Replace / Convert 4-way Mixing Valve to Automatic

Hello! I have a oil boiler that feeds a 6-zone radiant heat system. If possible, I would like to replace the manual actuator on this 4 way mixing valve with a motorized one that is automatically controlled to regulate the water temperature in the radiant heating loop.

What is the most economical way to get there?

I have a shared album with pictures of the setup here

Thanks!

Comments

-

this tekmar looks suspiciously like a Belimo brand. The color and country of origin give it away.

You might check them for pricing.

You also need the control to run it.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks - so can I just leave the existing mixing valve hooked up and swap out the actuator somehow? How?

As for a control to run it, do I need a Tekmar 360 or something like it? Or is there something…cheaper…that will do the job?

0 -

Instructions attached. The actuator is 24volt floating operation 3 wire drives closed drives open. I would call Tek mar and ask about a compatible control.

Penn Johnson makes a good control a system 450 available for about $200 that should do what you need. Supply House.com has them as well as the install manual you can refer to

0 -

So, I am learning a bit with your help and the help of the internet and some AI. 🙄

From what I can tell (and from what its installation instructions say), the Tekmar 743 is "compatible with tekmar brass mixing valves 710 to 724." What I have is a tekmar cast iron valve, model 017. So I am not sure if it is compatible?

"The internet" / AI thinks that to work with my 017 valve I'll need an M3061 adaptor kit and a GMB240-3 or Tekmar M3062 actuator. Is that true?

0 -

Cost wise…

It looks like the 743 would run me about $450. The M3061 + GMB240-3 close to $400 + $150 (if really available…seems iffy; or even more for tekmar M3062).

I had been thinking I would need a Tekmar 360 control, ~$650. If the System 450 C450CBN-4C for ~$200 will work about as well, that would be nice.

All of this is adding up to a bit more than I was hoping, but not quite "out of the question" range at this point.

0 -

I would call Tekmar and see what they say. The internet is sometimes full of rabbit holes.

0 -

OK, I will try to reach out to Tekmar. In the meantime, if anyone has experience putting a motorized actuator on tekmar cast iron mixing valves (specifically valve models 016 through 026), please let me know!

0 -

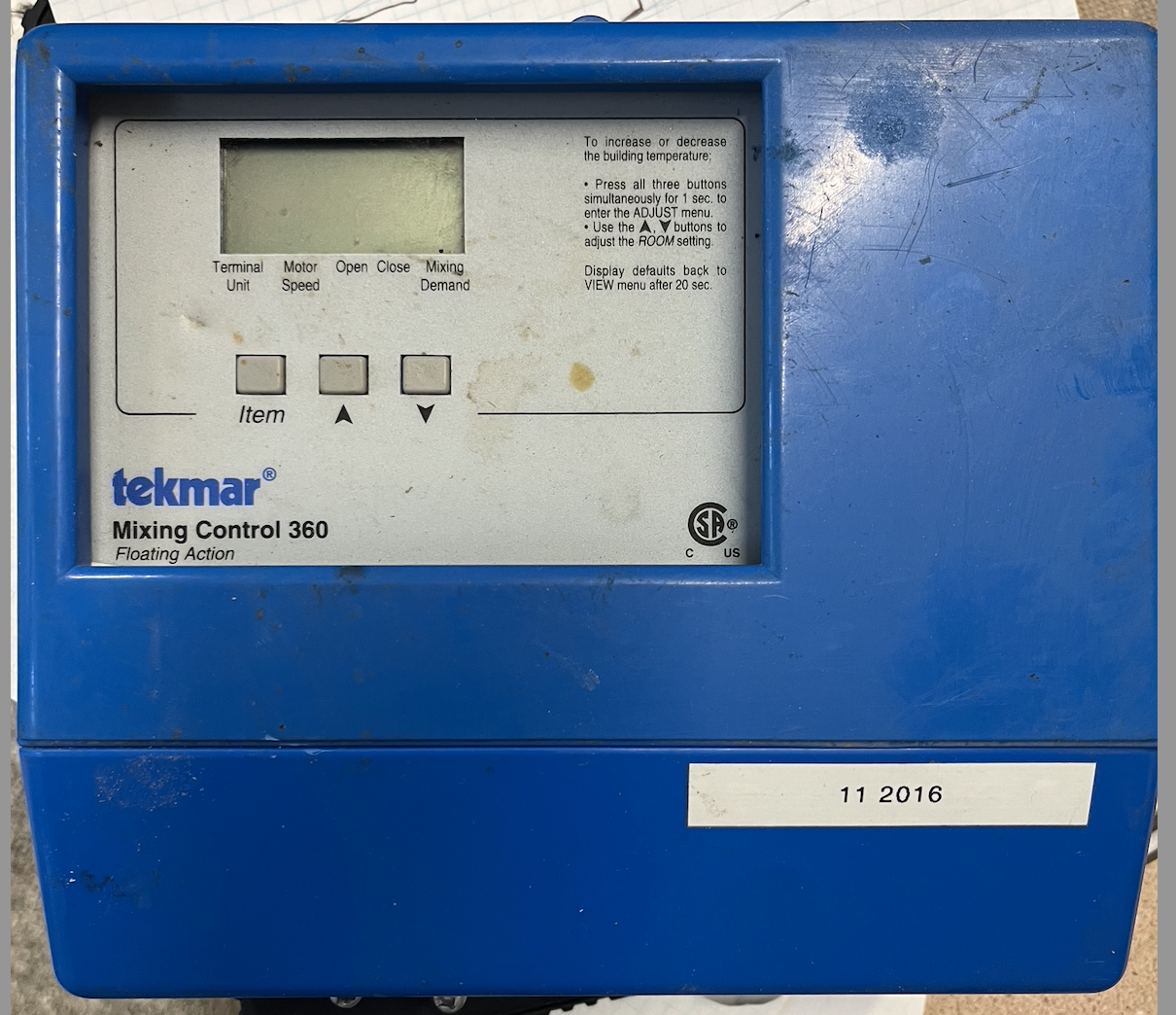

Somewhere on this site a fellow bought a new 360 to replace his and it wasn't the problem. Maybe cut a deal with him.

E-bay has various actuators and controls from time to time. If you shop I'll bet you can get the actuator and control in the $5-600 range

There is no bargin price actuator and control that I have found.

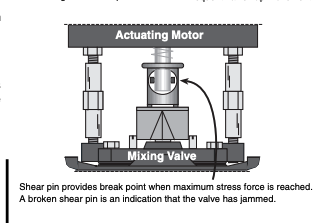

The bolt pattern from brand to brand are fairly consistent. Actuator manufacturers have the adapter kits to mount. Shown is a Danfoss/ Esbe, and tekmar mounting instructions

HBX, Danfoss, Belimo, tekmar are other options for controls.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Below is what Tekmar said…emphasis added in bold. Basically they say no-go on using the 743 to actuate the 017 mixing valve. :( For reference, even if it would mount on the valve (and they say it won't), the 743 has 88 in-lbs of torque, whereas the recommended M3062 (aka GMB24-3) has 360 in-lbs. So I guess that's what I am left with, unless an old Actuating Motor 011 (now discontinued) can be found somewhere.

Tekmar Support says: "The 743 will not work on the 017, it is meant for our newer brass mixing valves. It has different mounting and would likely not have enough torque to turn the 017. Our solution for the older steel valves is a mounting kit M3061 and a Belimo GMB24-3 Actuator M3062…. I don’t know anything about the Johnson Controls device but the Belimo is what’s referred to as a floating action actuator. It has electrical connections for forward and reverse so controls would pulse it once to open then check temperature then pulse it open or closed as needed to maintain the controls desired supply temperature."

0 -

I would try and find an actuator for the valve you have trying what @hot_rod said. Belimo is pretty pricy. You may want to scrap the whole thing (valve and actuator)

0 -

its getting complicated. You would need to shop an adapter kit, newer actuator, and the control

Might look at the Taco valve that has the control built in. Probably a tekmar brain in it🤔

I don’t think it has as much adjustability as the 360 but it may be enough

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Is the juice worth the squeeze?

Maybe you become the ODR ? Manually change the valve throughout the season as loads change

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Good question, I was hoping it would be easer! That said, manual adjustment with this thing has proven to be difficult. I found it to be a very course adjustment (fairly small move of the lever changes the loop temp quite a bit), and more importantly the loop temperature changes a lot depending on the actual conditions (such as how many zones are calling for flow, temperature in the house which impacts the return temp that's mixed in, and where the boiler is in its cycle).

What I am primarily wanting is something to regulate/control the temperature of the water in the radiant heating loop, with ODR just being a potential bonus that comes along with it.

0 -

Then yes, a motorized, controlled 4 way is the best device to accomplish that. With mod con boilers being so popular the 4 way valve market has dropped off. There used to be a handful of brands and sources, most of the pex manufacturers had a 4 way mix station in the offering. No so much anymore.

I'll bet a tekmar rep somewhere in the US has some old inventory on the shelf. I know Rathe Associates on L.I. has a large room full of tekmar stock.

I have a 360, been in a drawer for years. I'll power it up and check it. You are welcomed to it for freight cost. Maybe shop around for the 011 first?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

That is very kind of you to offer! If it's in working condition, I will take you up on that if you're sure. I will hunt around for old 011s…and if it comes down to it I'll have to get one of the M3062s. Presumably I'll also need an M3022 seal kit? As well as some temperature sensors to plug into the 360? What would you recommend for those?

0 -

Side question - the quality of the water in my heating loops does not seem good - it's very dark colored. I also have a couple of zones that seem to have restricted flow (one isn't getting any flow). Would you recommend I flush the system out along with this other work?

0 -

For sure clean and flush that black water. Bad fluid makes those old style 4 way hard to turn and can breal the coupler or actuator. It should rotate freely, stiff but free.

This kit works well, run the cleaner for a few days, hot. Flush, refill and squirt in the conditioner.

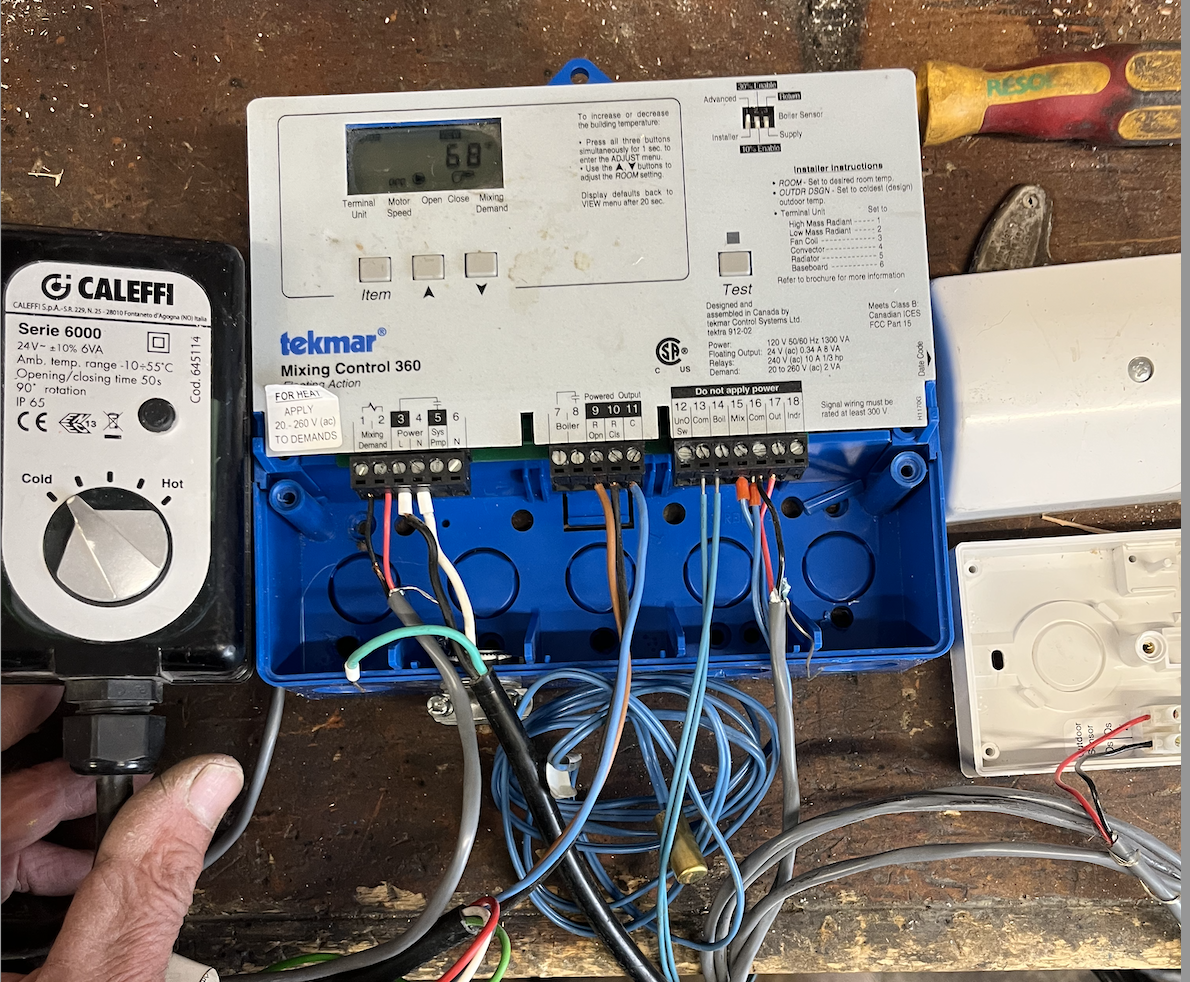

The control works fine, motors the actuator open and closed.

I have an outdoor sensor and two of the strap on universal.

One note, you need to send power to this control #1 &2 to get it to turn on. 20- 240V. That gets missed a lot so they added these white stickers :)

AND 120V power to 3&4 to power the control and any pumps or devices you wire to it. 5&6 will be that switched 120V that the radiant pump typically wires to. #1-6 are the only place line voltage connects!

9,10 & 11 is where the actuator wires, the actuator wires will be marked open, close, and common

Sensors go on 13-17, and yes you are short one common, I never understood why that is? No issue with two wires under one com. If you use stranded wire make sure strands don't touch, the terminals are very close together

PM me your ship to address

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Question relating to flushing the system, should we be able to get flow through these Grundfos circulators with supply pressure alone, or will there only be flow when the circulator is running? I had a contractor here a couple weeks ago servicing the boiler and supposed to be ensuring no air in the lines, and he couldn't get flow through one or two of the zones. He swapped the circulator out in case it was seized, but still couldn't get flow But it wasn't running at the time...he hadn't even hooked electrical up to the new circulator yet, but was just trying to add pressure to the inlet to push water through.

0 -

yes water should flow through and all zones without running the circulator.

If there are zone valves, they need to be locked open to purge.

If there are check valves,, you can only purge from one direction

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I still haven't acquired the other parts I need to do this job (011 or M3062 actuator) and M3022 seal kit, but I was looking again at what I think I have to do. It looks like I probably have to drain the whole system down in order to make this change, since I do not see a way to isolate all 4 sides of this valve…correct?

Also, I am still troubleshooting my flow issue. I decided to make a dedicate post for that.

0 -

Just came across this post! I'm in the mist of connecting the Tekmar 360 and Ed theHeaterMan has been great to help me out! We even had a phone conversation today!

0 -

So, just double-checking - am I correct in thinking I have to drain the whole system to replace the actuator on the 4-way?

0 -

Unless the valve is seized up, you should not have to get to the water side of the valve. Two or 4 bolts hold the motor onto the valve body.

Once removed the valve should rotate somewhat easily.

The older vane type were a bit stiff, probably need a pliers to turn that type

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements