How does this flow control valve work in my monoflo system?

Hey guys, my 70 y/o monoflo system has what looks like a flow control device made by Armstrong.

Does anyone have a diagram of how this specific flow control device works?

Comments

-

Is this valve in an attic or crawl space?

It is a spring tensioned straight flow check valve.

Find the arrow in the casting and you will find the heated water flow direction.

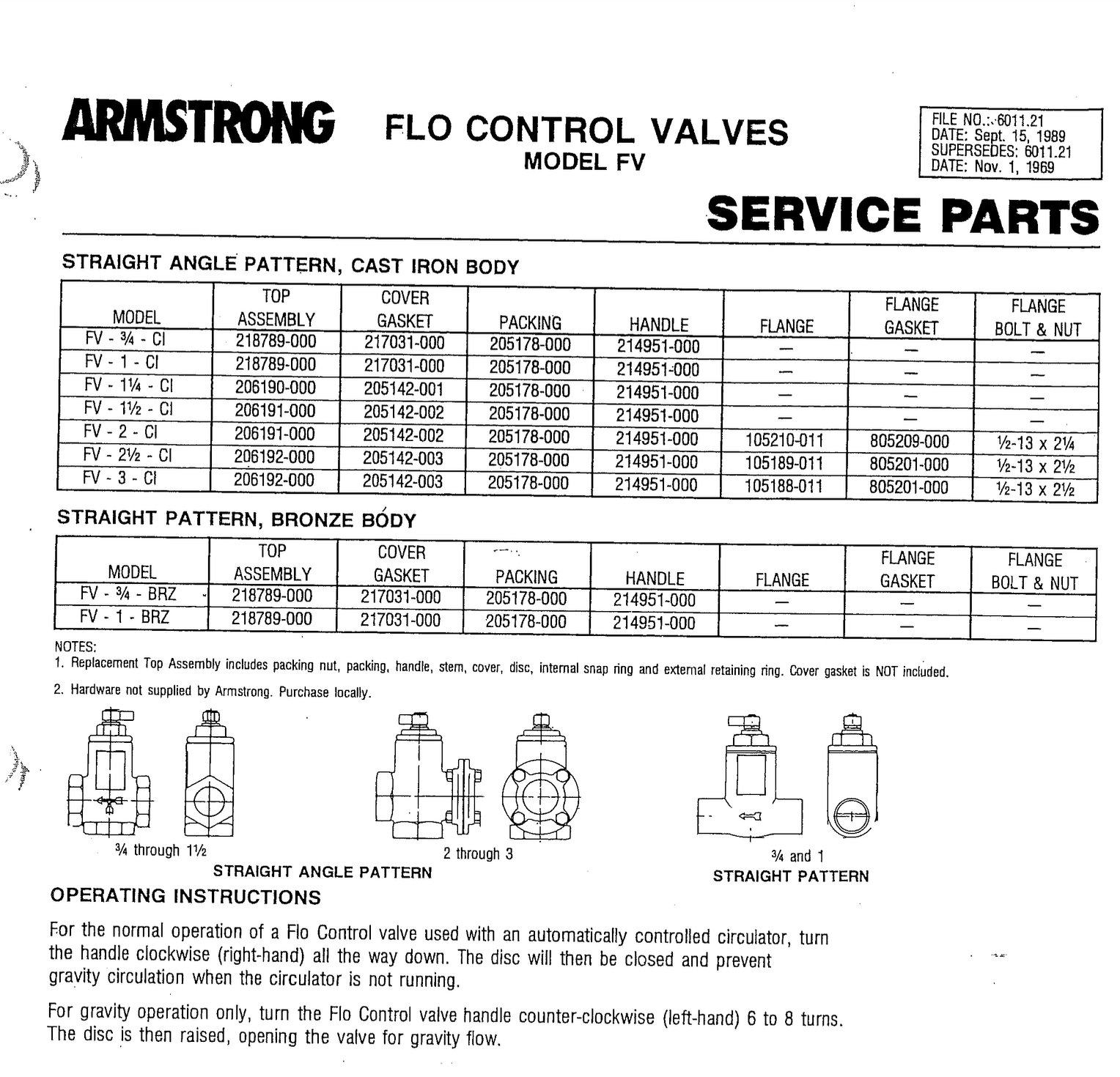

The valves design allows the cartridge and valve seat to be removed in one piece and cleaned if needed. 😀

0 -

A flow check is used if you have multiple zones, and each zone has a circulator. Or if you get domestic hot water with a tankless heater off the boiler.

If you have a zone valve system it is not required..

The screw on top should be turned clockwise in normal operation and turned counter clockwise for the open position

It is basically a weighted check valve. With no flow the weight closes the valve. When the pump starts the circulator opens the valve and moves water through the zone.

With multiple zones each zone has a flow check. The flow checks do not allow gravity flow when the circ is off (which is good).

And they allow flow only in the zone where the circ is running.

1 -

Mu monoflo has a 60' common 2" supply which splits into two 1-1/4" returns which feed upper floor and one 1" return which feeds the lower floor.

This valve sits at the end of the 60' common 2" supply. Looks like past the return for the lower floor.

What are the chances the "weighted check valve" is still intact after 70 years?

Do the integrated flow checks on the circulators make this 100% redundant?

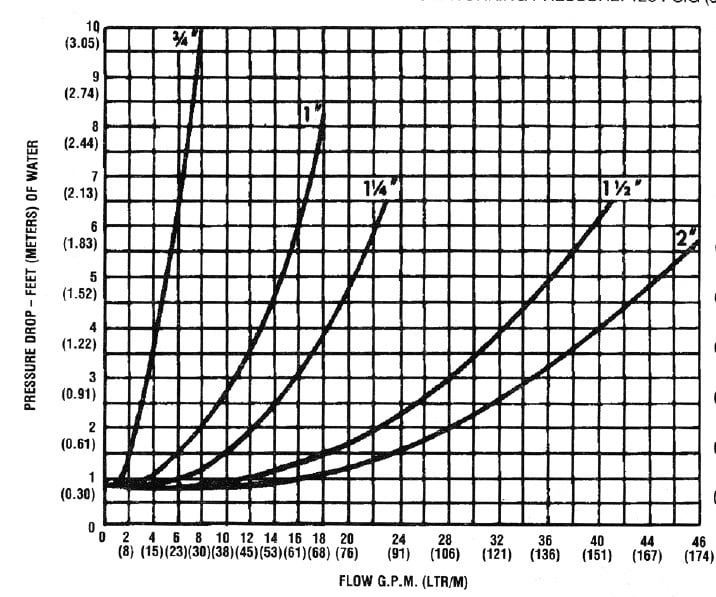

Below is what looks like a modern equivalent, and it looks like they are pretty restrictive.

If i don't need it maybe i should remove the internals to remove all of that unnecessary resistance.

0 -

Don't you really mean that it has a 2 inch main line that splits into 2 separate 1 1/4 take offs feeding the upper floor and 1 inch for the lower floor?

There is no weight in this valve, it has a spring to maintain resistance to flow. With the valve closed and the handle turned all the way down there is resistance to flow directing to each heating loop.

If your that concerned with flow just open it fully by turning it counterclockwise to fully open it. You may well end up with very cold floors as the water will go where there is less resistance.

0 -

That is not how flow checks work. They are a weighted check valve. They only open when the pump runs and there is no spring. It is done by weight only.

@sixplex You can be sure the valve is intact they last about forever. The only problem with them is they can stick open.

How many circulators do you have? Do you get domestic HW off the boiler?

If 1 zone and no domestic HW no flow check is needed.

with domestic HW (a tankless) with 1 zone of heat you need a flow check

If you have multiple zones of heat with zone valves no flow check needed

multiple circulators need flow checks

0 -

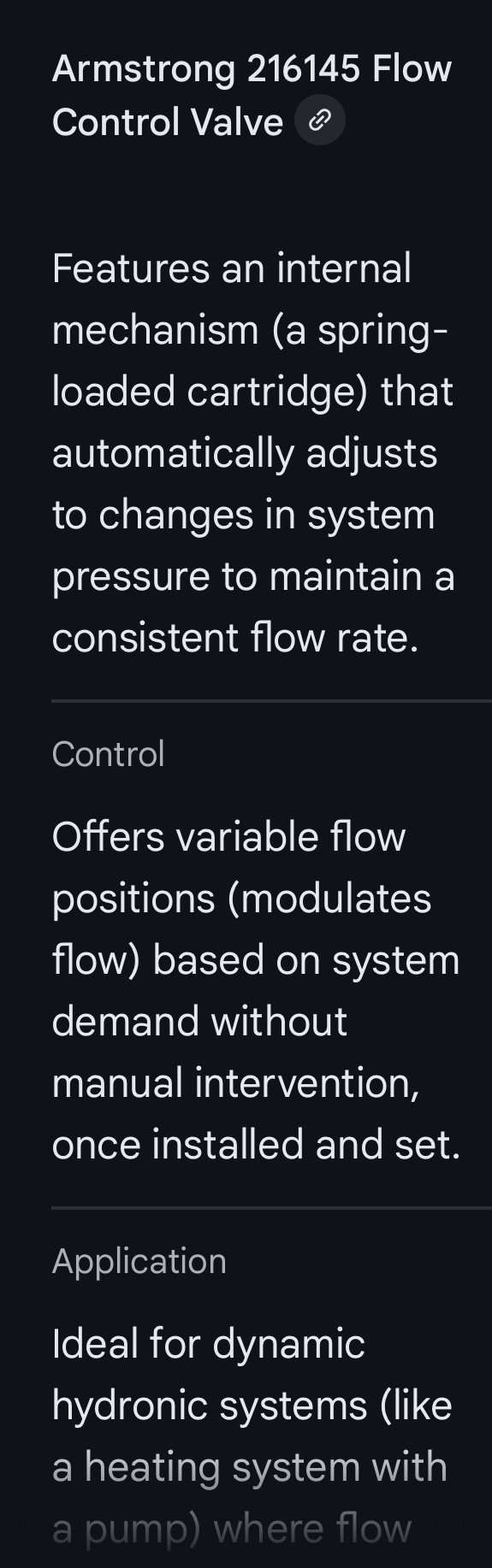

Is there s number on it? if it is a 216145 model , I believe it does have a stainless spring inside

The B&G one shown above is a weighted plug type

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Good research Hot Rod! The two "red guys" do look similar on the outside.

0 -

No number unfortunately, kicking myself for not taking better pictures when the wall was open(this is between floors).

Armstrong 216145 is newer, no way to tell if design got changed.

No DHWH. 2 monoflo zones each with a circulator, 1 is below the main.

This flow check is installed only on the zone above the main immediately after the common supply ends and separates and returns for each zone.

Even with zone valves or circulator IFC on the return, i still need this to stop heat migration from

the main to the radiators closest to it which are above, is that correct?

0 -

My mistake, sorry, I have not had flow checks in my system since 2015 and I had forgotten about the weighted check in the 2 B+G valves I had with my old system.

0 -

BOTTOM LINE?

Are you experiencing a problem that needs to be solved?

All I see is a question about how it works, and wether if might still work after 70 years. I have not heard anything about a cold area or a hot area that needs of be addressed. I would say don't fix anything that ain't broke. On page 9 of this book Zoning Made Easy is an explanation of how the weighted check valve works. If it is the spring loaded one, then it has a little helper to keep it closed when the circulator is not running

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

Stop the migration for sure and put two zone valves in. Open the flo check and leave it open. You have two pumps and two zones you need something to prevent migration. Put them near the pumps, thermostat opens zone valve end switch starts the pump. Two zone valves and two relays done.

0 -

It's possible Armstrong built a weighted style like the B&G also, the FV series. I found a number of sources that claim the 216145 is a spring cartridge style? Only one way to know for sure.

The FV series dates back to 1969.

I see 216145 on E-bay and some wholesalers still, if you Google that part number..

In either case either type could bind or stick after years of service. Not much to the weighted style, I've never disassembled the spring/ cartridge type Armstrong.

The label may be on the back side of the one you show?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

The things i do for heating…

There is a bathroom fan there, i took it out to snap a picture of the back.

It says "CD 866" whatever that means. The building was built in 1958, it looks original.

0 -

-

- I want to remove/disable it if it's not necessary OR if it's likely non functional anyway, which we be could reasonably guess if we knew the type of mechanism it uses. Main thing i don't understand, If there is IFC at the pump, will it stop heat migration from the main to the closest radiator, or does a flow check need to be closer to the first radiator?

- 1. IFC > 60' of 2" pipe with hot water > radiator above the main

- 2. 60' of 2" pipe with hot water > Flow Check > radiator above the main

- Wouldn't the very first rad still get gravity flow heat from what's in the pipe in case 1?

- My system is restrictive, i want to pump away (too many rads to check for air), and add a thermal bypass for protection. At that GPM/head (calculated) only the very pricy pumps have the constant pressure / gpm curve i would need, like taco 0034eplus. If i find a way to reduce head some, i can get away with 0026e and possibly cheaper more common 10cv zone valves.

0 -

You said you have 2 pumps and 2 zones.

You only have 2 choices.

Remove the Flo check (or open it) and install 2 zone valves 1 on each zone.

or no zone valves and put a flo check on each zone.

Weather the little check valves in the circs will stop you migration problem I don't know.

But 2 zone valves will

0 -

That's not a typical Flo valve. Its 180° in and out. No bottom port.

Its location (in the ceiling between the first and second floors?), and its 2 pipes into 1 going in, and 1 pipe into 2 going out is something I've never seen before. It seems like a regulator more than a Flo valve. There must be something on this design somewhere. I don't want to bother the retired guy even though he's been up since 5 at least. I'm sure he knows.

0 -

yeah, an old timer at one or the Armstrong reps would know

Armstrong does show some legacy parts on their website

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Pipes before it are the lower zone, below the main, needs no flow check.

After it are the two upper zone, where gravity flow may be an issue.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements