Replacing draft regulator or draft control on a residential fuel oil boiler

Residential one pipe steam fuel oil Weil McClain boiler installed ca 1974. I've owned the house since 2005 so have been caretaking this system for 20 years and eking a year of life at a time from this old timer. Y'all have been incredibly helpful over the years. Thanks again.

This time I'm asking about my draft regulator or draft control (not sure which I have or is they're synonymous). The flapper is hinged toward the bottom of the unit. Chimney is straight up in a two floor house plus basement about 30 feet. Only discharge into chimney is this boiler. 7" diameter. One of the hinge pins on the flapper works loose about twice a season and jams the flapper to a fixed position--often closed but sometimes open. I'm tired of checking and jiggling the pin back into place. What do I replace it with? Or do you have a better idea than replacing?

I found Field Controls offers a top hinged draft regulator available on supply house and they offer a bottom home draft control. Are either of these the right unit? If not what am I looking for?

Comments

-

either one will work

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Either will work but I think the RC is easier to adjust and is used on oil more often. The face of the draft control should be Plumb and the gate should be horizontal

0 -

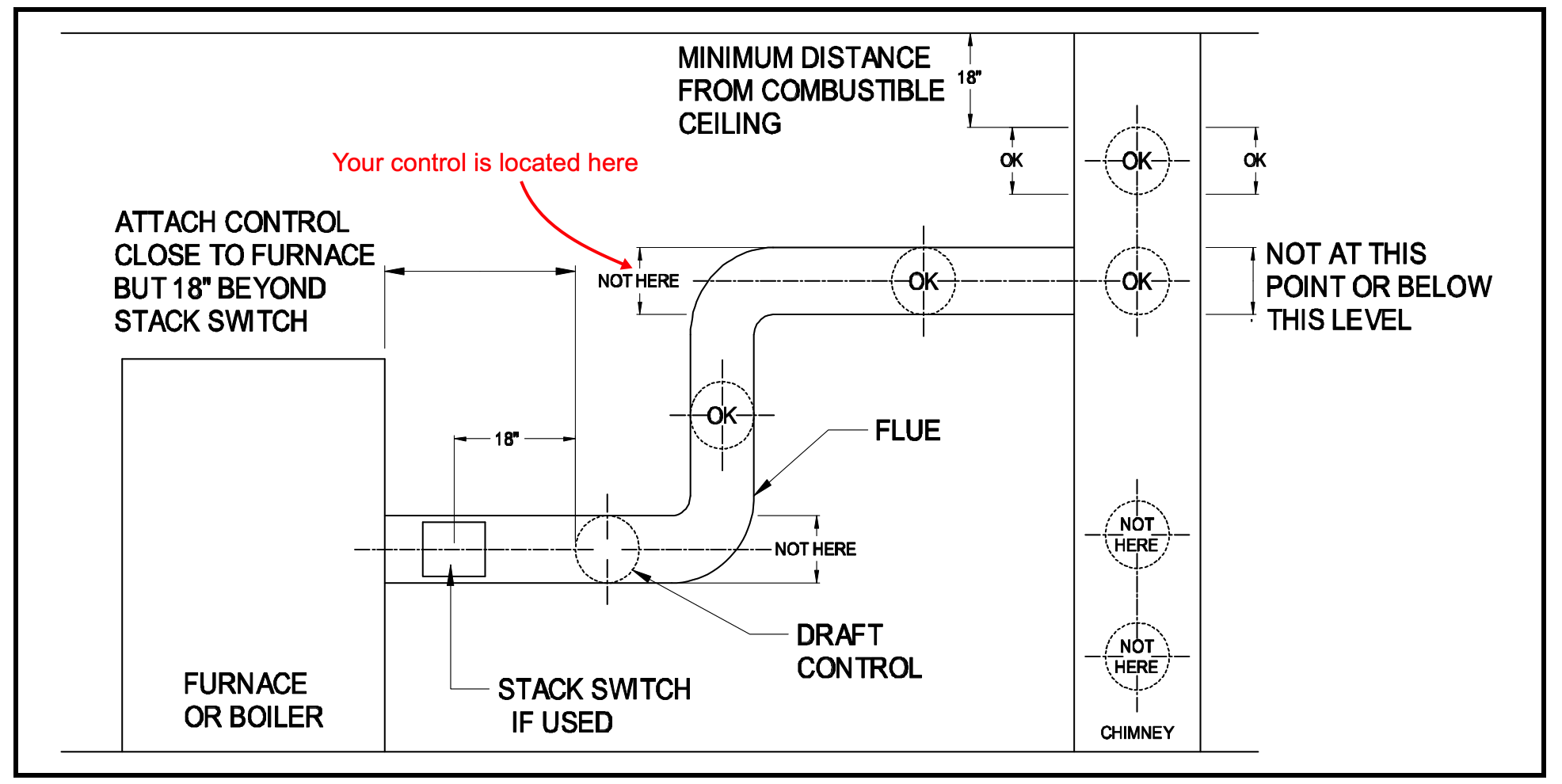

Actually that existing draft regulator is in the wrong location. You should probably replace all the sheet metal vent connector pipe (smoke pipe) and install the draft regulator properly.After collaborating with some of the world's foremost experts in the study of combustion, the highest self proclaimed authority in the land, and an intensive discussion about the proper ways to install barometric draft control devices in all different types of fossil fuel burning appliances I have learned that the manufacturer may not always be absolutely correct when detailing the DOs and DON’Ts of their product in actual field applications. This has led me to retract my original recommendation to redesign the flue pipe connector. Your barometric damper’s location is an acceptable location. The following illustration from Field controls has Five “Not Here” locations indicated. Four of those locations are not considered to be a proper location. The one that I have indicated with a red arrow IS an acceptable location. There is no need to change your vent connector.

And I like the RC better also.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

-

I have noticed many barometric draft controls installed the way also. The question I have is: why would Field Controls and other manufacturers specify that as a wrong location? Do you know something that the folks that make the item don't know? ( a kinder response might be to just say yes) Could it possibly be that the barometric is less accurate when placed there? Have you ever placed a draft manometer in the over fire position and watched the over fire draft under different drafting conditions when in that position versus the recommended position? I know that I have not since the time it would take was not available when on a job site to monitor that type of test.

So I just take the manufacturer's recommendation since they have the time and laboratory to do such testing. I would hope they know better. But that is not always the case as Honeywell and other manufacturers have proven in the past. I am not doubting your expertise on this subject. I know that you and @bobharper are the go to guys for this info and would like to know if I was wasting my time all those years when I could have used that Tee configuration many times , but took the time to incorrectly “Do It Right” by the manufacturer’s I/O sheet.

Inquiring minds want to know!

Hoping for a cordial response and learn something

and maybe even called "Quite Unskilled"

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

From what I know I thought that location is incorrect for oil but may be ok for gas. Some conflicting information from

Field.

See the attached

-1 -

Einstein once said: The unthinking respect for authority is the greatest enemy of truth.

No offense but I have never seen anyone from a manufacturing company with field experience that can address situation that aren't lab created.

Field Controls is well aware of my understanding of venting more than anyone. They were in the field with me when we did a study with AGA and they observed this type of installation and were amazed.

If I had followed every manufacturers recommendations or even Code, there would be a lot of dead people. Some people get away with guessing and assuming or letting others think for them. Testing in the field taught me that manufacturers are clueless when it comes to actual field operation. When I called them it was quite enlightening.

Ed you are brilliant when it comes to mechanical issues but quite unskilled with combustion issues.

0 -

Sorry I didn't see the Field Controls catalog. Barometrics can never face toward the flow. So all the wrongs are correct except one and the is the O position. Did that in our field test with AGA.

0 -

Einstein once said: “It is the art of the teacher to make the difficult appear easy, but not the easy appear difficult.”

@captainco said: Ed you are brilliant when it comes to mechanical issues but quite unskilled with combustion issues.

Thanks for the complement (I think) and I agree that I may not know as much as you about combustion. That is why I defer to you and Bob at times when I am not sure of certain points of combustion. But I believe that I am more skilled than the average technician when it comes to all things combustion. I posed the question after you contradicted manufacturers directions regarding my comment about the barometric location. Knowing your background and that you have performed more experimentation and field studies that “Testing in the field taught me that manufacturers are clueless when it comes to actual field operation“ is common. I was looking for your insight. There was no insult intended by my questioning your comment. I was just interested in learning something that I might not have direct knowledge of that you do have direct knowledge of. Thanks for the clarification. I will edit my previous comment regarding the recommended redesign.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

Wow! A lively little discussion here amongst some people I highly respect. Ok, before I discuss the baro. allow me my usual diatribe on the chimbley and chimney connector (vent connectors connect to vents/ chimney connectors connect to chimneys regardless of fuel). This is overdue for a level II inspection. All those years of oil burning will have rotted this chimney from the inside-out. The mortar and brick will be infused with soluble salts formed from the acids reacting with the lime in the mortar. If the chimney proper is sound enough, install a listed liner sized to the boiler. Use a smooth-wall type 316ss liner. It does not need to be insulated- it will be air insulated. It will contain the condensate, heat up quickly and contain the CO, CO2, water vapor, and stack heat.

The connector is old and rotten on the inside. It is not supported. As for the layout, straight beats curves and up beats down or flat. Go up as soon as you can, get as much vertical rise possible before turning horizontal, then slope up to the chimney. 3 screws min. per joint, no screws or seams btw 5-7 O'clock, pitched up, supported.

The Field Controls RC is the most popular for oil that I see. You want the baro. at least 1.5 duct diameters downstream of the appliance connection, stack control, stack safety switch, or confluence of other common vented appliances and any offsets or tees. In other words, look for the best straight away closest to the appliance if possible. The other locations will work. The locations amount to minor degrees of response to pressure changes. My #1 thing with baros. is if I see soot in the gate or not, and if so, just burping in the gateway to the Combustion Appliance Zone (CAZ) or the gateway into the flue. Soot in the CAZ gateway is bad. That constitutes prima facie evidence of backdrafting. Soot in the intake gateway that should be air-washed clean is worser (technical term) meaning there has been a very powerful, sustained backdraft. If youz have a backdraft/ depressurization condition, fix that before waking up dead or playing with this mess further.

Ok, let's ASSume you have a peachy chimney, all guten tite. You have resolved any CAZ depressurization issues so there's sufficient MakeUp Air(MUA). Anywhere you attach a baro. you need a tee. A tee introduces cold CAZ air into the hot stack. This creates a flow restriction due to the turbulence. A better approach would be to use a siamese (erroneously referred to as a 'wye' fitting). Think of an entrance ramp onto the highway versus a side entrance road at a right angle. If you use a bullhead tee, the stack gases collide with the far wall of the tee then look for directional arrows to determine which way to go. Seeing everyone else going up the stack, the mixed air/ stack gases begin sorting out who goes next, take turns and merge into the main flow. If the other direction is enticing you may get some errant flow bass-ackwards out the baro. IF there is a CAZ issue predisposing it the flowing in reverse. If the leg of the tee btw the baro. and the confluence of air and stack gases (Times Square) or intersection of the tee and snout/ bull, is short, it will assist spilling the errant burp of stack gases. Having a few inches of extension can help contain stack gases recirculate back into the intended flow direction.

If you want to prevent spillage or backdraft, use low sulphur oil, set up and fire the burner properly, You don't just want the proper draft pressure setting as a snapshot- you want a stable draft. That's what a properly set up baro. does. If you are finding yourself closing or sealing a baro. to force enough draft pressure, fix the chimney and CAZ and the appliance will work. Hot, stinky stuff wants to rise up once you remove the local hindrances thereof (Count Rumford, 1795 paraphrased). I always envisioned a kazoo or party whistle on a bullhead tee as a backdraft indicator. Perhaps a spill switch would be more effective…

Ok, play nice everybody and have a blessed Christmas.

1 -

Ed,

Thanks for the reply. I did mean it when I said you were brilliant on mechanical problems.

When someone is told to do something that is not necessary that would cost additional money I try to pitch in. I could talk for hours on how many manufacturers called me for help. Many factory reps told me to help their customers but don't tell their company they did.

I guess solving a problem that no one else could solve led to some different methods in the field that had never been tried could be considered experimentation. But if a combustion analyzer wasn't used then it was a no no.

I was told in the 80's when I first started to help or train techs, that oil didn't make much carbon monoxide, mostly smoke. The highest level of CO I measured was on oil equipment with no smoke. One the first condensing oil furnace was produced the manufacturer sent their field service man to my town to find out why my customers weren't having trouble like everyone else. He found out I wasn't following factory specs. Not because I wanted to but because that was the only way to get them to operate properly. They ended up redesigning the furnace based on my input but it was too late.

While I am still able, I think I am older than you Ed and probably more senile, I just want to help people to learn. As a few techs on here that have been to my training they know everything I have done and teach is real. It is unfortunate that they are too afraid to do things mechanically correct versus political correct. The people that make equipment are artists, but the people that make them run correctly are engineers - YOU!

Bob Harper and I are friends, and he is the smartest person I think I have ever met. I even taught him something he didn't know - I think?

2 -

@captainco mentioned "One the first condensing oil furnace was produced the manufacturer sent their field service man to my town to find out why my customers weren't having trouble like everyone else".

I was wondering if that condensing furnace company was equipped with a Blue Flame oil burner? If so, was that manufacturer’s field service man Bob Mandell? He taught me a lot of what I know about oil heat, back in the 1970s. He was the Service Manager at F P Young Co. when I worked there as a teenager thru to my early 20s. He ended up working with Blue Flame furnace co. until they fizzled out. Just wondering if you have ever collaborated. Bob would have liked your "outside of the box" approach to problem solving.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

One of the first things I caught from Jim that caused me to highly respect him was his unabashed recognition that blind adherence to some codes, standards and mfrs. instructions can kill or at least result in subpar performance, shortened equipment life, and operating malfunctions.

I sit on multiple cmtes. that write national codes and standards. I have grown weary of the ignorant peacocks who get on these boards and don't know which end of a chimney to light. In general, I find codes, stds. and mfrs. roughly 20yrs behind the times- at minimum. They promulgate ideas that are not only unproven but, more often, proven bad or contrary to the intent. Sounds like our government?

I have a reputation of teaching and preaching codes, stds., and mfrs. instructions. Much of that was born out of my work for a major hearth appliance mfr. as a regional quality assurance mgr. I worked in the test labs, met with inspectors and investigators on cases and dealt daily with corporate attorneys and risk reduction cmtes. Here are a few points to ponder:

If you violate codes, stds. and PMI, it's not a problem until its a problem

If there is an Oops!, someone will try to pin it on you.

To provide negligence, you must prove all 4- duty to act, loss, act or omission, and proximate cause.

To prove failure to warn, you only need to show the contractor failed to fully communicate the hazard, the risk of not confronting that hazard, the consequences of failure to mitigate or correct and the sequelae of that failure. Failure to warn relies on sentiment much more than facts. It's a subjective issue whereas negligence is based on facts and circumstances.

If you are trained, certified, and experienced in a field but fail to warm over a hazard that is clearly visible or should be expected under the conditions of use, REGARDLESS of what you're there for, you're toast.

If you follow The Rules but there is still a loss, you still incur liability.

So, the bottom line I've come to recognize is to follow the rules to the extent reasonably possible but in ALL cases, doing what works trumps what you "should" do. If you set the manifold pressure on a gas combination valve to 4.0 wci. instead of 3.5 but nothing goes wrong, there is no premature failure of the equipment and no one gets hurt, is it a hazard to the public trust? Compare that to setting at 3.5wci, testing and recording high CO but leaving it in service because you set it pmi? Can you live with someone losing their home or life because you "followed the rules"? THAT is why we all should be testing to prove we're leaving stuff in a condition suitable for continued use under the intended conditions and application.

I never met an appliance that could read a damned code book, std. or mfrs. instructions. I've met many that are going to do what they want under the conditions of use. I figured out it was up to me to take control of those conditions and not leave it up to a machine that can and will eventually fail.

3 -

@EdTheHeaterMan Wasn't it Blue Ray? Advertised by John Cameron Swazy!!! They had furnaces and boilers. The company I worked for thought they were great and installed them out of our Hartford office. I worked in Springfield mostly and we wouldn't use them. Maybe they worked in a lab but they built carbon. I only worked on one or two of them. I think it was a Thermodynamics boiler.

They had a "yellow Flame kit" to convert them back to a more standard burner I think.

1 -

The oil furnace was Yukon out of Minnesota. They used Wayne and/or Beckett burners.

I did help some contractors on the Blue Flame burner. When the flame was blue the CO was high. They got recalled because of the poisonings they were causing. Setting them for zero smoke was useless in evaluating their safety or proper operation.

Thanks Bob. I don't look as stupid or reckless when you chime in.

1 -

Oh, I've learned a TON from you and stand to learn a TON more so take care of yourself old friend and mentor. Thanks for the kind words Jim- check's in the mail but I think it goes the other way. One of the most honorable things about Jim is his unapologetic passion for what works and doesn't cause injury to people, equipment or buildings and having the balls to call out things that simply defy physics and logic. Yes, there are things in codes that can hurt or even kill. Also, codes are Minimum performance stds.- you can exceed them.

I still occasionally run into a plumber who told my customer the yellow flames on their gas fireplace are improper and need more air so they don't make CO or soot. I explain the ANSI test requires these fireplaces with half the embers off their burners at spec. manifold pressure and orifice do not exceed 25ppm on an air-free basis while burning with a luminous (yellow) flame. Open the primary air shutter and you get liftoff at full manifold pressure and extinction popping at high primary air at full turndown. At high primary aeration, the flame will shorten to a transparent non-luminous coalescence without yellow tips, without that lazy, hypnotic wave and bore you to death because it looks like a stove top. You have to make them work but you also must be able to sell them. You can have a CAT IV gas appliance burning with mild yellow tipping but still be under 50ppm CO stable and leave it in operation. It takes some horse sense, but that horse needs full information to base decisions on and that's where training, certification, testing, trade shows, workshops, home study and experience all count.Just ask yourself if you can and have documented that the equipment was operating properly within acceptable standards. You cannot make that claim if you have not tested. I teach my students: do what you can legally document then document what you do.

Peace

0 -

All excellent and informative. But to get back to the original break in this thread about the location of the baro in the run of the tee.

It’s great that Jim tested it extensively and proves it works fine, but what’s going to happen to a tech or company should a baro be installed that way and there is a problem. Say unrelated, the unit soots up, smoke and mess. Soot comes out of the baro. The HO sues. In court his lawyer questions the last tech out and shows the court the baro is installed 'incorrectly per the manufacturer’s instructions and diagram'.

For $20 in material and 15 minutes of time, I’d rather just change it and avoid that whole scenario.3 -

So we blame inanimate objects for things that happen, not our improper ability or knowledge. I like when I hear people say the flue caused the problem. Is there some discipline action we can charge the flue with? How about not enough combustion air and yet we are standing there breathing the same air the equipment needs. Will there be enough when we leave?

Things only happen when people guess or have opinions. 45 years helping solve problems no one else could solve, going against manufacturers recommendations (because they didn't work), thousands of field situations and nothing happened. Actually I was there because something did happen and they wanted to make sure it wouldn't happen again.

I have told and taught techs they are the smartest people in the field and need to believe in themselves. Want to guess how many years people have tried to disprove the things I have recommended or taught? If that was the case wouldn't I be in jail by now?

Again, thanks Bob. And additional thanks to those reading and commenting either good or bad. We never stop learning.

0 -

I guess if your smart enough you can go against the MFG or product listing and do whatever you want.

0 -

I think the Blue Ray was Thermodynamics. Blue flame. It used a Carlin 99 with a special Steinem or Monarch nozzle. The cad cell was wired in series with a flue pressure switch.

0 -

Smart is not the solution. Experience, confidence and caring are the difference. For some mediocre is just fine.

Code specifically states it is up to the user to make decisions. Manufacturers rarely provide any operational data that is functional. Ever notice every blower chart is a mathematical calculation and not actual measured data. What measurement determines the best blower speed on a furnace?

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements