Purging 7 Zones Dual Boiler Setup

Hi hope all is well!

Before getting the heating system up and running I wanted to make a few upgrades to the current setup.

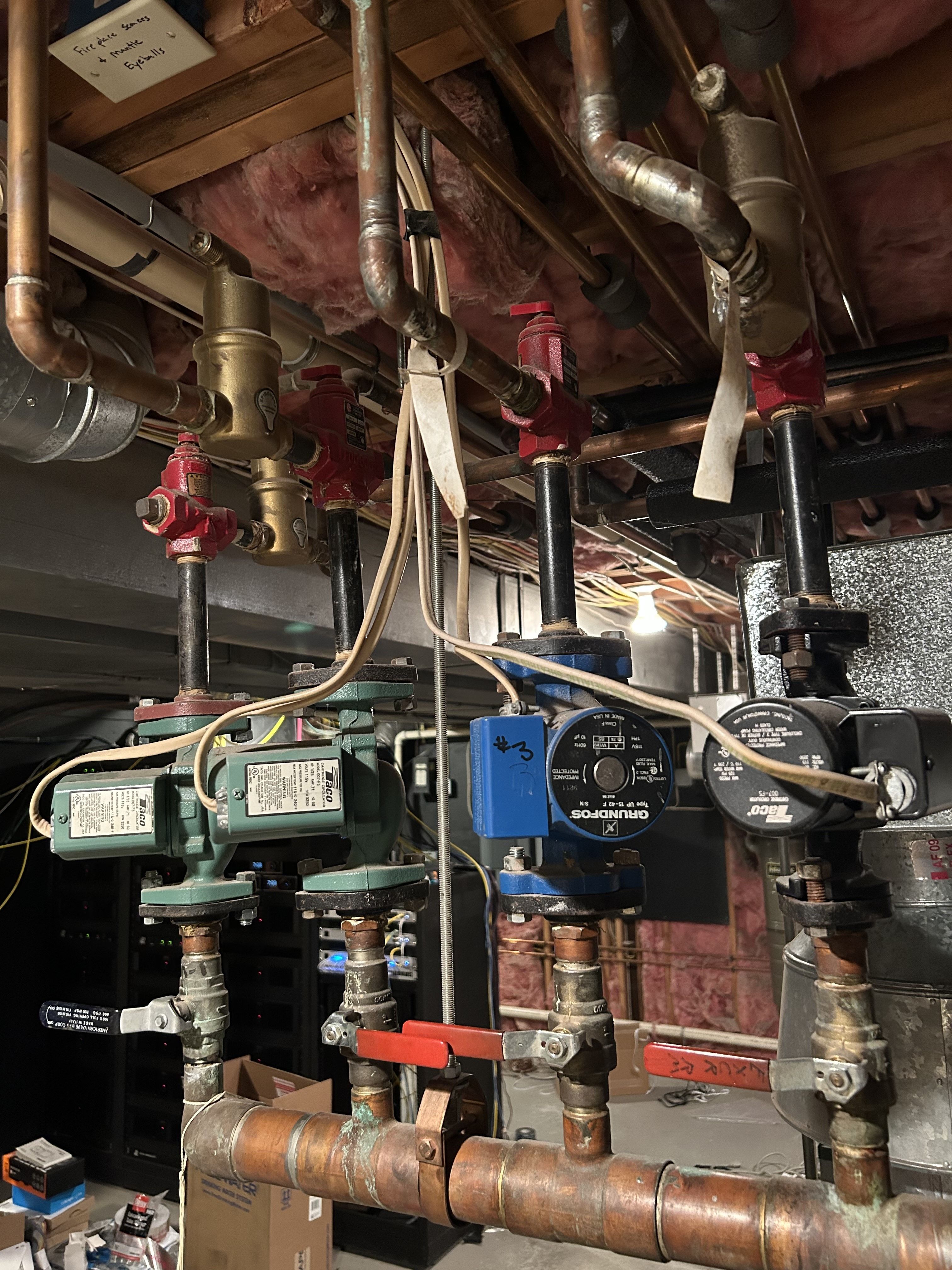

I have a dual gas boiler setup with 7 zones for hydronic forced air system.

The tridicator gauge, pressure relief valve, and air vent on the older Burham boiler were all corroded and/or no longer functioning. So I replaced all of those components which required draining some of the water out of the boiler to relief the pressure.

I want to fill everything back up with water, but want to make sure I perform the correct procedure for purging the air.

I have 7 zones each with its own circulator pump. Do I need to turn them on (by sending a thermostat signal for heat) or will the pressure of the incoming water be enough to purge the air from each zone?

If so, am I essentially connecting a hose to the spigot on an individual zone with the rest of the zone valves turned off. Then allowing incoming water from the Caleffi pressure regulator to purge the system until no more air escapes from that zone. Then rinse and repeat?

Thanks in advance!!!

Comments

-

0

-

0

-

You usually need more flow than the circulator can provide to purge the air. So, you need to figure out a way for each individual zone to run a lot of water through it and out a drain (the usual approach is either a dedicated high volume purge pump — or just a hose connection to the domestic water!).

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

The Caleffi fill valve will allow 5 gpm to flow, do 1 zone at a time, you have isolation valve and purge valves. That is the only valve you need to turn off.

Wow! with a spirovent on each loop, air should be eliminated within hours if you have any flow at all in the zones.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

Ok so as long as I leave the bottom gray knob at the bottom of the Caleffi fill valve open, that should provide adequate fill to purge the system?

Yeah I noticed there were prevents on each zone. There seems to me some corrosion on a few of them, would it warrant replacing now before purging or is that just extra insurance?

0 -

When you start up after a fill I would expect to hear air hissing or see some spitting from all those Spiro's. It's the only way to know they are working. The top end doesn't really disassemble for cleaning or inspection.

Yes the grey knob all the way open on the fill valve. It is a fast fill valve always, regardless of the pressure you set. If you want 15 psi, set it to 15 and it will fast fill for purging.

No need to, but if you do set a higher pressure to purge remember to set it back to the actual pressure you want to run at.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

If you see corrosion on the exterior of a pipe or device that is an indication of a leak. If the leak is small enough the water actually evaporates before it actually leaves a wet deposit for you to observe. Anything that is not actual water will be left behind making that tiny tell tale green stain or huge crusty build up. If you just wire brush the stain or build up away (part of the maintenance) you can see how bad the leak might be and take appropriate action on the more aggressive leaks. In some cases, the leak actually stops on its own as a result of the residual build up.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements