Relief valve keeps popping

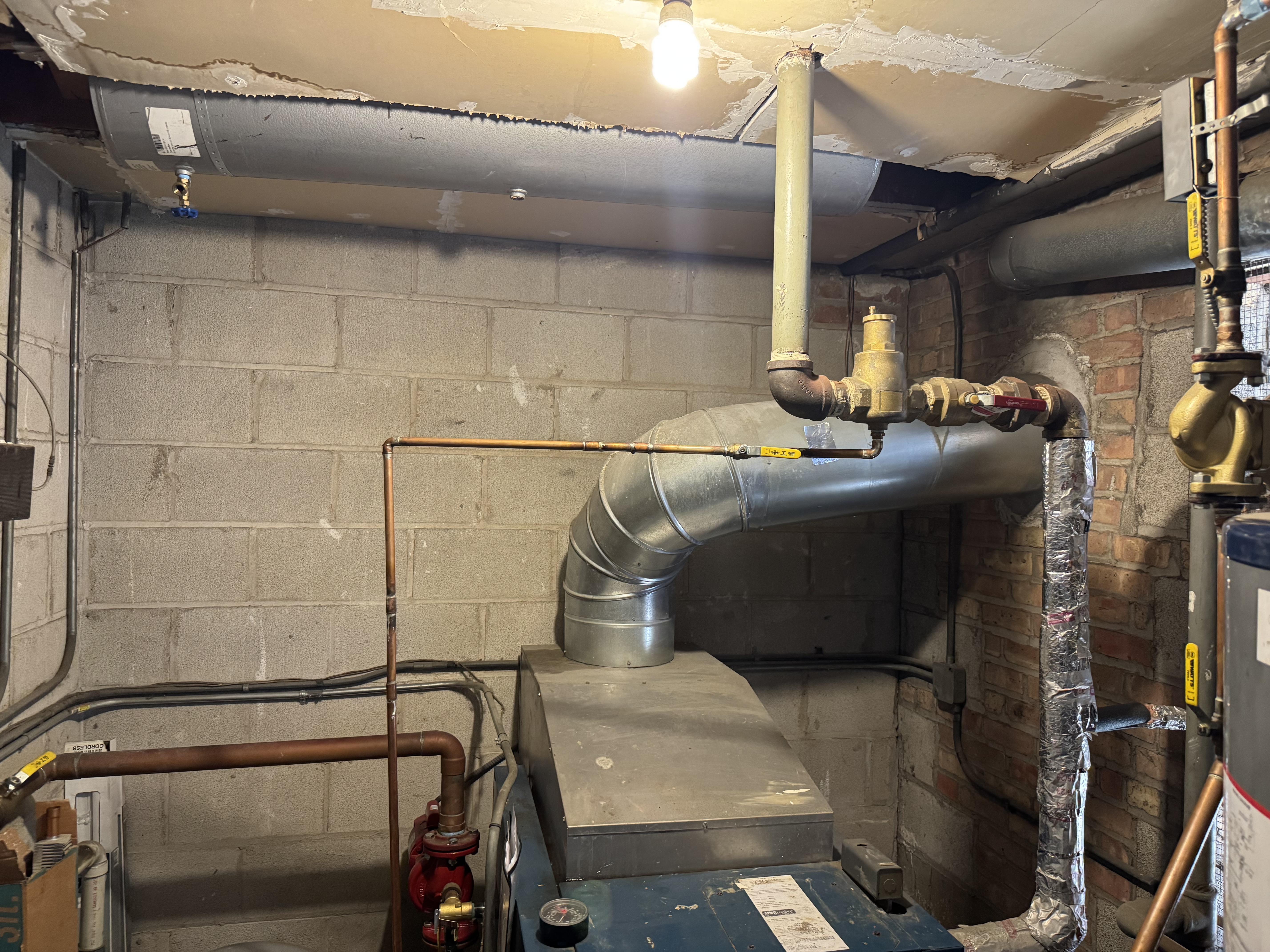

Hello everyone! I have a real head scratcher here in Chicago. We’re looking at a Dunkirk 500K BTU hot water boiler for a 12 unit apartment building that’s 2 stories. It’s all copper fin baseboard with 12 taco zone valves for each unit. We also have a B&G 102214 1/6 HP pump on the return and a 27.7 gal Extrol tank. There is an air separator on the 2” supply with the tank tied into it. So yes, we are pumping towards the tank

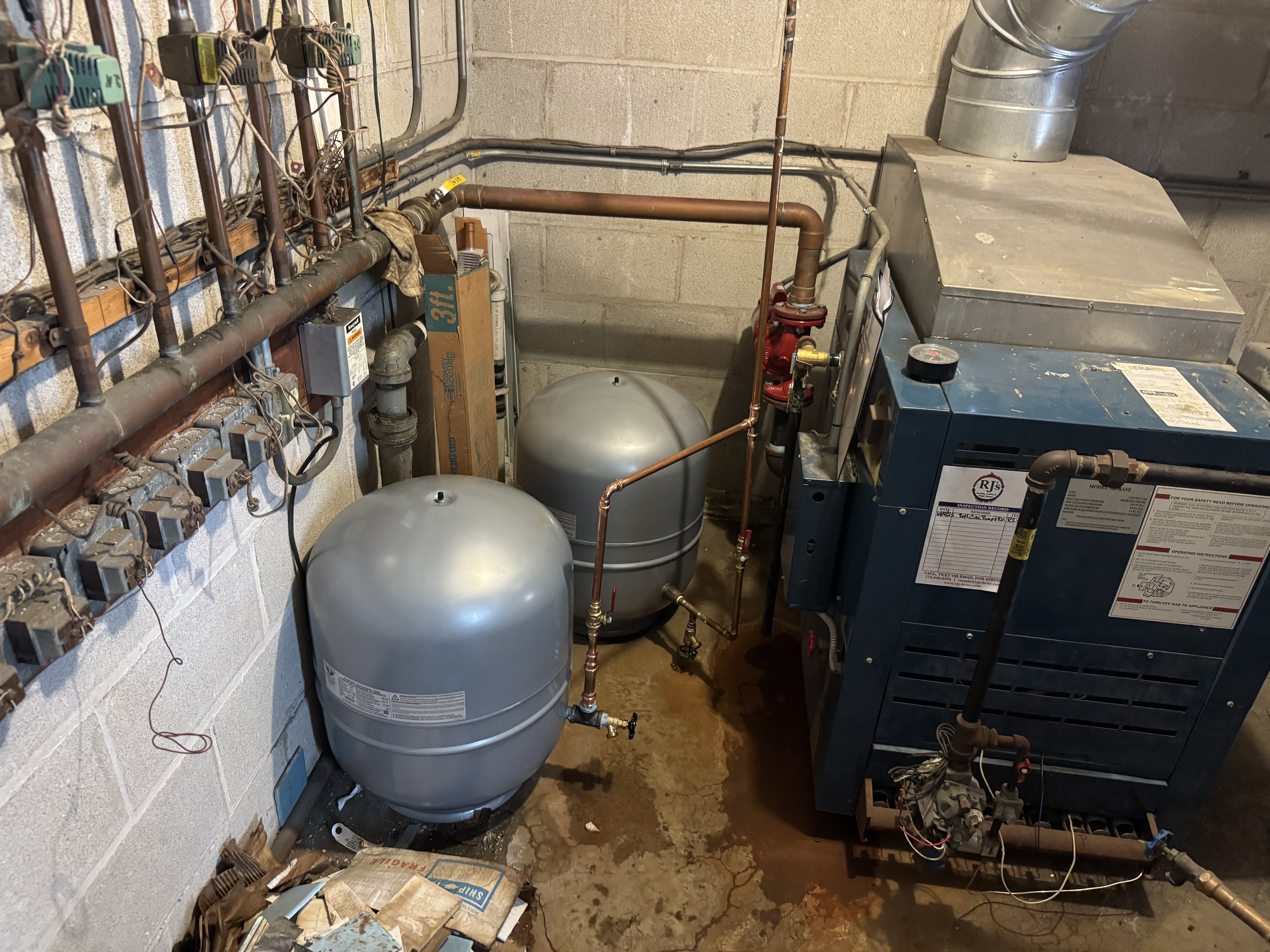

The pressure keeps raising to over 30 psi and popping the relief valve. I’ve testing this system in multiple ways to rule things out. I shut the cold water supply off to rule out the feeder bleeding through and left it for a day. It still opened. At that point, I assumed the bladder failed in the 1 year old tank. I T’d in a new tank to the existing one and put isolation valves on them. Ran the system with the new tank for about a week. Went back and the pressure was up again and popping the valve. Not a bad bladder in the existing tank at that point. I then opened both tanks and let it run. Guess what? Same issue.

A little more backstory is that a company initially came out and found the older expansion tank in the ceiling had a leak. They replaced it with the same monster type, and that’s when the problems started. The customer called and said there was an issue so then that company decided they don’t work on boilers anymore after that. From there, that’s where the Extrol tank came in. The Extrol was sized to the system. Not only by the contractor but our local old school boiler distributors.

At this point I’m looking at 3 things before I lose my mind.

- Is the pressure going up that high if only a couple zones are calling for heat and that pump is creating too much head?

- Could the tanks (cause now we have 2) being picked off the eliminator on the supply be causing this?

- Why do I get myself in these situation?

I have a vendetta with this boiler now. The customer is very appreciative about everything because the last couple companies threw their hands up and walked away. Unfortunately for me, that’s not how I operate and way to get this taken care of for them.

The gas valve is buzzing like crazy but I’ll bring that up after this is resolved.

Thanks in advance!

Comments

-

was the pre-charge checked and adjusted on both tanks?

What was the capacity of the old compression tank?

Did water come out of the air stem on. The tank that failed? That is an indication of a failed diaphragm

Has the pump been changed? Looks like you are pumping at the expansion tank? Pump on the return, expansion connection on the supply? Where is the fill valve connection?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

is that an indirect water heater or is it separate from the boiler?

there shouldn't be any automatic air vents with a compression tank, was the discal added after the bladder tanks?

what is the cold fill pressure of the system?

does the pressure creep up if you turn the boiler off?

does it go back down if the boiler cools?

0 -

Decent size boiler the EX tank could be too small 12 units in a two-story building is pretty big. That system holds a fair amount of water. What is wrong with the compression tank in the ceiling? That is brand new correct?

If the tank in the ceiling is good get a garden hose and a female connector and connect the compression tank to the boiler drain and try it temporally just to see what happens.

0 -

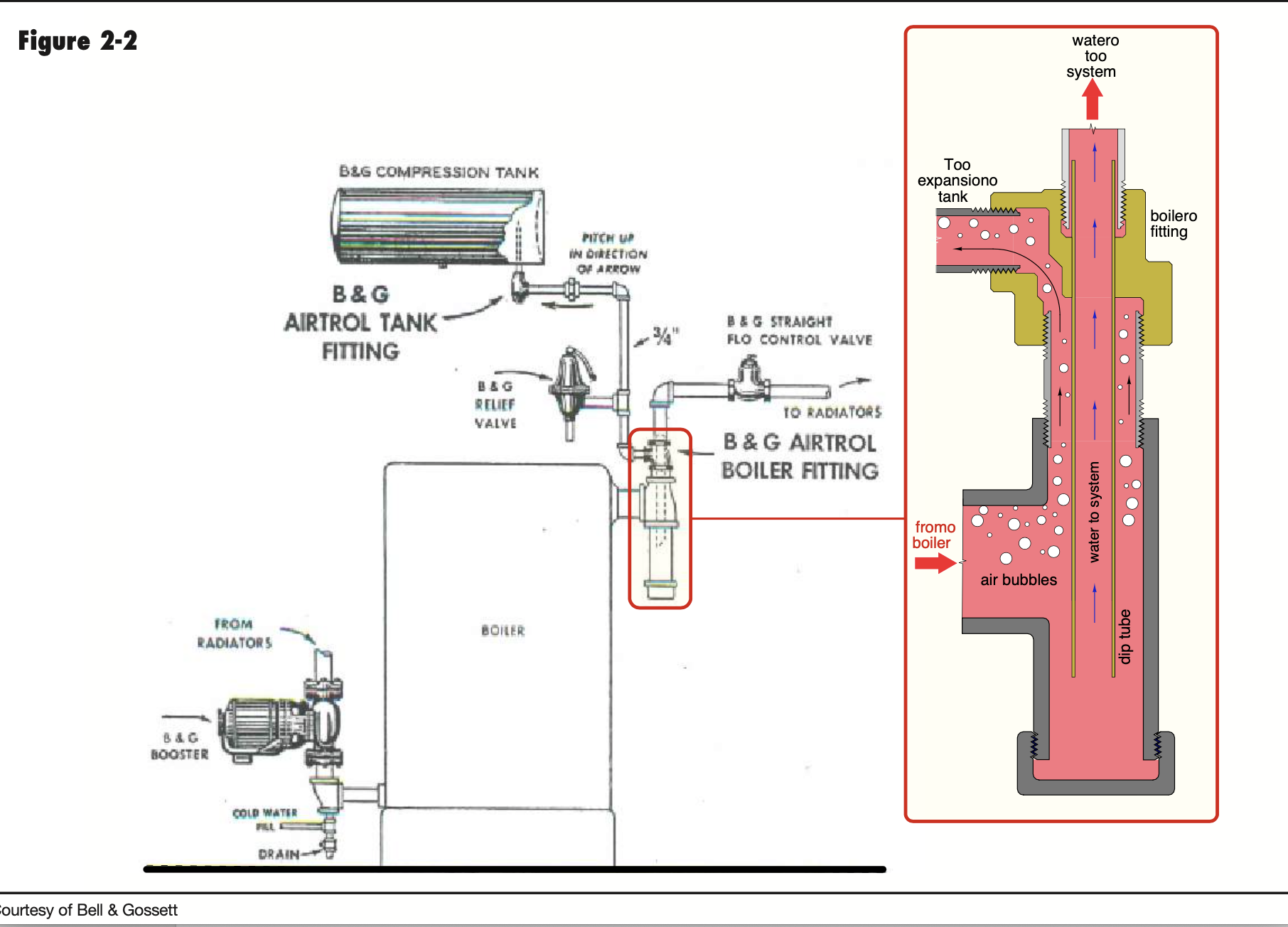

The diaphram tanks will be about 1/3 the size of a plain steel tank, typically. A partial or full acceptance style expansion tank would be even smaller.

Keep in mind with a plain steel tank you are adding water volume to the system, so more expansion space is required.

Compression tanks should have the appropriate fittings to work as intended, these B&G Airtrol for example.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

How many floors is your building? This should determine how much pressure should be in your expansion tank. Next isolate your expansion tank and relieve the water pressure from it. After that, fill the expansion tank with air to calculated amount based on how many floors your piping goes up in your building. Now open system back up and set the pressure to that calculated amount. Double check your pressure relief valve is rated for the pressure you need in your system.

0 -

As mattmia2, so aptly put it, does the PRV (pressure relief valve) release occur when the boiler is heated up with a rise in the psi on the gauge near the PRV rating or does the PRV release occur when the boiler is cold?

In the first instance, you may need a PRV that is probably rated 10 PSI above the static pressure of the sys . In the second instance it may be a faulty PRV. In either instance a new PRV may be warranted.

Also, an EX tank that has a inadequate air charge (lack of acceptance) or a water logged diaphragm, one would expect a PRV release when the boiler is heated (fully operational) and the leaking would stop when the boiler (sys) is cold.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements