Radiant heat plumbing design

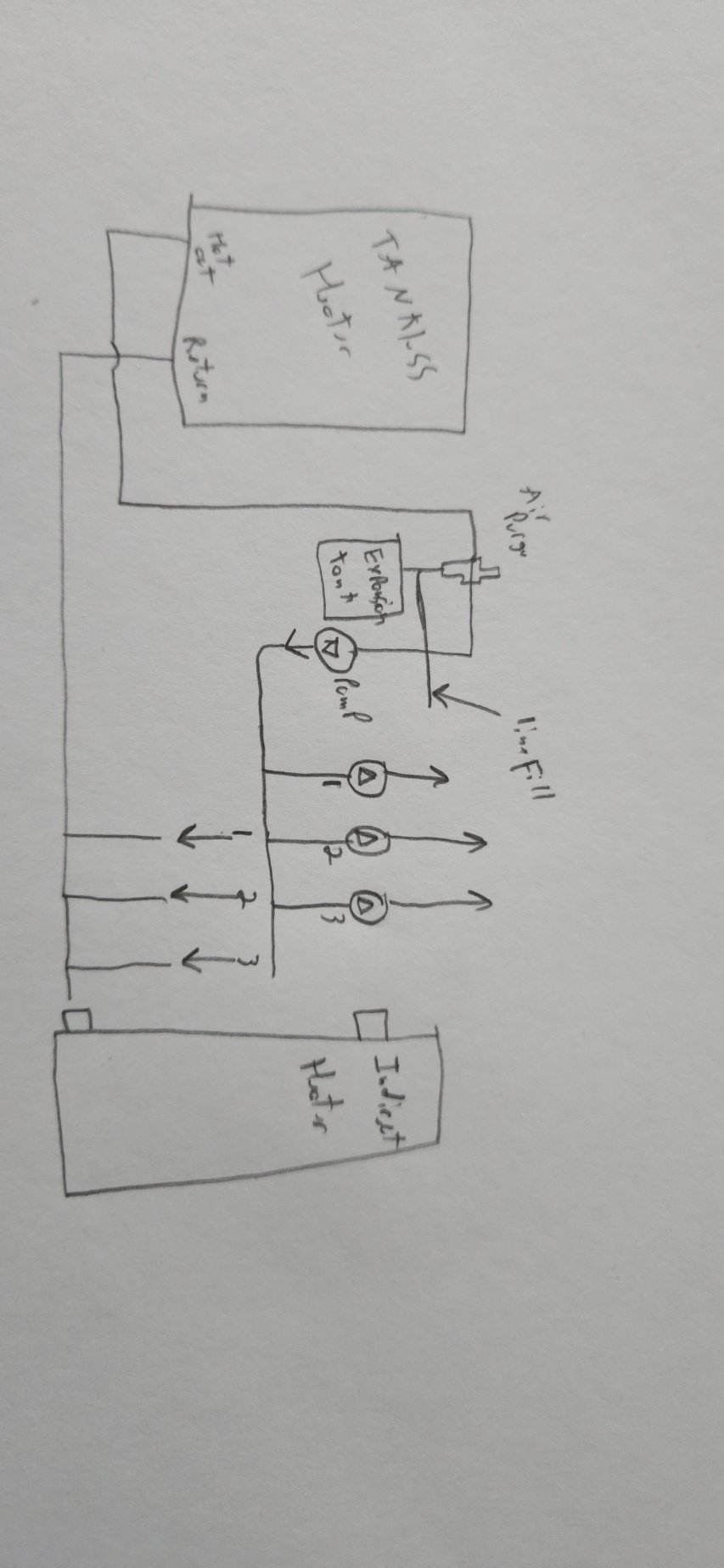

I'm looking for a new design for efficient proven design to include the 3 zone pumps, 1 pump feeding the tankless, and include the indirect water heater. Wanting to use 1-1/4 copper for feed/return headers for the zone pumps. I do have a taco mixing valve new in the box but before I spend a bunch of money, time I thought I'd ask the professionals what will work

The current setup consumes a lot of fuel, it's all 1" pex. The indirect water heater is not connected yet. It's to only preheat the water before it gets to the hot water heater, and add extra heat capacity to the system.

In the summer I thought I could run the garage zone through the indirect heater to pull the heat from the floor and help heat up the water before it gets into the hot water heater.

Zone 1 is not used but maybe staple up heat sinks, 1 loop

Zone 2 is garage, 6 loops, 64 degrees

Zone 3 is basement, 12 loops, 74 degrees

Comments

-

A thankless is not the correct appliance for the job. It wants to heat a small gpm flow across a wide temperature rise, say 50° incoming water to 120°

A boiler would heat a high gpm over a smaller temperature rise, maybe 100- 115 for radiant for example.

As such the HX is designed differently, controls are different.

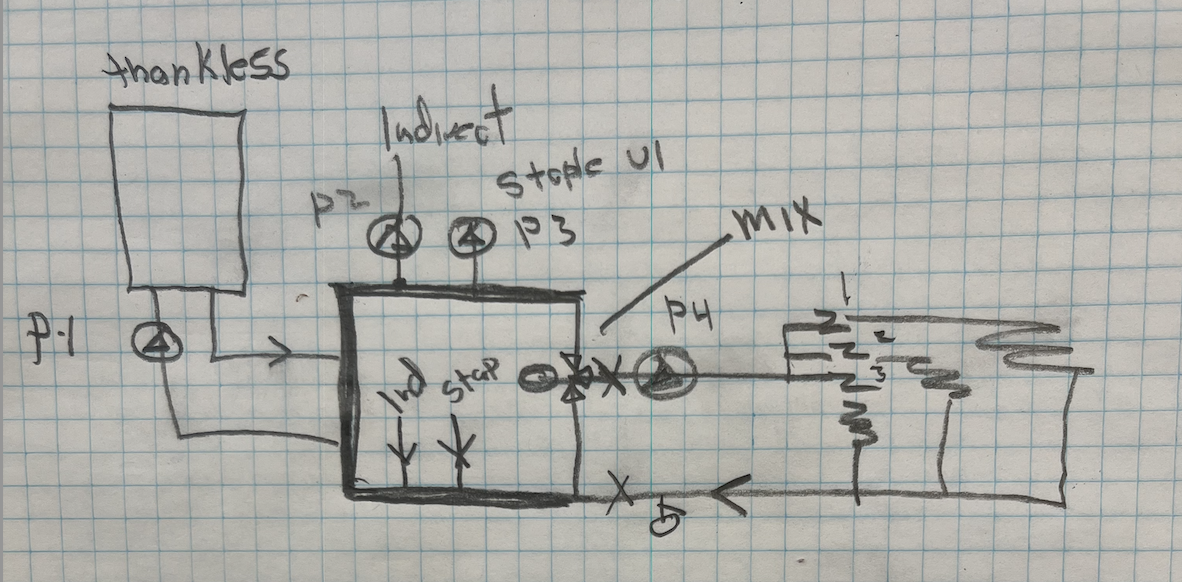

Possibly you can force it to work with a primary secondary piping, like this.

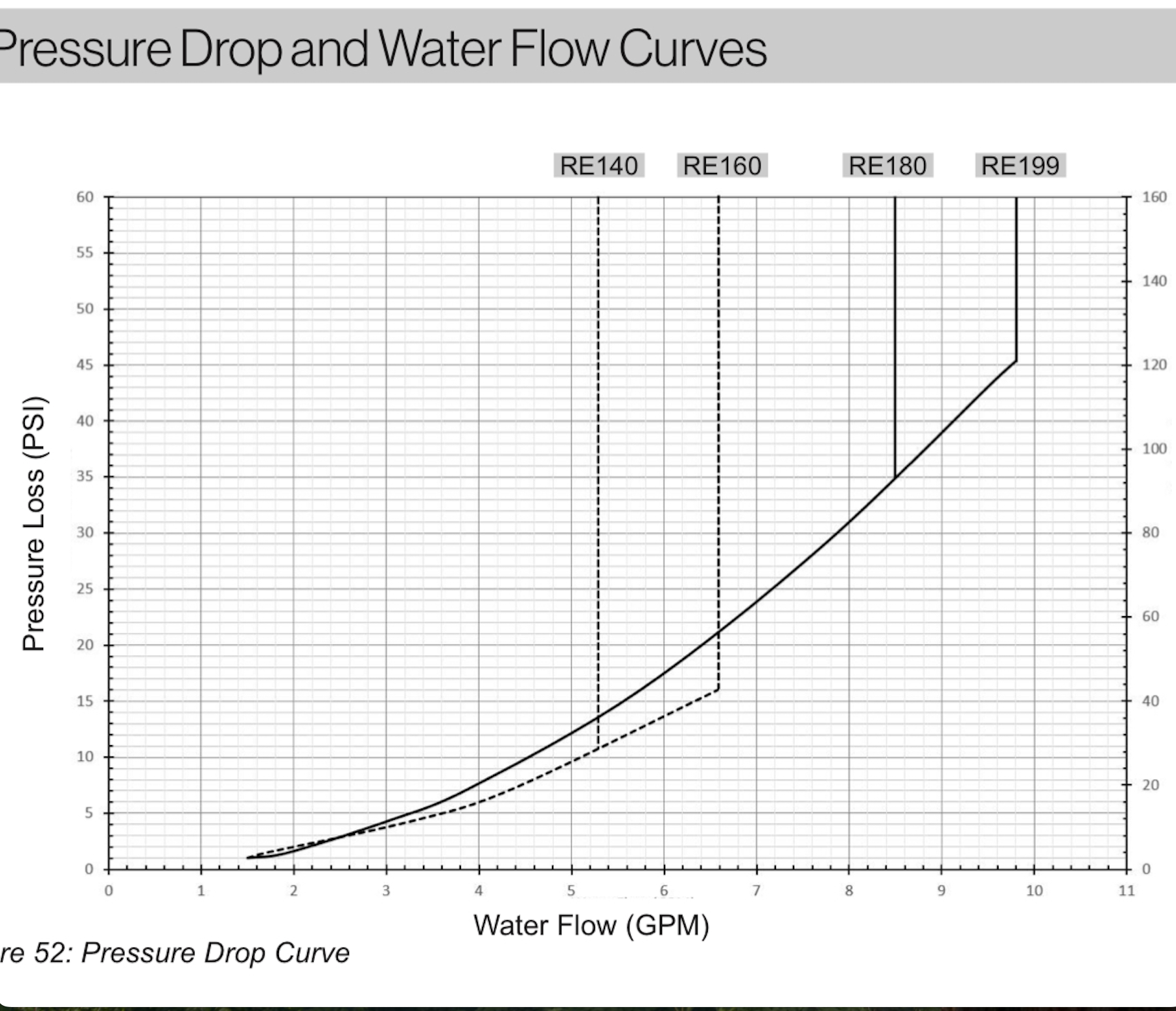

The manual should tell you how many gpm you need to pump through the heater to get full output. Some manuals show a pressure drop curve for flow rate sizing.

Somehow you will need to run up around 180 to get an indirect to perform to it rating, not all tankless go that high. If the one you have oly goes to 140F,the indirect performance will be low. Possibly the indirect manual shows various input temperatures?

Basically the boiler pumps into a loop, the loads pull off the loop. The heater may need a high head circ to get full output.

This would be a two temperature system, high for the indirect and staple up, a 120 degree from a 3 port mix valve for the radiant zones.

You need more info for pipe, pump and mix valve sizing. Don't fire the parts cannon until you do some math.

How many gpm to the indirect?

How many gpm for the staple up? What supply temperature

How many gpm for the radiant, what supply temperature for the radiant?

A small mod con boiler would have most of the controls and flow capability to pull this off.

One primary secondary piping option.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

I ran out of money building the house, they wanted $50,000 more for the pumps and layout. That's a hard no. This tankless heater is not getting replaced any time, it'll have to do.

Tankless will do 140 degrees 9gpm at 40 degree differential I've seen it take in 60 degree water,and put out 140 degree at 7gpm. Absolutely killed 200 gallons of propane in 1 week. I cannot afford that anymore. The lowest amount of gas burnt while maintaining the temperatures is ideal. Model is Ru180ip

Indirect heater is a triangle tube smart50. Manual says 12 gpm IF boiler water is 200. I want to use the indirect just to help heat the water. It is NOT the main water heater

All the pumps are the same, ALPHA2 15-55SF/LC Stainless 0-21gpm 0-19 head. Max head of 18

Zone 1 pump is not used but could be.

Zone 2 pump for the garage 5 gpm is good, thermostat is at 64

Zone 3 pump for the basement.this one concerns me the most. I am low on gpm especially if zone 2 pump is on at the same time. This pump says 5 gpm but the manifolds don't register a whole lot of flow on each loop Basement is 1800sq/ft, I thought I needed .5 gpm each loop to get btu/sq foot correct so it needs to be at least 6 gpm?

This is a how can we make the major compenents work by changing plumbing diameter, pipe circuit design,and water temperature.

The concrete seems to take ALL the btu. I've never seen anything more than 85 degrees return thru the garage slab, even with 140 inlet temps. The less burners the tankless fires, the cheaper it is. 180,000 btu is expensive if its on ALL the time and the concrete will take all 180,000. This is my observation from the last 4 years of tinkering, I can use some professional help now

What other info do you require?

W/R, thank you

0 -

Straight up ADDING an indirect heater, to then feed a regular water heater will just cost you more fuel so definitely do not do that.

A lot of what you are saying here doesn't make sense…. if the slab can use a constant 180,000 btu/hr without ever stopping and never overheating the space you have either WAY more slab than you mentioned, or you have a huge leak (like massive leak, one for the history books), or you are just running fresh well water through the whole system and then dumping it somewhere (also kind of a leak).

Adding components isn't going to fix your system (well maybe you need some component, just not your drawing), can you take some photos of how the space heating is set up currently? and just to clarify your tankless space heating system is completely separate from your domestic water yes? if you have a fill line you have a pressure reducing valve and a backflow preventer correct? what is your heating system cold static fill pressure?

1 -

12 psi regulated fill line with a backflow preventor. The hydronic is separate from the drinking water.

Sorry for the confusion in my wording. Zone 2 and 3 turn on/off with a thermostat, and are functional.

I assumed that the hotter and faster I push water through these slabs the hotter the return water would be, so the less fuel spent heating the water back up to the 140 degrees. That did not work. the concrete seemed to absorbed more of the heat from the water and I still burnt a ton of fuel heating it. Low flow at 120 degrees through the tankless still heated the garage to 64 degrees but cost way less compared to high flow and 140 degrees to maintain 64 degrees in the garage.

I experimented by taking running 2 pumps feeding the zone pumps. I disconnected the indirect I thought it was consuming to much fuel to heat up.

Can we return the slab water through the indirect?

2 pumps on the left are pulling from the tankless feeding the zone pumps. Pump on the right is pump for basement, then pump for garage, then the extra pump (I took and hooked to the main pump)

I DO have a taco switching relay I normally run these on

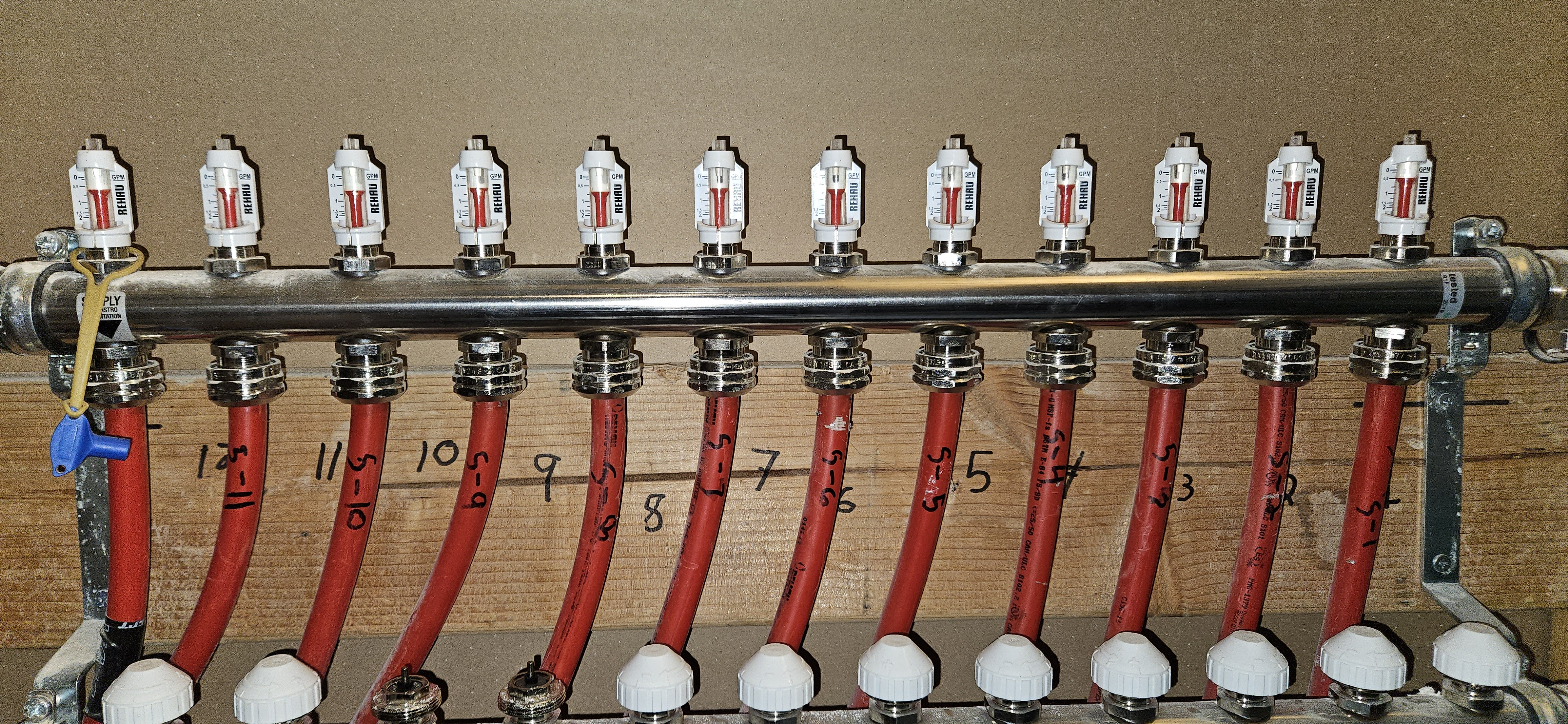

The manifold in this picture is getting 6gpm ONLY with the zone 2 pump shut off. About .75 gpm each loop. With zone 2 pump running at the same as zone 3 some manifold loops don't read any flow

0 -

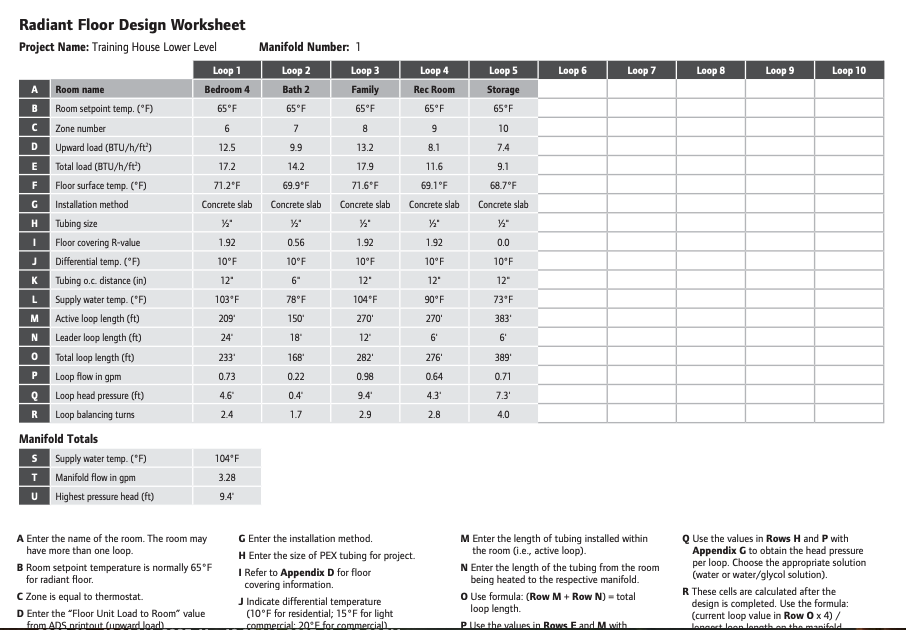

How long are those pex loops? How thick is the slab? What type of insulation under the slab, around the edges. Any heat load number for the areas?

The load, heat emitters, concrete slabs, dictate the operating condition of the heater. Cold slabs take a lot of energy and time to ramp up. Initial start up will take hours, maybe a day and near constant firing of the heater. Don't try and set back those slabs.

Is the indirect on a priority zone?

Looks like a recirc pump on the indirect. If so that recirc loop is another heating loop using fuel and tankless output.

12 loops at .5 gpm per loop, (typical for 1/2" pex) you need 6 gpm just for that manifold.

1" pex is good for around 7 gpm so the pex header at the pumps just covers that 12 loop manifold. Not much capacity for any other zones.

That pex header size needs to be able to handle the total gpm of all zones running, if that is what you want?

If you need the full 162,000 the boiler can put out, and if you can pump it to get that, then you want at least a 1-1/4" headed for 16 gpm. Does the building have a 162,000 load?.

Here is the pressure drop curve for the various sizes. 8 gpm through a 180 is 30 psi pressure drop. That will take a sizable circulator to get the heat out, which is why you need a primary loop with a dedicated heater pump, probably a Grundfos 26-99. And you still may not get the full heater 162,000 output.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Loop size I believe were 200' feet each for both the garage and basement

1200' in garage

2,400' in basement

5" slabs

2" foam on sides

Ultra CBF insulation under the slab

Climate zone 5b, northern Nevada

Using slab sq/ft x ceiling hieght x temp differential x.135= btu heat loss I got

Zone 3 about 92,000 btu

Zone 2 about 57,000 btu

The indirect is not hooked up. It's currently only running hot water recirculation pump through it to the home faucets, home has about 70 gallons of hot water

So we are needing

A bigger pump for zone 3, the 12 circuit loop

Minimum 1-1/4 headers

Is 1" pex OK for the loop on the tankless? It's only 3/4 inlets

Is the grundfos ALPHA2 15-55SF/LC good for the main loop feeding the tankless?

How do we connect the main loop to the zone pump loops?

Why is the current delta T so high when it's said to be 10 degrees?

0 -

-

I did not put anything under the slab, I do not build houses, I paid for the home to be built, I made specific request for great insulation, I don't know if they put 2" foam under that bubble wrap crap or not. I only recall them specifically saying the insulation was rated for under the heated slab.

0 -

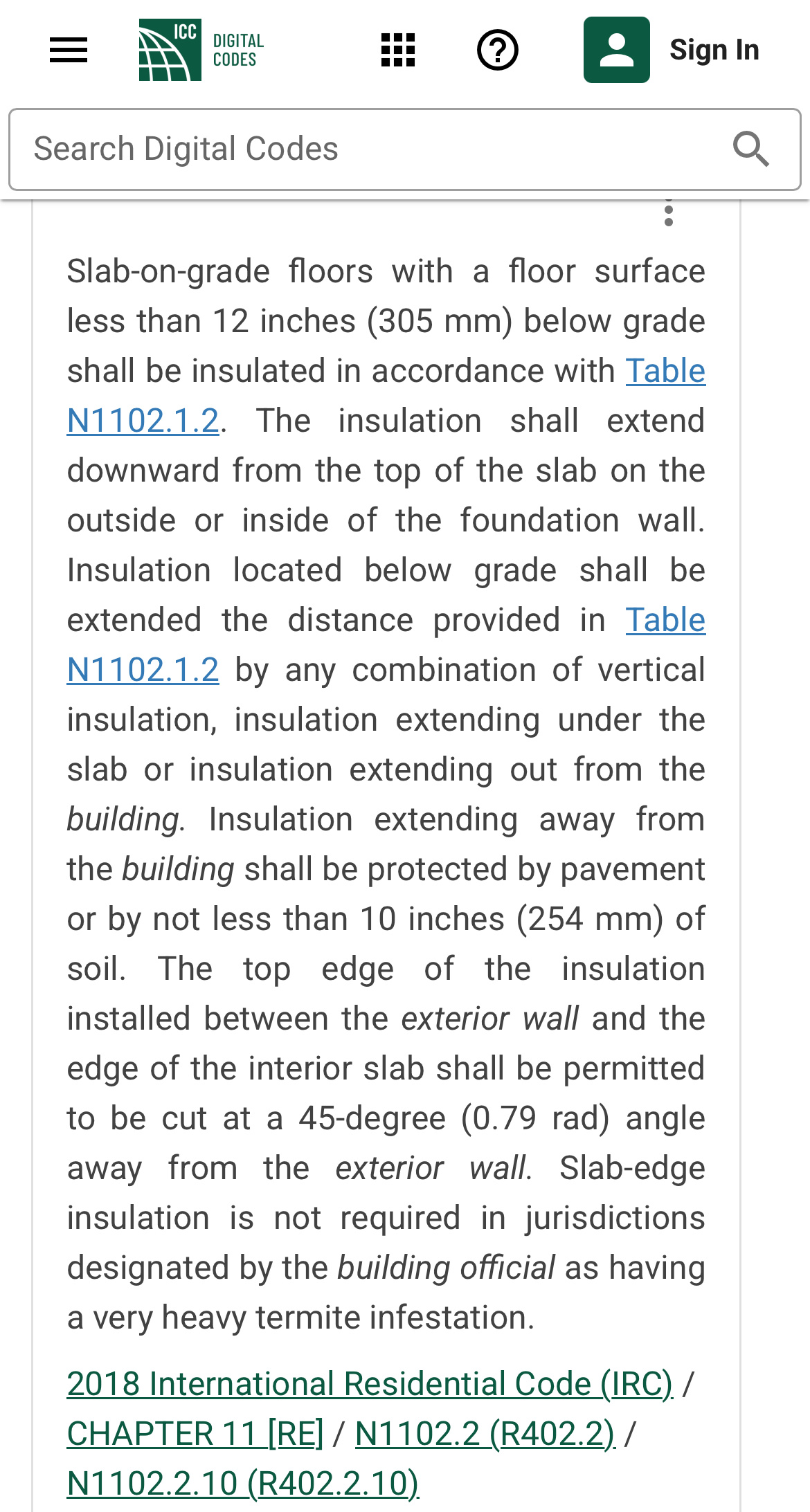

I would check what is actually under the slab. Check if you have an area where you can break a the concrete without risking any pipe damage to verify. Around me code min for heated slabs is R10 rigid, there is a reasonable ROI for even more.

The efficiency difference between a properly set up fuel burner is about 10%, so you are not likely going to save much operating cost by re-plumbing.

If you are missing insulation under the slab, the best solution is to abandon the heat and convert to baseboard or panel rads. Without insulation, depending on soil moisture, you are loosing somewhere around 50% of the heat to the soil.

0 -

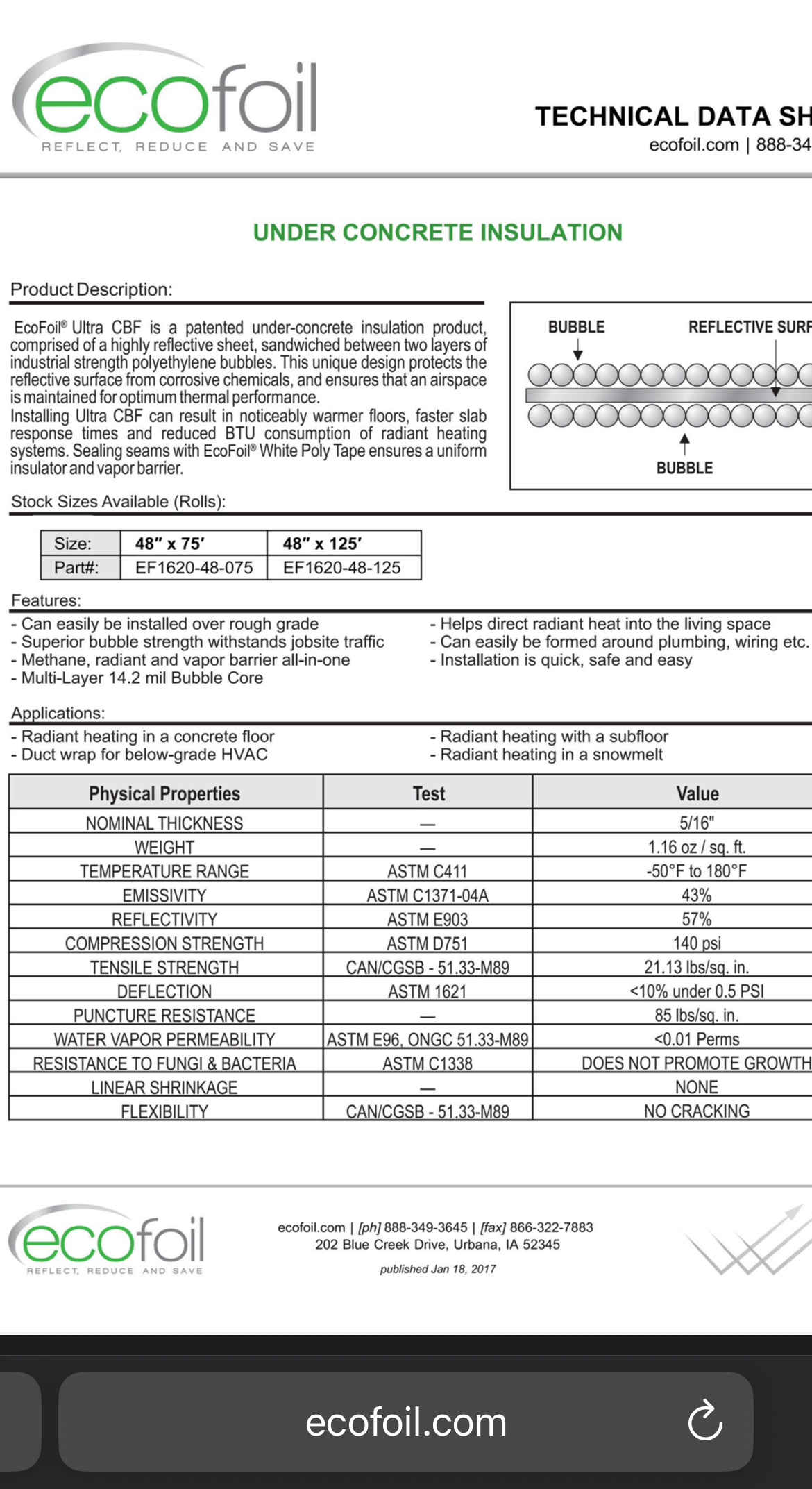

I know for sure that radiant barrier is under the slab. In the build pictures I can see that much and the 2" foam between the foundation and the slabs. I can not confirm if there's more under it.

They claim it's engineered specifically for under slab radiant heat insulation

Is that inadequate? I do not have any 1st hand experience with this product.

I wouldn't say I have problems heating these slabs. I'm just wanting to make sure the plumbing is as efficient as possible.

0 -

Provided your burner has enough BTUs you can heat any slab and get it nice and toasty. Look at some of the snow melt system out there.

The problem is if the slab is not thermally isolated from the dirt, lot of the BTUs the boiler is putting out is going into the soil not for heating the house. That is real heat loss that increases your fuel use.

Modifying plumbing won't help with that.

If there is really only a radiant barrier bellow the slab, your heat will never be efficient no matter what you do. You need to figure out what is actually under your slab and if there is no rigid, your best bet is to abandon it if you don't want to keep throwing more fuel cost at it.

0 -

in their video they claim it is 1/4”, their spec sheet shows 5/16”?

But no R value listed

Foam is typically R-5 per inch

So that small R value allows heat from the slab to go down into the earth

If the tube is at the bottom of the 5” slab, that hurts you also

Do to answer the first question, yes the piping can be upgraded to move whatever you can pump out if the boiler. But changing the heatloss is not going to be so easy

You might consider a different heat emitter for the garage if you plan on keeping it warm, maybe a hanging unit heater that can ramp up quickly

The heater has 3/4 connections because it is a water heater intended to heat 6-8 gpm, maybe.

You need more gpm for heating. So a bigger pump to force as much flow through the tankless as possible

Think if hydronics like electrical wiring , the more power you need the bigger the wire

Maybe send EcoFoil your fuel bill.

Check the mechanical code book for your area to see what is required to meet code

The drawing I attached above shows the tankless loop with big pump, then the Alphas will work for the zones, with those 200’ loops

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

R5 is required under heated slabs

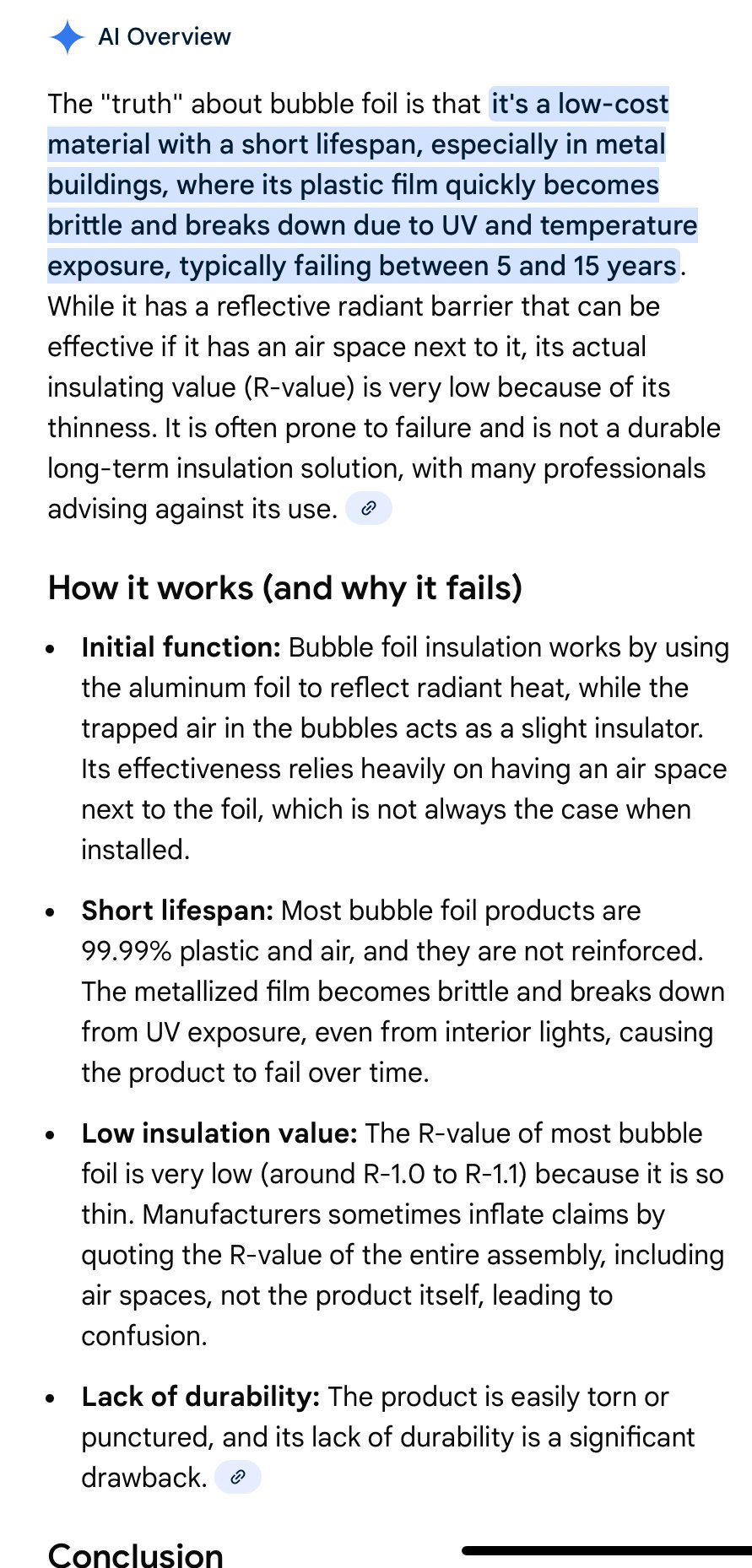

Have you guys never used that foil before? Is their claims all bs?

I'm not fallowing your drawing to well, I don't see the garage circuit which is zone 2, zone 3 (basement) using a mixing?

We can definitely ommit the indirect heater

What diameter do we use for the loops? You have the big pump feeding the tankless?

What temp water are we expecting to use?

0 -

If they cannot provide a tested, certified R-value?.

Even AI has the correct opinion

You have options to improve the distribution piping layout, the slab insulation will not be an easy fix.

If there is a code requirement in that area, either mechanical code or State energy code, I’d be having a chat with the builder and radiant installer.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Yeah, the bubble wrap is a scam.

Still air is about R-4 per inch, anything that relies on trapped air for insulation is going to be about that. Most materials are lower R-value than air so the combined assembly is slightly less.

Some closed-cell foams use a gas other than air to fill the space and are able to get higher R-values. Polyiso foam and closed-cell spray foam are both R-6 per inch. But as the foams age the gas leaks out and the R-value drops.

0 -

0

-

The foil is BS yes. if thats all you have for insulation there is your answer, you don't have any insulation and the heat from your slab is going to transfer more easily to the coldest area, which is down to the ground.

Would be curious what a load calc for your house looked like before construction began? That way we know how much over your load you are using. it's hard to tell from afar, some people use a ton of fuel. I figure you are using about 2 times (maybe even more than that) the btu/hr my house would be at design day conditions if that 200 gallons number is accurate . i have a 2500 sqft house in northern michigan

some highlights from the linked study

"Via email, Dr. Straube informed us that his results were showing Ultra CBF rFOIL with an R-value of approximately R-2 and that, because preliminary results were not looking favorable, Covertech ended this study prematurely before more accurate results could be determined." Manufacturer ended the independent test because the product does not perform well

"The insulating value of this type of product varies depending on what other insulation it is combined with and where it is installed on the slab. At best, its insulating value was only slightly better than two layers of bubble wrap without the reflective foil layer, or a maximum possible R-value of 1.5 to 2.0. This maximum is unlikely to be achieved in an under-slab application and impossible if the air gaps are not maintained." Max R1.5-2 if installed perfectly

" The least effective application of a bubble-foil-bubble insulation from an energy standpoint is an installation under the full slab area on top of R-10insulation. In this case, heat loss from the slab may be increased by as much as10% due to the thermal bridge effect of the aluminum foil, as illustrated in Figure 2. In other words, the R-value of the slab insulation system would be decreased by the addition of the bubble foil-bubble insulation" The product will actually decrease the effectiveness of regular R-10 insulation by 10%

1 -

I hadn't thought about that but yes, in a direct contact installation with no air gap the aluminum coating would act as a conductor and defeat any insulation power.

0 -

Confirmed, it's the only insulation under the slabs I see thru the foundation access cutout. I did message the builder with these findings. I did tell them I was talking to you and cited the company you work for as to solidify this as a professional oppion. Ironically I was watching all your webinars as I created this thread.

please, back to the main goal of mine, the distribution plumbing being correct.

Will you draw up a clearer schematic with sizing and only the 2 heating zone pumps

Zone garage @ 4gpm

Zone basement @ 7 gpm

1 loop feeding boiler

1 loop feeding zone pumps

I found this too..

0 -

Say the slab is 2000sqft and running 80F to heat the place, bubble wrap is about R2, sub slab soil at 50F. Assuming 70F room, the slab is delivering

(70-80) * 2(btu/sqft/F) *2000=40000BTU of heat to the room

and loosing

(80-50) / R2*2000=30000BTU to the dirt

Now in reality is not as bad as soil does have some R value and eventually some the dirt heats up but you can see the issue.

If your existing system is heating the place just fine, modifying the plumbing in any way won't meaningfully change how much it costs to heat.

1 -

@Kaos : "If your existing system is heating the place just fine, modifying the plumbing in any way won't meaningfully change how much it costs to heat."

To put a finer point on this, if your system is putting heat into the inside of the building envelope, it's contributing to the warming. The only way that changing up the plumbing makes things more efficient is if today the plumbing is pumping heat out of the building envelope — which is what we're talking about with the floor.

0 -

The builder messaged me back, I explained to him the situation, the issue, and gave him the literature backing it up.

Right now I've had just the water recirculating thru the system with the heater off and it's been maintaining the garage at 59 degrees. there's still usefulness in the system. It's pulling heat I assume from the ground/basement and putting it into the garage.

The house has 2 other heat options

The garage is only concrete floor heated and it's not negotiable it has to be heated. radiant heat let's my tooling and cnc mills not rust because of condensation.

These slabs cost $28,000. I bet today here they'd cost $40,000 in a new build.

What do you guys suggest?

0 -

you aren't pulling heat from the ground, its just got a ton of warmed thermal mass on that slab, it will go away soon enough, keep the pumps running to keep fluid moving and be careful you don't let anything freeze.

If you want the space heated then it will cost money, if its too much then don't heat it. You may find it cheaper if its just a wide open garage to use a unit heater of some kind, you will still have some downward loss but not anything to write home about since you would be using hot air which rises. You'll trade 90-ish percent efficiency from your condensing boiler (approx 50% eff when DL is taken into account though) and trading in for 80ish percent efficiency, and won't have warm floors. there is also some cost to install a unit heater, you need the unit, hanging materials, and a gas line sized for the appliance. If you go that route get some kind of manual J performed on the space so you know what size equipment you need, that is always step zero, the first step before anything else is even decided (well it should be anyway..)

I'm not sure what your recourse is against the builder, I have no clue how that plays out others may speculate but I can't. On a separate note i hate it when someone gets shafted…… Kind of makes me feel lucky I have such a strict building department in my county, drives us crazy most of the time but they would never let that slab go here

What is the square footage of this garage anyway?

0 -

You mentioned 6- 200' loops in the garage. If the tube is 12" on center, the garage is about 1200 sq ft? Even with a high heat load that 180 boiler is plenty to keep that space warm.

You just will being using more fuel to get the job done, with miimal insulation.

You have the boiler power to do more that the garage if that is what you want to accomplish?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

"Right now I've had just the water recirculating thru the system with the heater off and it's been maintaining the garage at 59 degrees. there's still usefulness in the system. It's pulling heat I assume from the ground/basement and putting it into the garage."

I really don't see how this is useful.

"The garage is only concrete floor heated and it's not negotiable it has to be heated. radiant heat let's my tooling and cnc mills not rust because of condensation."

The only kind of heating that won't keep humidity down would be an unvented gas burner, which I wouldn't recommend either.

It's going to be cheaper to put in a different heating system than replace that slab.

0 -

1200 square feet is fairly accurate. I thought the basement slab was little more than 1900 sq/ft the 200' loops is what I recall the builder saying . I didn't get a schematic of the layout,only pictures I took during the build

If you guys didn't mention the insulation is inadequate I wouldn't have known. This tankless heater absolutely will keep both the basement and the garage heated. it's only $$$$$

I was thinking I have a flow issue, maybe closely spaced T or mixing valve that could help lessen the fuel consumption.

What should I expect the builder to do? Empty all the stuff out, cut out both slabs, new insulation, new loops, new concrete, then move everything back in?

0 -

Was there any sort of heat load calculation and design done for the job.

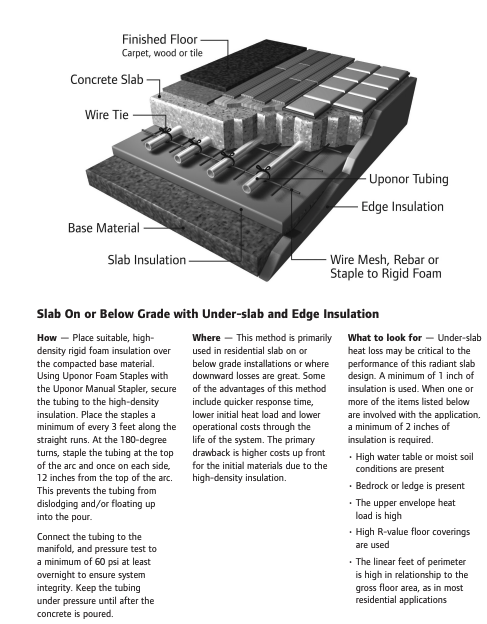

If so that spells out what needs to be installed as far insulation, tube lengths and spacing, pump sizes, etc, etc. An example below.

Also from this Uponor design manual their slab on grade method.\

i would start with a call to the building department in your town. Ask the plan check people or the mechanical inspectors what is required for a radiant installation.

In my area they need an official manual J load calc sheet. In some areas they have an insulation requirement. Also ask about an energy code that would cover under slab insulation.

With this info you meet with the builder for his thoughts on the system installation and cost of operation.

I would give him the opportunity to make suggestions for the fix.

Read through this manual to learn the terminology and proper design and installation steps.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

It's wild how different each building department can be lol. I watched them shutdown a job here when the builder messed up the perimeter insulation, it was all hands on deck to get that fixed ASAP. Next county over the same builder forgot to insulate an entire wall and got all the way through inspections and nobody found out until that first winter the family lived there.

0 -

Let's make an assumption that you do not get relief from the builder and are on your own.

The logical solution is to abandon use of the slab heat in the garage, and install some sort of heat pump there. The price per BTU will be much lower than trucked in propane when you consider the COP of a good heat pump. It would pay for itself quickly.

A couple of split minis could service that space. You have the power there, you have mills and CNC machines to keep warm.

1 ton units are $1000 plus install.

0 -

I hope not to go that route at all. it's so nice having all my equipment warm. This summer I converted over to natural gas from propane so hopefully the fuel consumption cost is lower. I'm sure somthing can be done. Might just be a slow go

0 -

Do I still need the check valves in the pumps With the 2" diameter copper pipe loop?

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements