New Energy Kinetics Boiler: Was Kettling, Now its a Water Hammer Issue

New Energy Kinetics EK-1 boiler/hot water heater installed in June. Up until a week or so ago, the system was called upon to provide domestic hot water only: all of our thermostats were turned to cooling mode. System ran fine, produced prodigious amounts of hot water, and was very quiet.

Heating season begins last week. We have thermostats in 3 heating zones calling for heat off and on to take the chill out of the early Fall mornings. We are now experiencing a phenomenon called kettling: sound of boiling water emanating from the boiler itself.

This sound is only heard when the oil burner is firing: once the demand for heat is satisfied, the burner shuts down and the noise immediately stops.

A few things to note:

-Its a 4 month old system

-It worked just fine until we started opening zone valves in the heating circuits.

-Noise starts about 30 seconds or so after burner firing begins.

-Water chemistry: we are on well water, although we don’t have a water softening system: never needed it. Out water test shows slighlty/moderately hard water. We do use a 1 micron whole house water filter.

The most popular answer I’ve encountered online in regard to this issue is: its scale buildup on the boiler wall. Not sure I am convinced that this is the culprit, given the system has only been in service for 4 months, and given that this problem did not exist prior to opening the heating circuit zone valves.

FWIW: I’ve never observed/heard the air vent bleeding any air from the system. There is just a single vent just above the main boiler return connection. I suspect air in the system may be a contributing factor but my contractor has dismissed this as a possible cause.

Contractor plans on doing an acid flush of boiler, per the manufacturer’s recommendation so we will be trying that next week. Given everything I’ve stated above, I have strong doubts that this cleaning will resolve the problem.

Any thought on what could be happening and possible remedies?

Comments

-

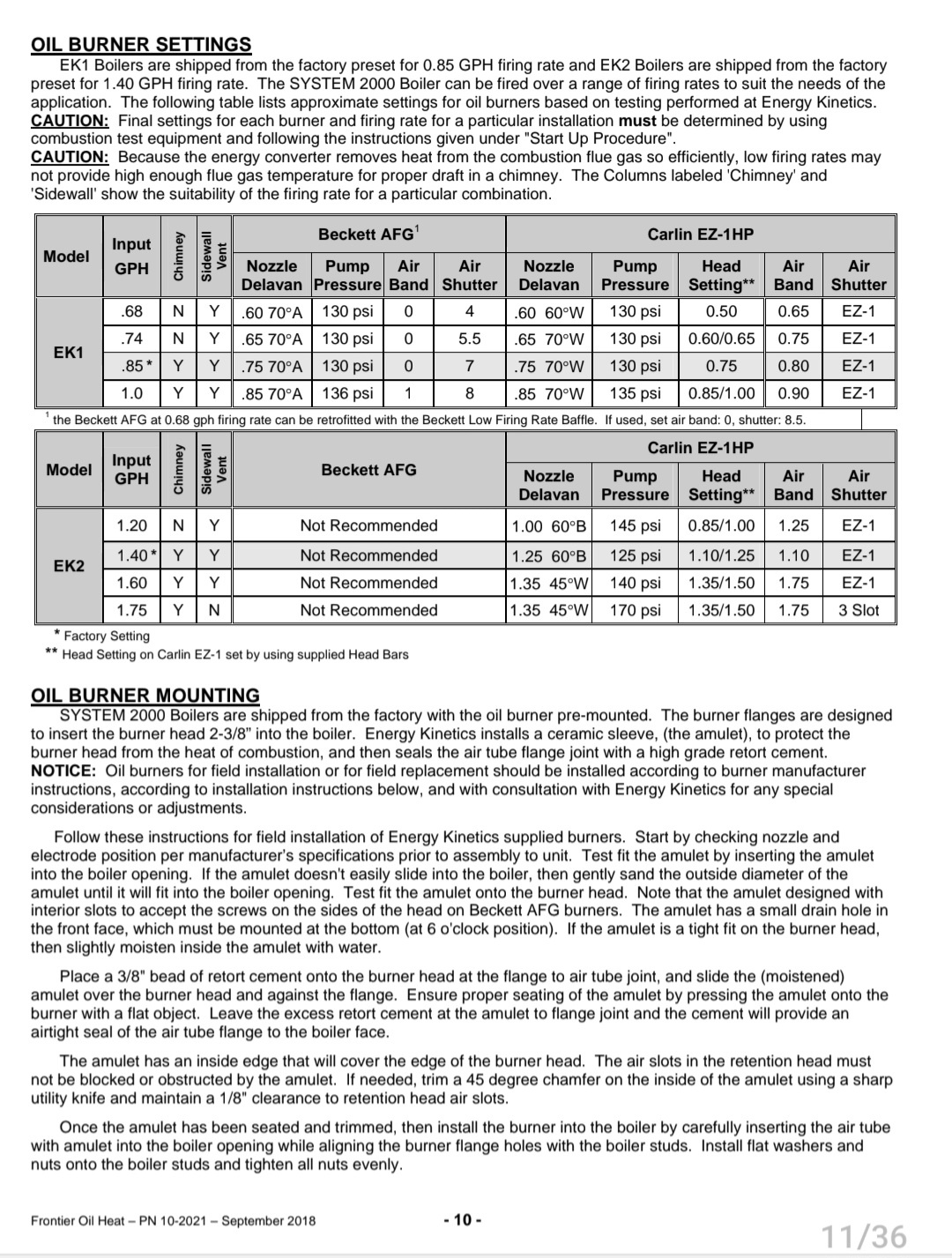

Check the burner's firing rate, also whether the correct type nozzle was installed. If that's a Carlin burner it should be a 60° hollow one.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

-

Steamhead: Unit came from factory with the Carlin EZ-1 burner which I believe is set up .85 GPH nozzle. As I mentioned, before we opened zone valves for heating, the boiler ran perfectly when it was supplying domestic hot water.

0 -

EBEBRATT: I agree; it makes no sense. Yes unit was installed by EK dealer and I have to assume at this point that it was set up properly. I discussed the possibility of air in the system at length with the contractor and he dismisses this as a possible reason for the kettling. He insists that the system was bled properly.

0 -

is there an air purger on the piping?

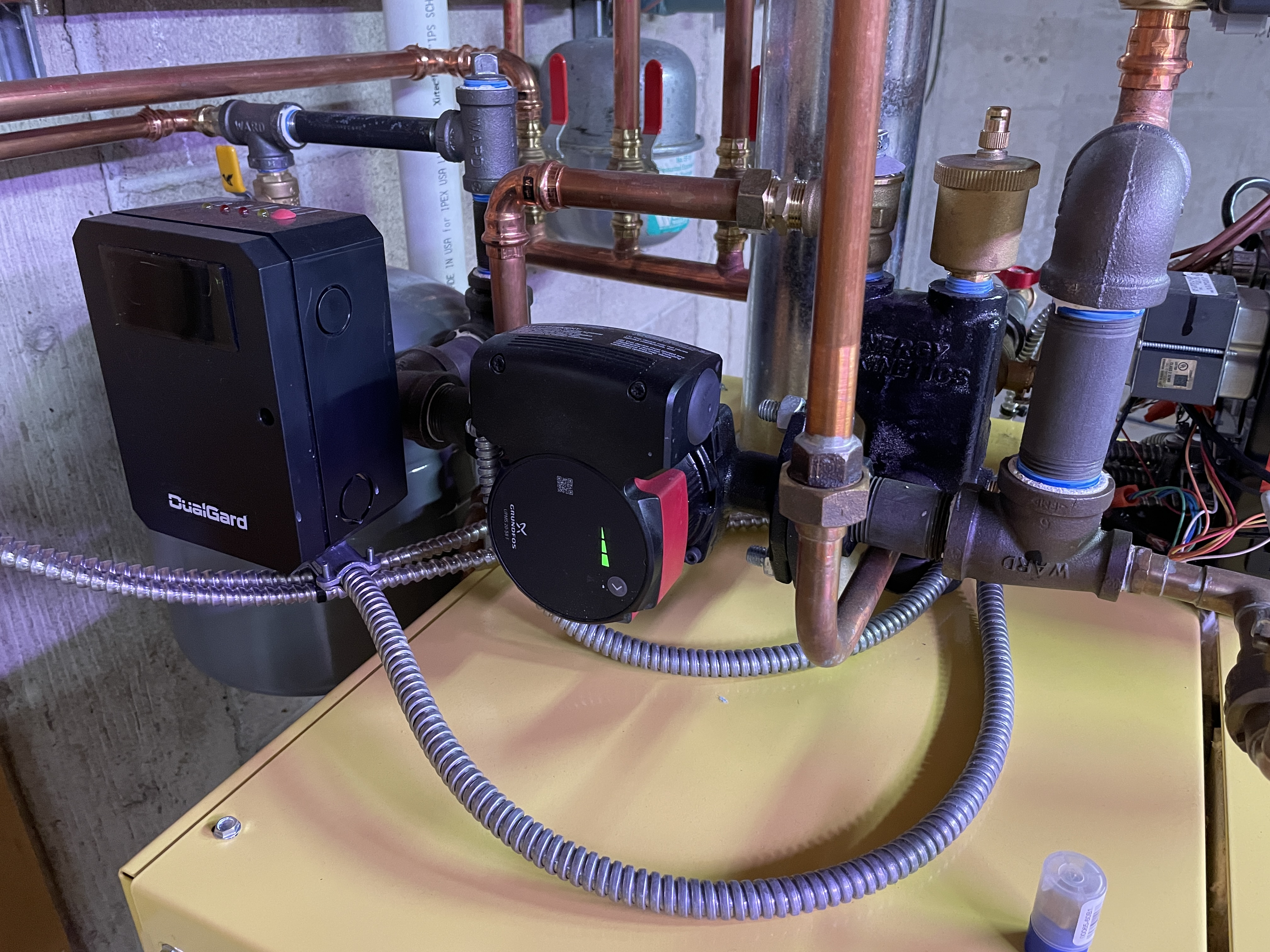

I don’t recognize that black component with the air vent attached

Make sure the cap is loose on the vent

It takes heating and circulating the system for a few hours to drive all the air out. Seems it is related to the piping loops throughout the home?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

HOT ROD: Yes, a Califfi air vent (hygroscopic no less) comes mounted on the boiler return manifold (the black thing) that is factory supplied by EK. Since it's hygroscopic, the vent can be loose or tight: cap has opening for air in either condition.

Yes, since this only started after we opened up the zone valves, the obvious/logical assumption (IMHO) would be that we have introduced either air or some other element that is either impeding flow or allowing localized overheating, thus creating steam.

1 -

The logo on that black air/ relief manifold looks like Thrush? I suspect the boiler is doing most of the air separation through that device since.

I don't see an air purger on the supply side, before the beautiful zone valves.

Kettling is usually a sound from an old scaled boiler, water on the boiler metal surface is flashing to steam under that layer of scale.

I think maybe you are just hearing some microbubble entrained air. How long has it been running? It should clear itself of air. Crank it up to 180 or so, if you can, that drives entrained air out quickly

It is a really nice piping job.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

HOT ROD: the black manifold is marked Energy Kinetics and I suspect acts like a standard Watts or Taco Air Scoop. Yes, the air vent you see in the picture is the only one in the system: it comes from factory this way.

Unit has been running since June with all zone valves closed. Starting using heating zones last week and this is when problem started. It's not all that cold here in CT right now so system does not run all that much. EK boilers are set to run hot: I believe 200 degrees F. I think you may have. nailed it: the air will need to work itself out over time: this makes perfect sense (to me at least, if not to my contractor).

I agree: very nice piping job: I was very impressed with the job and coincidently was planning on posting a short summary of the installation with pictures after I had fully tested the system this fall. This hiccup has put those plans on hold for the time being.

0 -

HVACNUT: that secondary loop is something I installed about 20 years ago. Flat plate heat exchanger supplies heat to glycol treated loop for a workshop. Pipes pass through unheated garage, hence the glycol. Zone 4 of the EK system feeds the boiler side of the this heat exchanger. This loop has worked like a champ from the day I installed it and allows me to work in my woodworking shop in comfort throughout the winter. The Taco unit on the side of the boiler controls the circulator in the glycol loop: it's energized when the EK controller calls for heat from zone 4. So when workshop TS calls for heat, both the EK zone 4 circulator and the glycol loop taco 007 are energized.

0 -

Thank you for all your comments. Sometimes flux and other contaminants can make their way back to the boiler and make it kettle as you describe. I think the acid flush will clear things up. I do see that it is a Press job, so that means it is likely something left from the system prior to install that flushed back when the heating zones opened. @CTYankee , do you know if they used the 8-Way boiler treatment that comes with the boiler? That will usually prevent kettling and keep the boiler cleaner.

Best,

Roger

President

Energy Kinetics, Inc.2 -

We still need to check it. In the first two pics above, we can see a nozzle container sitting on top of the boiler. The end cap on it is blue- which is the color Delavan used for solid nozzles. Hollow nozzle containers have red end caps.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting2 -

Checked the nozzle that was in that plastic case on top of the boiler. This was the original nozzle that was changed out a few days after initial system commissioning due to burner lock-out issue. The nozzle indicates 60 degrees and .65 GPH, so I misspoke above. Not sure how to distinguish a solid nozzle: this nozzle is not smooth: looks has sort of a rough surface: perhaps it atomizes through this???

0 -

That would be a 0.65x60. The letter following denotes the spray pattern: A for hollow, B for solid, W for in-between.

The installation manual is here:

On page 11 of the pdf, it shows that your boiler with the Carlin burner uses hollow nozzles. The containers for Delavan hollow nozzles have red caps, rather than blue ones as shown in your pics. Recheck what's actually installed in the burner. If it's not a Delavan A, replace it with an A and retune it.

The 0.65 nozzle in that burner runs at 130 PSI, for a firing rate of 0.74 GPH. This is by design.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

Steamhead: double checked: it's got a B marked on it, so it's apparently solid. So would wrong nozzle result in hotter or more concentrated flame that could cause the kettling? I wonder how the system worked with no problem prior to opening of the heating zone valves for the season? Same nozzle in use during both scenarios.

0 -

This!

0 -

I checked my manual to see about chimney venting when the burner is down fired to a .65 nozzle.

I know I've been using a .75 60°A with the EZ-1 burner on the EK-1, so maybe I need a new manual.

Anyway, my manual states sidewall venting only at that firing rate. How is your boiler vented, @CTYankee?

0 -

The current plan is to go with the manufacturers recommendation and clean the system. Finger crossed.

Stay tuned for more exciting developments!

A sincere thanks to all the pros that have shared their knowledge to help a humble home-owner: much appreciated!

0 -

That's wrong. Change it to a 60° A and retune the burner. If that solves the problem, you don't need to do any more.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

@Steamhead is correct. 60° A is the proper nozzle with 130 psi pump pressure.

@CTYankee Wondering if you could dm me a wider shot of the install as we have some questions regarding the plate exchanger location, and that loop circ on the wall behind the boiler.

Its possible some scale has moved around the system if you have cast iron free standing radiators. I cant see a dirt mag in your pictures. Have the tech thats doing the flush call me in tech support and we can go over the problem.

Robert W.

Energy Kinetics

1 -

I am not clear as to the noise that you are hearing, but it sounds like you are getting water hammer in your baseboards. I have a two year old Energy Kinetics connected to well water. I have the water softener screw on cartridge as part of the original install. After about one year I started to hear noise in the baseboards. It turned out that the Califi valve has cardboard like wafers in the cap. The hard water that is in my well water made the wafers brittle so they did not work correctly. I replace the cap and problem solved. CAP ON THIS VALVE MUST BE TIGHT NOT LIKE OTHER AIR RELIEF VALVES.

0 -

I wanted to update everyone on the status of this issue.

The contractor did a purge of the system and an acid flush of the boiler. The kettling seems to have gone away. No way to know if it was the purging or the acid flush that actually fixed the problem, unfortunately.

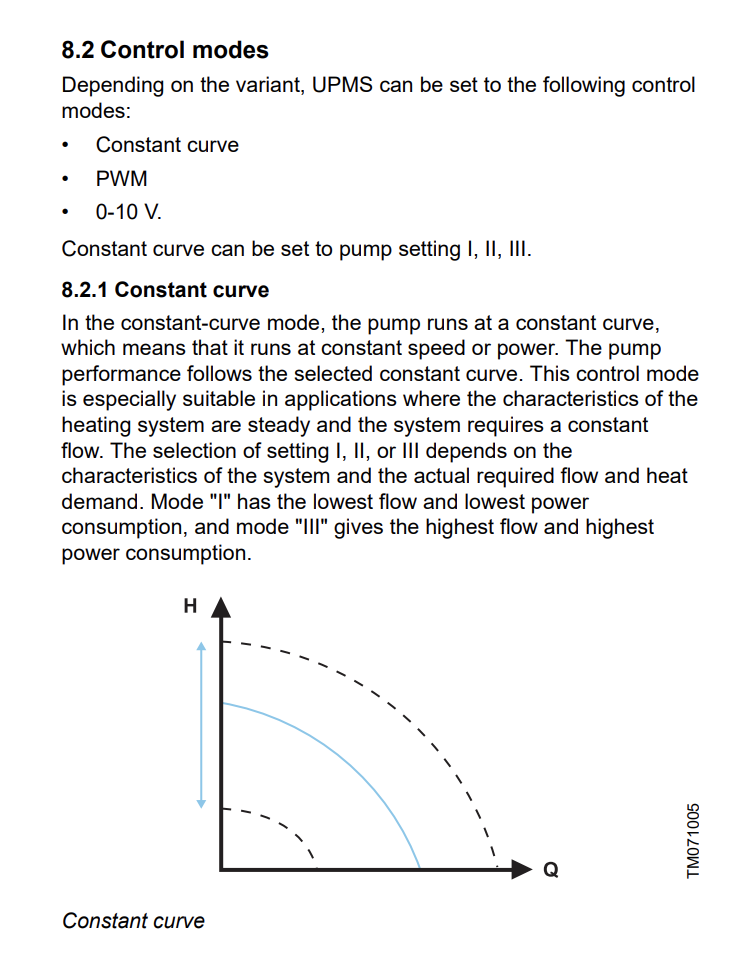

However, we now have another problem: water hammer. We are hearing intermittent banging of the pipes supplying hot water to the baseboard emitters. Four heating loops, all with zone valves. Our old system never had this problem (it had a circulator for each zone). FWIW: the old system had Taco 007 circulators on each zone. This new system has a Grundfos UPMS 20-58F. It would appear that the speed of this pump is selectable: no idea what speed it is supposed to set to. Elevation from pump location to baseboard location is roughly 5 ft.

Any thoughts on what might be happening?

0 -

Odd pump, it's s an OEM model, did it come with the boiler? That model is often controlled by an external control signal.

If the noise happens when a zone valve loses you may be over-pumped a bit.

For zone valves you want it in constant curve mode. It may take a day of so for the pump to calculate and adjust as valves open and close. Try constant curve Mode1 to start.

Search and download the I&O manual at Grundfos if you don't have one.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Are the valves open to the HX or bypass?

0 -

Has anyone checked the burner's firing rate? If it's too high, that can cause kettling…………….

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

@CTYankee , I’m glad the kettling noise is resolved. What you described was very likely cleared up from the cleaning that was performed as water side contamination is by far the most common cause of that type of noise. The boiler has exceptional air removal with the dynamic air eliminator that comes with the boiler, so it’s very rare that an Energy Kinetics boiler would have an air related kettling issue. An exception would be if the air vent were plugged or not working and air could no longer be purged.

What type of zone valves do you have? This can help us identify what steps may need to be taken to stop hydronic water hammer.You should set the Grundfos circulator to medium speed as the low setting will not provide adequate flow through the boiler.

Best,

Roger

President

Energy Kinetics, Inc.0 -

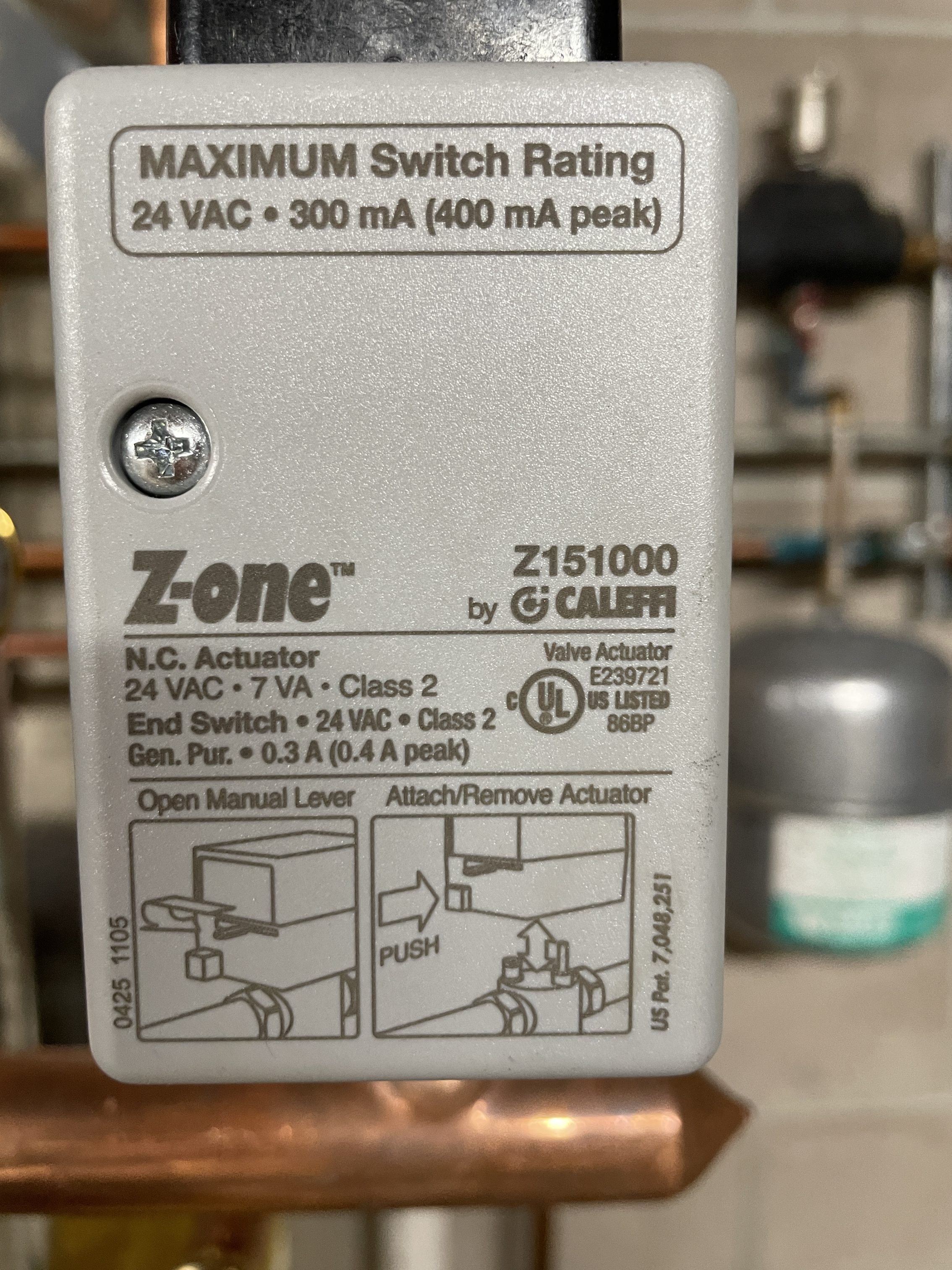

Roger: I believe the zone valves came as part of a boiler package from EK. They are Caleffi Z-One model 151000. These are installed coming off the supply header, just downstream of the circulator.

The circulator had been set to the high speed setting. I changed it to the medium setting over a week ago and observed no change regarding the water hammer issue. It remains at the medium setting. Phil

0 -

Thank you, Phil.

Please coordinate with your service contractor, Bob, and our territory manager, Mark Santangelo. It is not common, but sometimes those zone valves can experience water hammer. Caleffi is a great company and if that is the issue it should be easy to resolve.

RogerPresident

Energy Kinetics, Inc.0 -

Already sent emails to both: waiting for a reply.

0 -

Roger:

Looking at the specs on these valves, they are designed to take around a minute to go from full closed to full open, and around six seconds to close at end of call for heat. They even mention in their literature that they are specifically designed to avoid water hammer. What is it about these valves that causes them to sometimes experience water hammer?

I am also wondering about the circulator: is this a delta-p circulator? Is the EK controller actually controlling the speed of this pump? Is it possible that the circulator is contributing to the water hammer issue and is it possible that a different circulator could also fix this problem?

Phil

0 -

Water hammer is very site specific and difficult to duplicate in a lab, but it can be addressed with a soft close valve spec that Caleffi has developed in response to the rare instances where it occurrs. For anyone reading this post in the future, this should not be confused with water hammer on the domestic side for hot and cold water fixtures; that is a separate symptom with different solutions.

President

Energy Kinetics, Inc.0 -

Ha: our messages crossed in the mail: please see my amended question regarding the circulator.

0 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements