Homeowner and plumber disagreement

Comments

-

Just one more thing

If we put the washing machine on its hottest setting. There is no water hammer.

73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

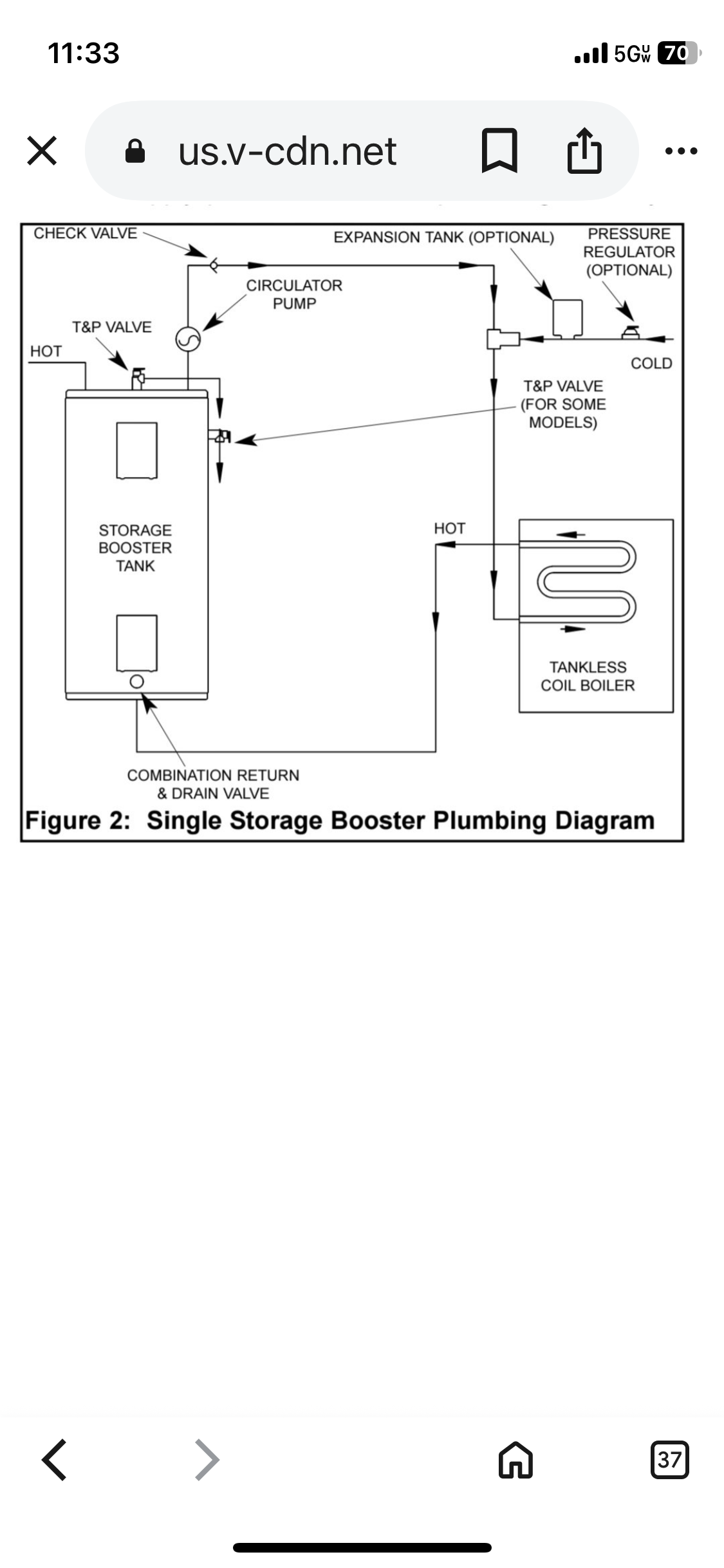

So I took a good look at the diagram posted by Hvacnut.It’s not exactly like my set up. But, it is extremely close.

Correct me if I’m wrong, but it does seem in the diagram that the expansion tank is on the cold pipe coming from the street, feeding the entire system.

Just like I thought.

Hats off to Hvacnut.

His comment, and his diagram, seem to me to be right on the money. So does anyone else agree?

73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

Keeping in mind that I have had this set up in my basement for 40+ years. There have been many plumbers over those years. Most of them have mentioned to me that the pump should be on the top. Just like in that diagram we were just talking about.That diagram is perfect. It explains everything. And I think that’s what should’ve been done.

But now I’m stuck with what I got. A pissed off plumber.

And a house that’s banging and banging and banging.

73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

What i want to know is where the cold comes in and the hot goes out and how it is routed to figure out if it is ghost flow within the same pipe or between 2 different pipes. If it is just from gravity then a pipe loop should stop it. If the circulator for the aqua booster is pushing it between 2 different cold water pipes then it probably needs a mechanical check valve.

0 -

HvacnutI believe you are exactly right. One check valve. Right before the pump. Makes a whole Lotta sense to me. And additionally, your suggestion to move the pressure tank to the cold side. I also think is correct. Where exactly would you move that pressure tank . My thoughts are to move it just above the red handled shut off valve. That’s the pipe that brings the cold water in from the street.

Does that sound about right to you?

from steam rookie

it sure does. Thank you very much. Thank you for the diagram and thank you for saying I’m right.73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

If it goes all the way back to the service before anything branches off, it is probably gravity ghost flow from just having essentially boiler hot water below the riser with the red handle valve and putting a deep loop in that riser would stop the ghost flow.

The hammer is only in the cold pipes because the hot pipes have free access to the expansion tank, there is no check valve to slam shut when the pressure drops back down after it briefly surges up.

0 -

Mattmia2

What do you think about the diagram and comment from Hvacnut

73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

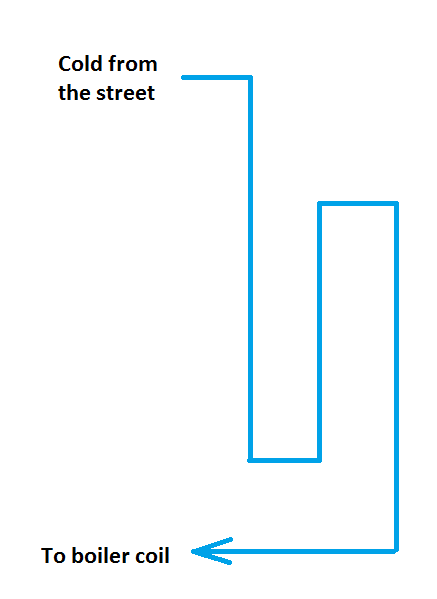

I think that @HVACNUT knows way more than I do so that is the correct way do to an aquabooster, but I don't think that your problem is with the aquabooster but that where the cold connection is tapped in, it makes a good thermal syphon to bring the hot water in to the cold supply. It has very hot boiler heated water at the bottom of a tall riser to the cold supply, that is the perfect condition for gravity circulation within that pipe. 90 it down where it tees off the tankless coil, loop it down to the floor, then bring it up or loop it 360 to the floor and connect the cold there if you want to be extra cautious and the need for the check valve and expansion tank goes away.

0 -

something like this

0 -

Unless you put a tire gauge on the ThermTrol you don’t know what the pre charge is, lower the system pressure and check it yourself.

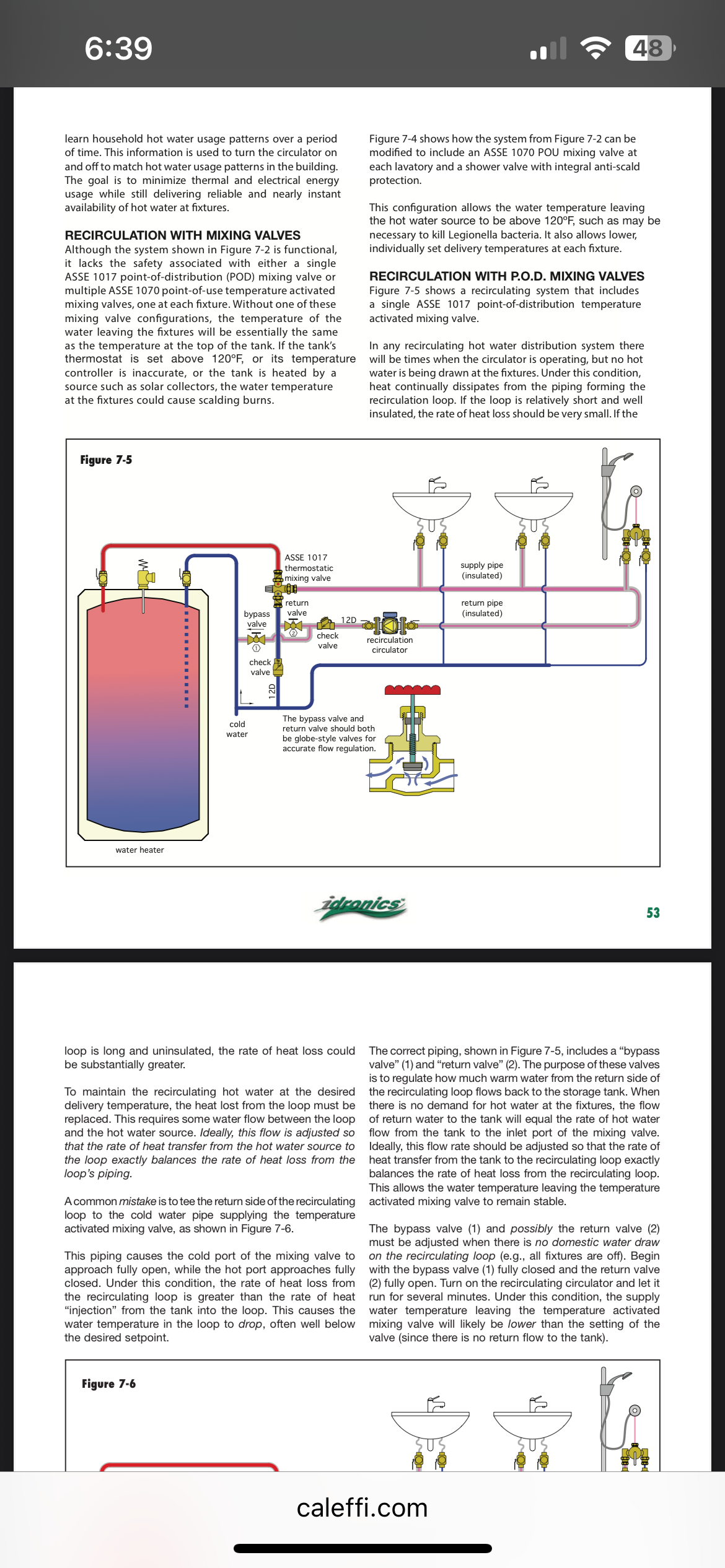

there is a specific way that a 3 way mix valve needs to be plumbed when a recirc pump is usedWhat ends up happening is recirc water enters the cold port of the mix valve and then the valve is unable to adjust. The cold port needs to see cold water not blended warm. You end up with temperature creep and the hot outlet from the mix valve will be the temperature of the tank or coil. .Ill attach a drawing

Also, 3 way valves do not necessarily need to have check valves on the h&c if they are plumbed properly

More about DHW systems here and a screen shot of the recirc piping This shows a building recirc, I think the loop from coil to tank would behave the same.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

the thermostatic valve, if plumbed right, is on the outlet of the tank to the dhw system, the circulator should be circulating full temp tankless water directly in to the storage tank.

you would turn off the supply to dhw then open a hot water faucet to relieve pressure, then check the precharge on the expansion tank. it should match the pressure from the street.

0 -

IMO where this all went horribly wrong was the plumber's desire to re-engineer a system that worked fine for decades. He should have just come in, did some troubleshooting, and repaired / replaced whatever changed causing the ORIGINAL problem. Now with the newly engineered system there are worse problems that did not exist before.

With all the check valves and a NEW added pressure source (the air in the expansion tank on the Hot water side) you have issues. Normally an air cushion helps minimize water hammer. In this case it maybe helping to cause it.

Two old school things to minimize water hammer, larger piping reducing the flow velocity in the piping, using 3/4 inch pipe instead of 1/2 inch pipe and simple pipe based air cushion.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

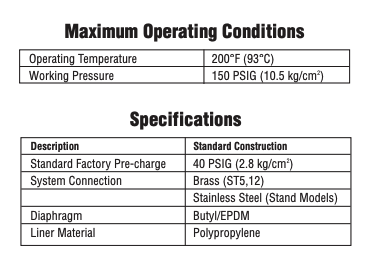

If you and or the plumber expect the expansion tank to work you need to do the following.

Look on the tank. They do come pre pressurized. But the pressure in the tank (with no water pressure on the bladder) has to match the pressure in the city water main. If they don't match the expansion tank will not work.

I would get rid of the mix valve and the check valve in the cold water going to the mix valve. Leave the other two check valves.

0 -

water hammer generally starts when a fast acting valve suddenly stops flow. The higher the velocity, speed of the flow, the higher the potential for hammer

So you may have two issues, high flow and a valve slamming quickly closed. Aka a swing check.

Water hammer arrestors really need to be at the point where the hsmmer is starting. An arresters 10’ or any distance has lost the ability to catch that shock wave, adequately

That is why there are so many versions of arresters for washers, dishwashers , ice makers, etc

Regardless, treat the problem not the symptom, an arrester treats the symptom. Find the cause of the hammer, plenty of systems like this work without issues. As you already know

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Hello everyone, I’m back again.

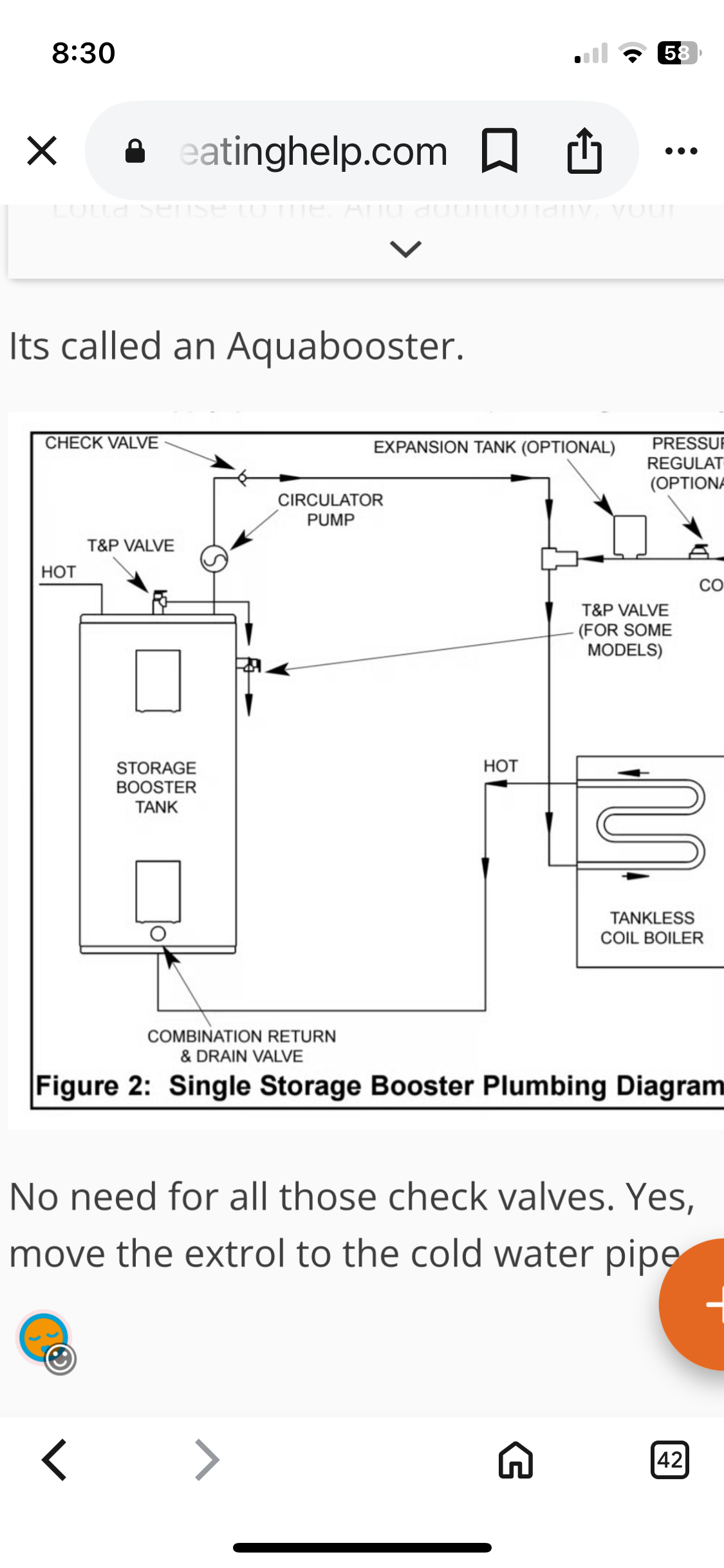

Hvacnut is totally correct. The system that I have is called an

“Aquabooster”.

I have researched this system on the Internet. Because the Internet, and all of you guys on this website, are all that I have to go by. I have no formal plumbing training, and very little experience. Yes, it is true that I am very handy. But that is no replacement for an actual experienced licensed plumber.

I know my limitations. And when the hot water started mixing with the cold water, I had no idea what to do. So I did what I thought was the smart thing. I called in a very experienced licensed plumber.

This turned out to be a very depressing situation. I don’t know much, but I think I know enough to know when something is wrong. When the plumber left, I called him the very next day to tell him I now had a new problem. I told him that I did not believe that the pressure tank was installed correctly. I told him that I was now experiencing intense waterhammer all throughout the house. I told him that I did not think the mixing valve that he installed was working at all.

I told him that his idea of throttling the ball valve directly before the mixing valve seemed wrong to me. And I told him that removing the handle and leaving it on top of my water heater seemed wrong to me. Was I supposed to just leave the handle laying there on top of the water heater forever?

Anyway, his solution to all of this was for me to buy another big box of expensive parts. This box would be including three more ball valves, and an industrial sized hammer arrester.All to be installed behind my washing machine. None of that solution seemed right to me.

He told me that he would only do it his way. And he told me if I didn’t like it. “Good luck”.

Honestly, none of that seemed right to me either.

Now I am stuck with a very expensive repair and none of it seems to be working correctly. And has caused more problems than before he came.

I am very stressed out. I am also very depressed. And I am also very disappointed in the way this plumber talk to me.

The photo from “Hvacnut”tells it all.

Plus a few more that I found on the Internet.All of these photos show the pressure tank correctly positioned in the vertical position. All of these photos show the pressure tank on the cold water supply to the system before anything else.

All of these photos show the work that he did is wrong.

So the bottom line is, I guess I’m going to have to do this work myself. I do not know if I can reuse the pressure tank. I might have to buy a new one. I also do not know if I can remove the mixing valve in a way that it can be returned. Seems unlikely.

I am going to dive in. And move that pressure tank to where it should be in my opinion and apparently pretty much everybody else’s.

Please wish me luck in this endeavor. I will post before and after pictures. And of course, whether or not it was successful.

Signing this note off, extremely depressed, extremely stressed out, and extremely disappointed.

All of this, because of the plumber that I hired.

Thank you for all the replies. They convinced me that I am correct.

I don’t know what kind of recourse I have against this Plumber.

I guess I’m going to wait until I change everything around and see if it works.

Any additional words of advice would be very helpful to me

73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

there are a number of States that require a listed thermostatic mix valve on any DHW device. If you are in one of those States a licensed plumber would be required to install one.

The mix valve can both protect against scalding and also extend the amount of DHW available.

There is not much you can do to damage an expansion tank. Is there is any air pressure at all when you depress the tire stem on the end, the tank is fine.

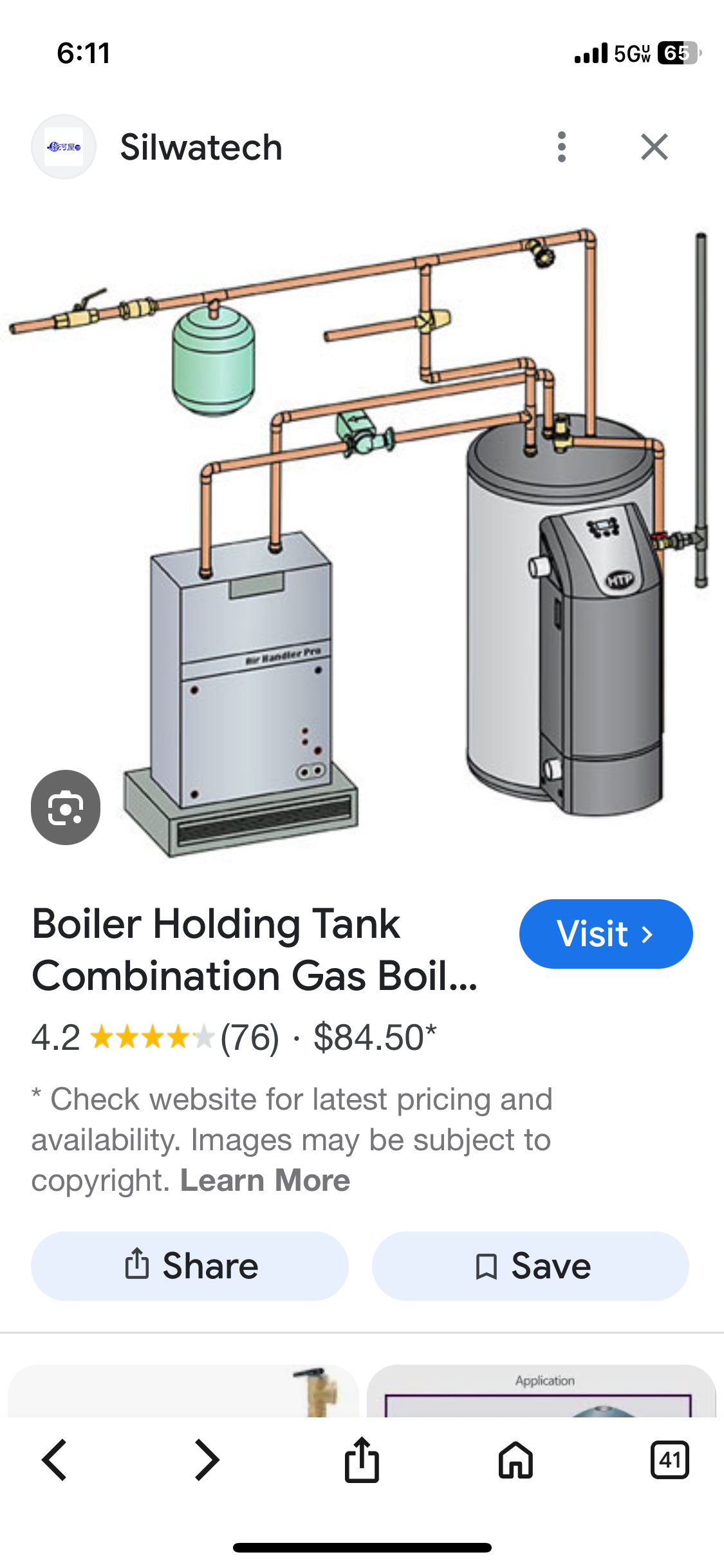

DHW tanks typically go on the cold supply, but anywhere in the loop before check valves, they will work. Think of it as a spring in the system, it responded to pressure change created by expansion of the water as it is heated.

In that fig2 above, that system would not even require a thermal expansion tank unless the cold supply had a check or backflow preventer on the cold supply to the building. That is why the note shows “optional”

But it is a wise idea to install an expansion tank, as the water providers are adding BFD to most systems nowadays for liability reasons.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Hot_rod

Thank you for the reply.

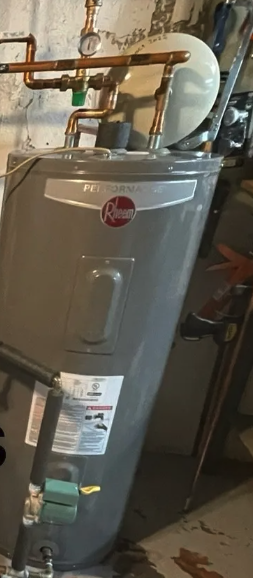

“DHW tanks typically go on the cold supply, but anywhere in the loop before check valves, they will work”.

According to your statement. He has it on the hot pipe. It is also after at least two check valves, as apposed to before them.

My plan is to move it on the cold water coming in from the street.

Just above the red handled, shut off valve.

That cold water supply from the street is connected to the “loop”.

Photo shows where.

Tell me what you think.

73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

where "before the check valve" is depends on your perspective. the expansion tank and the water that is being heated in the tankless coil and the storage tank have to be on the same side of the check valve. in this case they

what the plumber did isn't exactly wrong but they didn't diagnose the problem correctly. I am pretty sure you were getting thermosiphoning/gravity flow out of that hot water pipe in to the cold water supply, not the circulator for the aquabooster forcing the water in to the cold water system. they solved the wrong problem using types of check valves that are noisy.

i think they own the problem now and some of the check valves they added are redundant if that mixing valve has integrated check valves which most do but what they did wasn't wrong per se. the extra check valves gives you more places for potential noise from the check valves.

i'm also not sure why the plumber didn't supply the parts, that makes responsibility more tricky, especially if it was your idea to supply the parts.

0 -

he gave me a list of parts to order.

told me to let him know when they get there.

he is doing the same thing for his “fix” behind the washing machine.

he wants me to order another shitload of parts to be installed at my cost.73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

I can certainly understand why your stressed out and unhappy with the plumber. Anyone would.

The way I understand your problem as it now exists is that you have a water hammer problem. Nobody knows what is causing this but my suspicion is that it is a check valve issue.

Moving the expansion tank will not fix the water hammer IMHO I don't think it will have any effect on your system. Yes it should have been installed vertical and the air pressure in the tank must be set to the city water pressure to operate properly. And it should be on the CW line but IMHO that is not causing your issues.

Why no one besides me has mentioned this I don't know as most are aware of this. (proper expansion tank air pressure)

Not trying to add to your stress but I hate to see you do all this work and end up with the same issue.

1 -

thermosiphoning I’ve seen this word a lot. Could be, but the mixing always began when the Taco pump would go on.

Also “depends on your perspective”.

From my perspective,

That cold water coming from the street dumps directly into the hot water loop. Just inches downstream from that pump.

73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

the "before" and "after" the check valve depends on your perspective, what part of the system you are looking at it from.

@EBEBRATT-Ed i think i rementioned the precharge on the expansion tank a time or 2 in with other things.

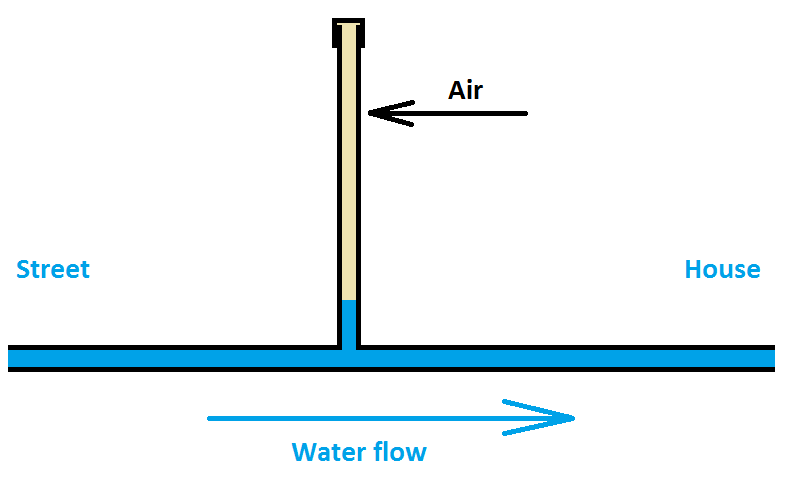

i think what was happening was that when there was boiler temp water at the bottom of that ~3' riser in the feed to the tankless coil the stack effect from the height of the pipe was making the hot water at the bottom circulate to the cold water pipe at the top. there are less invasive ways to solve that.

0 -

@steam-rookie A few days ago you wrote;

" That Hot Water could be felt all the way to the street. "

What exactly did this mean ?

I fear since the cause of the original issue was not thoroughly understood, it still may still exist just hiding behind check valves that are causing other new issues.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Focus on just this part of the system. The tank and the tank :)

The HW tank can "communicate" with the expansion vessel through a few inches of 3/4 copper tube, an FIP adapter and the tee. That looks like a brass 3/4 X FIP tee that the tank screws into?

I don't see any check between the top of the HW tank and the tee connection for the expansion vessel? Is that true?

That being said the HW tank probably has heat trapper nipples on H&C. Red and Blue. They have a small ball or rubber flapper to prevent thermosiphoning. But they are not a 100% bubble-free seal, so expansion should push by.

So the only way the expansion vessel could not accept that expanded volume as the tank is heated, is if it did not have any air charge, was completely waterlogged? Usually you can shake the tank a little and determine if it is empty or full of water. Looks like someone wrote a pre-charge pressure on the tank? Or is that an install date? I always wrote the pre-charge that I put into the tank for the next service person to know. I have heard of new expansion tanks coming out of the box with 0 psi. The schrader valve leaked the pre-charge out.

I believe in California the tanks cannot be shipped with over 30, maybe 40 psi? @Larry Weingarten would know. So most every tank needs to be adjusted.

If for some reason incoming water pressure gets elevated, the tank pre-charge should be matched. That expansion tank has plenty of capacity for your system even if pre charge is off a few psi.

I agree with others IF the tank is pre-charged properly, regardless of the connection location, this is not the water hammer gremlin.

My money is on the swing checks, get them out and I'll bet the problem goes away.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Hi, @hot_rod is right. I understand it is a DOT rule that limits things to 40 psi. I can't see it from the photo, but I'd want a shut-off between that expansion tank and the rest of the system. I like to use stop and waste ball valves, so the pressure can be released easily for recharging the tank.

Yours, Larry

0 -

" Everything has always worked fine. Until one day my hot water started mixing with the cold water. I called the plumber to fix this problem. "

" But it is just a replacement for a tank that was there for 30 years. The plumber did not do the tank replacement. That was done a few years ago. "

The problem I have with the with the thermosyphoning theory is, if so why did it just recently start ? Why was it not happening for decades ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I may be mistaken because it is hard to see in the older picture, but I think the galvanized cold water piping was replaced with copper relatively recently.

0 -

hot and cold mixing could be caused by a single handle tub shower valve, or a cross connection at a laundry tray. @Larry Weingarten has a simple method to determine if you have a crossover somewhere in the piping

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

If i'm following right the numerous check valves did fix the hot water in the cold problem, it just caused a new problem with the check valve slamming shut.

0 -

@mattmia2 Looking at the pictures I would say the galvanized may have went away with the 30 year old tank. With the installation of the Rheem the galvanized was removed and replaced with copper, however the galvanized may have been removed at some other point in time.

If the original complaint started at the time the galvanized was replaced the thermosyphoning theory may be much more plausible, since the galvanized may have been very restricted, where the new copper is not.

I don't have a good time line of all the events, so I keep circling back to what changed when the original complaint started, is it an unknown or known (but not realized) change ?

If the problem actually started when the galvanized went away, a pipe configuration like this may have helped, I think you already mentioned a strategy like this.

I do wonder what @steam-rookie meant by;

" That Hot Water could be felt all the way to the street. "

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Some fixtures have anti-scald features. If that has a leak hot to cold the circulator may cause a parasitic flow through the leak.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Hi, There is a lot going on and I see a lot of things done poorly… not in a workmanlike manner as a plumber is supposed to know how to do. A general approach I'd follow in fixing this is to start with a crossover test. This lets you know if cold can leak into hot, or visa versa. Simply turn off power to the pump first. Then close the cold feed to the tank. Now open a hot only tap. It should run for a second or two, then stop. With the expansion tank you have it might run quite a bit longer, but still it should stop running. If it doesn't stop, cold is leaking into the hot side. For this discussion, let's assume no leak. Next thing is placement of the expansion tank. Installed correctly, it should never see hot water. This will only degrade the rubber in it faster. Also tanks are pre-charged to 40 psi per shipping rules. The tank MUST be brought up to your system static pressure, or it cannot work as it should. Good plumbers know this. I would install it as others have said downstream of the red main shut off. A spring check needs to go just after that valve and then the expansion tank can go in. Do make sure there is a shut off with a waste in the line to the expansion tank. Now you can get rid of the two check valves in the cold supply, (one going to the mixer and one in the main supply). This way, thermal expansion is taken care of and one swing check is removed. Test now for water hammer. Any better? While you're working with this, a few other things jump out at me. Plain Romex, not in conduit, is not acceptable in my area. It's viewed as a safety hazard. There are no unions on top of the tank. What will need to be done to change out that tank when it's time? Fittings are pretty close together, so it will be a pain. I'd replace the swing check near the pump with a spring check. It will likely help quiet things. Once everything is behaving, insulate all of the lines properly. A good job will look clean and prevent a lot of waste. Insulate at least five feet back on the cold side too. Does this all make sense? 🤔

Yours, Larry

0 -

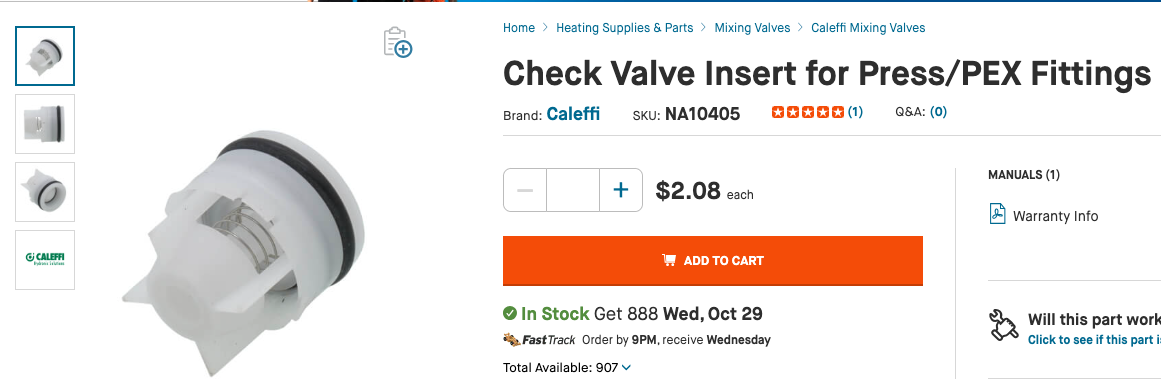

This is the type of check to look for. It has a conical flow friendly shape, rubber sealing surface, high Cv and low pop pressure. This is the check that you find in circulators now, most mix valves and many other plumbing and heating applications.

A serviceable check is a good option, they do get crud in them, from time to time. Or you may need to replace the check assembly some day.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Just to be clear, the diaphragm in the tank is rated to 200F, same as the hydronic tanks. So in the cold line if you can, but hot line is not a deal breaker.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Hi @hot_rod , I may be overly cautious about this. I've had the experience of degrading rubber from these tanks getting into the hot tap water as tiny black bits. That tank really should have a stop and waste on it. Perhaps creating a pipe heat trap also will help it to live a long and prosperous life. 🖖

Yours, Larry

0 -

rubber degradation on a dhw tank may be more water quality. Like toilet tank flappers

The EPDM diaphragms should be perioxide cured for best chemical resistance. Chlorine and chloramine can be tough on many rubbers. Especially over doses

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.2K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 59 Biomass

- 427 Carbon Monoxide Awareness

- 118 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.7K Gas Heating

- 111 Geothermal

- 163 Indoor-Air Quality

- 3.7K Oil Heating

- 73 Pipe Deterioration

- 1K Plumbing

- 6.4K Radiant Heating

- 393 Solar

- 15.5K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 49 Job Opportunities

- 18 Recall Announcements