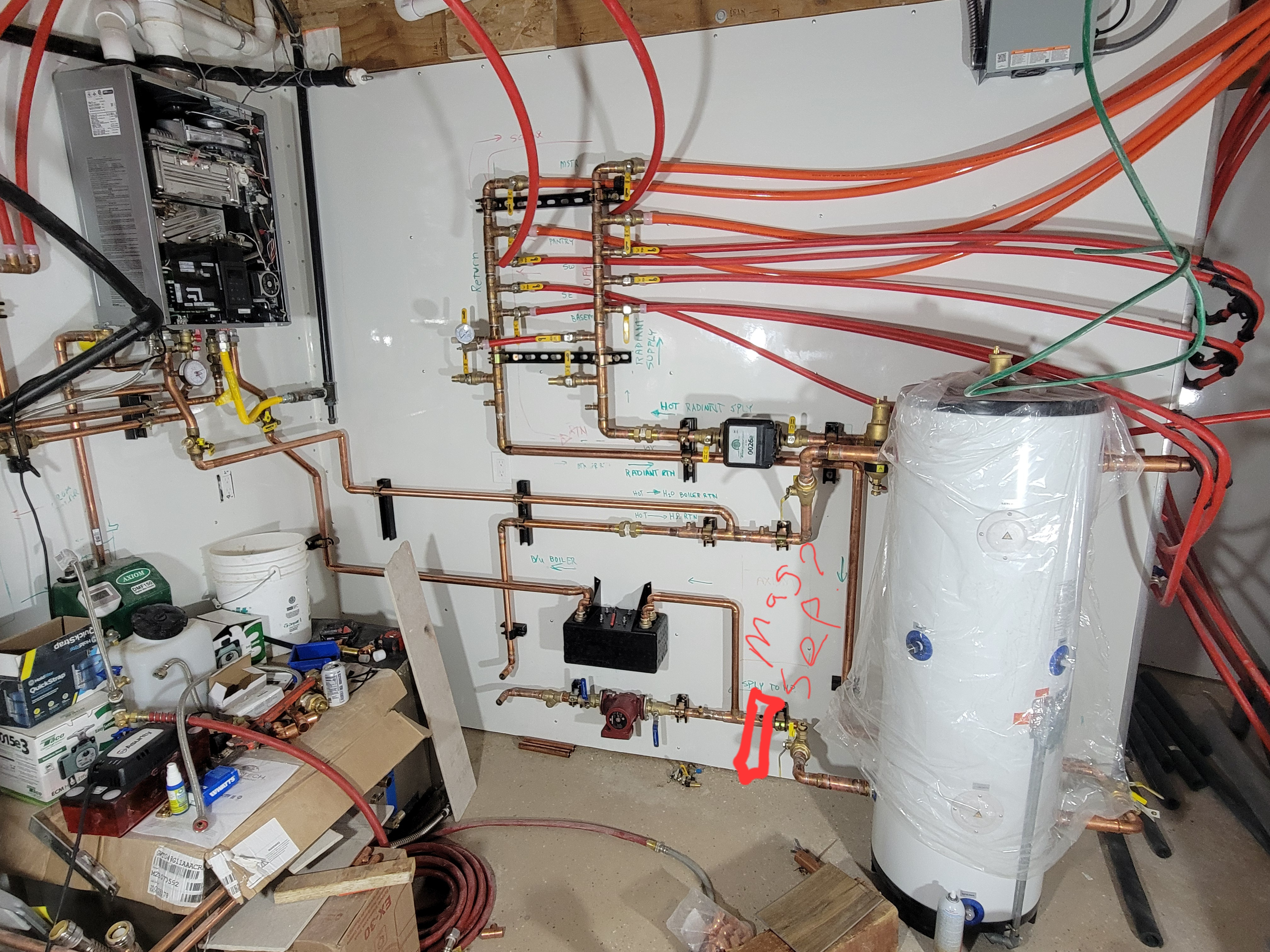

Should a Magnetic dirt separator be added

High level overview:

ICF house build, Geothermal heart pump w/ground loop, B&D pump station, backup Combi-Boiler for snow melt (or if HP goes down and DHW), radiant ceiling loops with 4 manifolds w/6 loops each, solar load shedding to buffer tank and water heater tank. Design temp is 95° system temp other than when snow melt is required.

I am in the final stages of assembling my system that i designed and just read a few other posts and thinking i need to add a couple magnetic separators into my system. (in the marked up location just after buffer tank before HP/Combi supply line)

My water has high iron content to begin with, 350. I still need to do a test after my Iron /Manganese filtration for well water to see how much that helps to lower the iron for the water I intend to use with the glycol mixture. (on a well)

I currently have one magnetic/air separator in front of the 0026 for the radiant distribution.

I'm thinking I should also add one just after the buffer tank feed to the HP (in lower left corner, currently acting as a shelf :) / Backup Combi-Boiler?

What are your thoughts?

Additionally, thinking about adding one to the geothermal ground loop.

Thanks in advance.

Mechanical Engineer

Building ICF House

Comments

-

I would like to see a dirt/mag on both sides of the HX. No harm having one on the loop field either.

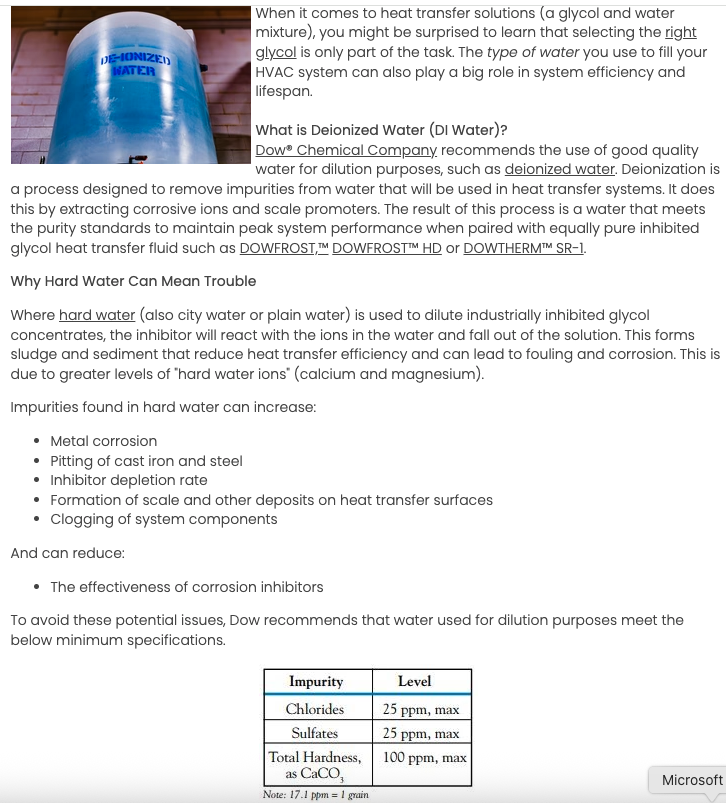

If you plan on blending your glycol on site, here are the water specs from Dow.

Either consider buying pre-blended glycol, no mixing required, or purchase some DI water from a local treatment company. A 55 gallon plastic barrel is a good way to buy and haul water.

I have seen people loading up5 gallon containers at the water machines at Walmart, etc. I think those are large RO machines?

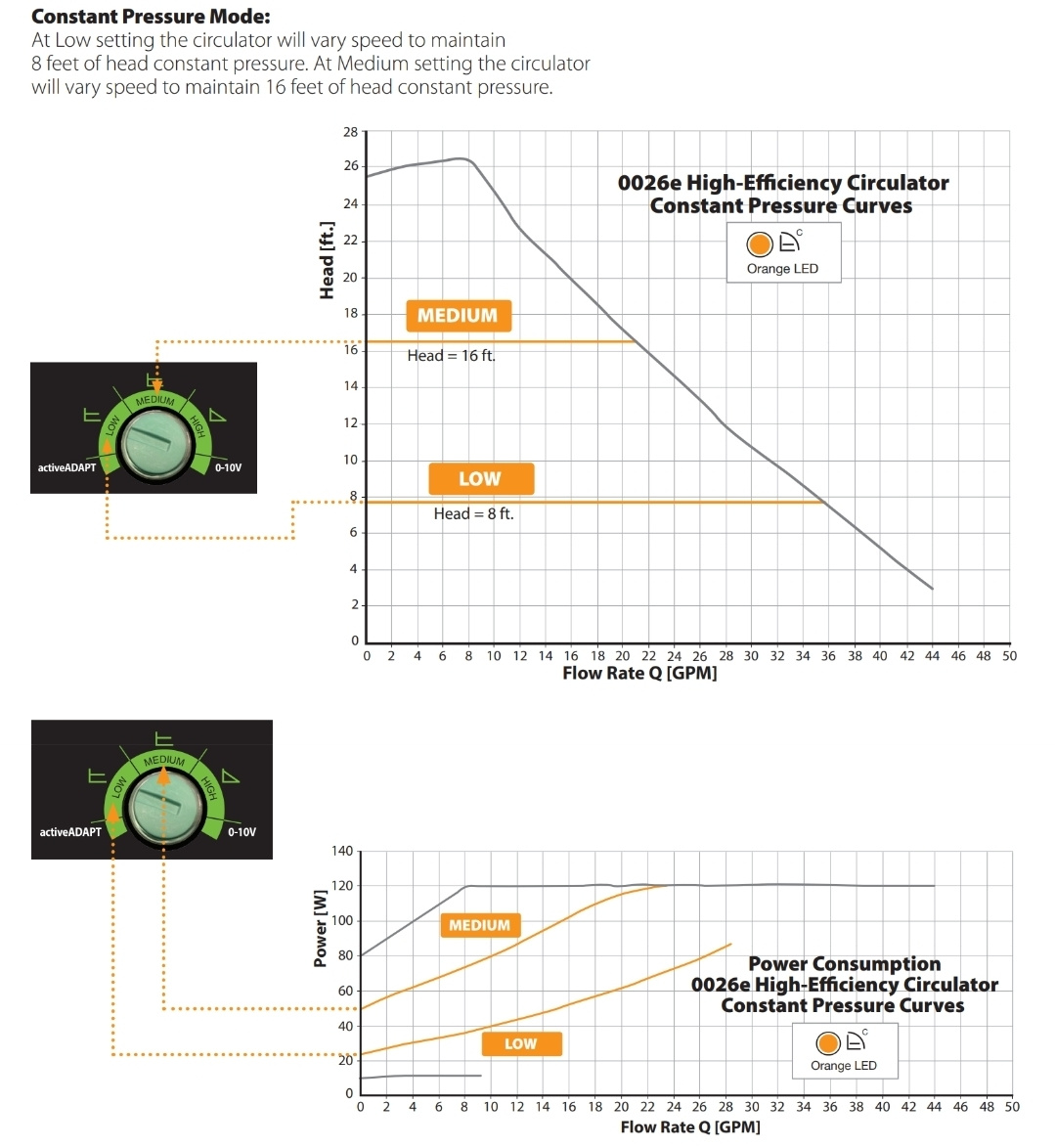

That is a substantial circ on the radiant manifold, what is the total GPM needed? What size is the manifold?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Thanks for the reference. I thought that I've read that you don't want DI water and for sure not RO water. I'll have to call around for that one.

The manifolds is 1.25" with 3/4" to most manifolds and 1" to a couple to minimize head loss. (and 1" for garage/driveway snow melt)

The boiler loop is 1" as well as the feed into the Heat Pump.

GPM, if all is running it's 18gpm without snow melt running. The 0026e circulator is extremely versatile and can be used in constant pressure modes (low or med) or if i choose later to run it with 0-10V. And use only 20-80W on low.

I'll be able to run it on high and also use it for purging the system is my hope.

Stepping back and looking at it again, it appears i missed my check valve in the boiler return when cutting my copper last night. Will add that tonight before sweating the rest together.

Carson City, NV

Mechanical Engineer

Building ICF House0 -

The antifreeze has corrosion inhibitors in it, those will keep the DI or RO water from filling itself with metal from your system although even in a system with just water the first initial corrosion from the DI or RO water is not any worse than using tap water.

You will probably need a pump cart of some sort to fill the system. That could just be a submersible pump and a large trash can although a pool pump has a better curve for that application.

0 -

I do have a hot tub I'll be decommissioning soon and could use one of those pumps, although might be a little large. 😅

Carson City, NV

Mechanical Engineer

Building ICF House0 -

There is not a huge difference between deionized water distilled and reverse osmosis, different methods to get the same result.

DI uses a media bed to remove + and - ions, similar to a water softener.

RO's uses filters and a tight membrane to filter out ions

Actual distilled water is boiled, condensate collected off a stainless plate typically.

The advice to use DM de-minerlized, or DI de-ionized, water to blend comes from Dow. Dow actually supplies the base product to many other repackagers. So you may see that same spec at other glycol manufacturers.

Regardless, it is good to know exactly what is in your water. If you have high chlorides that is tough on stainless components, like indirect tanks, heat exchangers, etc.

Here is a quick read on hydronic water quality

A plastic garbage pail with an inexpensive plastic sump pump from HD is another option.

I have seen a plywood lid on the garbage pail with the pool or spa pump bolted on. A 1/2 hp spa pump would be plenty of flow. The larger the pump, gpm capacity, the more loops or circuits you can flow at once.

Avoid leaving the glycol exposed to air for very long, it sucks O2.

It need not be fancy.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

Sounds like I'll get my iron filter working this week and bring a sample in for testing to see where it's at with all the filtration before and after the water softener to see if that would work.

I don't recall any chloride in the initial well test, so should be good there.

After your DI suggestion (dow recommendation) I found a place i can get the water for $1 a gallon if it comes to that. Filling 5 gal at a time might take a while from the do it yourself station.

What velocity are you looking for initial purge of the lines?

Carson City, NV

Mechanical Engineer

Building ICF House0 -

you want to get flow velocity at or above 5 fps. That is what it takes to move solid particles through the piping.

If you can get a copy of the well test, you will learn more. Typically they are looking for conditions more health related than boiler water quality.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements