Oil boiler and outdoor Wood Boiler

Comments

-

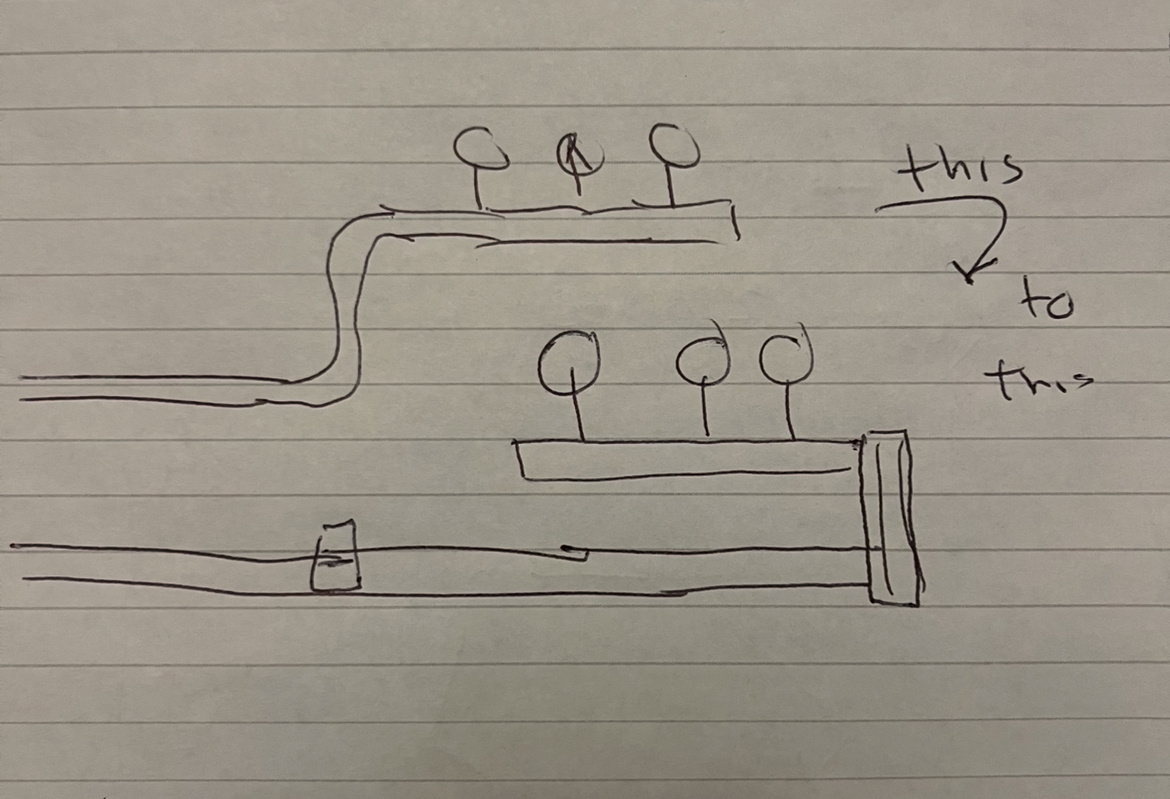

Assuming 15-20 gpm total per say through three pumps into the return, the 1" is not able to support that so would it make more sense to add a loop for the hx to flow through

0 -

Like this

0 -

0

-

It would be a extra pump to run but should eliminate possibly reducing flow through the HX, tying the other side of the return into the bottom elbow going back to the boiler with a tee.

0 -

you could repipe like this and eliminate all that

copper fitting complication at the HX, if that is some of the restriction concern

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

My concern really all of the bends that I was planning on using on the copper more so the diameter of the tubing. Either way the flow would be reduced to 1 in internally of the heat exchanger

0 -

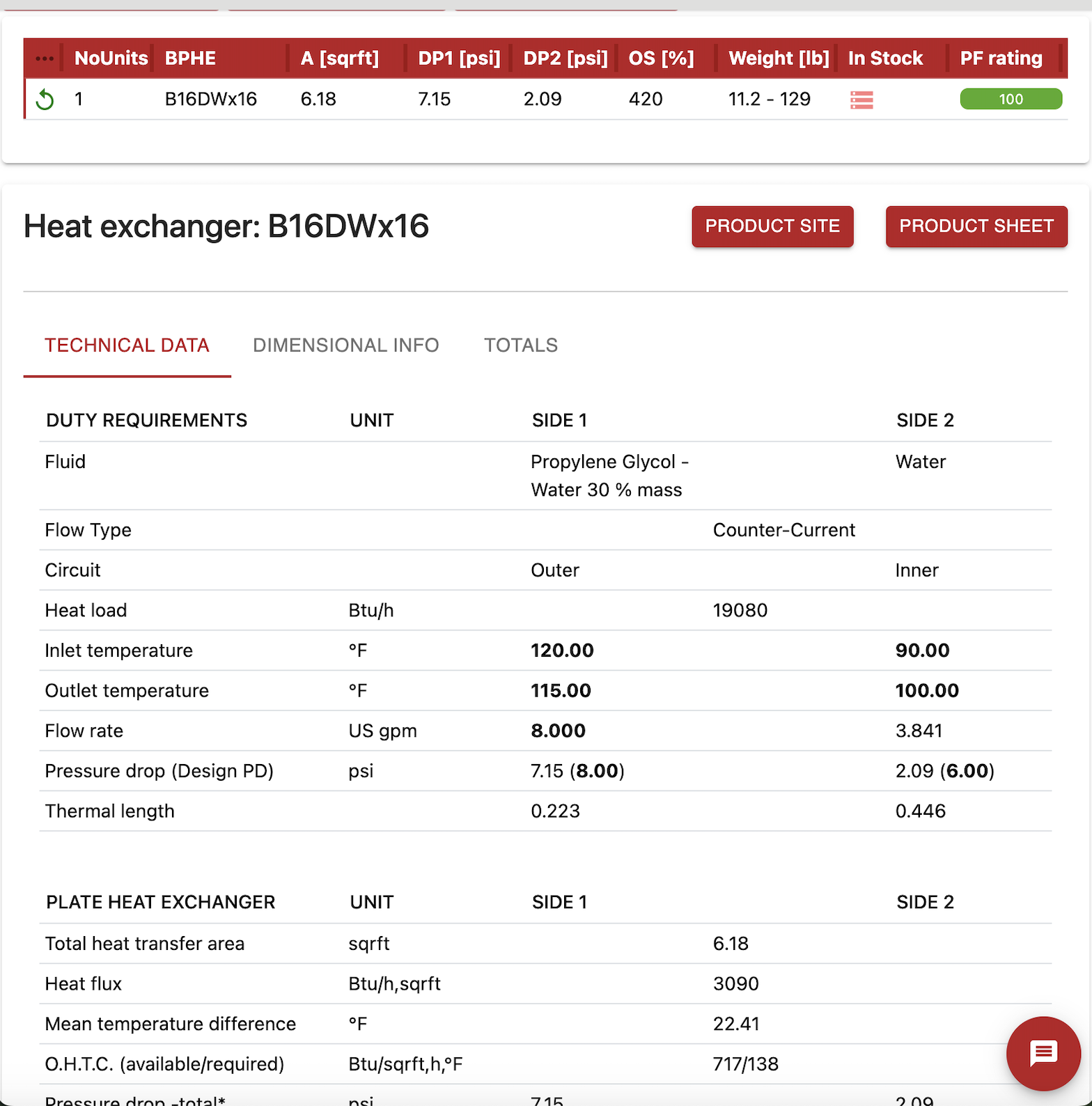

Don't worry about the flow inside that HX, it will handle all that you have to give through the pex from the boiler. Very little pressure drop in a HX of that size, regardless of the connection size. It's all about the square footage of the HX not the physical size.

Typically the HX has some flow rate and pressure drop info on the label or any documentation provided.

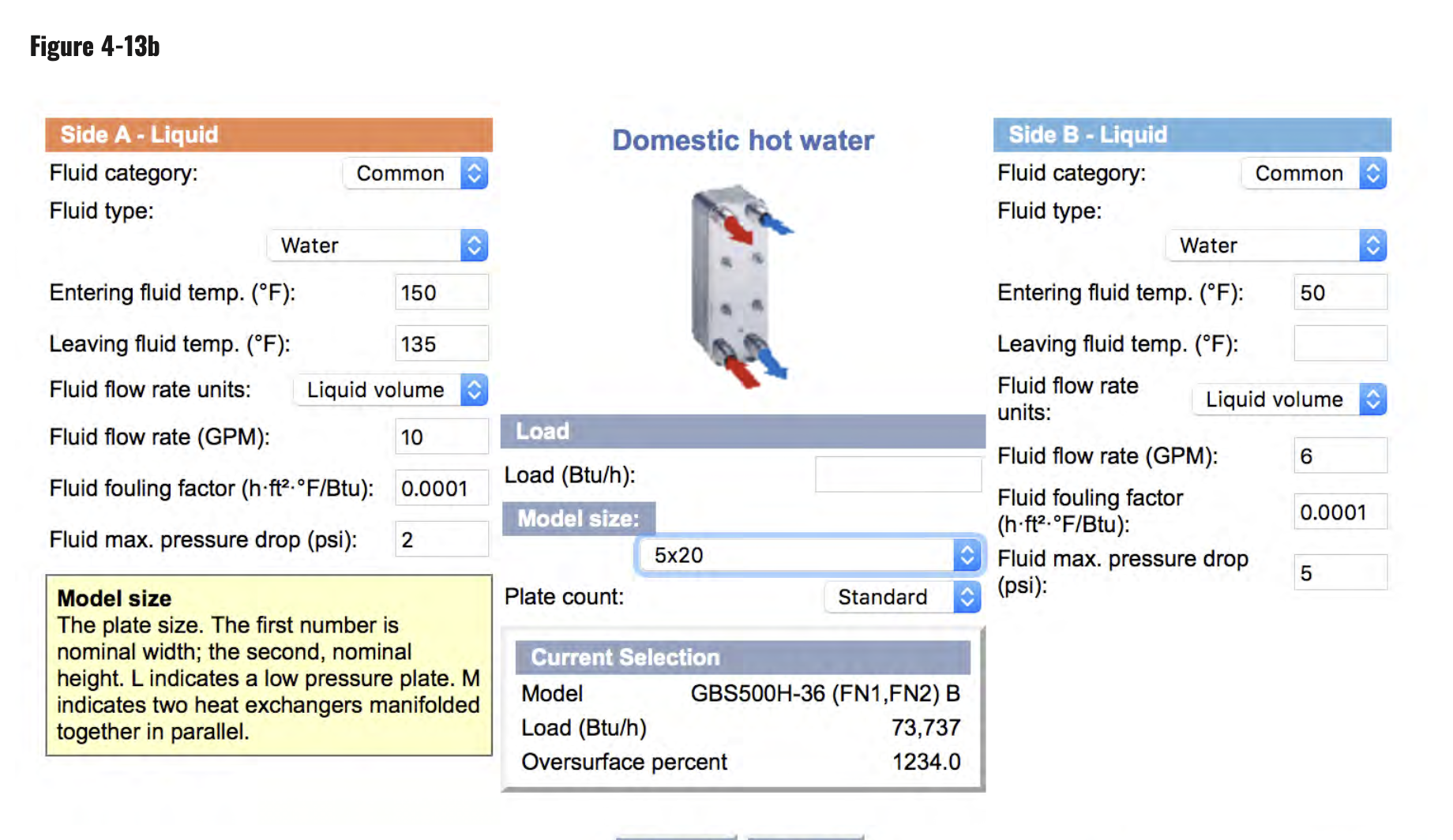

Usually you select a HX with the design software, free online. You enter flow rates and temperatures, it spits out the choices. A couple examples. The 5X20" in this example moves 73,000 btu/hr

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Okay restriction that I would be causing would be my piping going to it

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements