multi zone - water hammer

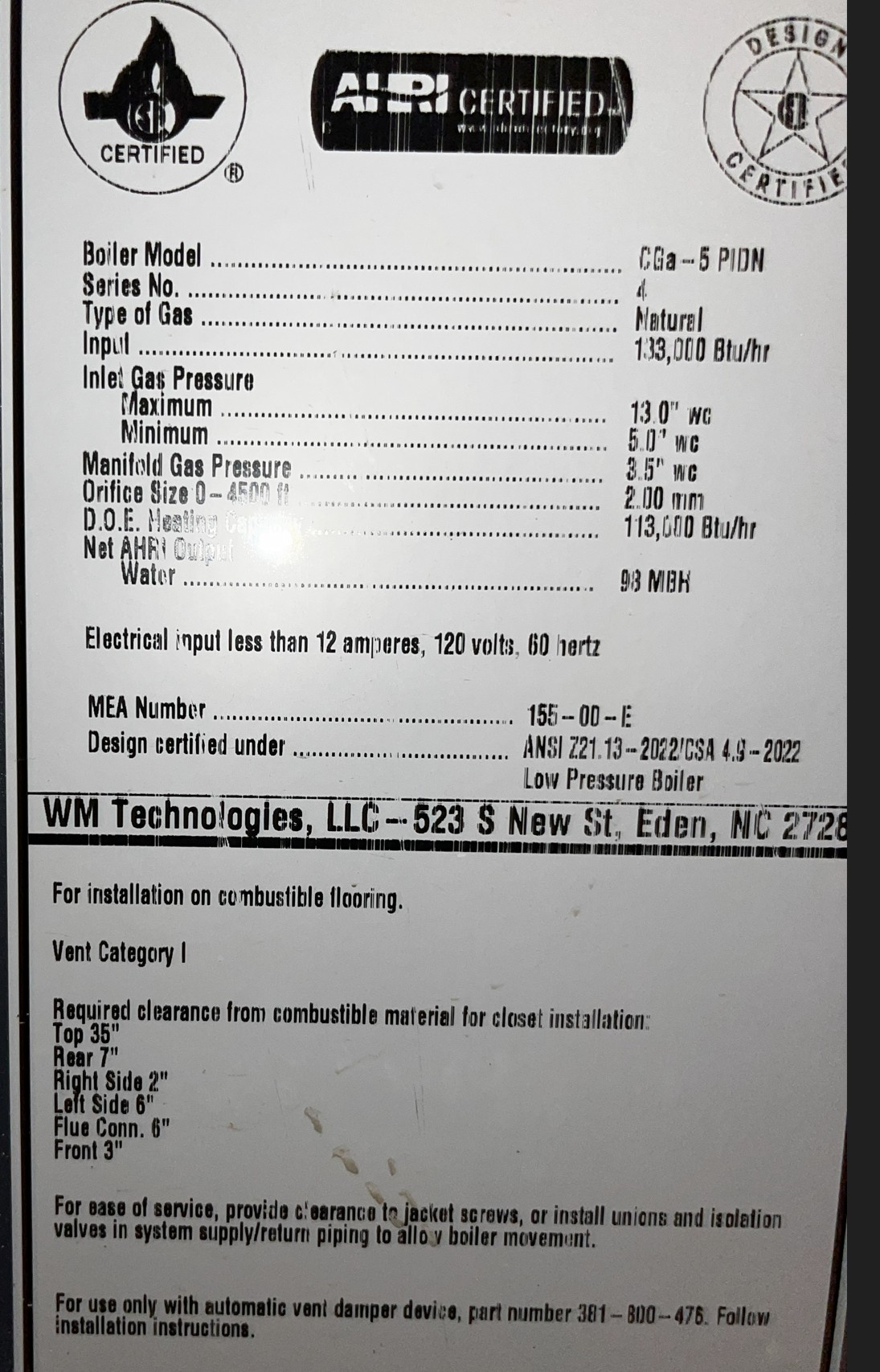

I had a weil mclain cga recently installed and also replace baseboard via radiators in one of the zones. experience a very odd behavior. I have 3 zones using zone valves. zone 1 is basement, zone 2 is first floor and zone 3 is second floor. zone 2 has the new radiators. when zones 2 and 3 are active, then turning off zone 3 creates a rattle in the zone 3 pipes (water hammer). when zone 3 is active by itself, turn it on and off does not do that. I have bled the system already, it does seem to be a bit better but not entirely gone. never had this problem before zone 2 was replaced by radiators. any suggestions is greatly appreciated.

Comments

-

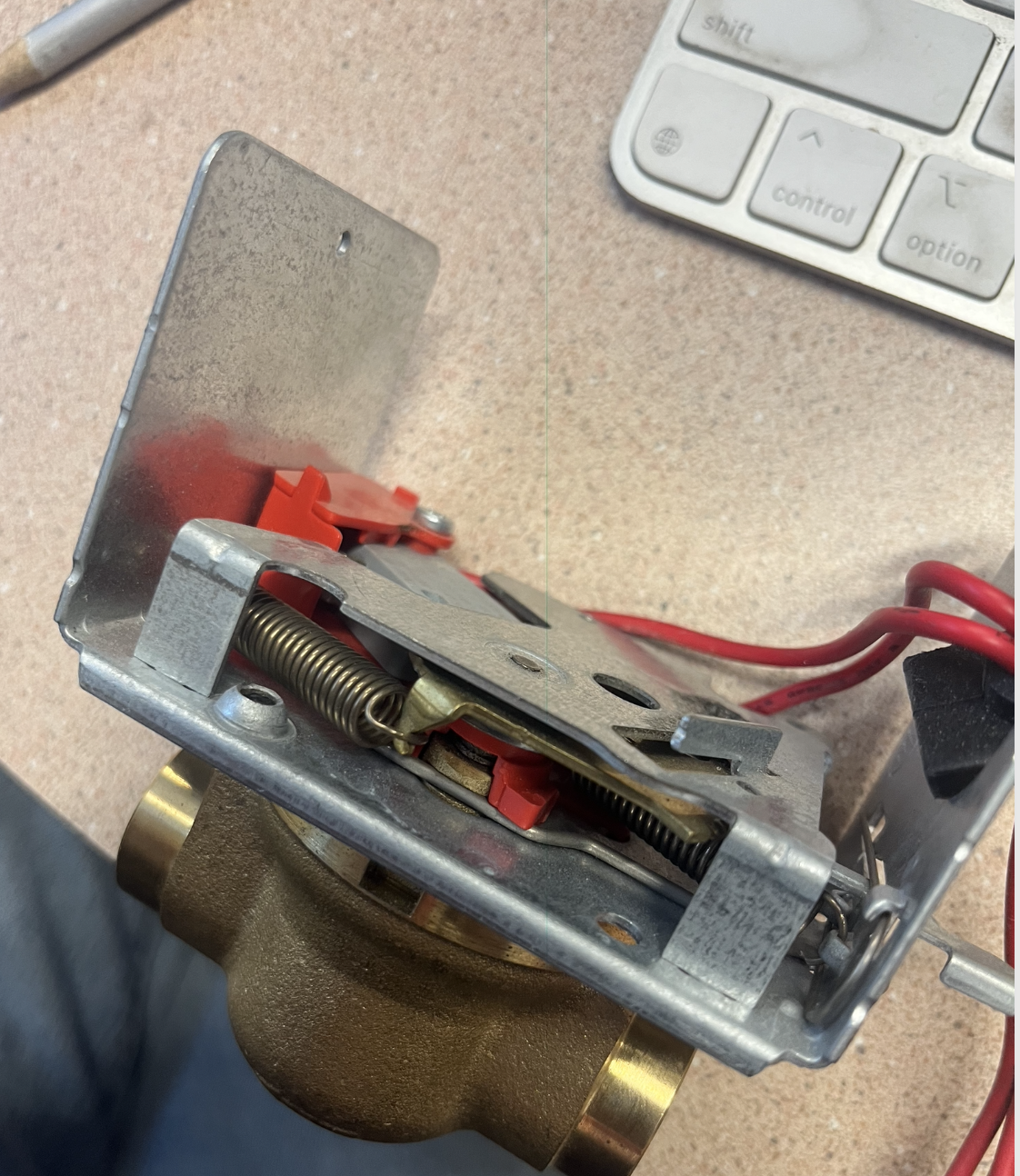

What type of circulator? A pic of the zone valves. Flow is going through the valves in the correct direction?

A zone valve hammer is often caused by excessive flow velocity that the valve is trying to stop.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

attached are photos of my setup. also the expansion tank is on the hot side, not sure if this is the reason. Excessive flow does that mean the pressure is too high.

0 -

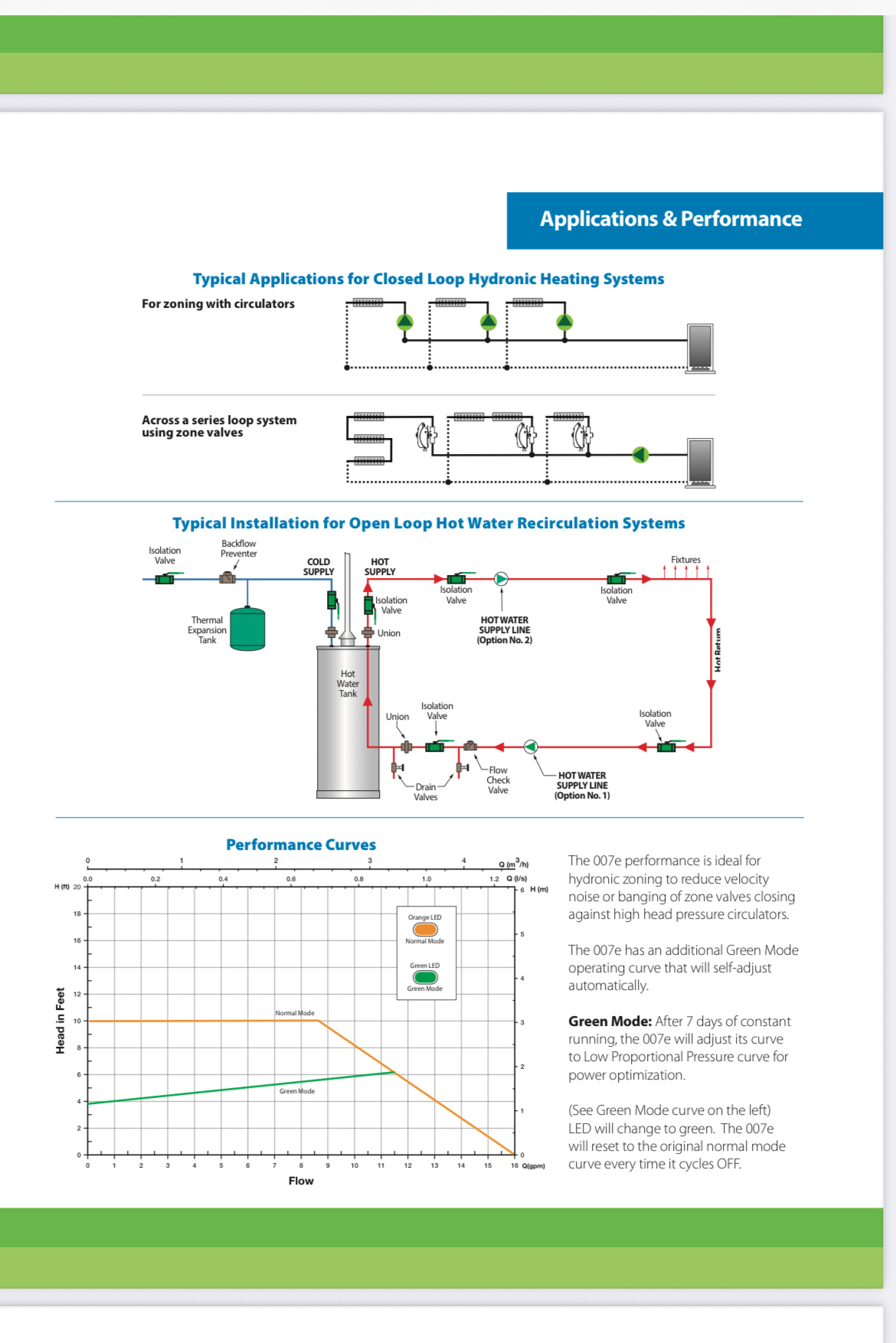

what mode is the 007e in?

It was designed to manage zone valved systems, eliminate banging

some would suggest removing one of the springs inside the HW zone valve

This slows close off a fee seconds

But watch for ghost flow as it also reduces close off pressure

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

It has an orange light and according to documentation it is in normal mode. do you think when it goes into green mode it'll be better?

by the way, the water hammer sound is not at the valve. It is somewhere in the second floor for the zone in question. Not sure if this additional data point is helpful.

Also the boiler is running 20 psi, can that also create a problem?

0 -

is the 20 psig cold fill or with the system hot? how high is the highest emitter above the boiler?

0 -

the noise from a water hammer can often be heard or felt where the piping is not secured well enough

The force, or shock wave starts at the zv the further it travels the more extreme the noise, often times.

No harm in trying the pump in the other mode if it is selectable It sounds like it takes a week to learn and adapt

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I had the plumber re-pipe my system. water in-let value → expansion tank → circulator (TACO 007e) → boiler → zone valves per the manual for the weil-mclain boiler. The water hammer problem is not resolved. Also adjusted the PSI to around 15 when it is cold.

more context in the piping.

Zone 1 - about 50 feet and it uses radiator.

Zone 2 - about 30 feet and it uses baseboard.

zone 3 - about 20 feet and it uses baseboard.

Symptom only when zone 1 and zone 2 are active, turning of zone 2 while zone 1 is active creates the water hammer otherwise it is whisper quiet. Am thinking of adding a balancing value to zone 2 to slow down the water. Any feedback from the community is welcome.

Thanks

0 -

Hmmm, that pump should have solves the banging.

A work around with most HW valves is to disconnect one of the springs below the cover. This slows the close off speed by a few seconds and that is often just enough. A simple enough hack to try.

It does reduce the close off pressure a bit, about 3-4 psi, but if that pump is working properly it should not push the valve open.

Does that pump give you any gpm or W reading as the valves open and close? Or can you hear the speed change?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

thank you for your feedback. I disconnected the spring in the zone valve that is causing the problem and the problem went away. I don't see any reading from the circulator. The circulator seems to be louder when both multiple zones are activated. Is there any negative side effect with this DIY?

Is there a more comprehensive solution than this DIY? Would adding a balance valve after the zone value help in this case?

0 -

This HW workaround have been used for many years. You may find that is you use the search function here :)

I don't know that Honeywell corporate has ever acknowledged or even officially suggested it. I have heard of the workaround from HW dealers, reps and contractors.

From a technical standpoint, you basically slowed the close off speed. It should not cause any harm to the system. Less load on the synchronous motor to open the valve😉

Has the boiler or pump been changed? Those look like an older vintage ZV, I assume it has worked properly in the past?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

The whole system was recently changed. The contractor told me all the valves are new.

As long as it does not cause the banging and wake up the whole family, this works.

many thanks for your suggestion. this saves the day!!!!

0 -

removing the spring definitely remove the water hammer rattle however I noticed a different sound. It is short of like the swoosh as the valve is being closed.

Do you think by changing to a taco valve will help? based on my research it is a motorized valve for closing and openning. not sure if there is a way to control the speed.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements