A2W heat pump as primer for 4 bank hydrothermo ( 864,000 btu )

57 unit building - 1969 construction, wood frame, few energy upgrades.

152F supply, 127.2F return ( 25F delta T) at start of heating season.

I am wondering if we could add an air2water heat pump to prime the water on the return to reduce the amount of time that the boiler spends heating it.

Any recommendations on models of a2w heat pumps that might work?

Thank you!

Comments

-

A BTU is a BTU, to what end would preheating benefit? Is a heat pump's electric energy consumption going to cost that much less at creating the increase in the water temperature. Then why not just swap all the heat to A2W HP? Find the lowest cost energy source and go all in if it is that much better.

It sounds like you want to use a low cost source to preheat then revert back to the higher cost energy source to make the water hot. That is assuming that the electric to operate a A2W HP in fact costs less than the current energy source. I would research that before thinking about buying equipment.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

-

Assumption is that COP of 4 would mean 50% cost of the BTU from heat pump.

Swapping 864,000 BTUs over to an a2w heat pump would require more land space, more money and more electricity than the building currently has available. Ideally we'd start with something and see how it goes before 100% committing. Too often projects are contemplated in an all or nothing scenario resulting in nothing.

We have our domestic preheating with 3 HPWTs before final heating with a gas hot water tank. The proterra units are each 4200 BTU. The gas hwt is 385,000 BTU. While the HPWTs aren't providing a huge portion of the hot water it did enable us to reduce from 2x 385,000 BTU tanks to one and leave the redundant one as backup. The setup likely was overkill to start with but the hybrid solution has saved ~10% off the overall gas bill with minimal impact on the electric side.

In order to justify the project I'd want to see making the money for the installation back in 10-15 years (ignoring interest). I can't see a full swap ever paying back so a full swap point could only happen once the current hydrotherm hits end of life. 1985 cast iron - it might be around for another 25 years? The heat pump tech is still in flux so it is nice to start small and realize the improvements in the technology rather than bleed out on the cutting edge.

The HPWTs are an easy win as they are used year round whereas the boiler is only used Oct-April and I think the heat pumps will generally have a hard time heating water at 127F a lot higher before the boiler while maintaining a high COP.

My sense is that given the project requirements a heat pump can't work for this application but I thought I'd post and get a sense from the experts. Can assume 46F+ as air temperature during the majority of the heating season.

2 -

At 46F it can work. An EVI unit should be able to provide 130F water at about COP of 3. I'm mostly familiar with residential units which max out at around 5tons but there are larger commercial units out there. Quick google:

Roughly how many therms of fuel are you using in a heating season to get a feel for actual heat load.

1 -

-

I recommend the article outlined in this article to get an estimate of your actual heating load:

https://www.greenbuildingadvisor.com/article/replacing-a-furnace-or-boiler

Since — according to the article — heating equipment is routinely oversized (typically by a factor of 2 to 4) you need to get a handle on your actual heating load before doing anything.

1 -

Heat pumps don't play well with boilers, they have different control strategies.

What might work is to turn the boiler off above a certain temperature, and turn the heat pump off below that temperature. Then you can run the heat pump at a temperature that it's better suited to.

I'm not generally a fan of dual fuel solutions, the money saved doesn't justify the complexity in most cases. But in something of this scale it might.

1 -

This is a sound strategy. The control system does not need to be that complicated. Whenever water is returning to the boiler the heat pump operates. I don't have any experience with air to water HP with the exception of two customers that used geothermal for their HP which is W2A. (I wonder how installing them backwards might work? LOL). I’m sure there is something out there that will work for you.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

2500-2600 gj annually that includes the hwt so 26,000 therms. Thanks for the link ! Just trying to start the research and not stray too far down the rabbit hole.

0 -

Thank you. It wouldn't surprise me that the heating system is oversized. Why would someone spend extra time to properly size a system and make less money off the deal. Throw 4x the gear at the solution, never have a not enough heat call back and make 4x the markup.

I'll review the heat loss article. The building is going to be modeled in CAD soon so I might be able to leverage that and throw it into LoopCAD and do the heat loss calculations there without too much work.

At this stage I'd just like a quick easy win. Throw something residential in for pre-heating if possible and save 10% pay back in 10-20 years is fine. Eventually the boiler needs replacement and it looks like high efficiency gas is likely to be the best choice given the heat loads. I had one quote just for the boiler of $52,000 and that is without installation. We'll likely run to failure for the existing heat plant - really I think until one of the 4 units dies I won't be serious about putting the work in to figure out a replacement plan. Yearly gas bill is ~$26,000.

My napkin numbers.

Going from the 80% to a 96% ( assume you only get 90% ) would save $2000 a year ( some of that gas is for the domestic ). $52k for the boiler assume optimistically $26k for install? would be a 39 year pay back which is too long. I like mechanicals but right now seems like doing things to decrease heat loss are going to be the biggest bang for buck.

1 -

-

I'd be pressed to install high efficiency boilers in your situation. You might save $2,000 in fuel costs, but that savings will get eaten up by repair costs. And you'll be replacing those boilers every 15-20 years as that's how long they last. There are exceptions; Polaris comes to mind.

Love those Hydrotherms.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab1 -

Thanks - that is definitely a worry! Is it still possible to replace the hydrotherm units? If one of the four fails?

0 -

I haven’t seen a new HydroTherm boiler in years. My local dealer lost the line ages ago.

I would look to replace it with a Burnham cast iron boiler or even a Peerless. Quality American products.8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab1 -

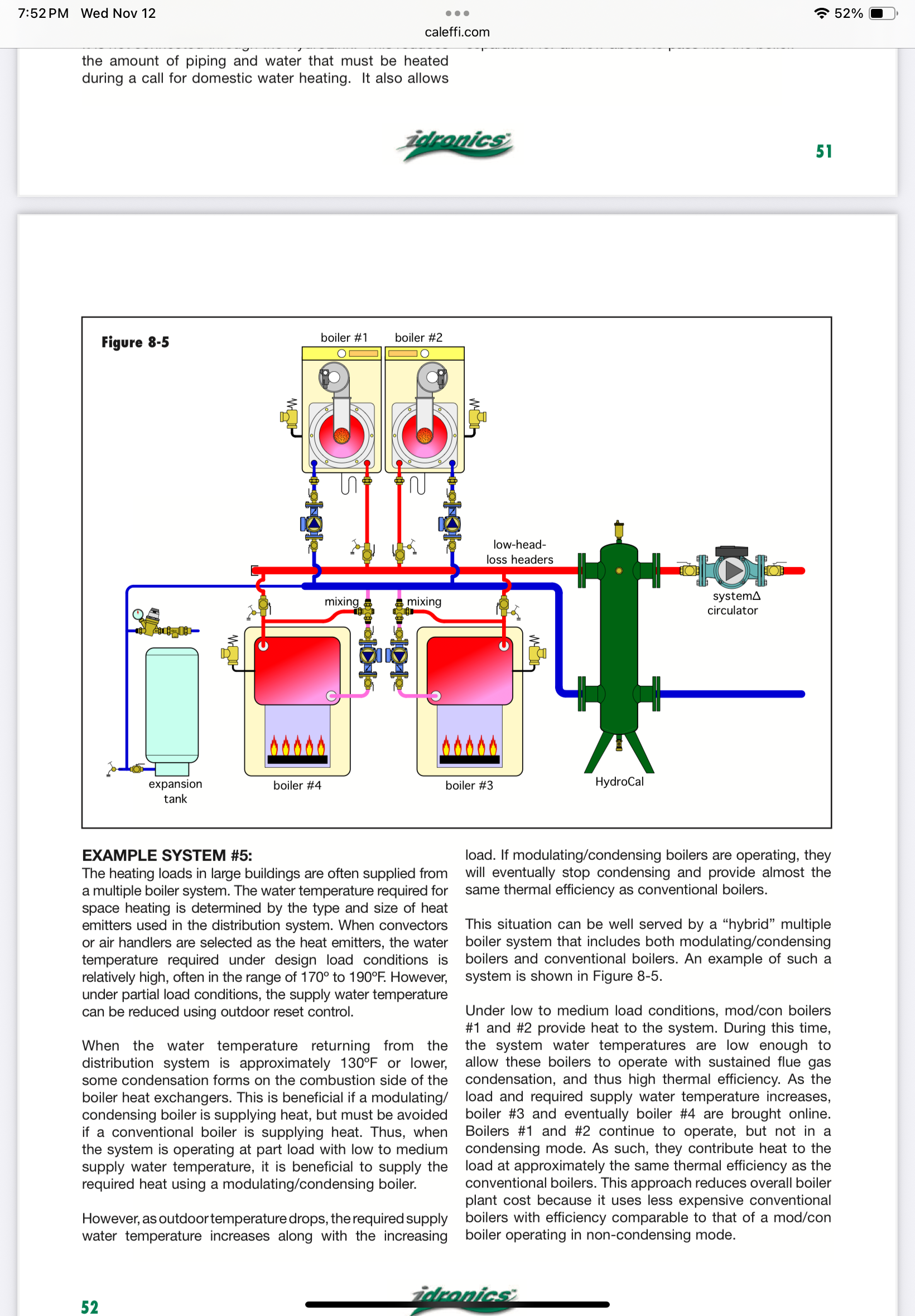

hybrid pipingisa good option for a system like that.

We do it with hydraulic seps all the time.

Mostly with mod con boilers and conventional boilers. This explains the concept.

But also with A2WHP now. An assessment of the heat emitters would tell how low of a temperature is possible. If there is a cooling option, with air handlers, then a hp makes more sense

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

40f outdoor (so 30F delta) is somewhere around zone 4 say 3000 heating degree days.

26000therms, say 20% for DHW and 75% boiler is 16000 therms of heat.

16000therms / 3000hdd*24h=0.22 therms/degree hour

30F delta *0.22therms=660k heat load. Those boilers are not that far off actually.

Heat pump makes sense if your electricity is cheap. Lets say you size to supply 1/2 your heat cost (so most of the shoulder season plus part of heating) from heat pump, you need 8000 therms of heat out. COP3 that is

8000term*29.3=234MWh of heat/3=78MWh of electricity.

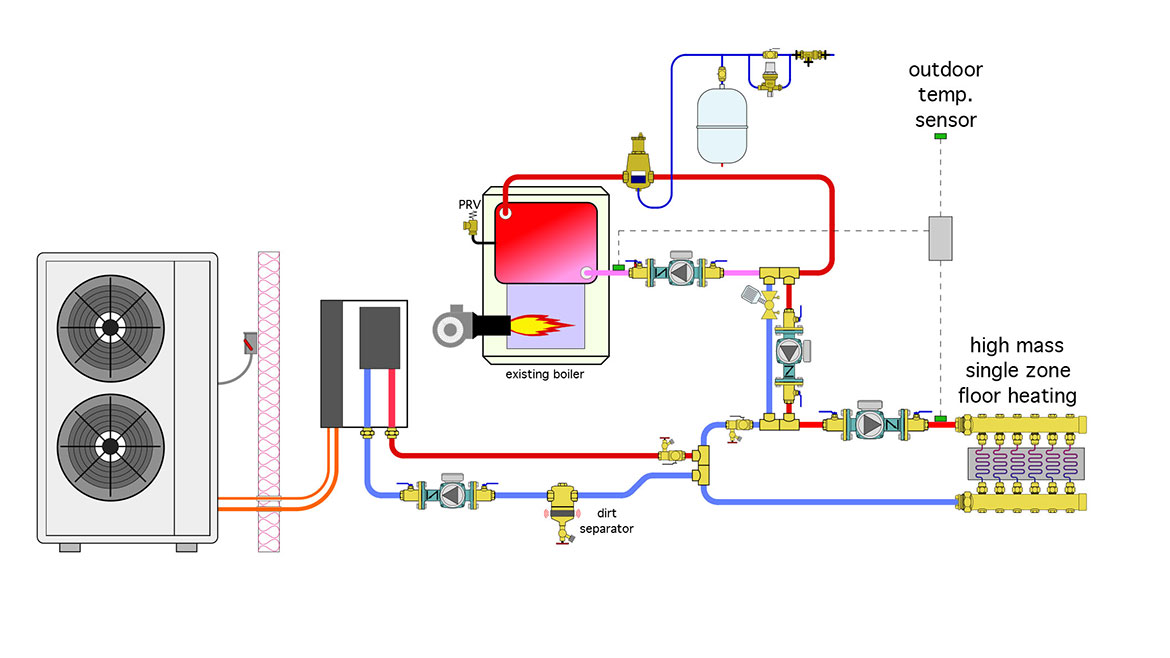

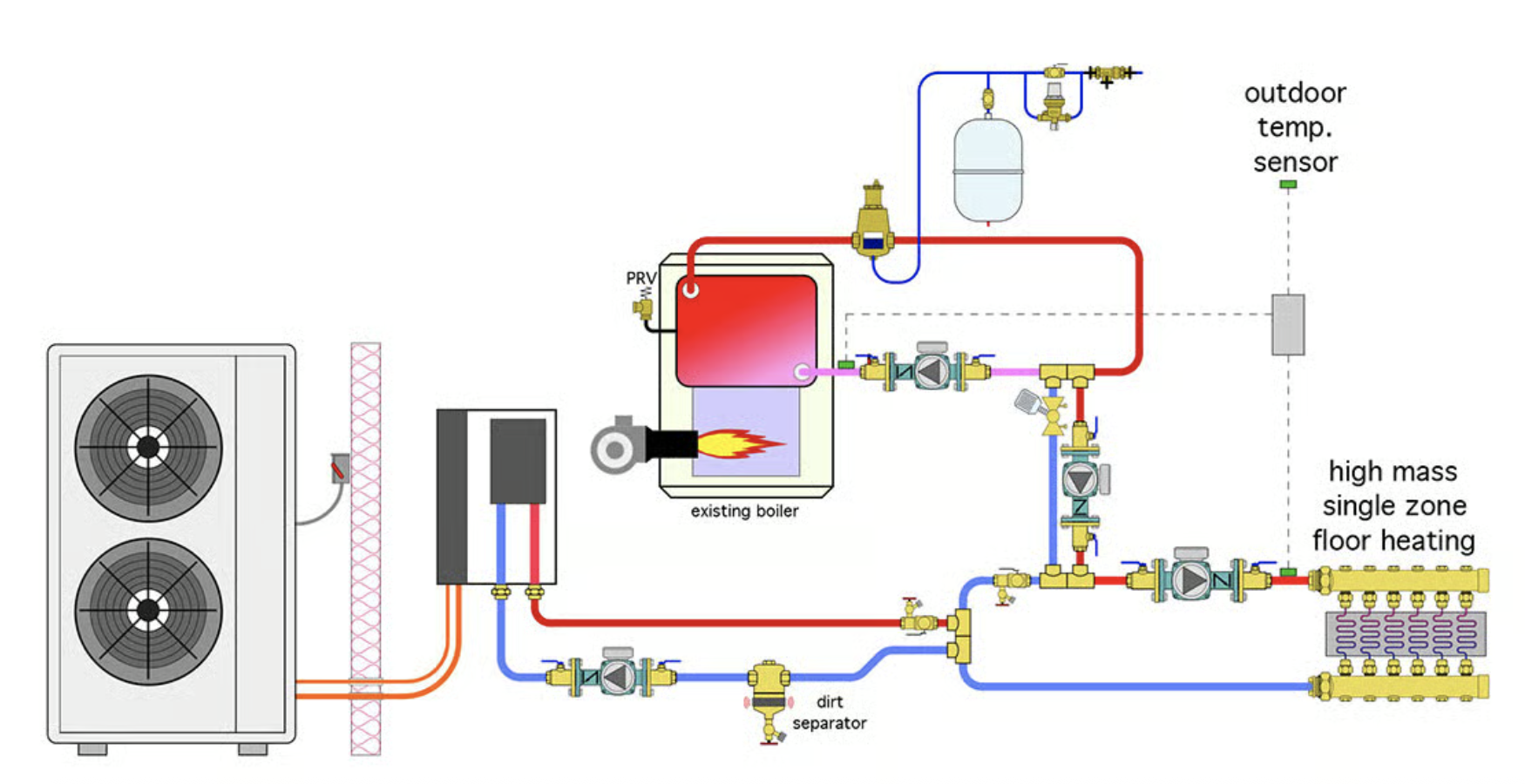

As for piping, @hot_rod I think this is the better option here

This puts the two heat sources in series and controls is pretty simple. Heat pump runs all the time, boiler runs only if the supply to building drops.

I think in case of the OP, the better option is to figure out a way to stage the boilers so only one needs to fire in the shoulder season (thus higher efficiency and less wear) and can pick up a bit of extra efficiency with a flue damper kit to reduce stack losses.

The above diagram would also work with a modcon pre-heater. You could install a big residential modcon which are cheaper and have it run all the time. This would provide a decent fuel savings without a big cost plus gives you backup in case a hydrotherm or two fails.

1 -

@Kaos , where are you getting 40F design temperature? If that's the case I'm thinking heat pumps all day long.

1 -

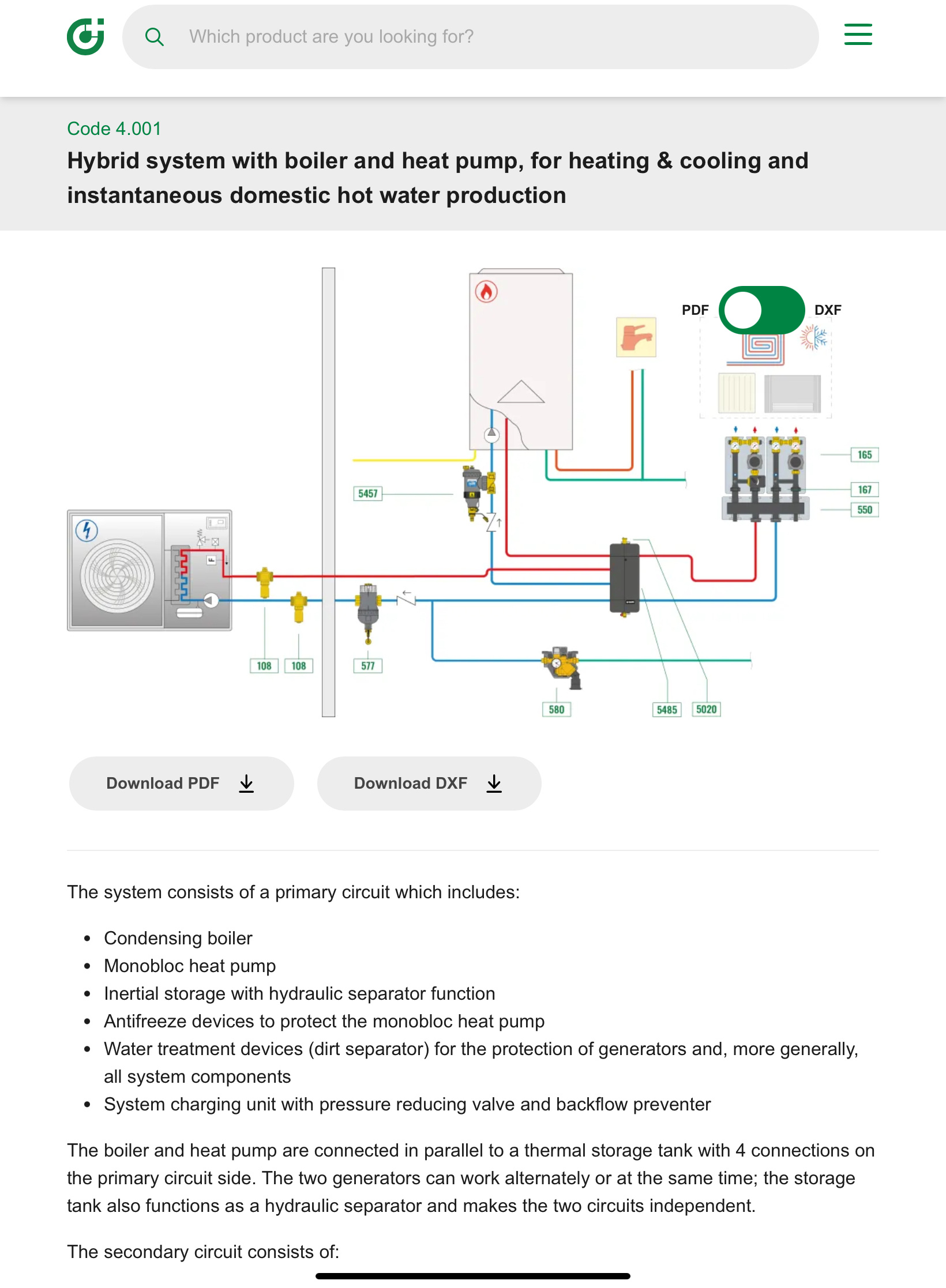

Another good piping option.

That was showing a HP addition to an existing system that had injection piping used on a cast boiler/ radiant system. That was a common method in the early non condensing boiler/ low temperature radiant installations.

If starting from scratch a sep or small buffer could make more sense.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

"Heat pump runs all the time, boiler runs only if the supply to building drops."

But once the boiler starts running the return temperature to the heat pump rises and the heat pump shuts off. Once the heat pump shuts off it never turns back on again.

There's only two ways I know of to make this work. One is just to have an outdoor thermostat that turns the heat pump off and the boiler off at a fixed temperature, and then switches back when the temperature rises. The other is to have a heat pump that can request auxiliary heat when it's not keeping up, and wire the boiler to that auxiliary heat.

The heat pump is going to have two temperature inflection points. One is where the cost of electricity becomes greater when the cost of gas. The other is where the heating load becomes greater than the capacity of the heat pump. There's no fixed rule about which one is going to be at the higher temperature, it depends upon the cost of utilities and the specifics of the the installation.

If inflection point one is at a higher temperature than inflection point two, all you need is strategy one (outdoor thermostat). If inflection point two is at a higher temperature, you need strategy two between point two and point one, and strategy one below point one.

That's a mouthful.

1 -

@DCContrarian With a series setup, this is not an issue, you need slightly different reset curves on each unit. One on the heat pump (or modcon) that is say 5F higher than the one for the boiler.

If the AWHP is targeting 130F and the boiler is 125F, as long as the heat pump is SWT is 130F, the boiler won't run. When the AWHP starts loosing steam and say output drops to 120F, the boiler will fire. This will bring the loop temps up to 125F and return will rise a bit. As long as the return doesn't go above the AWHP setpoint, the unit will continue to run. My AWHP runs at max power with a 10F delta, so as long as the return stays bellow 120F in this case, it will continue to supply full power even with the boiler running.

Most AWHP units can be set to shut off bellow certain outdoor temps. You can set this at the cost crossover point.

@hot_rod The issue with a standard hydraulic separator is that it will make controls difficult as now both units operate in parallel and there is a high risk of mixing flows. AWHP efficiency tanks with very hot return water, something you avoid completely with the series closed spaced Ts. Even though not floor heat, I also think with cast iron boilers, the injection loop is a good idea as it lets you run a much more aggressive outdoor reset on the heating loop without condensation risk.

@walnut This is all fun to think about, but I don't think the cost pencils out. About the only way to make this work is if you are looking to renovate units and switch each to their own water source heat pump. This is a common setup for high rise construction as each tenant is responsible for their own heating cost plus they also get AC. The building still needs to supply a heat/cooling loop but it is now at much lower temperature (50f-60f) which is easy for commercial chillers.

1 -

@hot_rod The issue with a standard hydraulic separator is that it will make controls difficult as now both units operate in parallel and there is a high risk of mixing flows. AWHP efficiency tanks with very hot return water, something you avoid completely with the series closed spaced Ts. Even though not floor heat, I also think with cast iron boilers, the injection loop is a good idea as it lets you run a much more aggressive outdoor reset on the heating loop without condensation risk.

All the pieces to the puzzle.

It falls on the designer to determine the loads, piping, controls and specific equipment that best work together.

The more complex the job the harder it is to check all the boxes. A hybrid system will be complex, and finding affordable off the shelf controls, or merging multiple equipment controls is a challenge beyond best piping.

I'm not sure how often a boiler and HP would run at the same time? That would need to be defined. Or maybe avoided?

Injection mixing adds some $$ cost to the already expensive HP installation. The schematic you showed was for an application of HP to a system already in place with boiler and injection setup. Just another retrofit option.

If the the combined flow rate of a HP and boiler into a parallel header, off a sep, exceeded the load flow rate, then yes you have blending.

In your schematic with the HP upstream, if flow is greater than the load flow in the primary loop same thing happens and the HP return is increased. My HP flow is varied by the onboard control. And from what I have watches the HP circ never turns off, just modulates down. So I don't have a static flow to work with.

So you still need to put some numbers to the flows, to design around and avoid this if maximizing the HP is the ultimate goal.

I'd wonder how may installers think it through to this level?

I agree also, maybe there is not a HP for every application. Yet!.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements