To hot - Boiler Control and Thermostat CG8

Hi everyone,

Trying to wrap my head around a “too-hot” condition in my 4-family apartment building.

Current Installation:

- WM CH8 series 11 (202,000 output)

- 2-Pipe reverse return hydronic system with fin-tubed recessed heat emitters.

The previous boiler control (which I do not remember, yet used small mechanical inserts that set times, and a knob to set the temp — very easy), was replaced with a Tekmar 256 with outdoor reset and pipe-probe.

I’ve had too-hot issues since the 256 was installed.

256 parameters are:

- Outdoor design is set at 10 degrees (Cincinnati, OH)

- Min 140 / max 180.

- Design 68 degrees

With these settings, I’m still nearly 78 degrees in room.

There is no external room temp sensor.

Curious if anyone has some tips or a better solution.

Thank you!

Comments

-

Constant circulation in the radiation and primary/secondary piping?

If so, start playing with the outdoor reset curve on the Tekmar. Your problem is running the ater through the radiation at too high a temperature.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

thank you @Jamie Hall . Yes, constant circulation. 1 zone.

I’ve been using the “automatic” boiler differential on the 256.

How would I start to adjust the outdoor reset curve on the 256v0 -

Here is the manual Tekmar 256. at the bottom of page 2 it reads "To make an adjustment to a setting in the control, press and hold simultaneously for 1 second, all 3 buttons. The display will then show the word ADJUST in the top right corner. Then select the desired item using the Item button. Finally, use the and / or button to make the adjustment."

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

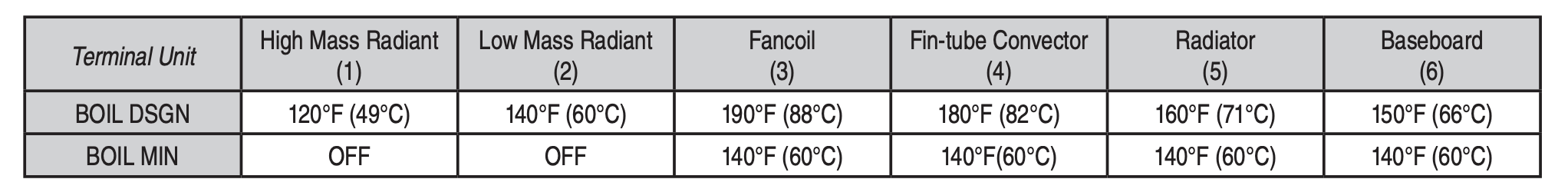

Check to see if the 256 is set for the type of Terminal Unit your system uses (Terminal Unit is their way of saying the tyoe of radiator you have).

You describe "recessed fin tube" as the radiators you have. In this case you set the Tekmar 256 to

BOIL DSGNto 180° and theBOIL MINto 140°. This appears to be where you are already set. Try to adjust those numbers toBOIL DSGN172° andBOIL MINto 140°. See if that reduces the room temperature to 70°. This will move the curve for the coldest day to be a little cooler. it may not adjust the top of the curve (the warmest days) enough to notice.Next try moving the

BOIL MINto 135° and see if that helps. Always wait 24 hours between adjustments to see how each change makes the room temperatures to change.Remember to record all your settings and then record the results after at least 24 hours of operation. It sometimes takes time for all the parameters to get your temperature just right. Eventually you will get a feel for that control and how it works in your building.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Thank you, @EdTheHeaterMan .

Yes, chose 4 as the heat emitter type.

I'll make the initial change of 180 to 172 and report back.

More soon!

0 -

to be clear, the Tekmar 256 does not have a setting number four (4) for a heat emitter type. The chart gives you the starting point for the two settings. BOIL DSGN and BOIL MIN based on that type of emitter. Your tekmar 256 is already set that way. I am suggesting that you adjust BOIL DSGN from 180° to 172° for the first step in adjusting the reset curve.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

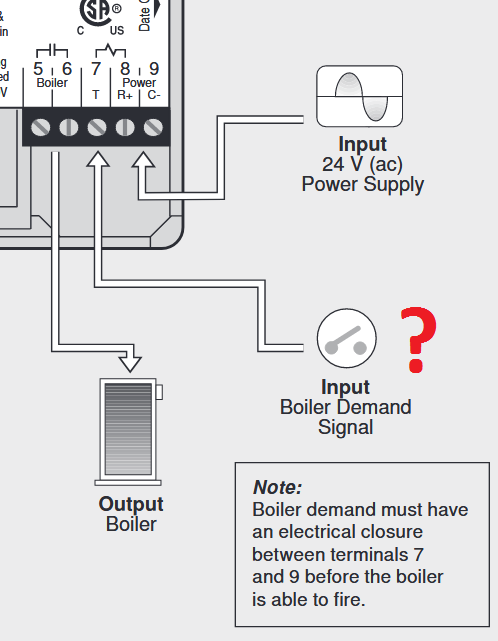

The demand input may be there for a reason.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Thank you @EdTheHeaterMan

Seems there is a heat emitter type that corresponds with a number in the menu system on the 256. The choice of number "4" chooses the fin-tube variety.

Thank for @109A_5 — Seems that is connected properly and the boiler is firing.

Curious if using a 260 with a indoor room air sensor input could also help even out the heat? Or is this overkill?

0 -

Seems to me you no longer have the temperature set knob.

I would not consider my self a 'Outdoor Reset' expert or even a Tekmar 256 Expert.

However, I find it hard to believe there is a outdoor reset curve that would be an exact match for the buildings heat loss in every weather condition. The Tekmar 256 is only looking at outdoor temperature, not other conditions like Sun, wind speed and direction. I see the building's heat loss as variable to other conditions beyond just the outdoor temperature, outdoor temperature is the predominant weather condition.

The Tekmar 256 provides a demand input that you could connect a thermostat to. So in my opinion this input is to limit the heat demand, when needed. In my mind a thermostat would replace the knob on the old unit.

Although you did not say what temp knob on the old unit controlled, water temperature or room temperature.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

with a cast iron boiler you probably can not make the swt low enough to match the load of the building on mild or moderate days without the boiler condensing (unless you have a separate mixing system to make the system water cooler than the boiler).

you probably need a t-stat input to cycle it on warmer days.

0 -

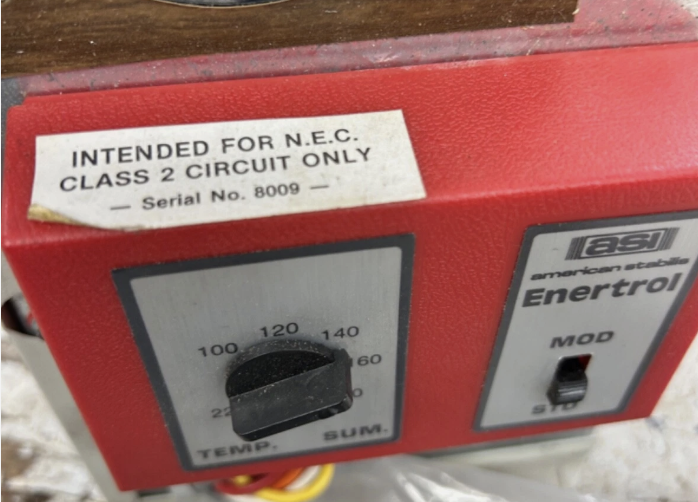

I am just wondering ig the old control was made by AMERICAN STABILIS? They has a device called the ENERTROL that I installed on several of my customers' boilers in the 1980s. There was a red box that contained all the ODR parts. You connect a boiler temperature sensor on the supply pipe and an outdoor sensor on the north side of the building. Two other wires were connected in series with the high limit to shut the burner down when the boiler temperature was hot enough to heat the building.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Thanks @EdTheHeaterMan and @mattmia2 .

Yes, cast iron boiler.The old boiler control I remember has a small knob for temp, and some sort of pin timer circuit. Maybe white or beige. All analog it seemed.

0 -

That sounds exactly like the ENERTROL. The pin timer was for a boiler with a tankless coil. You would set the SUM TEMP dial on the red box for the outdoor reset curve you wanted for you radiators. The pin timer was to disable the ODR when you wanted the boiler to be hot enough for taking a shower. This ment that if you took a shower when the timer was set for ODR to kick in, your may get a lukewarm shower.

Do you have a separate water heater now, or do you still have a tankless coil for DHW?

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

When using the Enertrol with or without the Pin Timer, you still used the existing room thermostat to control the room temperature in the homeowners living room. That thermostat was not removed when the Enertrol was added.

You have a one zone building with 4 units that overheat. The ODR from American Stablis or Tekmar did (does) not have any provision for room sensing. That is done with a standard room thermostat placed in one of the dwelling units to sample a representative room for the entire building. That thermostat is (was) subject to tenant tampering so you may want to use a remote sensor thermostat an locate the actual control in a locked room away from tenants.

That thermostat will connect to the system the same way it would if there was no ODR at all. The ODR just connects in series with the burner limit. The thermostat connects to the control the brings on the burner and the pump to heat the rooms. If that does not make sense… ask me to explain it in more detail.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Thank you, @EdTheHeaterMan !

The unit you suggested isnlt quite what I had previously but close. Still looking for a photo example.

In the meantime, some additional info and questions if you're willing:

- No DHW. This is just for heating the building.

- I think I'm starting to understand how a room tstat may help but unsure of how the heating curve and feedback from a room tstat works in this siuation.

I'm assuming that the CG8 was a bit oversized when installed many years ago. There is PLENTY of heat output and radiation from the fin-tube emitters. The current 256 has a pipe sensor on the supply and ODR on the northside of the building. Yet that calculation is not taking into account the actual temp in the living space.

So, when it's TOO hot in the living space, the boiler still fires. Curious if adding some feedback from a room sensor would help. I don't see that feature on the 256 but I do see that on the 260.

0 -

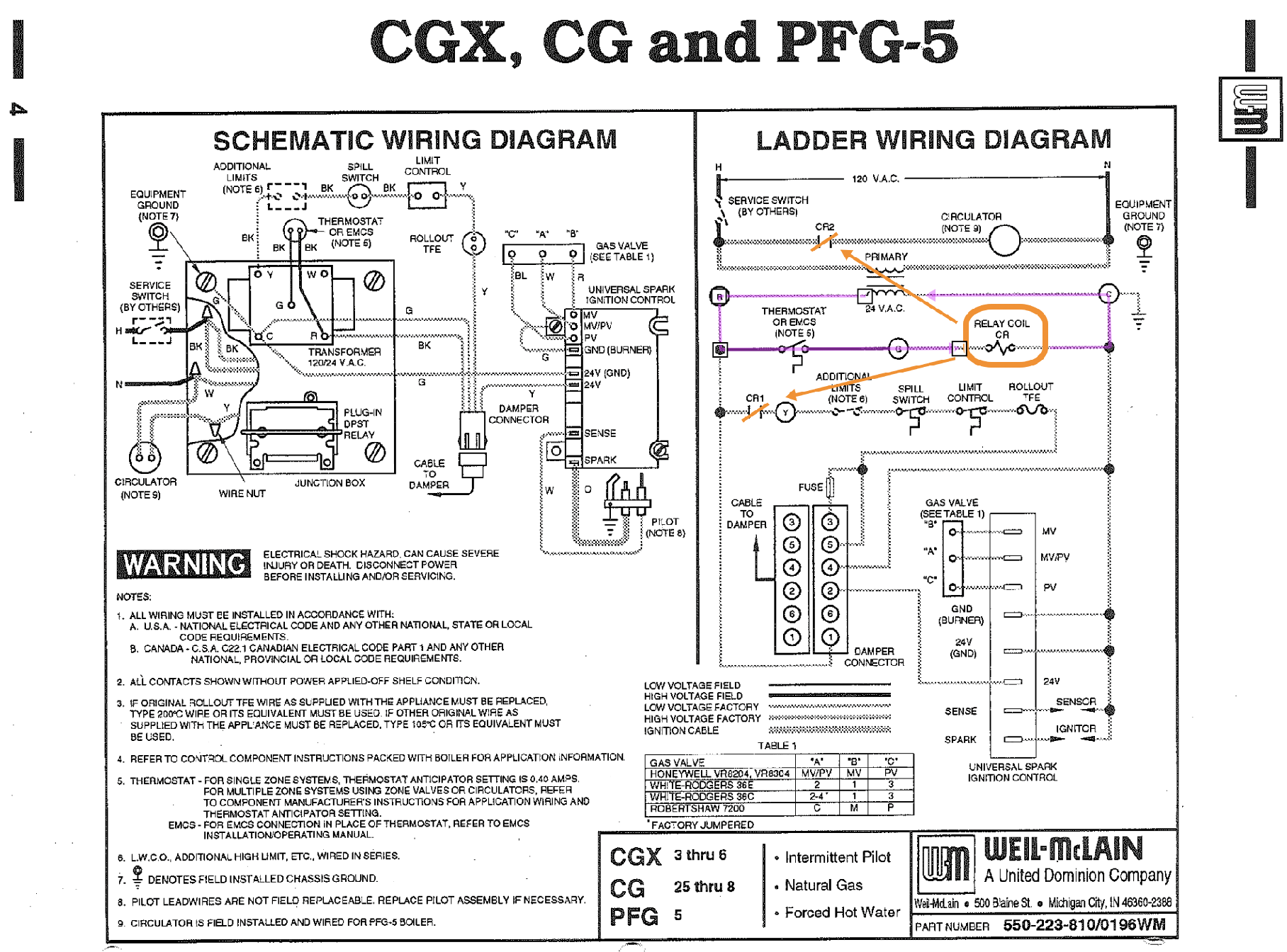

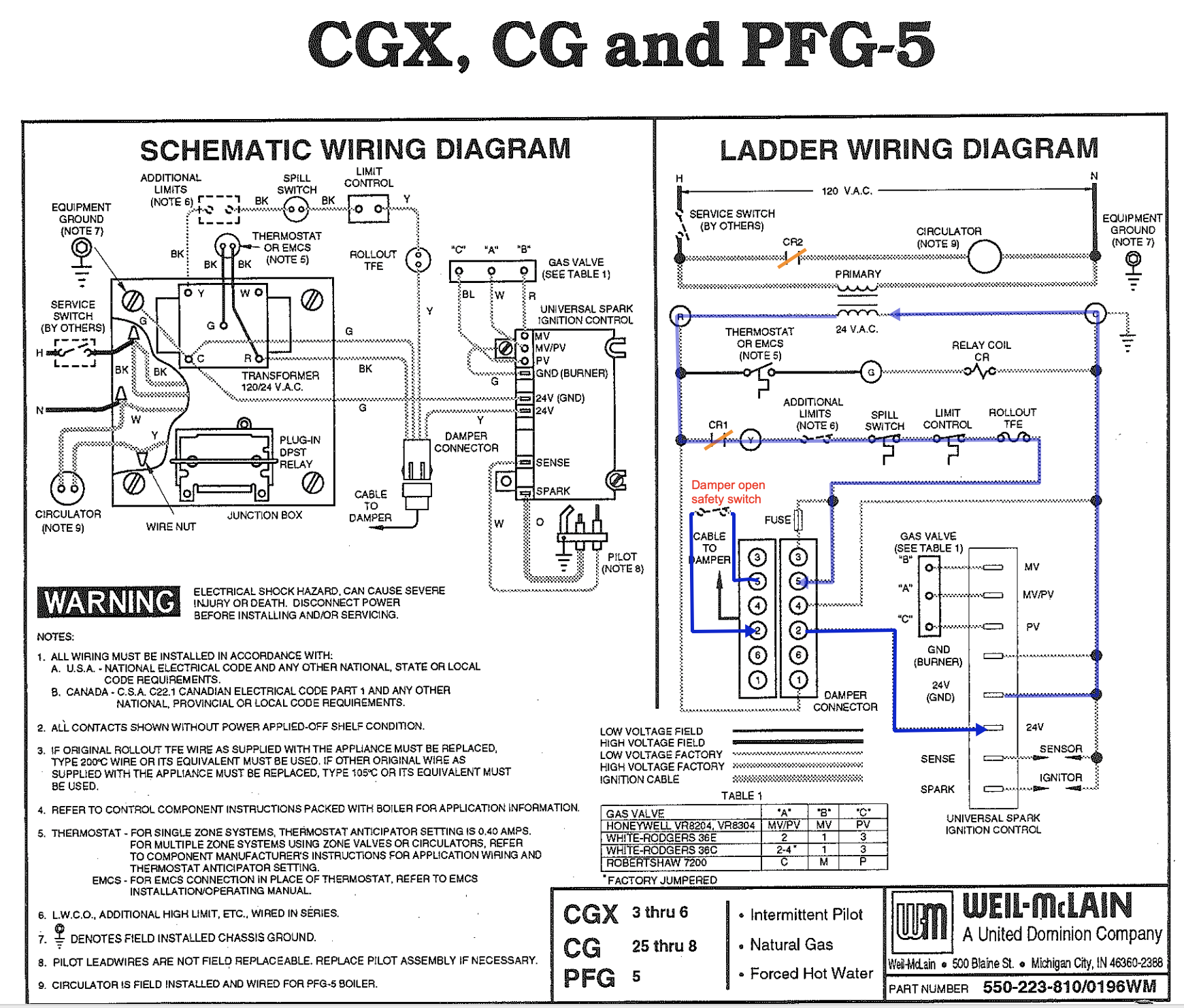

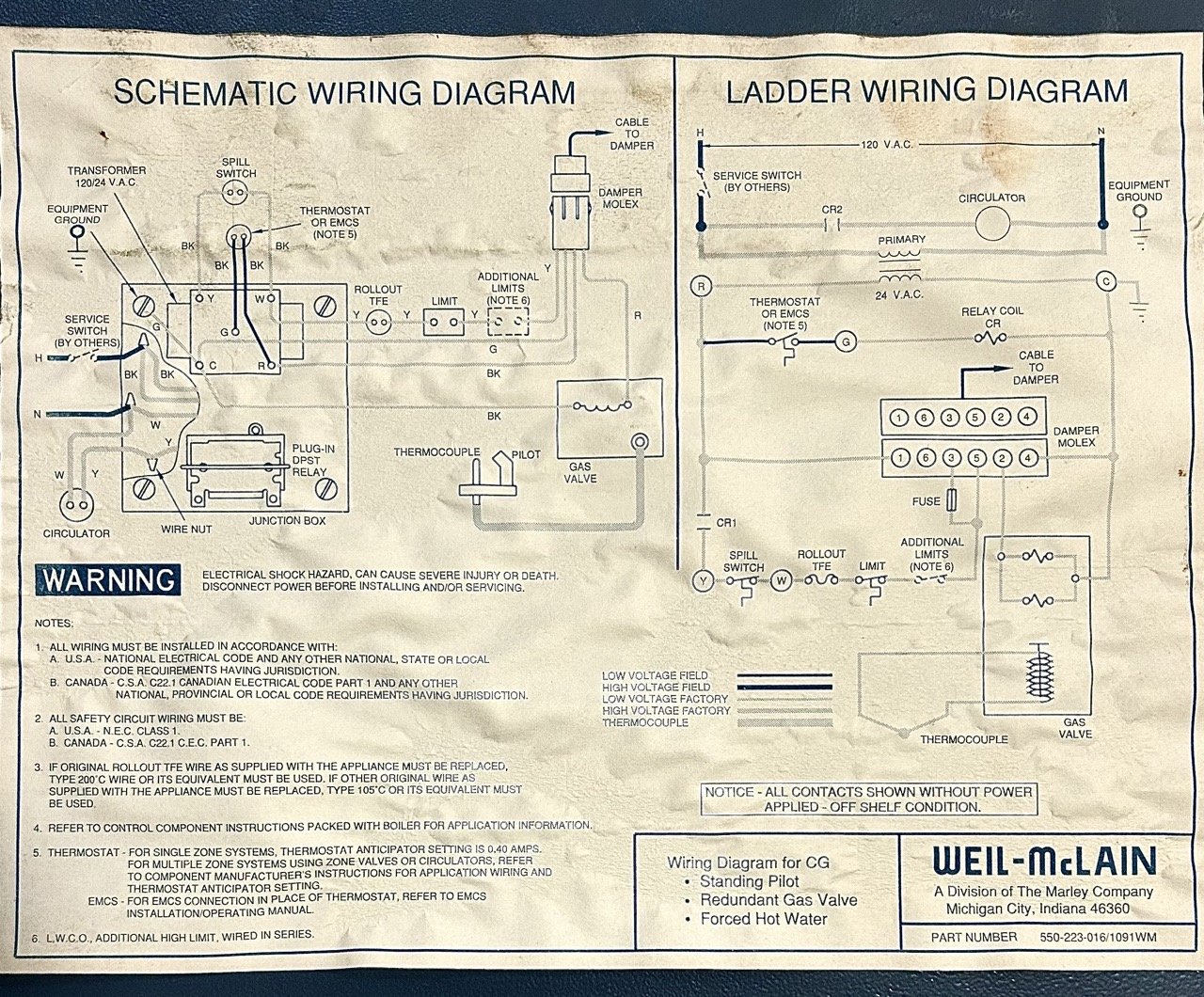

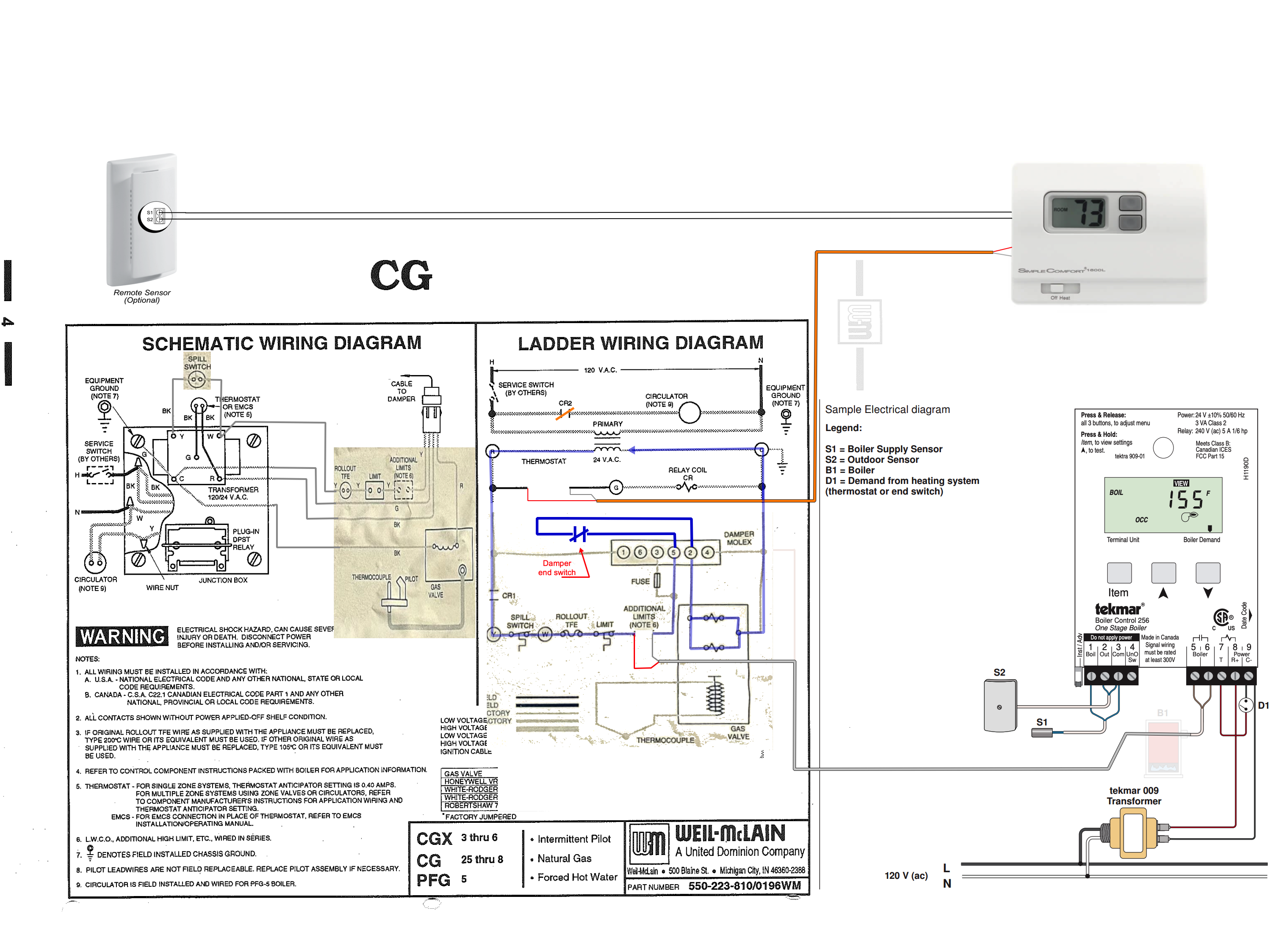

I can not be sure if this is your exact wiring diagram since I do not know if you have a WM CG-8 series 2 or series 12 or any of the other intermediate CG series boilers from WM. But it should be close enough for this explanation. I believe this is one that is close to the 1990s CG boilers from WM. So let's start with the basic diagram here

You can see how Weil McLain recommended the boiler be connected to a thermostat by looking at the purple line. It starts at 24v. transformer, then goes directly to a thermostat. From the thermostat the power continues to the relay Coil CR in the orange box. From there the power has a return path back to the 24 v. transformer. When the thermostat calls for heat and completes the circuit, the CR gets energized and closes 2 sets of contacts. CR1 and CR2. Contacts CR2 complete the circuit from 120 v. to the circulator pump. Contacts CR1 complete the 24 v. circuit thru all the safety limits to operate the burner.

There are no outdoor reset devices in the original wiring recommendations from Weil McLain. With a 4 unit building and only one zone for the entire building, I can see that overheating some rooms may become a problem. That is why someone may have decided that outdoor reset was a good idea.

In order to add outdoor reset the control that measures the boiler temperature and the outdoor temperature must be able to turn off the burner but not turn off the circulator so that control must be set in the LIMIT circuit shown in blue. The limit circuit has no control over the circulator so that pump can continue to operate regardless of the water temperature. There is a limit on the diagram that is labeled “ADDITIONAL LIMIT (SEE NOTE 6)” This is where the outdoor reset control can break the circuit to the burner without affecting the circulator operation.

I have added the automatic vent damper end switch that proves the vent damper is completely open. Once the vent damper is completely open, that safety switch completes the circuit to the burner circuit by powering the ignition control with 24 VAC. then the return path from 24 V. (GRD) is connected with a return path to the 24 v transformer source. As you can clearly see in the blue line on the diagram, all the safety devices like the high limit, spill switch, vent damper end switch, and rollout fuse are all in series with the burner circuit. If any one of the safety controls, or limits or operating controls open for any reason the burner will stop operating and that main gas valve will close.

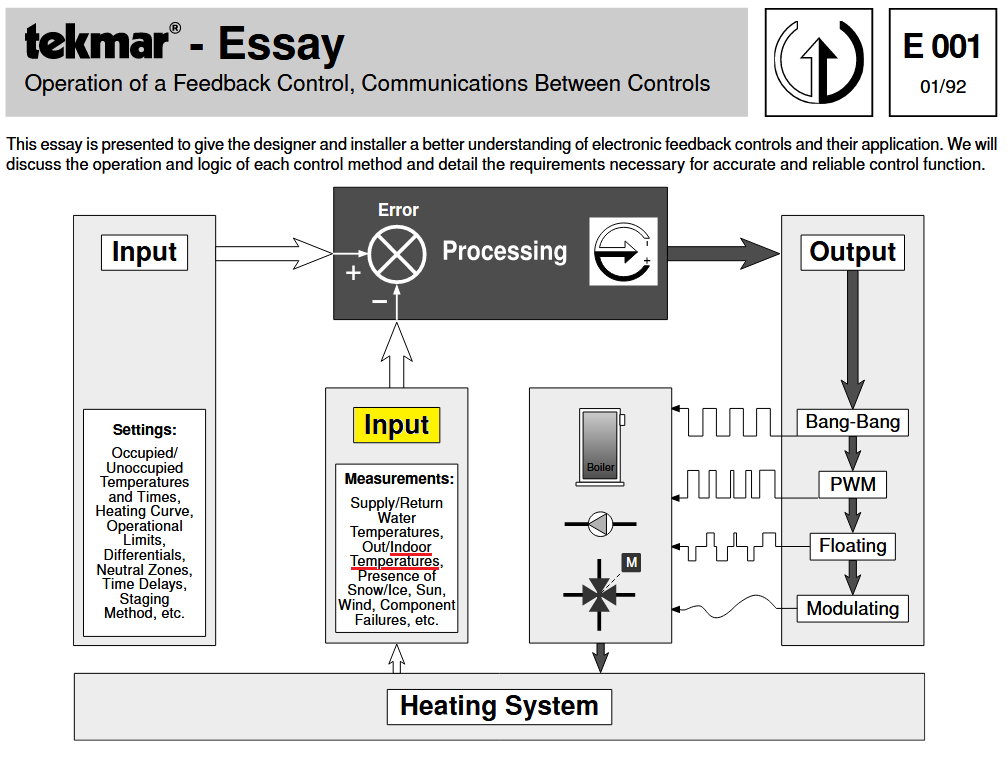

Now understanding the simple logic of outdoor reset will help you understand that input from the room temperature sensor may not be easily added to the equation. The outdoor reset measures the outdoor temperature with a resistance change from the outdoor sensor. The boiler temperature sensor is then measured the same way and added to the equation to determine the ideal temperature to shut off the burner.

The equation or Logarithm calculates the two temperatures and determines at what combination of the two temperatures the limit contacts should open or close. It is just that simple. As one temperature increases the other temperature should decrease and at that set-point of the two temperature calculation will always equal a constant number in the reset control to open the contacts or close the contacts. This is the simplest control for ODR. Here is an example of how it might work. The operator selects a desired temper combination. It might be when the outdoor temperature is 32°F the boiler temperature needs to be 170° to heat the building properly. If you add the twi numbers together you get 202°. On a 1 to 1 reset curve the number must always be 202 so when the outdoor temperature increases to 52° the boiler temperature of 150° will be sufficient to heat the building. When the outdoor temperature reaches 62° the boiler temperature will drop to 140° and the reset control will open the contacts to stop the burner.

As you can see, a 1 to 1 ratio may not be ideal so the reset curve may need to be adjusted to a 1.5 to 1 ratio or a 2 to 1 ratio depending on the conditions at that particular location. That is all the Takmar 256 does. You get to select the reset ratio and the start and stop boiler temperature based on the outdoor temperature.

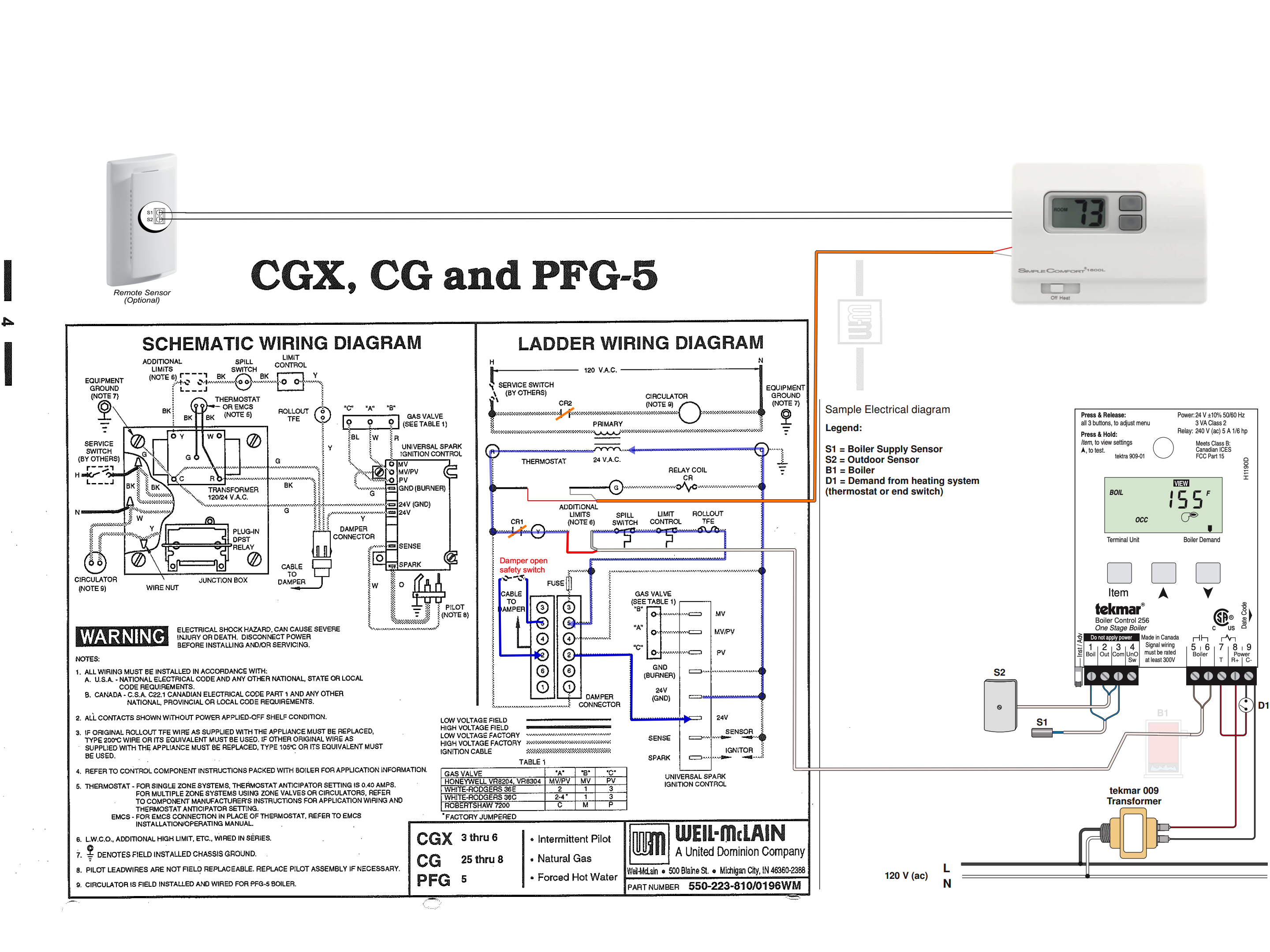

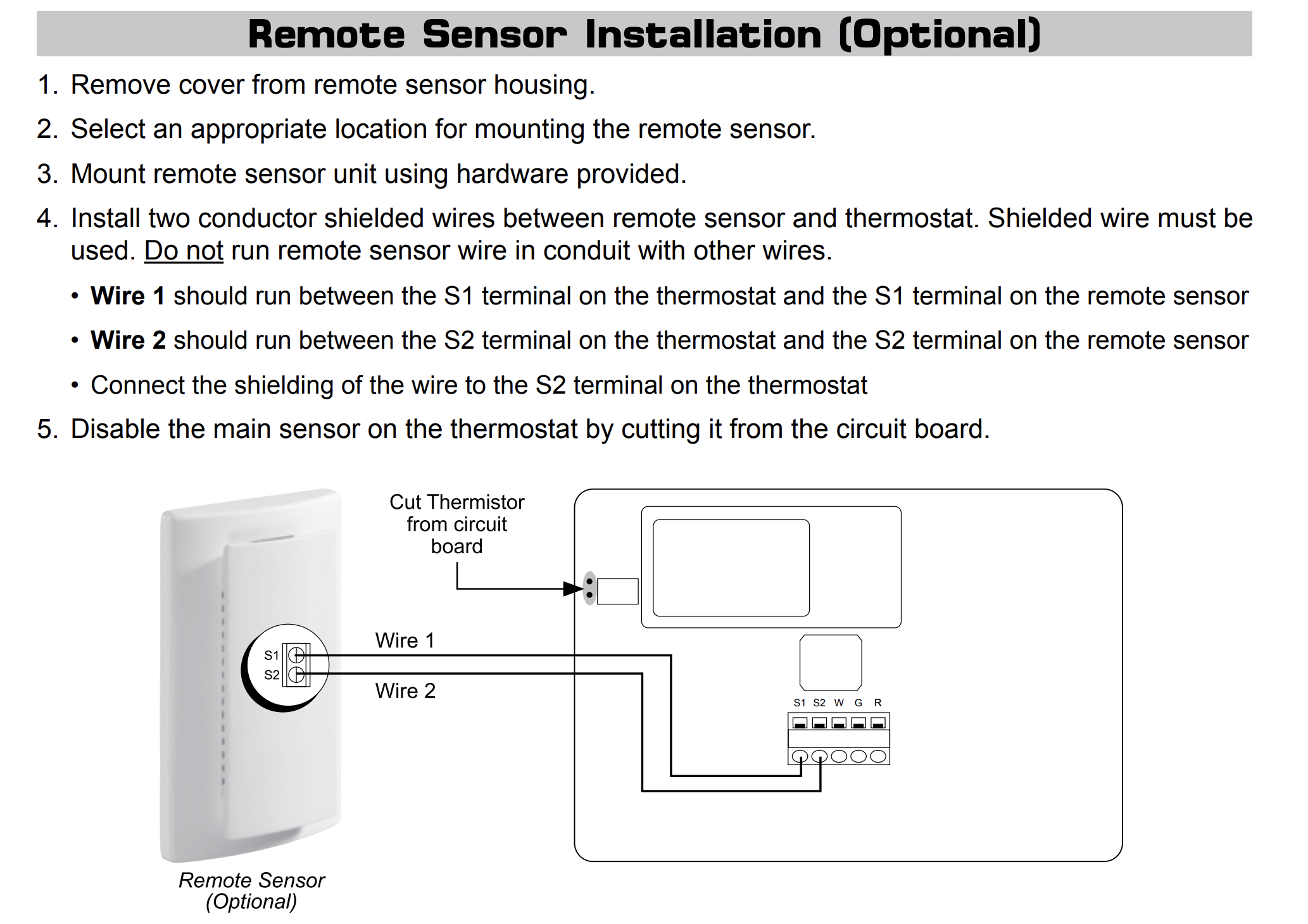

Adding the room temperature to this algorithm is doable but that control now becomes more expensive because you need the logic of the control to prioritize the room temperature over the other two temperature inputs. In your case you can just put the indoor temperature sensor in one of the rooms and connect it to a standard thermostat that can turn the circulator pump on and off, as shown in the following diagram.

here is an inexpensive room thermostat that can use a remote sensor ICM thermostat you will need to purchase the optional outdoor sensor and connect it this way: ICM remote sensor

I hope this helps

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Thank you @EdTheHeaterMan ! This is incredibly helpful! Your diagrams, links and explanations are wonderful!

I'm digging into all of this now. I've attached an image of the actual boiler plate wiring diagram, too.

The Tekmar has been in use with the ODR and pipe sensor. Circulator is always on, flue damper operates as expected.

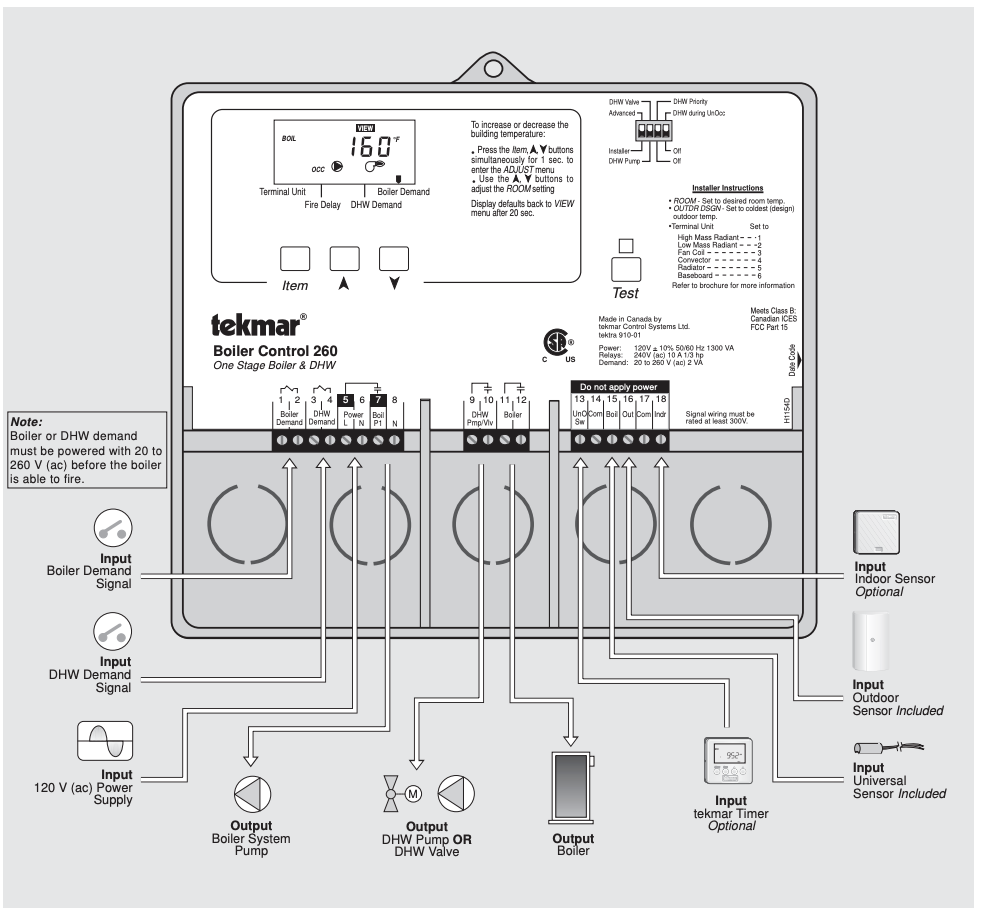

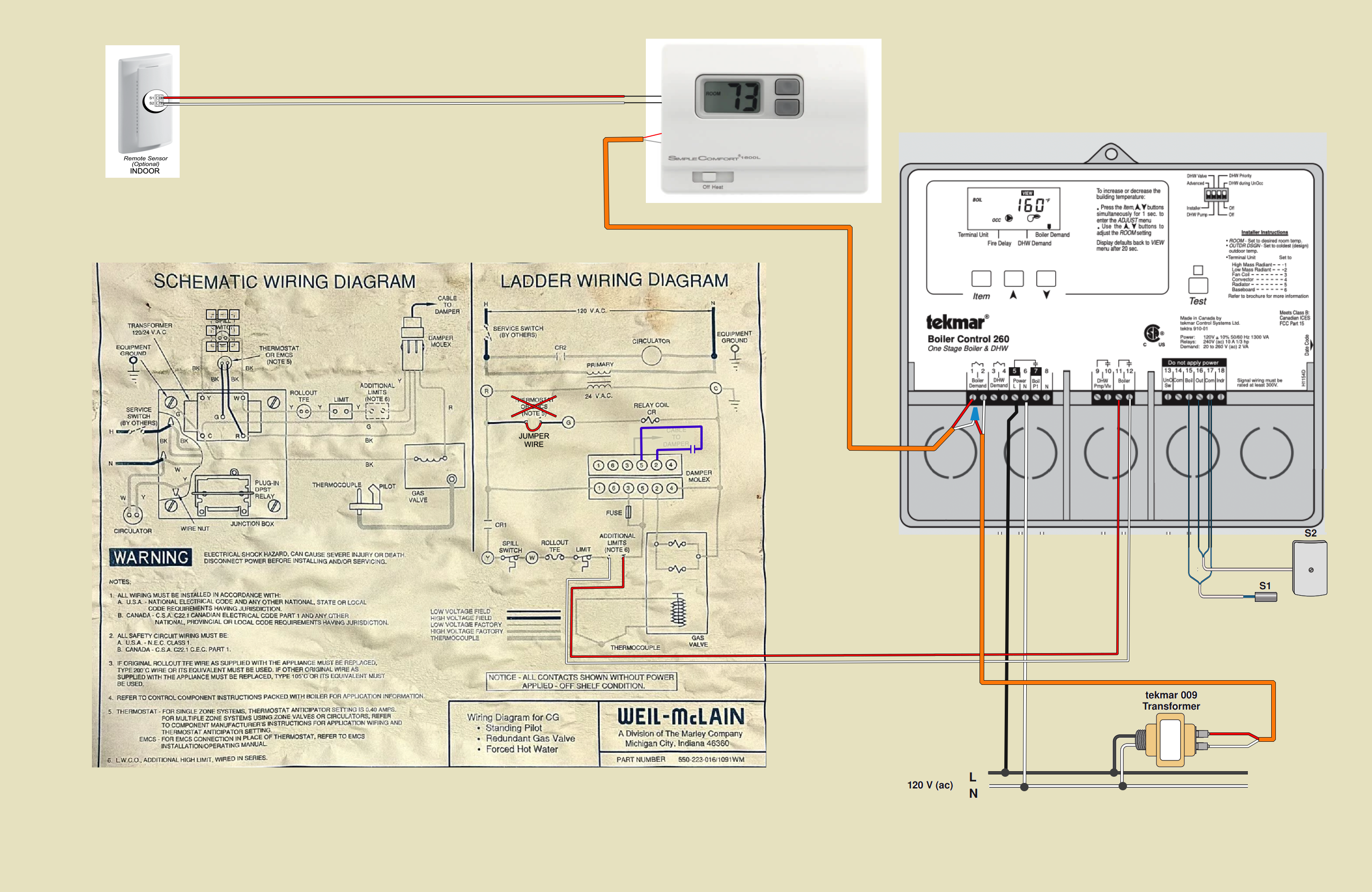

I did find a manual and pinout (below) for the Tekmar 260 which I may able to find for not much $$.

If using a remote indoor sensor connected to the INDR point, could this be a solution?

0 -

I don't believe you need the Tekmar 260. What you have will do the job

Your diagram is very similar to the one I used.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Here is the diagram for the Tekmar 260. it is almost identical to the Tekmar 256. The only change I see is that you still need a thermostat to turn on the burner. The ODR wiring is the same…

Since you still need a room thermostat I used the same thermostat as the one for the 256. I juast connected it to the 260 and placed a jumper between the R and the G on the WM CG-8. This way the circulator operates even when you are not calling for heat by the thermostat.

So you completely understand the room thermostat function in the 260. The room thermostat does not have any input to the ODR algorithm. The thermostat just turns off the Tekmar 260. (the LCD will stay lit and will read standby) If you look closely at the wire terminal 1 & 2 on the 260, that is a relay coil that will allow the ODR from the 260 to calculate the boiler temperature based on the outdoor temperature sensors connected to 15, 16, and 17. If you add a thermistor temperature sensor to 18 and 17 you can eliminate the need for a thermostat but you still need to power 1 & 2 with 24 VAC to turn on the 260, and you need to place the temperature sensor connected to 17 & 18 in a room somewhere in the building. I can draw that for you if needed.

I don't see the point of the 260 when you already have the 256.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I get the feeling the Tekmar does use the 'Demand Input' for its algorithm. Although IMO Tekmar does a very poor job of explaining the overall use of the 'Demand Input'. Since the indoor temperature is what determines the demand. In this case it is the only way the Tekmar 256 can monitor indoor temperature.

If this was my system I'd add a relay that has 2 independent output contacts, so the thermostat controls the overall use of the boiler (the boiler's thermostat connection) and the 'Demand Input' to the Tekmar 256. The Tekmar 256's boiler contacts will control the boiler's burner as described above.

More info here;

https://www.watts.com/our-story/brands/tekmar/references/essays

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements