Delta T Circulator- Boiler Loop

I've been reading some literature regarding the taco VT2218 and am curious as to your opinions of replacing my 3 speed "boiler side" circulator w/CST's, on a Primary/ Secondary (with baseboards) system, Lochinvoir NKB 150 Noble. The Knight has a 0-10v reference to control the circulator however the Noble does not. Could the Delta T circulator provide better efficiency? Or, fight with the boilers internal adjustments??????

Comments

-

the Lochinvar Knights all come with an ECM circ that is controlled by the Smart System control. So it modulates with the firing rate of the boiler. Piped as P/S.

I wish they would show a hydro sep stead of just mentioning it 😙The selling feature is reduced energy consumption from both the ECM technology and the reduced speed. Changing to a fixed speed ECM boiler pump( the green block on the graph) gets you a 50% or more efficiency gain. That is power consumption on the pump, not boiler efficiency increase. If you tracked pump run time and applied your kWh costs, you could determine the $$ saved. If you get an ECM rebate from your power company, it may pencil out to change that circ?

We are close to the day when boilers will ship with ECM. Unless the DOE changes its mind. Again,

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks Hot-Rod, Exactly what I found. What I was pondering is putting a ECM Delta T circ. instead of the UPS 26-99 .Lochinvoir doesn't mention a Delta T circulator as an option in the install manual and I am still in warranty. Looks like an easy swap, but as a homeowner I don't want to screw the boiler.

0 -

You can swap it out for an ECM style to save some power, but I don't think the Nobel has the output to operate it in a specific mode.

The pump you are considering. does it match the 26-99 for performance?

Is that the goal to reduce electrical consumption? Is the system comfortable?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

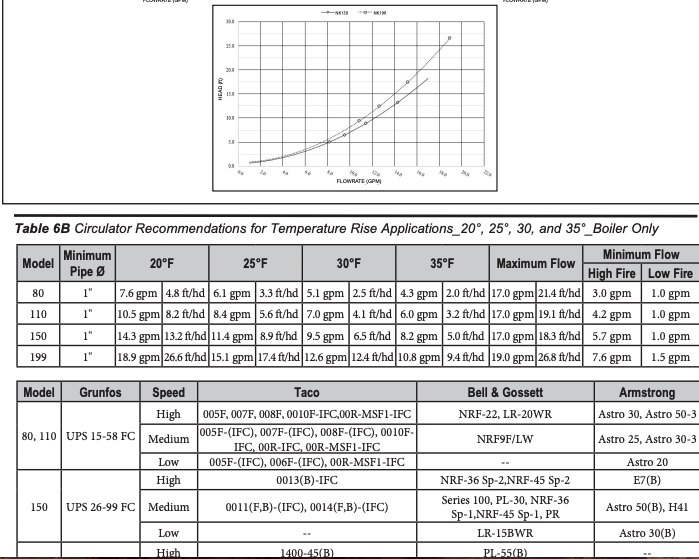

The plumbing company installed B&G NRF 25's on everything. Boiler, Indirect, all 4 varying sized zones. The pumps have been noisy, a low frequency hum throughout the house. The 25's are not listed by lochinvoir in the install sheet. The 26-99 is, 0013, NRF36 & 45. I was just going to buy a pair of 26-99's for the boiler loop and indirect tank loop, then I got into the weeds of energy efficiency and ECM.

0 -

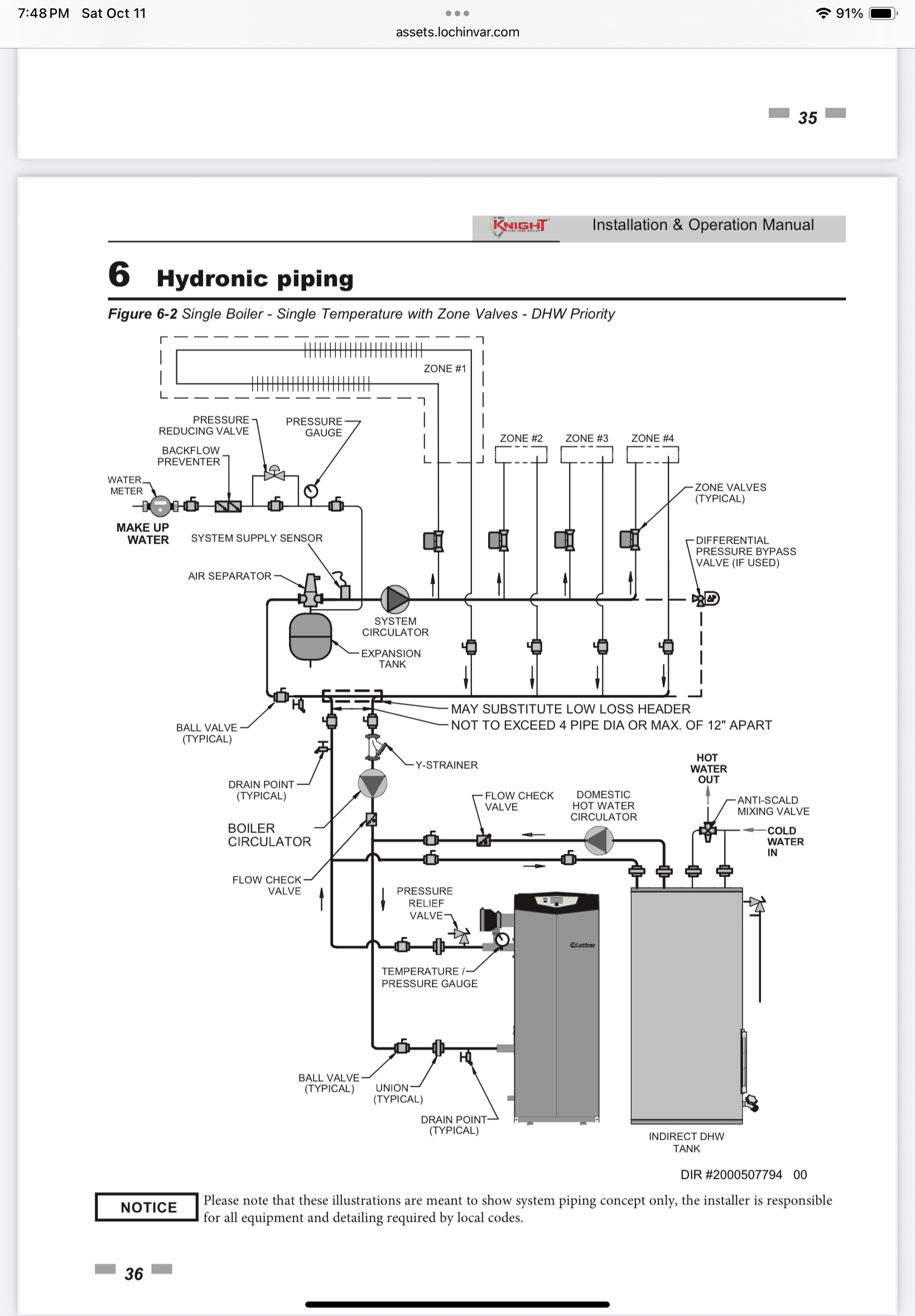

If it is piped as a primary secondary then the NRFs are zone pumps? We need to see your exact piping to confirm that. Plenty of misinterperted P/S piping out there :)

Those should be 3 speed pumps, run them at the lowest speed that gets the job done. That pump should run as quiet as any other brand. A slight hum could be lessened by isolating some piping from the framing members?

The boiler needs to have the pump that Lochinvar shows in the manual. Lochinvar does a good job of showing and explaining which pumps to use on the boiler based on the operating deltas you choose. Looks like the 26-99 is fine.

There were some rebate for switching to ECM circs. In some cases the rebate covered the pump cost. Check here for your state and local programs.

www.dsireusa.org

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Greatly appreciated response. I’ll check for those rebates. 🤞

0 -

Do a quick sum of all your emitters in the house. There are very few places that have enough rads for 150k, common is around 40k to 50k. Most likely you won't need a big pump on the boiler as you never need to run at max fire.

The delta T circ should work , the min flow on it in delta T mode is about what the min boiler specs call for. If you run into control issues with it (pump cycles from max flow to idle to max) you can always set it to fixed speed mode. An ECM pump will still save significant energy of the PSC, usual ROI is the range of a couple of years of operation. Getting a decent delta T across the boiler also saves a couple of precent of fuel as well.

0 -

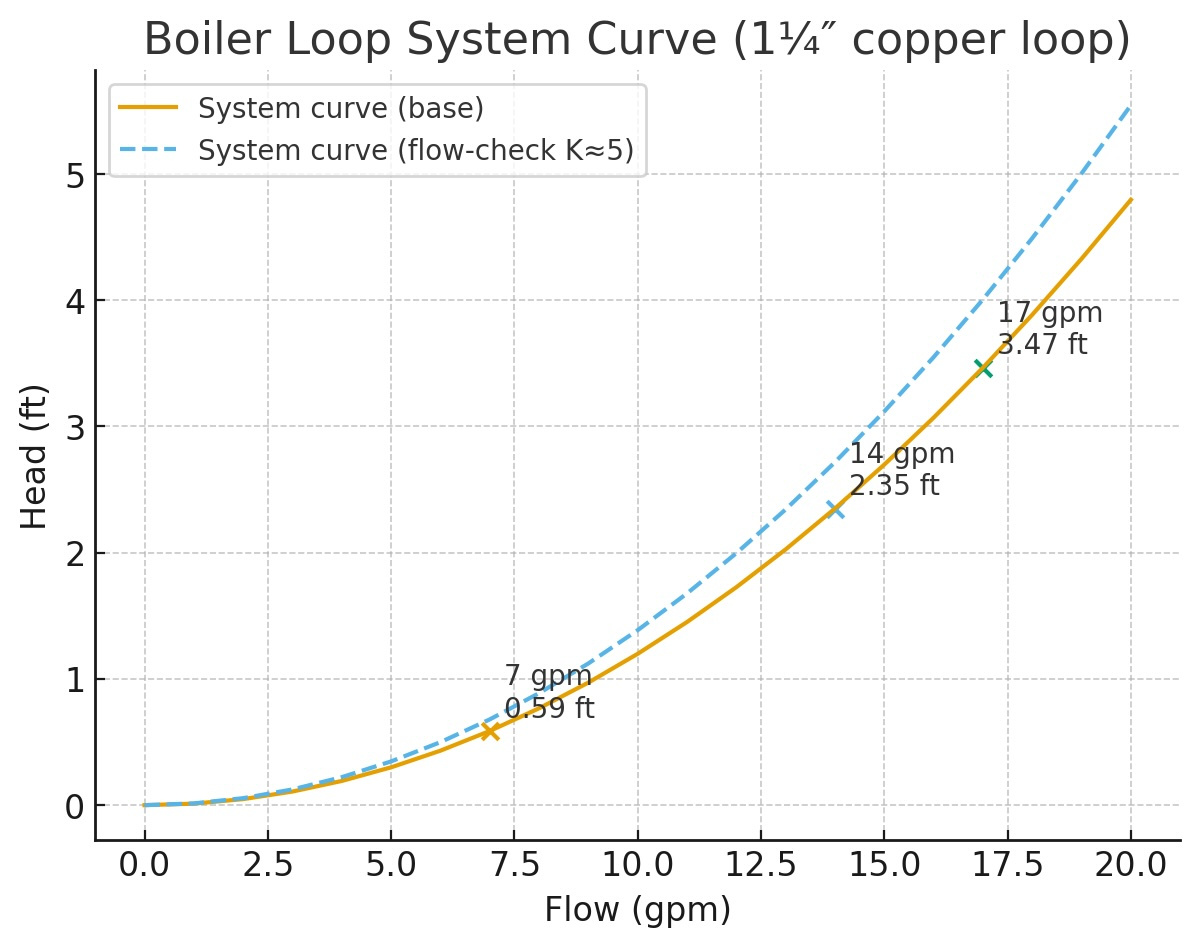

thanks Kaos. After reading Hot Rods reply it got me thinking I should dig a little deeper. I did a quick calculation of the head and flow of my boiler loop compared to the Lochinvoir install manual. My piping is shorter and 1 1/4” vs 1” piping used as an example in the manual so it seems some of the recommended circulators are too powerful. I am considering a 0018e set to zone mode. It connects to an app to read the flow gpm’s. You are right about the boiler size, I believe it’s oversized too.

0 -

I the 0018e will be around few hundred bucks less, also

Is the boiler a combi? That would explain some over-size

That boiler turns down to 15,000 btu/ hr and you can limit it to any output

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks guys for directing me towards the ECM's. I swapped all 4 Baseboard Zone Circulators…. After 5 years and several contractors who couldn't figure out the low frequency tone emanating from my zone piping; simply swapping the B&G NRF 25's for taco 0018e's solved the noise issue. Now the only tone sound is coming from the boiler circulator also a B&G NRF 25-Speed 2.

(Hot _Rod, Not a combo There is a indirect on its own zone.)

Boiler Loop:

- 14’ 1 1/4” type copper pipe

- 6- 90 degree elbows

- 2- 45 degree elbows

- 2 full port valves

- 1- 1 1/4” In Line flow check

- 2 closely spaced T’s

- Boiler HX, Lochinvoir says minimal? NKB 150 Noble

Working on circulator sizing. Do these numbers look OK based on the above?

- 7 gpm: head 0.6 ft (conservative 0.7 ft), ΔP 0.3 psi

- 14 gpm: head 2.4 ft (conservative 2.7 ft), ΔP 1.0 psi

- 17 gpm: head 3.5 ft (conservative 4.0 ft), ΔP 1.5 psi

0 -

looks like 14 gpm for the 20 delta which is the lowest they show

In any case the 150 requires a 26-99. But you have 3 speeds to play with.

Or an Alpha 26-99

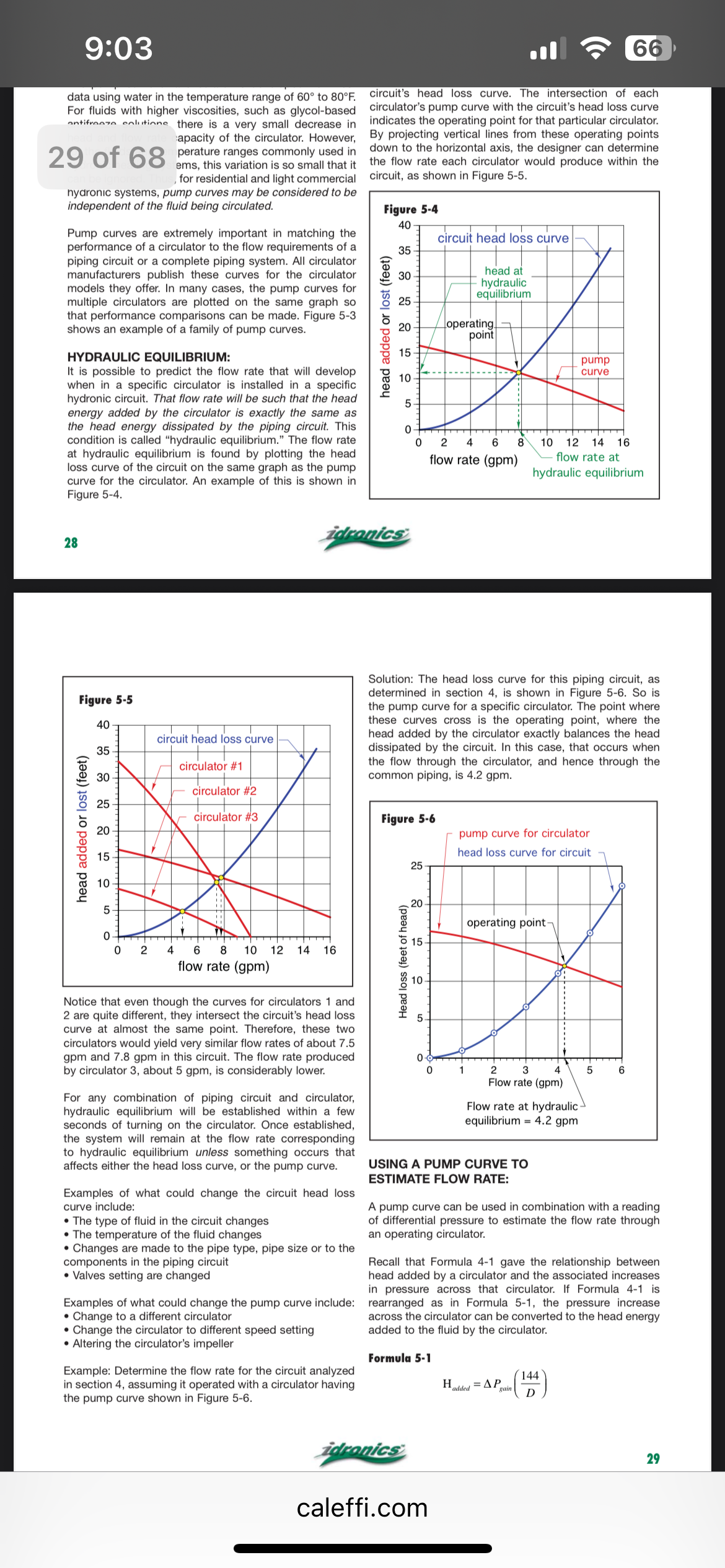

If you want to go a step further plot the system curve over the pump curve. Where the lines cross is the OP operating point. That is where the pump is actually running.

Idronics 16 explains the steps to do that math,

Unlike thermal equilibrium, hydraulic equilibrium happens within seconds of a circulator bring reved up

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements