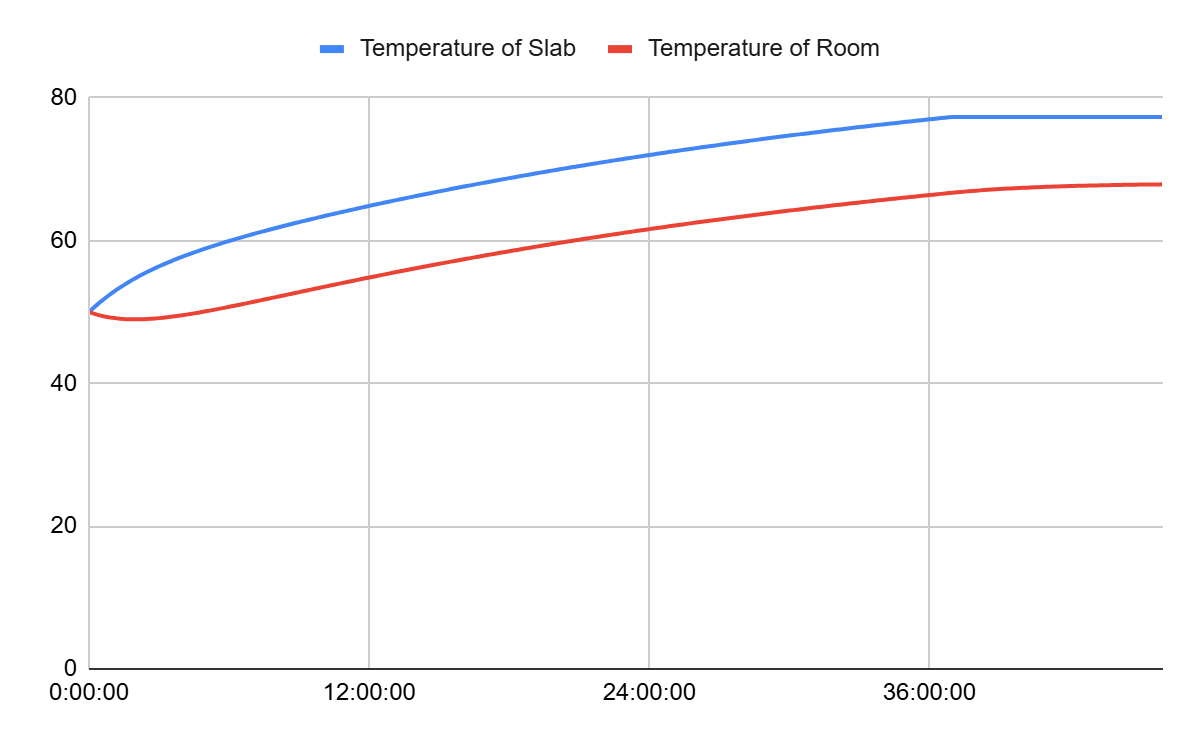

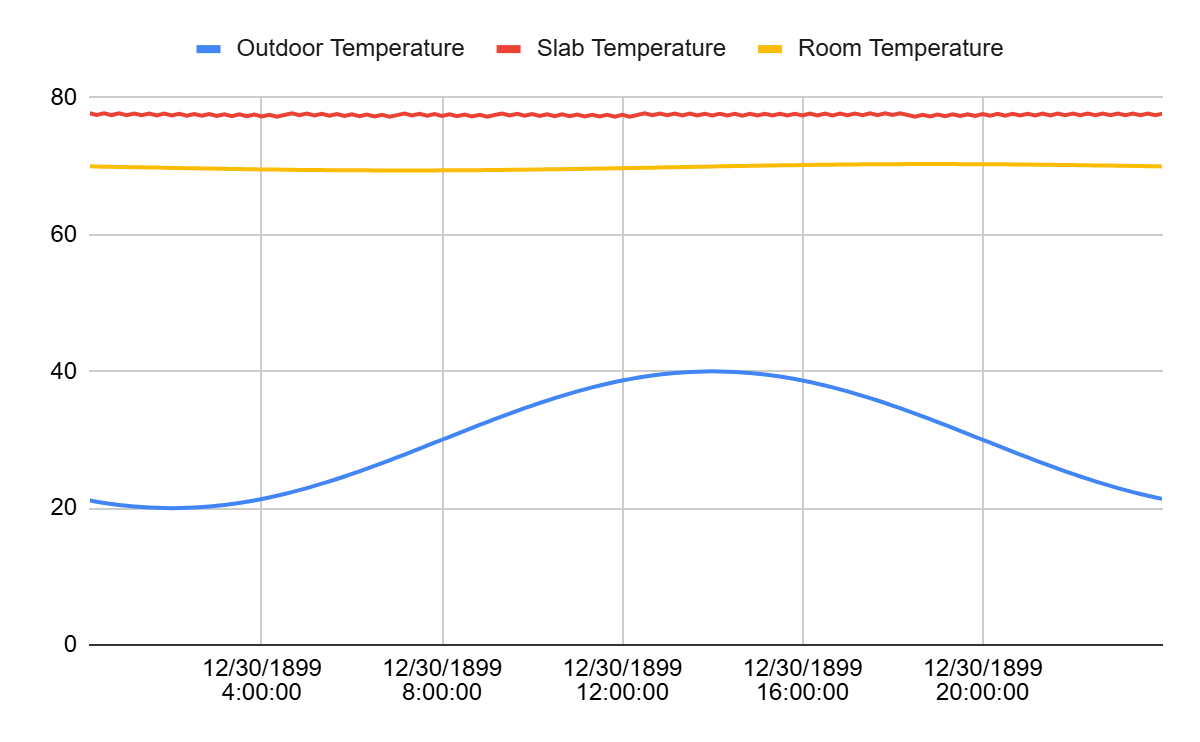

Luckily I'm a hermit with no social life on a Saturday night, so I was able to make up a spreadsheet using the methodology I outlined a few posts ago. Here is the chart of slab temperature and room temperature vs time:

Under these assumptions, it takes about 48 hours to get the room up to 68F from 50F.

At 77.3F the slab is meeting the heating load at 68F, so once the slab hits that temperature I have it stop warming, as if there were a thermostat in the slab.

You can see the spreadsheet at:

These are the assumptions I used:

Starting temperature of slab

50

F

Starting temperature of room

50

F

Heat Capacity of slab

14700

BTU/f

Heat Capacity of room

15000

BTU/f

Heat provided by boiler

45000

BTU/hr

Room to floor constant

3000

BTU/f/hr

Ground temperature

50

Ground to floor constant

300

BTU/f/hr

Outdoor temperature

20

Room to outdoor constant

579

BTU/f/hr

The three constants that are in BTU/f/hr — room to floor, ground to floor, and room to outdoor — represent heat transfers between the various pieces. The room to outdoor constant of 579 was calculated by taking the stipulated heating load of 27 BTU/hr/SF, multiplying by the stipulated 1500 square feet, and assuming a design temperature of 0F.

0 -

sounds like diff eq

0 -

don't forget that as the slab heats the water is going to dump most of its heat at a front that progresses along the pipe, it isn't going to be evenly distributed in the slab so all of those things will be complicated gradients through the slab

0 -

you just need a slab sensor and odr for the final result. the boiler will ramp up to full output to try to maintain a setpoint it has no hope of maintaining until the slab is warm.

0 -

-

Well, this conversation turned out to be very timely. I woke up this morning and the house was dark. The house across the street was on fire and the firemen had turned off power to the whole block. It just came back on, it was off for about 4-1/2 hours.

I have radiant heat but I also have air handlers which are programmed to run if the inside temperature dips a half degree or more below the set point. When the power came back on the inside temperature was 1.8F below the set point; the upstairs air handler ran for about ten minutes and the downstairs ran for about 45 minutes to get back to setpoint.

0 -

And the people with air handlers or fin tube will recover faster that cast iron radiators. And radiators will recover faster that high mass slabs. So there are pros and cons to all the various types of emitters.

A wealthy person like you may have multiple systems for redundancy or use on shoulder seasons :)

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Since most homes have AC now I think having a HW coil in the AHU is a simple cost effective back up plan for heat if you have HW radiant from gas or oil.

0 -

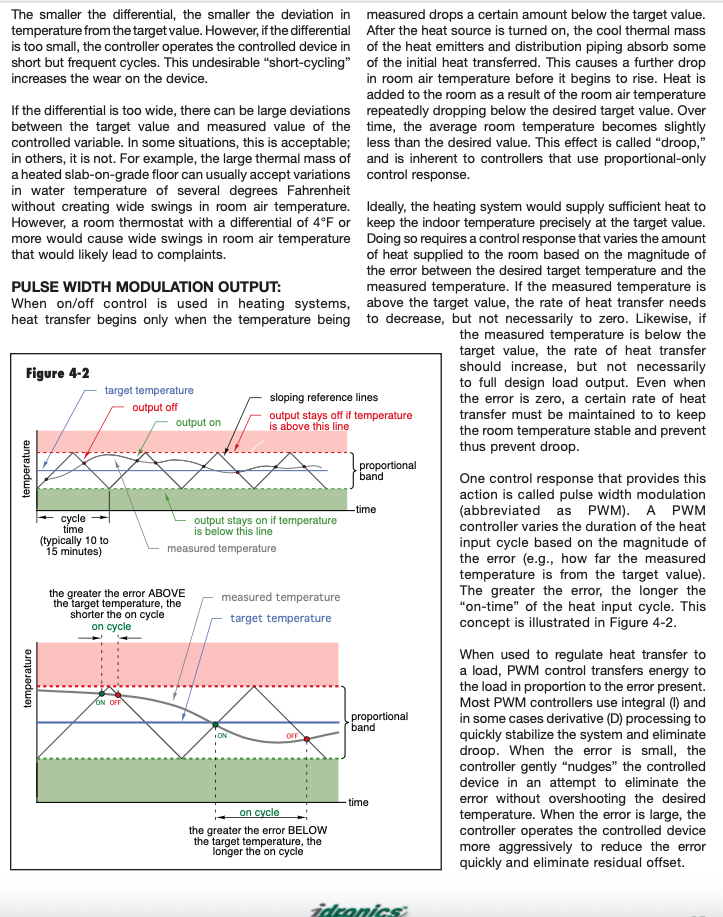

Since I had the spreadsheet all set up (and I'm no less of a hermit on Sunday than on Saturday) I decided to run some more simulations. This time I'm modeling three different control strategies for keeping the inside at a constant temperature:

- Thermostat in the air

- Thermostat in the slab

- Outdoor reset of the boiler

All of the assumptions are the same as yesterday's model, except the outdoor temperature is now assumed to vary over the day, peaking at 40F at 2pm and hitting a low of 20F at 2AM.

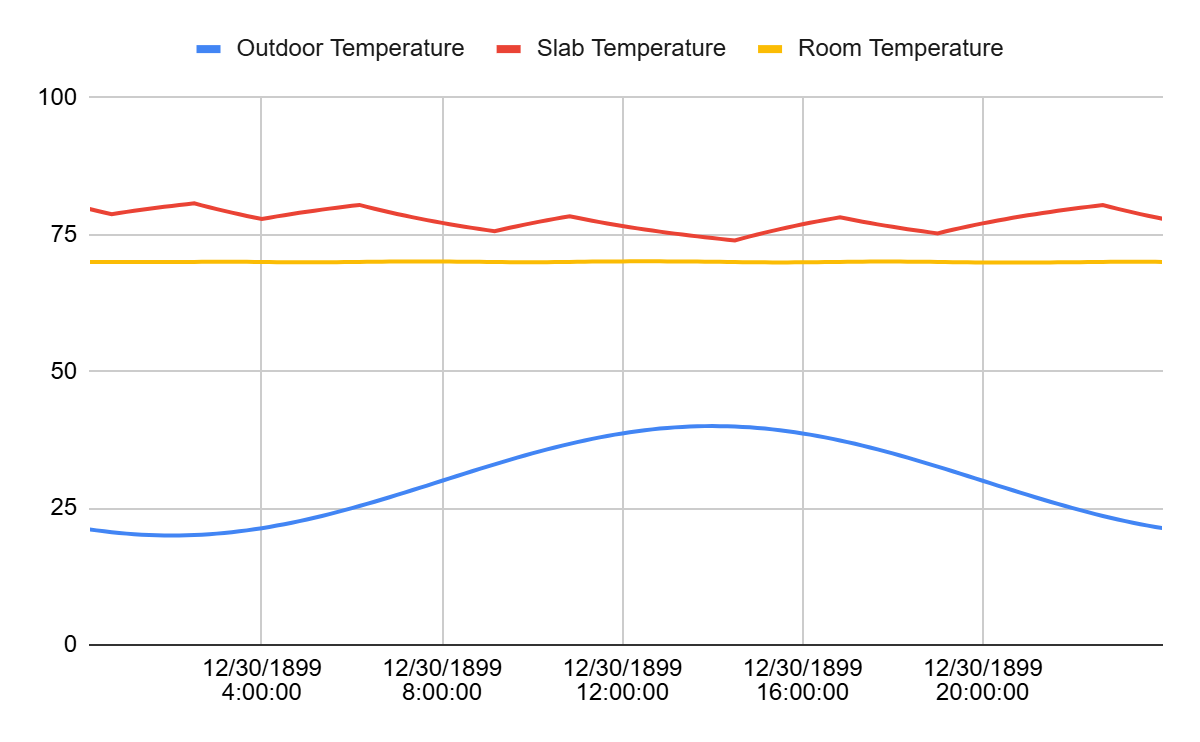

First up, the thermostat in the air:

The control strategy is very simple: if the air temperature is above the thermostat set point (70F), turn off the boiler, otherwise have it on and applying its full load to the slab.

This has very good temperature stability, with a minimum temperature of 69.9 and a maximum of 70.0.

1 -

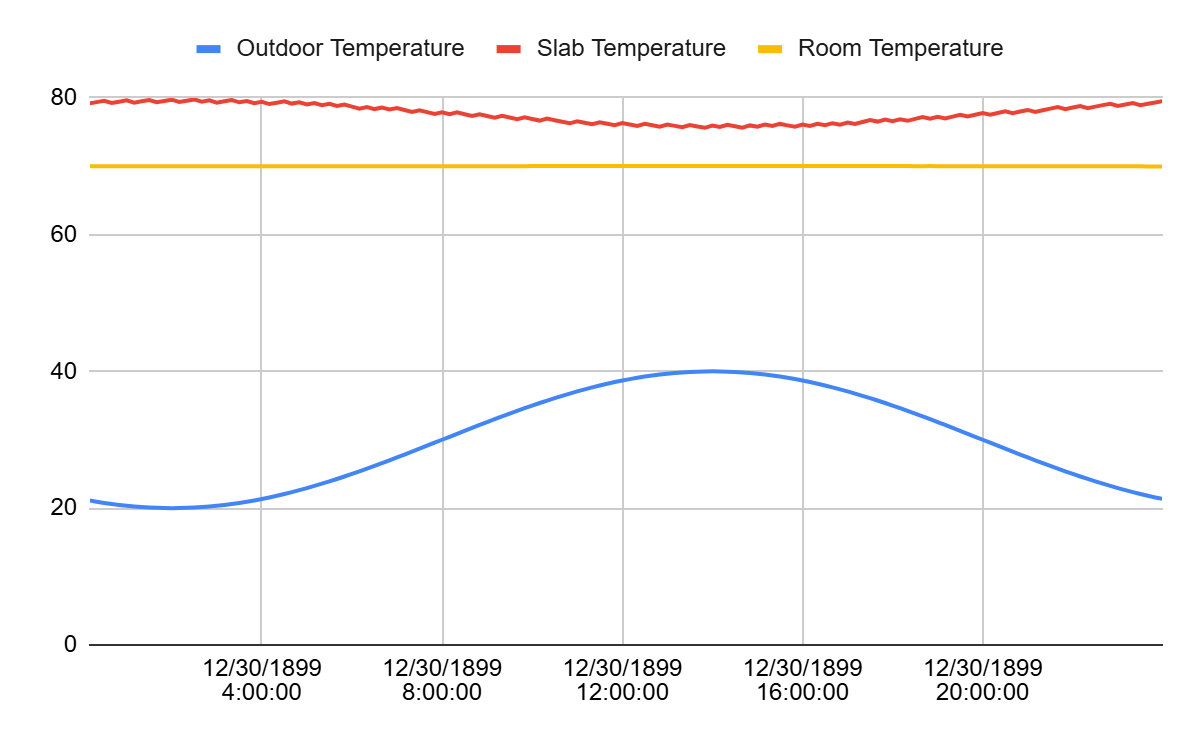

OK, control strategy #2: slab thermostat.

At each outdoor temperature, calculate the slab temperature needed to meet the heating load. If the slab temperature is above that, turn the boiler off, otherwise turn it on.

This gave the best temperature stability, staying at 70.0 throughout the 24-hour period. Notice that the boiler cycles on and off a lot more than the air thermostat method, as evidenced by the jagginess of the slab temperature line.

1 -

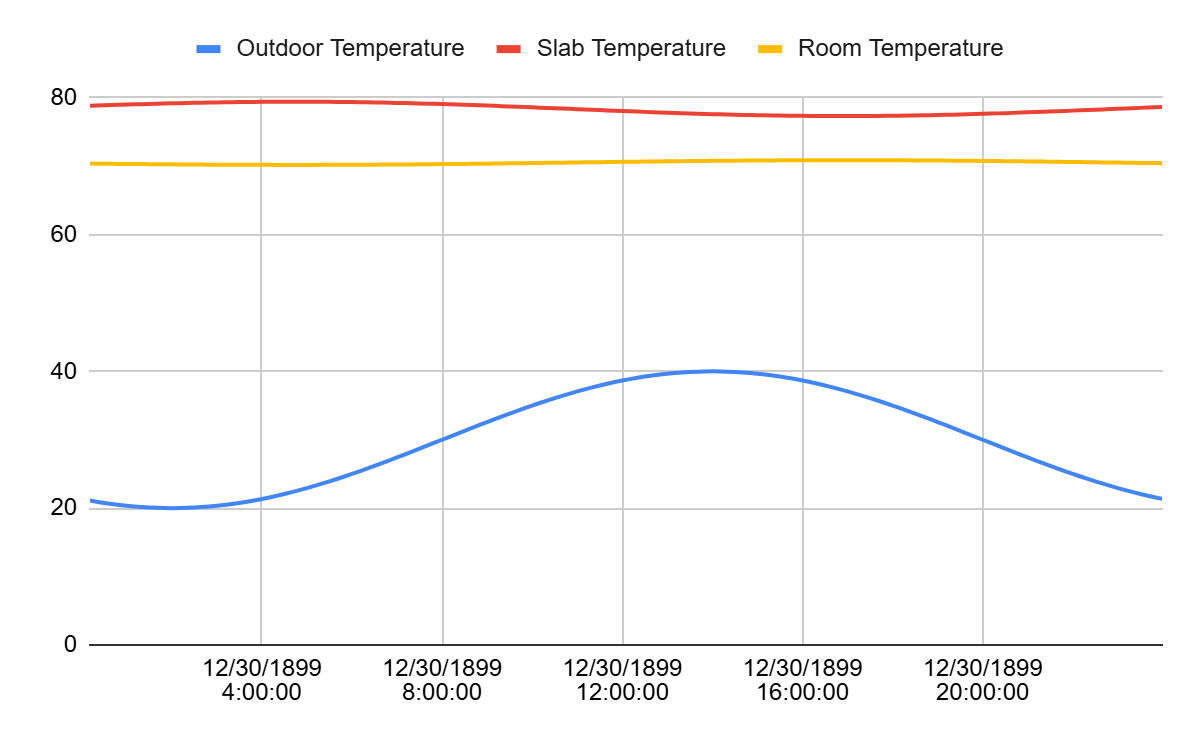

Last up is outdoor reset:

The control strategy is to calculate the actual heating load at each temperature, and have the boiler deliver that much heat to the slab.

This has the worst temperature stability, with the temperature varying between 70.2 and 70.9. However it is potentially the simplest, requiring no indoor sensors or zone valves.

I tried an alternative where there is an indoor thermostat that cuts off the heat when the temperature is above the setpoint, but that wasn't any more stable.

1 -

OK, one more control strategy: keep the slab at a constant temperature.

This is very simple, imagine an on/off thermostat in the slab, turn the boiler on if the temperature is below the set point, otherwise turn it off. I ended up with a setpoint of 77.5F just by plugging in numbers.

This has the biggest range of any strategy yet, a minimum of 69.4F and a maximum of 70.3F. But it's still not that extreme.

If you look at the jaggedness of the slab temperature line you can see that the boiler cycles frequently.

Part of the stability of the temperature is due to the outdoor temperature curve I chose.

At a constant outdoor of 0F the inside would stabilize at 64.95F.

At a constant outdoor of 20F the inside would stabilize at 68.21F.

At a constant outdoor of 40F the inside would stabilize at 71.43F.

That's not horrible but it's not great either.

0 -

One final comment and I'll call it a night:

Based on this analysis, it really seems to me that the best control strategy is the thermostat in the air, the other strategies don't seem to offer any advantage. Conceptually this strategy has the advantage that you're measuring the thing you actually care about, which is the temperature of the air in the room.

With any of these strategies, if your heating load changes faster than the slab can change its output, you need to have some sort of supplemental heat that is more responsive.

0 -

@EBEBRATT-Ed Im confused about the AHU being a backup. My AHU blows on the 2nd floor, but sources it's heat from the same oil boiler as the radiant on the main floor. When you said A/C into AHU did you mean with a heat pump ?

30+ yrs in telecom outside plant.

Currently in building maintenance.0 -

I was meaning that most homes built today have air conditioning which in most cases they will have an air handler for the air conditioning.

Do to the lag in heating the home with a radiant slab or if you have an issue with the radiant system adding or purchasing the AC air handler with a hot water coil is a small investment and it can be used as a booster to bring the house up to temp. The HW coil in the AHU would be heated by the same boiler.

0 -

@EBEBRATT-Ed Ah. I thought you mean backup as in boiler failure. Booster works for sure. For most of the winter here, my upstairs gets heat 'naturally' from up the stairwell or via the returns in the main floor (returns only in those radiant rooms, mainly to circulate the otherwise stagnant air in rooms of a radiant system). Its only when it's bitterly cold outside that the circ in the AHU comes on, but boost it does.

30+ yrs in telecom outside plant.

Currently in building maintenance.0 -

Thermostats like tekmar the use PWM or PID add some accuracy to the temperature control.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

You're going to get better temperature stability if you have a thermostat that can report gradations rather than just on/off. That's the special sauce of any heat pump with a modulating compressor, if you can run a compressor at a speed that exactly matches the load rather than cycling on and off it's going to be more efficient and deliver better comfort.

But in addition to a modulating thermostat, you need an emitter that can vary its output and change rather quickly. Which brings us full circle to the beginning of this conversation, because the problem with slabs as emitters is that they can't change their output very quickly. Going back to the 1500 square foot slab with a boiler capable of delivering 45,000 BTU/hr to it, when that slab is at 77.5F and the room is at 70F it's delivering 22,500 BTU/hr to the room. If you run the boiler full out for ten minutes the slab temperature increases by 0.3F, which increases the output to 23,400 BTU/hr, an increase of 900 BTU/hr or 4%.

On the other hand, if you have that same boiler feeding a hydronic coil in an air handler, the output will be zero when the fan speed is zero and the full capacity when the fan speed is at maximum. Simply by controlling the fan speed you can get any output between zero and full in a matter of seconds. So if you connect a variable speed fan to that modulating thermostat you can match the output to the load.

Many people prefer the feel and quiet of radiant slab, so the ultimate in comfort is to have the slab to do what it does best, but also have the air handler for times when the heating load changes more quickly than the slab is capable of handling.

0 -

-

Yeah, but nobody's asking a radiant system to provide IAQ or odor control. It does reduce vibration, sound and draftiness, and generally is more visually appealing. So it does part of the job but you still need other systems.

I've been thinking a lot about humidity lately, I think the next frontier is systems that control temperature and humidity independently.

0 -

It would be nice if thermostats could at least share the actual and desired temperatures with the rest of the equipment. Most thermostats, even the smart ones, are really just on/off devices. Tekmar is one exception. They will modulate the supply temperature based on indoor and outdoor temperatures, while minimizing and synchronizing cycles.

0 -

equipment manufacturers typically don't want a 3rd party to control their burner firing rate, they all put the 0-10v burner mod terminals on there because if they didn't they would lost jobs. A few would use a 0-10v temp target input which allows the boiler to run the burner itself. makes sense when you figure how much money everyone just spent on that burner control. There are also companies that sell communicating room feedback sensors and thermostats for their boilers. Viessmann and NTI both come to mind. In Europe there is something slightly common called open therm, which is essentially a universal room feedback system for boilers. It used to confuse a lot of contractors because Viessmann's wiring diagram had 2 terminals labelled "OT" for open therm, and most here thought it was outdoor temp lol.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements