Want to add water to increase boiler system pressure but stumped

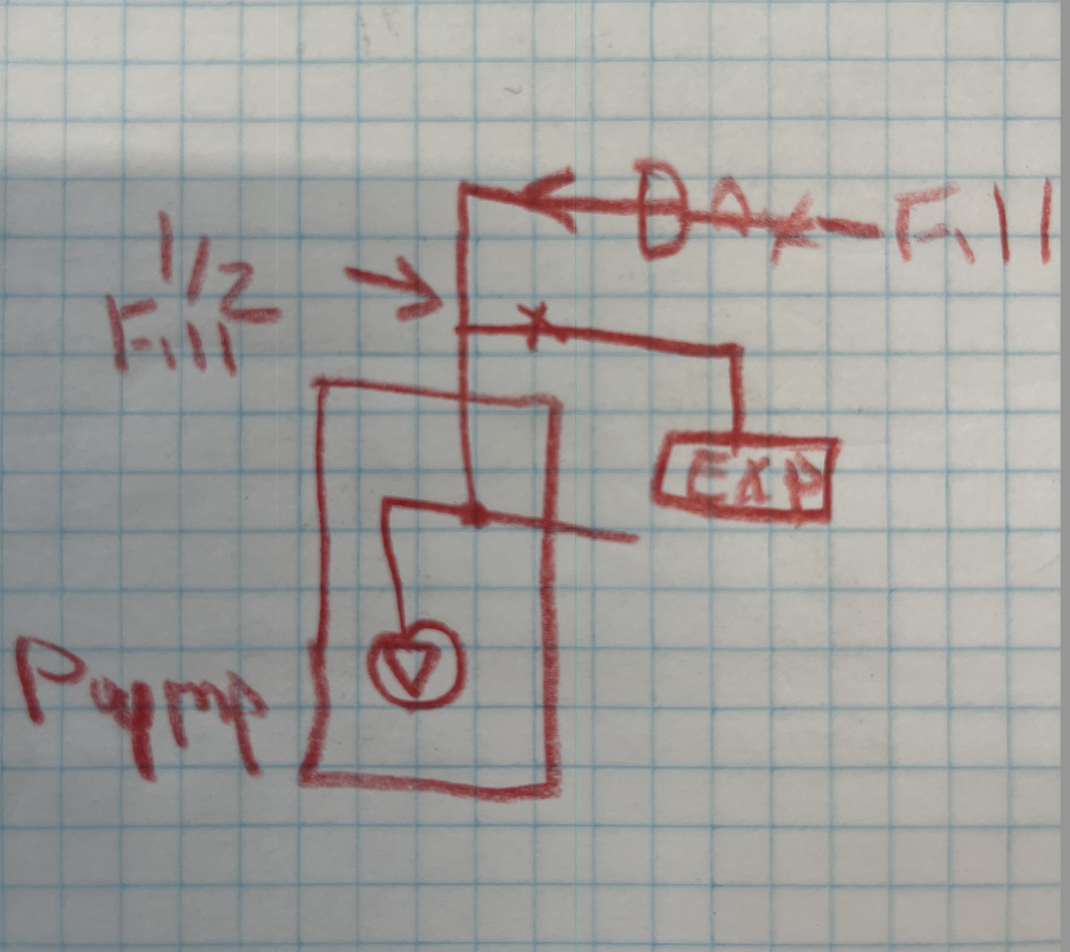

Hi, homeowner here, new to this forum. Recently attempted pre-season radiators-bleed in 12-yr-old Lennox GWB8-150 boiler system but no water came out. System is heating 1st floor fine but not 2nd floor (2nd fl heat was never great but zero now). Pressure gauge reads 6-7 psi, def low. After much research, I'd like to add water to / remove air from the system, at least as a diagnostic (but yes, hoping it may be a fix, at least for a time), before paying someone to come in. Fast-fill valve is a Honeywell sparco fillmatic fm450 (hasn't been made in a while so looks ok from outside but maybe this is the ultimate culprit?). Seems this 'fast fills' just by lifting the lever from vertical to horizontal, and I'd need to monitor pressure to keep under ~20 psi. (I know to turn off/let boiler cool before doing this). Multiple add-water videos show them adding a hose to the drain valve and closing another valve, then fast-filling. I've tried to follow the flow path, etc. but can't figure out which valve to close, so I've come all this way but am stumped! Might it be possible, if I send pics and maybe a rough flow diagram, to get help figuring out which valve to close? And of course, open to other advice on this situation as well. Thank you kindly!

Comments

-

Pictures (from a bit back) to get the whole boiler and piping in. Or as much as possible. A diagram would help as well. Does the fast fill valve work? If so you can fill to the desired pressure about 20 and run the circulators. Depending on the system the air might come out on its own.

Miss Hall's School service mechanic, greenhouse manager, teacher, dog walker and designated driver

0 -

OK, will report back with pics and diagram — thanks!

I don't know if fast fill valve works — would i just lift the lever and listen for water flow to find out? I did wonder if I could just fill and skip the draining part as a 1st try but the videos seemed to emphasize the draining so wasn't sure. If I can fill-only, wondering if the mystery valve still needs to be identified and closed…

Anyway, pics next…

0 -

You don't need to do anything but lift the fast fill. If the PRV is not working on its own it may need to be replaced. Make sure any valves between the cold water supply , through the PRV and into the boiler are open. Pictures may help if you have a backflow preventer before the PRV that could be the issues.

What you can do in the meantime is get a garden hose and a female x female hose connector (or a washing machine hose) and add water to the boiler by connecting the hose to a cold water supply (outside faucet, washing machine valve etc) to the drain valve on the boiler and fill it that way.

The correct pressure would be 15psi should be enough for 2 stories.

This should get you running until you figure out why you are not able to add water.

1 -

-

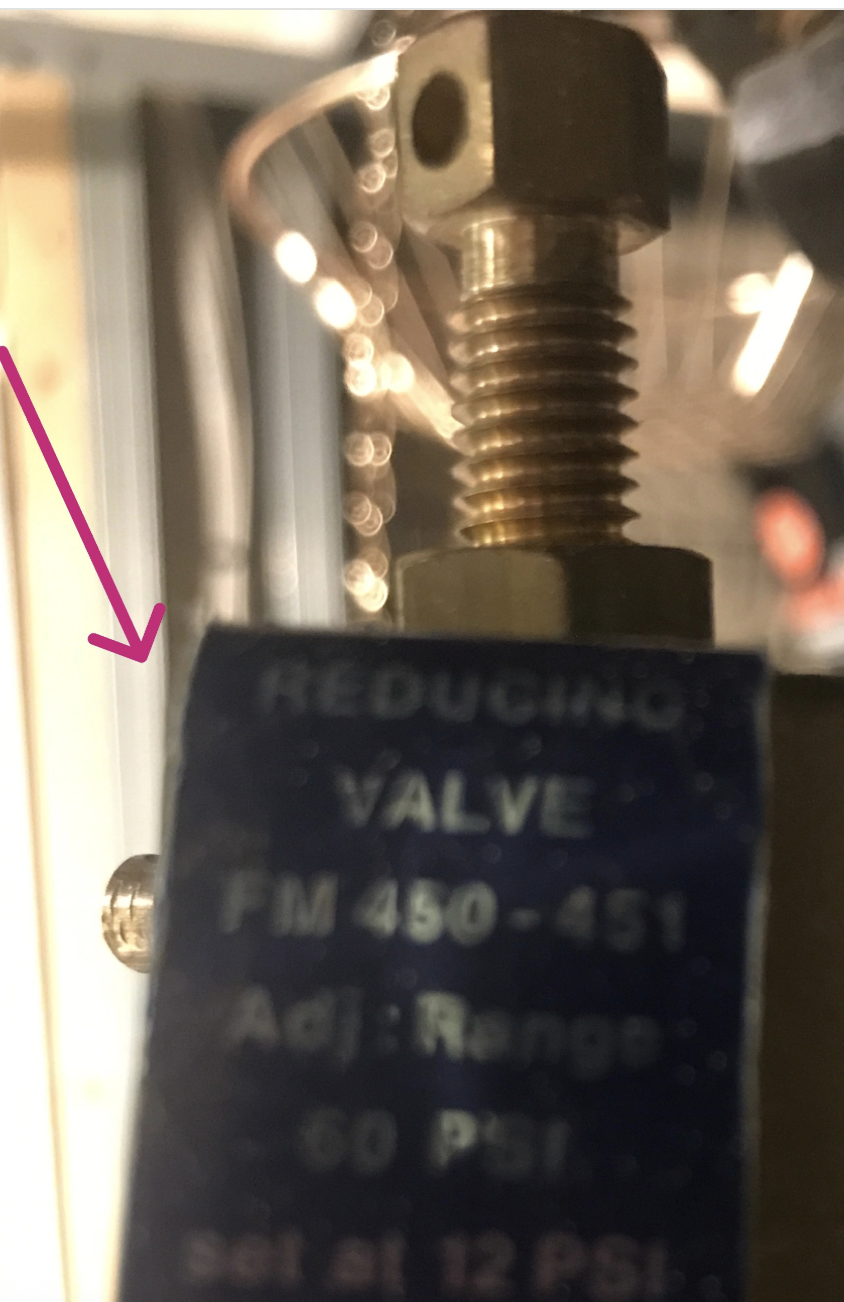

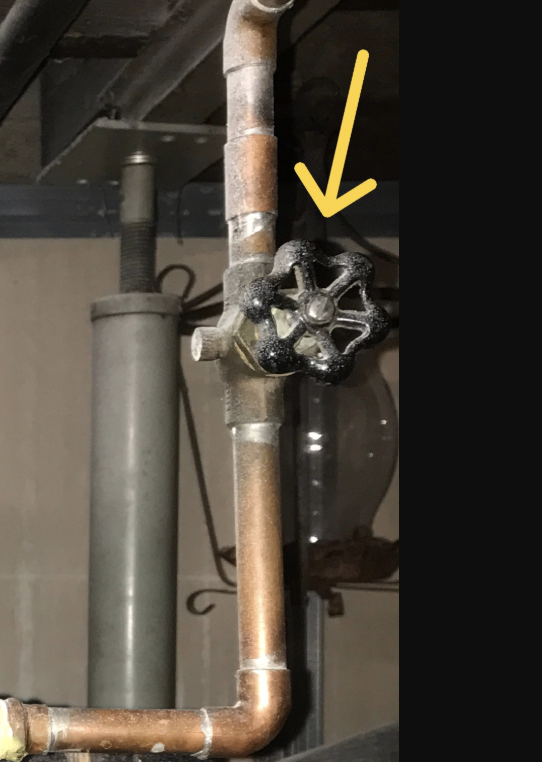

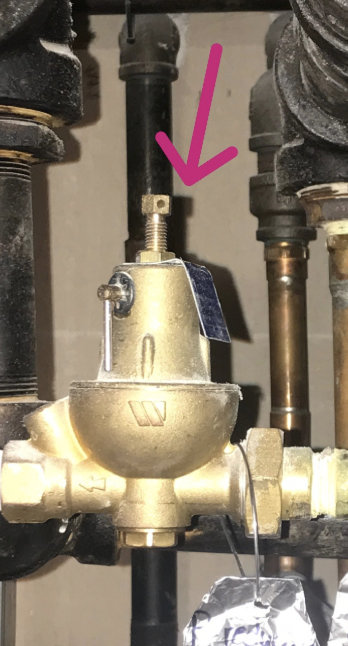

Struggling with a diagram that makes any sense but let's see if these pics work. Color code (arrows) is: yellow = valve from water main. green = Watts 9DM3 backflow preventer. pink = FM450 P reducing valve / fast fill combo. red = drain valve. blue = Watts M335 safety P relief valve. orange = valve on pipe going to radiators (isolation valve for maintenance?).

0 -

0

-

0

-

0

-

Sorry if this is too many pics, and please ignore my homemade foil tags!

0 -

loosen the bottom jam nut, turn the upper hex clockwise to increase pressure. Slowly

Assuming that wheeled handle valve upstream is open fully CCW?

\The lever on the side is the fast fill enable, flip it to fast fill. But to increase permantley, the nut and bolt on top

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Well, here's some maybe key info: that black handled upstream valve is turned fully CLOCKWISE (so closed, correct?). Is that ever normal? If it's been closed then there's been no access to supply water, correct? (I certainly didn't close it, this was to be my first attempt at anything on the boiler. It would had to have been done the last time it was worked on, a couple years ago.) The system is on now b/c it's cold out but should I just turn system off, let it cool and then turn the black valve totally CCW / open and see what happens?

0 -

Correct. Black valve was closed. Open it so that the automatic fill valve can add the proper amount of water to whatever pressure setting it is preset for. 14-15 psi is normal. This should be done whether the boiler is running or not. If you are certain the auto-fill valve is working properly, let the system run a proper cycle and then bleed any air out of the system manually if you have bleeder valves out on the radiation system, baseboard etc. There should also be some automatic air bleeding mechanism near the boiler. Noise of air sloshing in the pipes is an indication that you need to fill and bleed. Also if there is no heat in the pipes during a call for heat to the boiler that also means there is probably no flow and somewhere the system is "air bound"— often at the circulator.

1 -

I want to make sure I'm not misinterpreting: do I understand correctly that it's ok to open the water supply valve and let room-temp air flow into a hot boiler?

I am NOT certain the auto-fill valve is working. Is there a way to confirm it is working right? And if there's no way to confirm that, does that change your direction to fully open the water supply valve?

I am not aware of an auto air bleed mechanism near the boiler but if someone provides direction, I'll try to locate it.

Thanks for the info, and for your patience! I'm really trying to understand this, though it's not my wheelhouse and I def don't want to make anything worse.

0 -

It seems like you should get someone on site who is familiar with general hydronic heating systems. A professional willing to explain things while doing things like filling the system and bleeding air out is preferred. Or even another homeowner who has a boiler and hydronic heat, and is very familiar with their system. You are asking questions that are very basic and if you genuinely want to learn you should have someone on site helping you understand the basic principles and the devices on the system.

1 -

Let the boiler cool to 120 or so. Then open the manual valve (counterclockwise) you should here water running into the boiler.

Sometimes the PRV valve may leak by. You want the pressure around 15 psi. If the PRV leaks by the pressure will go up. If it get to 20 shut the manual valve and have the prv replaced. You can run it , bleed it fine just control the water pressure manually until the prv gets changed.. Keep in mind that the water pressure will vary as the boiler heats and cools. When the water is heated it may rise to 22 psi or so. This is normal as long as it doesn't continue to rise

0 -

Thank you! Please let me confirm:

- let boiler cool to 120 or so

- fully open black water supply valve

- watch pressure gauge; since PRV is set at 12 psi (per the tag, though I guess could've been adjusted since then), system should stay (on its own, even with water supply valve open? so in other words, is that the correct default setting for this valve?) near 15 psi, correct?

- continue to watch P gauge; if it goes up to 20, may indicate PRV is leaking so close water supply valve and get PRV replaced

Thanks again for the info and patience!

0 -

-

Thank you, I will do that before I add water. Is it better to do this while the boiler is hot, after it has cooled, or does it not matter for this step?

0 -

-

Got it — thanks again!

0 -

No water dripping from schrader valve but tire gauge is indicating no air pressure in the expansion tank, which shows an installation date of 2011 so…probably time to call in the pros, but with much more knowledge and confidence than I'd have without you. And I'll now watch what they do and understand, ask questions and (probably) understand the answer.

I can't thank each of you enough for all the info and patience, it's amazing to me that you are 'out there somewhere' and willing to take the time to help people like me. Thank you for what you are doing!

0 -

-

With the age I guess I assumed it needed replaced but I might as well try that — thanks again!

0 -

Sometimes "technicians" close the water feed valve because the pressure reducing valve is leaking internally causing frequent pressure relief valve incidents. Watch the pressure gauge after opening the feed (the pressure will go up as the system heats up though). If the pressure keeps slowly rising with the boiler off and the pressure relief valve pops now and then dumping water on the floor, the PRV is leaking internally. A bad expansion tank can also cause this which might explain why it was left at low pressure and locked.

1 -

Thanks, that makes sense. Wish I could remember what they said last time; will keep better records in future.

Update: Pumped with bike pump into the expansion tank until tire gauge read ~8 psi then decided to get the compressor to finish. By the time I got back to it a couple hours later, tire gauge on expansion tank once again read zero. Current questions:

- Does this likely indicate a bad bladder / need for new expansion tank, so leave it be, or OK to try again with the compressor?

- Given how low the pressure is, OK to still open the water supply/feed valve and allow some pressure to build up, to see if it helps the 2nd fl heat a bit, or would that be detrimental if the exp tank is faulty?

As ever — thank you!

0 -

try some soap on the schrader to see if it bubbles, it might just need a new core. it should hold pressure if you put the cap on tightly even if the schrader is leaking. the bladder also might have been stuck and got unstuck and released the pressure. With a good bike pump it shouldn't take much to pump it up. I'd try the compressor and see if it leaks from the schrader or if you can't build pressure before condemning it. Is the system open so that the pressure can escape from the water side if it is leaking out there?

if it is bad you will get water on the air side eventually if you re-pressurize the system. Ideally you wouldn't run it with a bad tank but you could run it enough to keep the house from freezing up until you can get a new tank if you keep an eye on the pressure and make sure the relief valve is working.

0 -

Regarding, "Is the system open so that the pressure can escape from the water side if it is leaking out there?"…I can't answer as I don't understand the question — again, thanks to all for your patience with my limited knowledge!

Update:

Soap on expansion tank Schrader valve did not bubble. Also, tapping on tank's side, sounds seemed to indicate hollow/air on the valve end of tank and not hollow on the connected / bladder end of the tank. So maybe tank is OK?

Recharged tank with bike pump to ~13 psi and put cap on tight. (Gave up on new compressor for now: purchased air hose with plastic connectors where I expected brass, like compressor itself, and never did get the right air-hose-to-Schrader connector, but bike pump worked fine.) I could hear the bladder groan ever so slightly when I inadvertently pumped to just over 15 psi; I pressed the Shrader valve core until it came back to 13 psi.

Opened manual water supply valve to see if that alone would allow system to fill. Nothing happened (though I did only give it a few minutes).

Opened fast fill valve and filled until P gauge read 15 psi.

Turned boiler back on and let system heat up: P gauge reads 20 psi and some of 2nd floor radiators are hot (that's as good as this system gets)!

Should I go back to where all this started: give it a day or so and, if system keeps working as is, turn off and bleed radiators, to get air out of system?

Thanks again!

1 -

you will have to bleed it and let some more water in after a couple days because there will be air dissolved in the fresh water that will come out of solution as it is heated. you may have to do it a couple times. the air may come out at the automatic air vent but since the prv isn't working you'll have to add water manually to make up for that air that is released. check it frequently for a couple weeks, it should stabilize after a while.

0 -

I concur with Mattmia. Get enough air in the tank before adding water and bleeding. The tank needs to have enough air so that when the water in the system heats up and expands the pressure won’t change much. That’s the tank’s job.

try pressing the red button

0 -

OK, will watch and bleed rads as needed.

Is there a way to know where in the system the automatic air vent is located? Not important, I guess, would just like to know.

Mattmia, when you say PRV isn't working, is that bc it should have filled when the water supply valve was opened (I'm still wondering if I just didn't give it enough time to work?) or is there another indicator?

Servicemonkey, would you please clarify what it means to get enough air in the tank before adding water and bleeding? Does that mean redoing the process of checking tank P with gauge and pump in air if it's below a certain level? If so, is that level anywhere between 12 and 15 psi?

Thank you!

0 -

I have read this entire thread and have some observations:

- You have a classic design flaw that was causing a problem from the date of the original install.

- As a result of this design flaw, there may have been all kinds of attempts to resolve this problem.

- Since each tech that tried to resolve the problem didn't understand the problem, all the attempts have been unsuccessful.

- The final answer was to just close the manual boiler feed valve (black handle Yellow Arrow) and hope for the best.

- As a result of this "Fix" the auto feed valve no longer feeds water and over time may have failed, or may just need to be exercised to get it back working again.

- Set the auto feed pressure to 10 PSI and let the problem design add the pressure gradually.

- Then vent one radiator each day after the pump operates and the pressure will go back to 12 or 15 or whatever the pump differential pressure causes the pressure to increase.

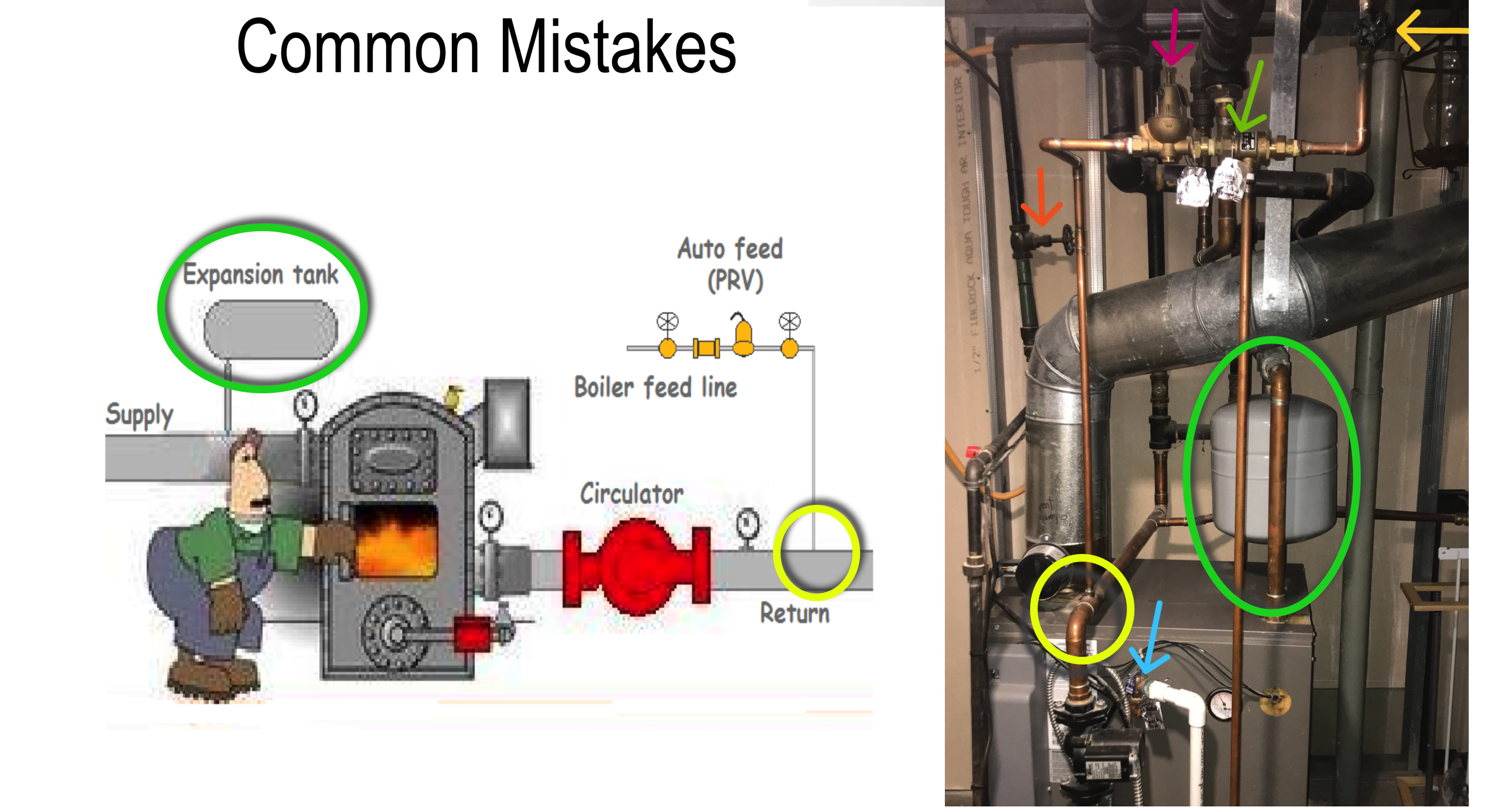

Common Mistakes explained:

If you look closely at the “Common Mistakes” slide I used in my one day Hydronics seminar, the Auto feed (pressure reducing valve) is connected to the inlet side of the circulator pump. And the expansion tank is located on the other side of the boiler. When the boiler was filled that very first time the pressure in the expansion tank was 12 PSI and the auto feed was set at 12 PSI. and all in the world was good.

But at some point the circulator pump comes on and then

$#&Tstuff happens. The pump needs to have a pressure difference (∆T) to move the water thru the system. Now let's say that ∆T is 6 PSI. And since the expansion tank is the point of no pressure change (PONPC) Google it, When that pump runs and pushes water thru the boiler and it comes out at the other end where the expansion tank is connected the pressure must be 12 PSI there. Now if we account for some pressure drop thru the boiler, (like 0.5 PSI) then the outlet pressure of the pump can only increase to 12.5 PSI. Since the inlet side of the pump needs to be 6 PSI lower than the outlet of 12.5 PSI, the pressure on the inlet side of the pump MUST drop to 6.5 PSI to circulate the heated water thru the pipes from the boiler to the radiators. And everything in the world is good.Except the pressure at the inlet of the pump is 6.5 PSI and the auto fill valve is set to 12 PSI and it is connected to a pipe with 6.5 PSI water pressure. What do you think might happen? You guessed it… the auto feed will make the inlet pressure to the pump 12 PSI and the discharge pressure from the pump will be 18 PSI.(6 PSI higher). To do that the Auto feed added water. Since the system is full of water and there is no place left to add water in the boiler or radiators, the water goes into the air space in the expansion tank. This makes the cold start air pressure in the expansion tank 17.5 PSI. This only happens once, the first time the pump starts, and the system will operate at this elevated pressure forever, (or until someone vents some air or water from the system).

Now that the expansion tank has extra water in it, there is less room for thermal expansion of the hot water in the system. And since the cold start pressure is now almost 18 PSI when the water expands as a result of heating up, there is less room in the tank for expansion. The hot operating pressure may increase above 20, above 25, maybe even above 30 PSI. Oops that can't happen. Above 30 PSI = relief valve discharge. Now we need to replace the relief valve because it is leaking, right? Wrong!!!

You need to reduce the water pressure in the boiler so the relief valve does not need to discharge. So just close the black handle valve (Yellow Arrow). The correct thing to do is to move the circulator pump to pump away from the expansion tank. But that is a subject for another book.

But for now, just set the boiler pressire at 12 PSI after you have all the radiators blead.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Thank you for slogging through the entire thread!

I appreciate the bottom line recommendation, and definitely would like to solve any root cause if that's an option, so I'm going to study your post to better understand what's going on.

0 -

-

The tank pre-charge needs to match the cold fill pressure.

If 12 psi is what you want to fill too, pre-charge the tank to that, BEFORE you fill the system to 12 psi.

Once pre-charged properly, It is the size of the tank that determined how much the system pressure will rise as water is heated. Do not try to change tank pre-charge to change tank acceptance.

The tank is not in the very best location in the system piping, but systems like yours are not uncommon and will work properly.

Two things if you do repipe.

The tank needs to be on the inlet side of the circ, somehow. And the fill valve connection needs to be at the tank connection, not elsewhere in the system piping.

A simple fix to change the PONPC is move the expansion tank connection to the 1/2" line that comes down from the fill valve. Now you are pumping away.

Air purger stays put.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

There are many ways to fix the problem. Each one has its advantages. The simple ones have the lowest cost. The more you do the higher the cost.

You have one major problem now. Air in the second floor radiators. Make the system air free now by first setting your expansion tank air pressure to 12 PSI (that must be done with no water pressure on the system side of the expansion tank). Pro Tip: you can charge and adjust the expansion tank pressure with your static pressure (pressure on the boiler gauge) lower than 10 PSI. Next, increase the pressure until all the radiators are vented (no air left). As a child I remember helping my mom do this by opening the radiators and letting the air out until water spilled into a tin can while she was in the basement watching the gauge so the pressure didn't get too high. With all the radiators air free, and the system at ? PSI, raise or lower the system pressure on the boiler gauge to 12 PSI. Now the boiler pressure and the expansion tank pressure match.

Now you have a system that is full of water and an expansion tank that can accept the full amount of water it is designed for, as it is heated. Close the Yellow Arrow valve and you should have good heat for the season.

Next summer you can address the major problem and re-plumb the system for the best performance. Now you don't need expense of a plumbing redesign and all the discussion associates with it.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

@Bungalowgirl228 Here is a video that explains a lot about Hydronic design and engineering taught in regular person language. The technical points are made easy to understand in real life examples like Ferris wheels. . At time stamp 1:09:14 (1 hour 9 minutes 14 seconds) Dan explains how the expansion tank is the point of no pressure change and why pumping away from the expansion tank is better for the system.

You can stop at about time stamp 1:20:00 because Dan starts to talk about 2 zone systems and you only have one zone right now.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Sorry I didn’t see your question to me right away. “Get enough air in the tank” is my general answer meaning drain the old-fashioned expansion tank or pump up diaphragm tank to the correct system pressure, usually 12 psi. Here’s the method I used to use for what it’s worth.

Check the pressure of the tank. Release some water to bring the system pressure down below about 10. Pump up the tank to 12. If the system pressure on the boiler gauge increases then release some water. Check the tank again. If it’s below 12 then pump up the tank again and repeat subsequent steps. You’ll probably have to do this several times. When the tank pressure hasn’t dropped, then you can add water to 12. There are probably other ways to achieve this, but the whole point is to be sure that you have one tank full of air at the correct pressure with little or no water taking up space.

The title of your request caught my attention. How to add water? Make sure the expansion tank is right before adding water before increasing pressure!try pressing the red button

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements