2-1/2" DHW return loop piping? Minimum velocity requirements?

Hello Heating Help folks. It's been a while. I hope all are well. I'm looking for some wisdom about DHW recirculation on an existing commercial system, with 2-1/2" copper return piping.

Existing are twin 200 gal. 399K H.E. WH tanks that are on the second floor of a two-story hotel with 65 rooms. No mixing valve and with 80 gallon storage tank that has a 2-1/2" B&G on a tank aquastat (as a transfer pump). Ignore this bit, I'll be disabling the pump and valving it off. Someone had a bad idea. The add 80 gallon tank is piped in series after the water heaters balanced piped outlets. It's just added hot loop volume.

There is an existing B&G 2-1/2" bronze circulator that is the recirc. pump. It looks like it has not been reliable, multiple coupling failures are evident, lubrication maintenance was likely not done. The current pump looks new and has a bound impeller bearing. These two B&G's pushed at each other using the same smaller balanced cold inlet piping to the 399K heaters.

The loop is 260-290ft. Should be under 10ft of head at low flow. I have no idea about heat loss of the loop.

It looks to me like this is a poorly adapted system, maybe the tanks replaced a volume WH design that needed the high volume return flow.

Here's my understanding for the existing case: The recirculation pump needs to move enough water to compensate for the heat loss of the loop, and that's it.

Air removal would not be a problem. Maybe with low velocity flow, debris would settle out and accumulate?

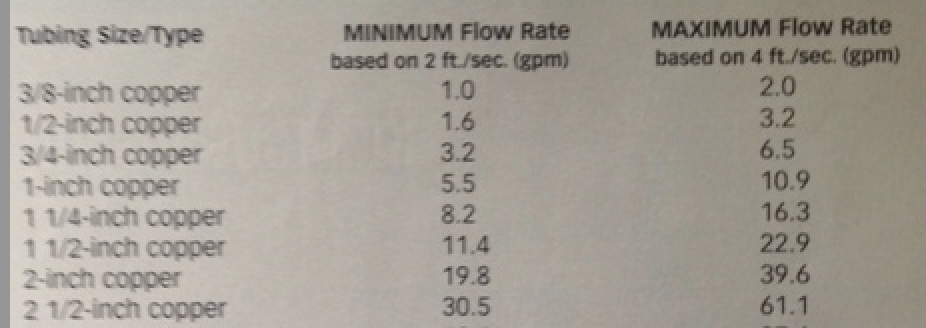

Is there any good reason I need to maintain a minimum velocity in the 2-1/2" return?

I have my local supply house expert telling me a smaller pump will cavitate and insists I must produce a min. velocity for 2-1/2 piping, but he fails to explain why. I hope, if he is right, someone here can explain it to me.

I'm trying to spec. a modern wet rotor for the recirc. task. I'm consisdering the 15-55 sf-t hwr alpha but I not sure 3.8 gpm will be enough. With 3.8gpm @ 5F delta that's 9,500 btu/hr, seems like that might keep it hot in CA, but I want to be sure I have extra capacity. The unknown with the above hwr alpha pump is that it uses an internal temp. sensor and it has a max temp. setting of 102F. That seems like it's too low. Like, 20F too low. Maybe I'm not fully understanding Grundfos's logic.

Alternatively, a standard 15-55sf on high would likely give 6-8 gpm. Worst case would be a 26-99sf on med.

I don't want to do what all the others have done repeatedly, rebuild the B&G and walk away.

As always, thanks for being here and for any input you offer.

Comments

-

You are correct, as long as the tank water heaters do not have a required flow rate, a a DHW recir pump is just responsible for is maintaining temperature at the distant fixture within 3-5° of what it leaves the tank.

Realistically you don't care what the ° drop is from the distant fixture back to the tank.. Other than the heat loss is costing fuel $$

There are a few reasons for maintaining a velocity however. One is to prevent lime scale build up in the piping.

The second is legionella prevention. There is a movement starting to increase recirc velocity for a period of time every day to scour piping of the film where the bacteria lives and breeds. Taking flow velocity above 4 fps could accomplish that. In 2-1/2" copper you are looking at 60 gpm or more!

Bottom liner. it sounds like the recirc line is grossly oversized for the job it needs to do. So you have a bit of a catch 22.

You would like the minimum amount of flow to match the loop heat loss. But that large diameter piping could cause other problems.

In a rental or public use property you need to cover or make note of legionella potential.

Now elevated temperature once a day, or a chemical injection are the other code accepted methods of dealing with POTENTIAL bacteria issues.

Just be careful putting your name on that without a signed disclosure.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

-

That's a good idea. I'll find out what group is researching that velocity concept for legionella mitigation.I think it is that California water heater group with Gary Klein, @Larry Weingarten may know

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks for the feed back. The city water system is chlorinated and there's frequent water use. I know that doesn't eliminate risk, but many millions of water heaters are in this same condition daily and the cases aren't there. I find a lot of public hot water systems operating at 125-127F. Not my design! It's hard to know what to do, where liability starts and stops. I've never seen any domestic water line look like that scaled pipe in these parts, municipal water system or well.

There's also a high velocity problem. This existing series 2-1/2" B&G is likely on the curve above 35gpm continuously. The water inlets for the WH tanks are 1-1/4 balanced. The 2-1/2" cold and the return water share them. They see 17 or so GPM each from recirc. With 60 rooms at peak use, those cold inlet pipes must have very high velocity. It might be causing the recirc. head pressure to spike at those times, pushing the pump off the curve. Now consider, at one point there was a second functional 2-1/2" B&G with a very low head loop periodically competing for flow on these same two 1-1/4" cold tank drops. What a mess. It's troublesome to see the faults. The manager and lead maintenance are both new so they have no history or understanding of the building or water systems at all. I've found if you try to inform them and their higher up's of the situation, they will promptly start looking for someone without all the complexities and strange things to consider.

Bear traps, landmines, piles and pits. Maybe I should just rebuild the old pump and walk.

0 -

i will point out again that the only people that died in the flint water crisis were some people that died of legionella from the water system in a hospital.

with a recirculation system the water hangs out a lot longer and there are more pockets for it to stagnate in so the risk of the residual disinfectant being consumed ad it breeding legionella is a lot greater than with a simple hot water tank.

i like the velocity thing for this because you don't have to retrofit tempering valves all over the place like you would with running it hot enough to kill bacteria.

there is a car talk where they talk about the hot water always being there immediately in a hotel and don't realize that virtually every hotel in the 1st world has a hot water recirculation system.

0 -

Hi, @hot_rod is right to explore ways to mitigate bacterial growth. Biofilms do grow in the lines and harbor bacteria, preventing chemical treatments from being fully effective. Normally maintaining one fps is considered good, but taking friction into account, what would center of pipe flow have to be to get one fps at the pipe walls? I'd be tempted to provide for flushing periodically under line pressure, to move a LOT of water through the line. When I've done this with recirc lines, I always get brown muck out of what were thought to be clean copper pipes. The pumps just weren't moving water very fast. Then there are possible dead legs to consider… or branch lines off of the recirc loop. You know there are places which live at ideal Legionella growing temps. Also, intermittent high flow is best if you can get it with good controls. 24 hour fast flow will cause erosion in the lines.

One approach would be to suggest getting a legionella expert involved, to make recommendations. That would take you off the hook, and just maybe management would listen and let things be made better. 😇

Yours, Larry

1 -

legionella codes and guidance from ASHRAE and other such groups make this a concern that will not go away. Already law firms specialize in legionella lawsuits.

Least we forget licensed plumbers take an oath, not unlike doctors do. Its on every plumbing exam, that I have taken.

“The plumber protects the health of the nation”

So @Teemok you have two tasks to juggle here. I know which you prefer, the one with known measurable results.

Larry is spot on to call in the experts for the other task

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

I have written out an explanation to the manager detailing the concerns, including my duty to inform and imperative to avoid liability. Fixing the B&G doesn't achieve high velocity or eliminate the risk from sub 140F water. It does keep it moving. Right now, there is a stagnant recirc. pipe and it is in the peak temperature danger zone. It is very short, the last room on the loop is less than 20' feet away. I'm recommending to repair existing pump and for the owners to engage with the problems. @Larry Weingarten I will recommend, in writing, that they seek expert Legionella advice . I don't think there's much else I can rationally do. I don't want to be involved in making it worse, and I'm not going to become a crusader and stop the line. These are the owners' problems.

@mattmia2 I will mention periodic high flow as an option, but I think letting an expert spec a solution is best for me. The potential for being the cause of much money spent and someone still gets sick is a trap I want to avoid. One idea I had is to reconnect the 2-1/2" low head hot water loop to be able to hit high velocity and injecting mixed down 140F from the tanks into the loop with close tees to maintain the temp. Then both velocity and loop temp could be easily periodically raised if a safe window for that could be created.

I know there's good reason for the ASHRAE guidance. I also know there is a vast disconnect between best practices and real world happenings. It would seem the majority of today's hot water systems are on the verge of killing hundreds of millions this morning, but they don't. I understand there are some cases, and they are often from very specific conditions that are rarely related to domestic water heaters and piping. Spa's! Lawyers would build an empire to profit from the damages due to hen's teeth if they could. That's not to say there's no harm potential from Legionella, it is not hen's teeth or a very common killer.

Thanks for all the guidance. I'm lucky to be able to consult with the wise here.

0 -

Bacteria has been in our systems and lives since the begining of time. We want and need healthy bacteria, in a septic tank for example.

The issue is the earliest case, and deaths in Philly, 1976 put a name on the outbreak, and this was in the air conditioning system, not the plumbing distribution. Pontiac Fever 1968, named after Pontiac, Michigan could well have been called legionella.

Knowledge is power. Sounds like you have a good plan.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

@hot_rod in a book I just read, The Arrogant Ape, a biologist calls the human a bacterial life support system invention. Each of us has about three pounds of gray matter and three pound of non-human DNA life on broad at all times. The bacteria in and on us out numbers our own cell count by a lot. Bacteria had already done much of the inventing in life systems long before we were around. The Mitochondria structure is a bacteria symbiotic invention. The long history of life, in a way, is really their show. We just recently grasped CRISPR-Cas9 the very old bacterial invented gene editing tool.

1 -

-

Nerdy Harvard professor book, but It's really not that off beat. "The Arrogant Ape is #2 for non-fiction books New York Times readers say they're most eager to dive into this season." I would not have been accepted into Harvard if I had tried and could not have afforded it, but I can read the professor's books. The title is the same as a course offered there for a while. There are few books I regret reading, even ones I didn't really like.

0 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements