Am I blind? Not seeing the gas shut-off valve.

Comments

-

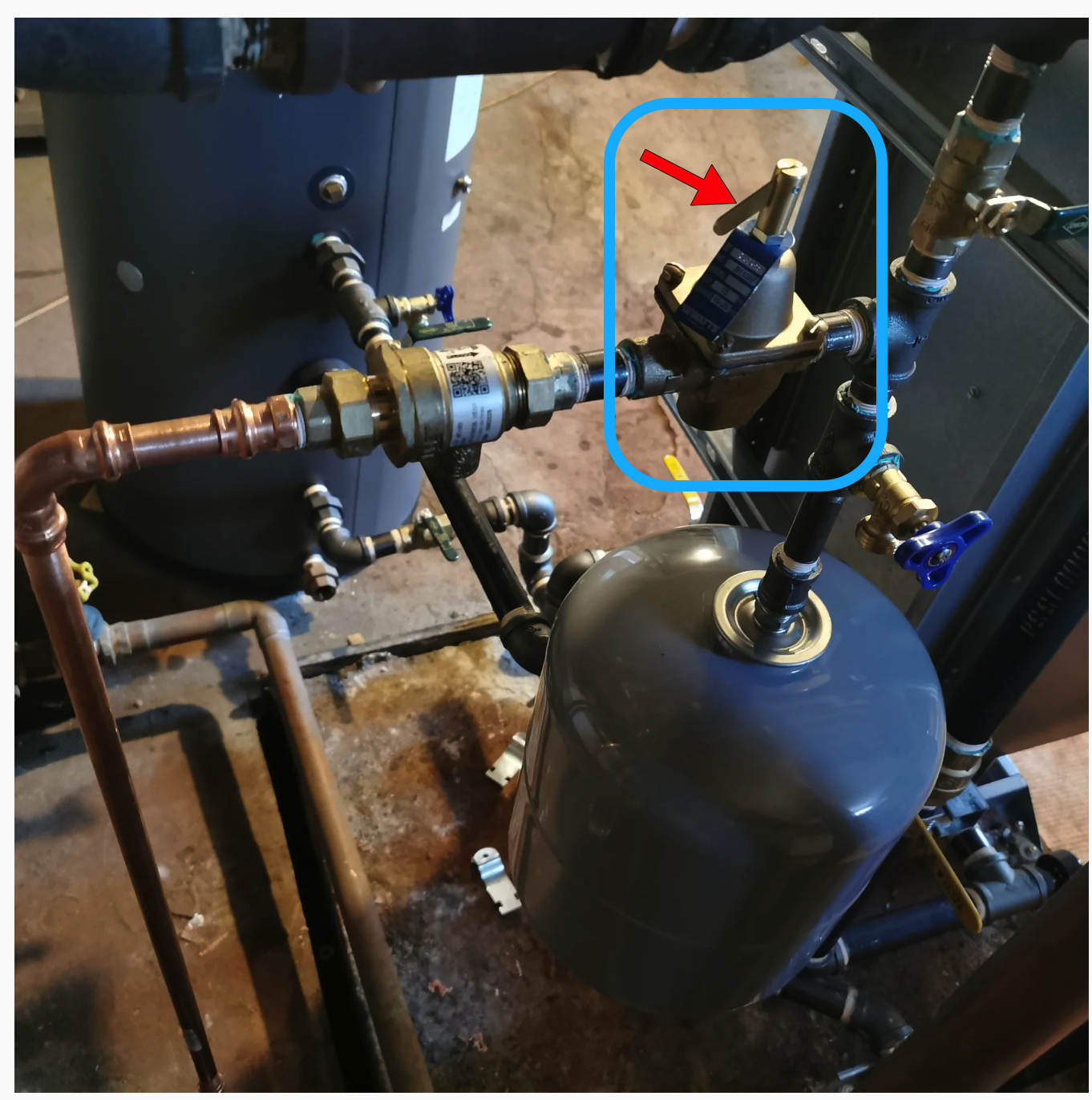

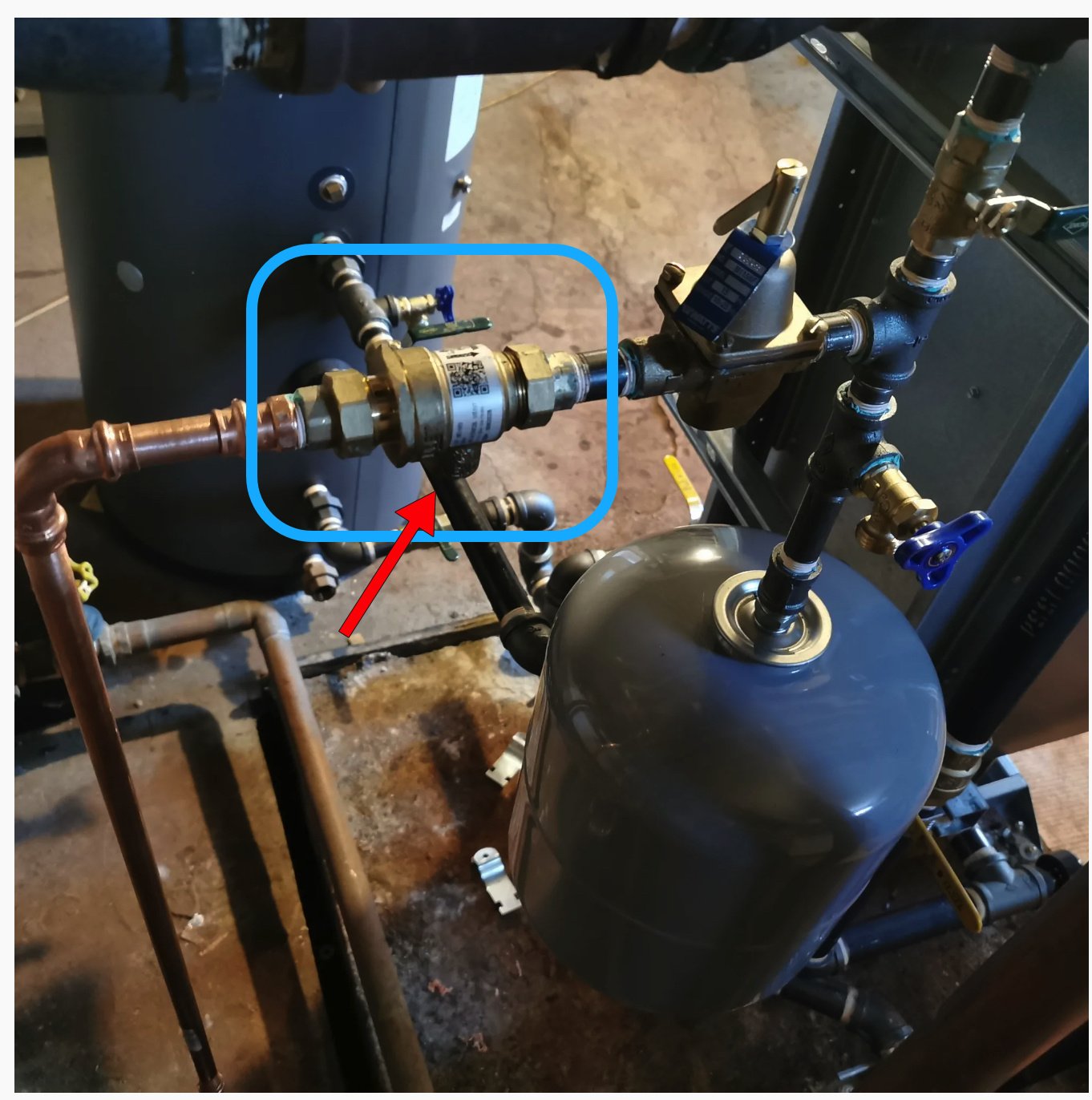

come back to this picture, yes, that's your pressure reducing fill valve, get us a wider shot to the left (the right is connecting to your system and shows your compression tank), to the left there should / could be another manual hand valve, follow that pipe back to a closed valve, or your water meter,

known to beat dead horses0 -

you need to see pressure in your system, 18# to get to that 3rd floor, you can get a hose bib gage at home depot or lowes, hang it on a boler drain or purge bib, and confirm 0, or what ever pressure is in there,

known to beat dead horses0 -

@sjh said "I lifted the lever on the pressure release valve, thinking that would increase pressure in the system. Did it slowly and carefully, only lifting it a little at a time. Gauge showed no increase in pressure. I increased the pressure I was adding to the system at a faster pace. Still no difference. Then I added it a bit faster, still no difference in pressure showing on the gauge. Then, the release valve for the boiler started shooting water out:" and showed us a photo of water pouring out of the relief valve white safety drop tube.

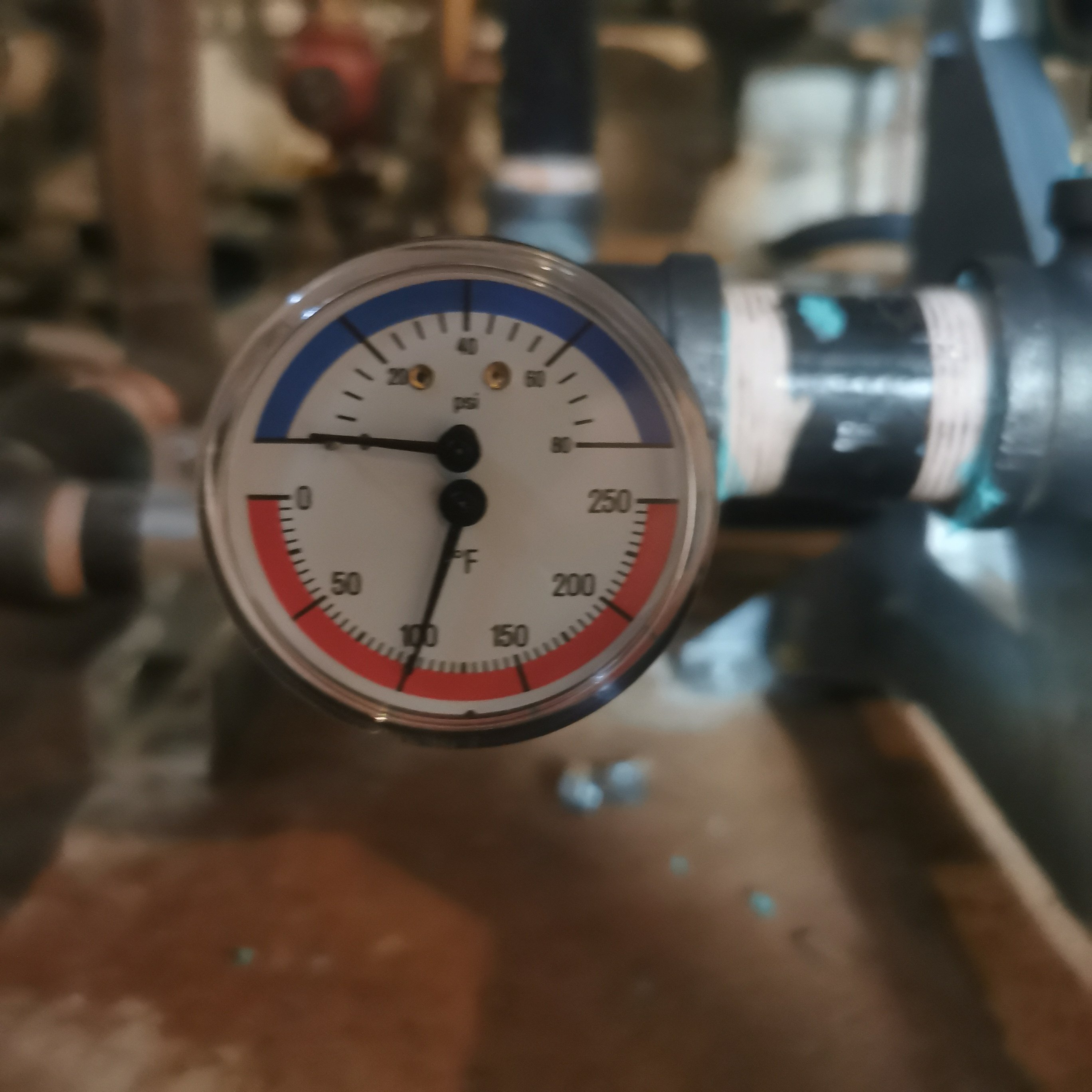

In reading this thread I believe that @sjh is calling this valve a pressure relief valve. In fact this is a pressure reducing valve NOT a pressure RELIEF valve. There is also a photo of a Tradicator or boiler gauge that has three scales on it. One of the scales is for the boiler water temperature and that appears top be near 100°F. The other dial points to the water pressure and height the static pressure (boiler pressure at the gauge location) of zero PSI and zero Feet. The boiler pressure gauge is reading ZERO and the water flowing out of the pressure relief valve indicates that the gauge is bad or the gauge is not in connection to the boiler gauge location.

I believe this is the same job we talked about last week when the fuel oil dealer was going to be there soon to remove an old oil boiler and install this new gas boiler that the gas company is paying for through some sort of grant program where the homeowner does not get to select what they are installing and who gets to install it. We offered advice on how the best way is to install the replacement boiler and if they were going to re-use all the old circulators.

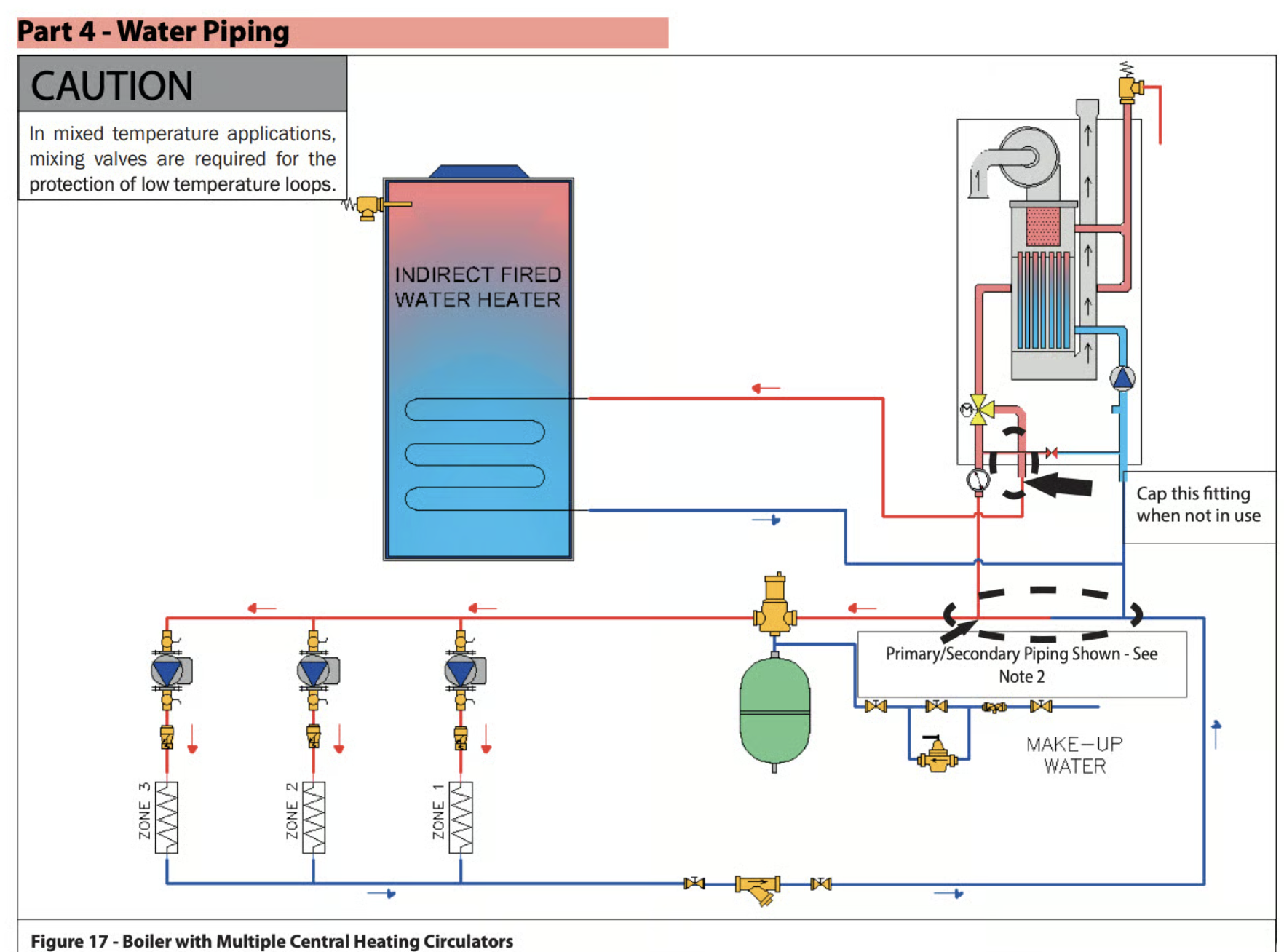

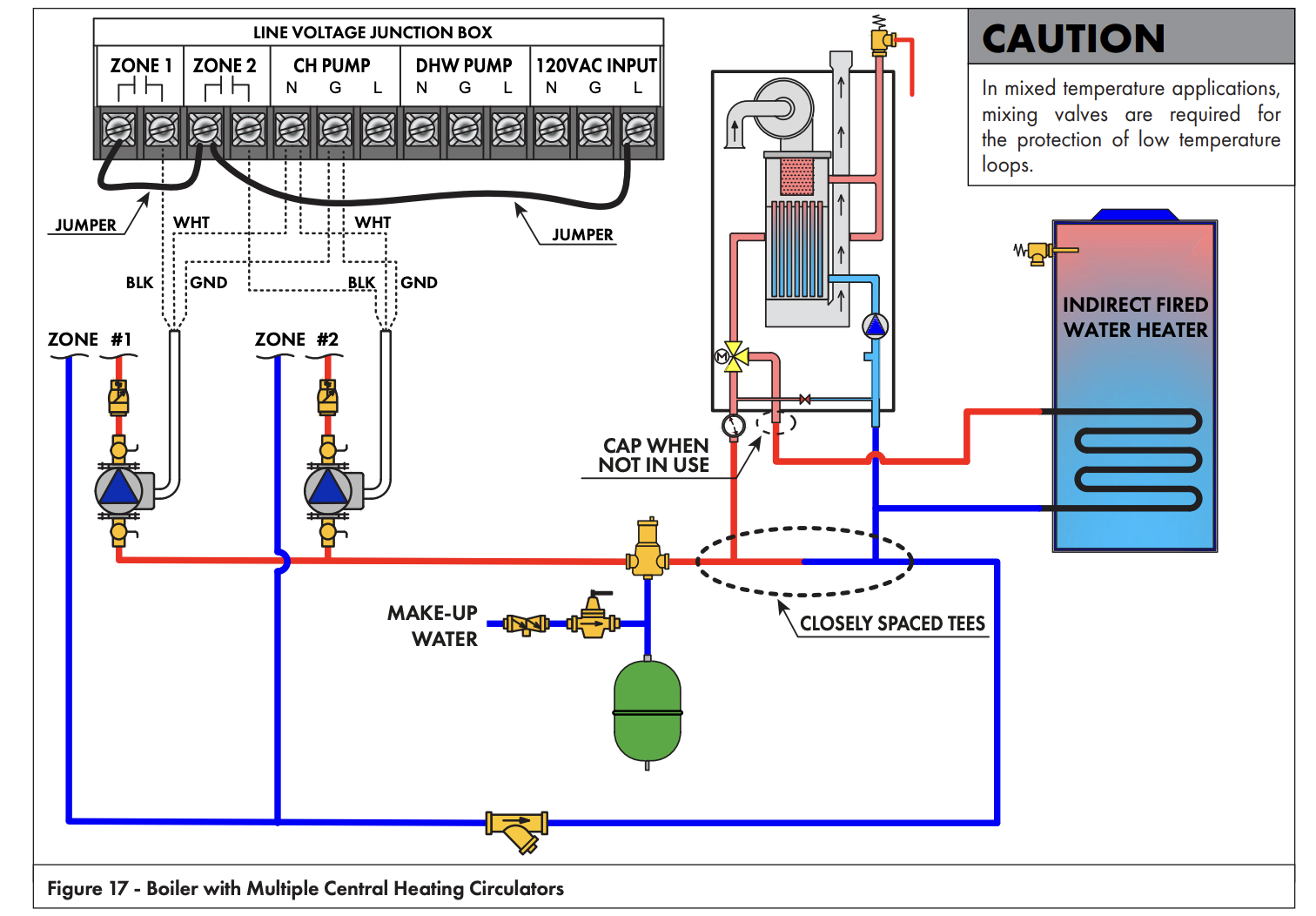

The installing company assured @sjh that they were not going to make a mess of piping behind the boiler and that they would follow the manufacturer ’s diagrams like this one when installing the new boiler and cleaning up the existing circulator mess. This obviously was said just to satisfy @sjh at the time and they had all intentions of making a mess of the piping behind the boiler because it was the easy thing to do . Use as much of the old piping and circulator locations as they could to get it to run. Now there are problems and @sjh is looking at what they can do to make it work themselves , rather than let the contractor solve the problem. The only way that @sjh has leverage is if the final payment to the contractor has not been received yet and he does not sign off so that they can get paid . If @sjh already signed the completion certificate for the grant money, then there is no leverage. I hope the contractor will stand behind the work they have completed.

I'm going to study the photos of the old oil boiler and the new system and see exactly what is going on there. This may take some time and may reveal why the gauge reads 0.0 PSI and the 30 PSI relief valve is blowing off pressure at the same time.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

3 -

Sounds like the gauge is bad. Do this. Shut off the water MU and drain the boiler a little. Replace the gauge. If you can't get the MU water to work you can fill the boiler with a garden hose connected to the city water on one end and to the boiler drain valve on the other end. You will need a female x female hose connector, or you can use a washing machine hose to do this

0 -

This one? I turned that one open. It was closed for some reason. Then a little while later, I came back to try and repressurize the boiler, only to discover that it was already at its recommended pressure, and I was mistakenly overpressurizing it. Here we are.

0 -

Most of the job is already covered by the gas company on the expectation they are going to make more off of me but I have to make a payment of I forget the exact figure but in the neighbourhood of $4000, to the heating company, for doing the installation, and that is due this week. Then I'm supposed to get a rebate of $3500 or something. I don't have the figures right in front of me, it's been a hectic week. Thank you for offering to figure out what is going on here because the heating company never solves the problem, whatever the problem is - they just paper over it and are out before I can get enough of an explanation of what they did, so I never know what to do next time something happens. They don't have time, and they're there to make a profit, not teach me how to operate this very complex plumbing and heating system.

0 -

replying to @EBEBRATT-Ed

Is that all you have to do to replace the gauge?

It's brand new, and I don't think I should have to pay for a new one if it is defective. The manufacturer should replace it. So I need to know if it's actually defective. But if that's how to replace the gauge, I can get another one temporarily to test it out.0 -

I totaly missed the discharge from the pressure relief valve(safety), and no, I don't, can't tell if that is a feed valve, or isolation under the circulator there, but a second gage on a drain is your friend right now,

can you post a wider shot of that valve you opened(white arrow), maybe a different angle so we see where the pipes go, and of the picture I first called out saying yes to, of the pressure reducing FILL valve, show as much as you can, floor to ceiling, side to side,

known to beat dead horses0 -

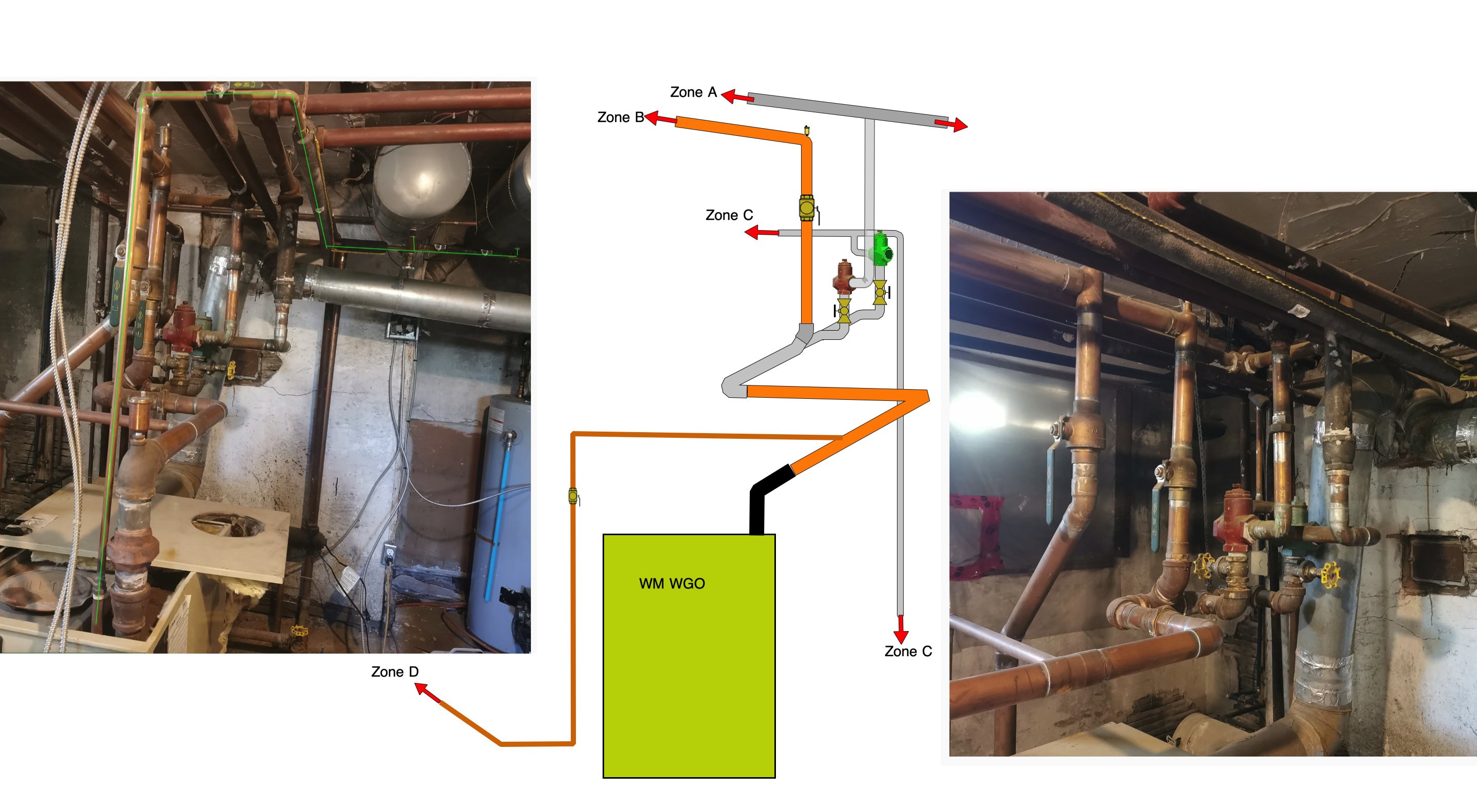

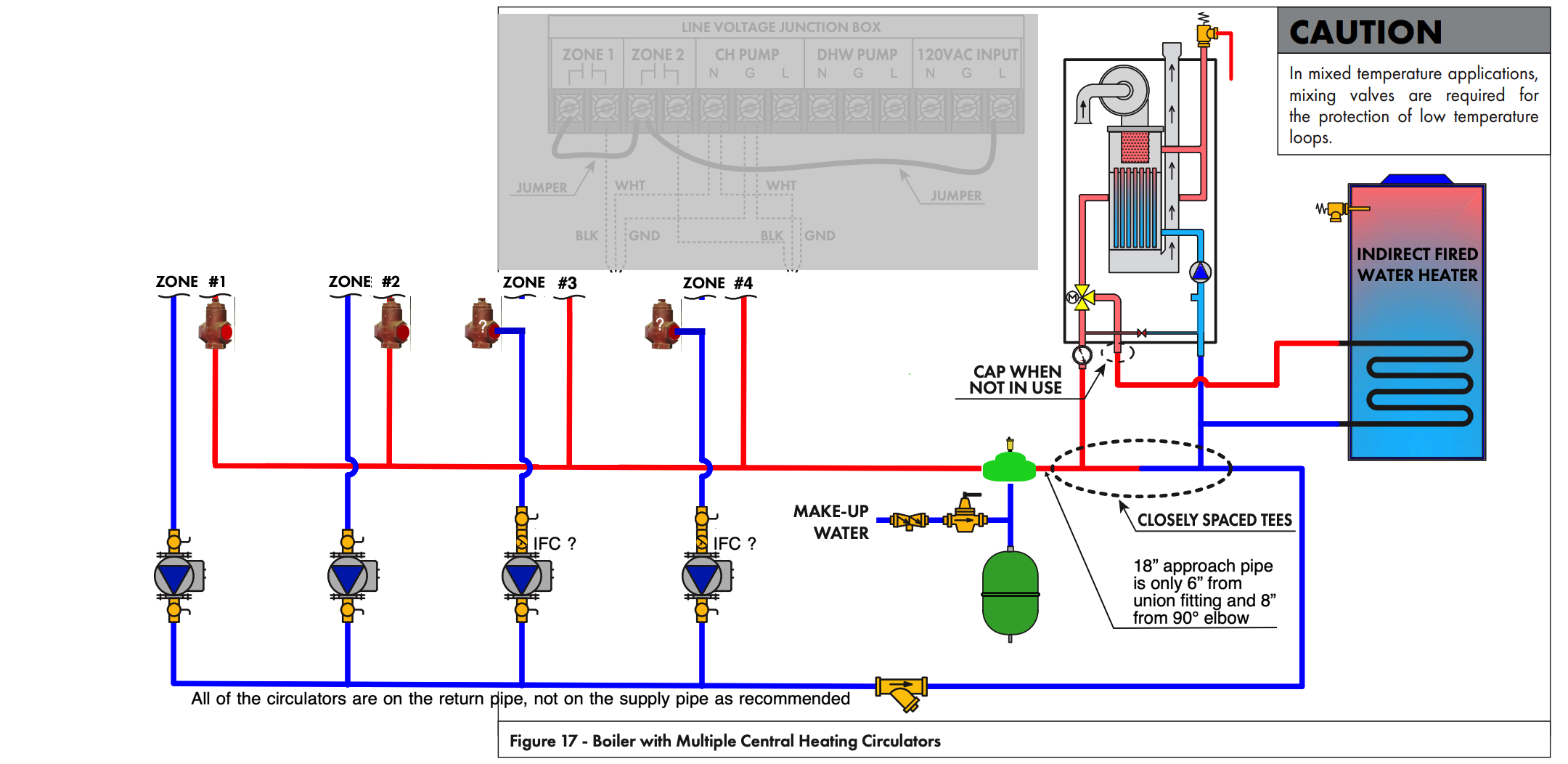

This is interesting. It appears that the suggested piping design for a zone system using pumps that is on page 28 in the manual was not used. in fact they piped it as I feared and this design may not yield the results that the manufacturer intended. Here is the supply piping from the oil boiler:

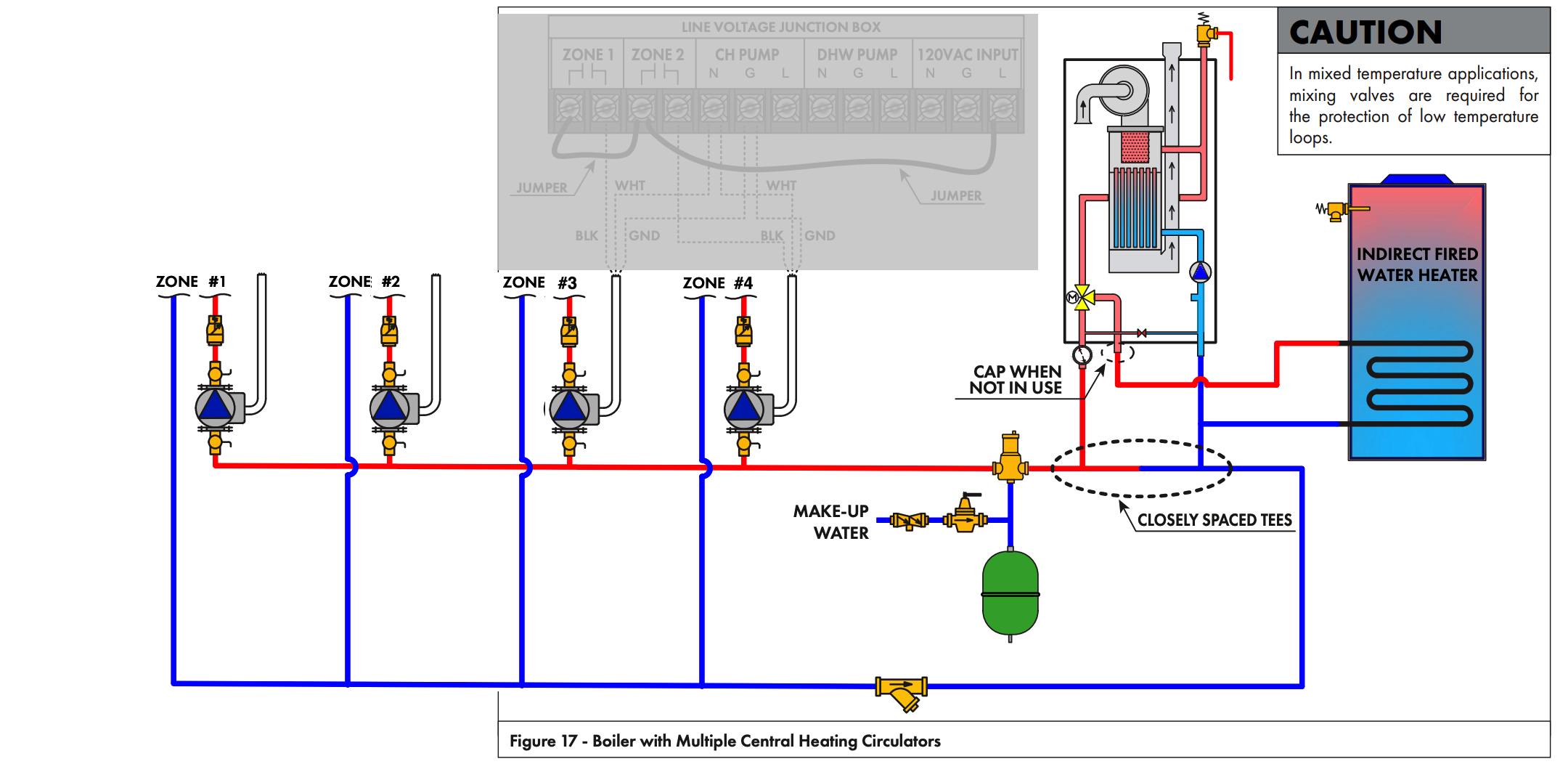

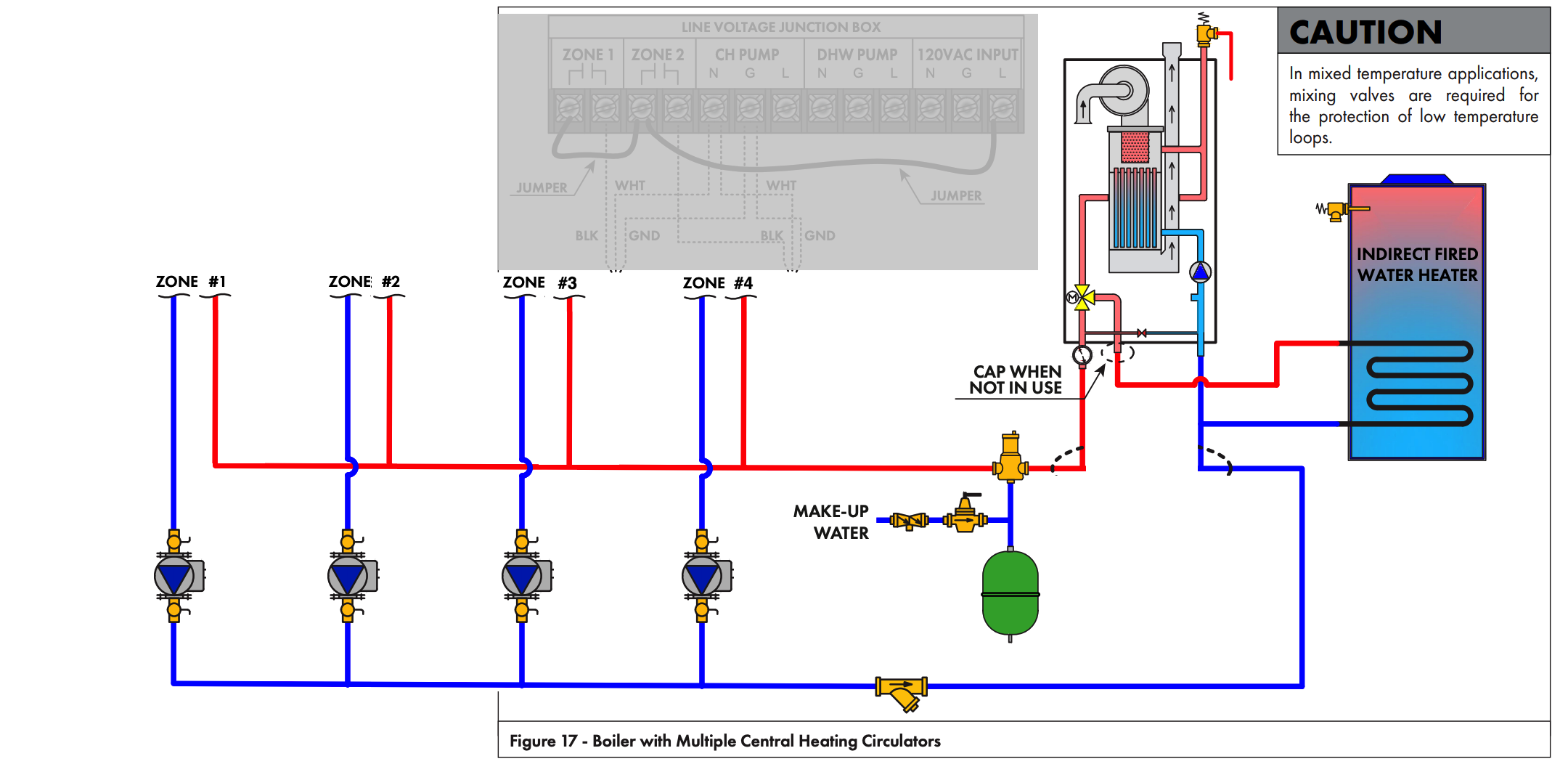

This is the closest I can get from the photos. Now in the new boiler piping That was not going to be a cluster of piping behind the new boiler (which in my opinion that IS a cluster of piping) and be installed in accordance with the manufacturer's I/O manual (this is the closest one to what you have) using a primary secondary layout.

You can clearly see that the as built piping is not using a primary secondary piping design here:

In fact this piping design is based on old school direct piping from the supply to the return of each zone. Also I can not see zone D piping in the as built piping. This piping design lends itself to improper hydraulic separation of the zone pumps from the internal boiler pump which may cause a problem in transferring heat from the boiler heat exchanger to the system if for some reason all three (or four) zones call at the same time. All the zone pumps are forcing all the flow of all the zones thru the boiler heat exchanger at the same time. The primary /secondary piping will create the hydraulic separation that the manufacturer requires for the best operation and longest boiler life.

If the installing contractor will not make this right, then I would contact the manufacturer's representative, the gas company that is supplying the money for the contractor, and the authority having jurisdiction and lodge a complaint that you believe that the installing contractor did not follow the IO manual and you would like them to put whatever influence they have with that contractor and make them install it properly.

I hope you followed my recommendations to withhold payment until you are satisfied that the system is operating properly. Which it is not at this time.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

2 -

-

In order to be exactly clear using what I believe is the actual diagram from your IO Manual I believe this is your Figure 17 from Page 28

This is what that might look like if you have 4 zones

And this is the way it was piped by the contractor

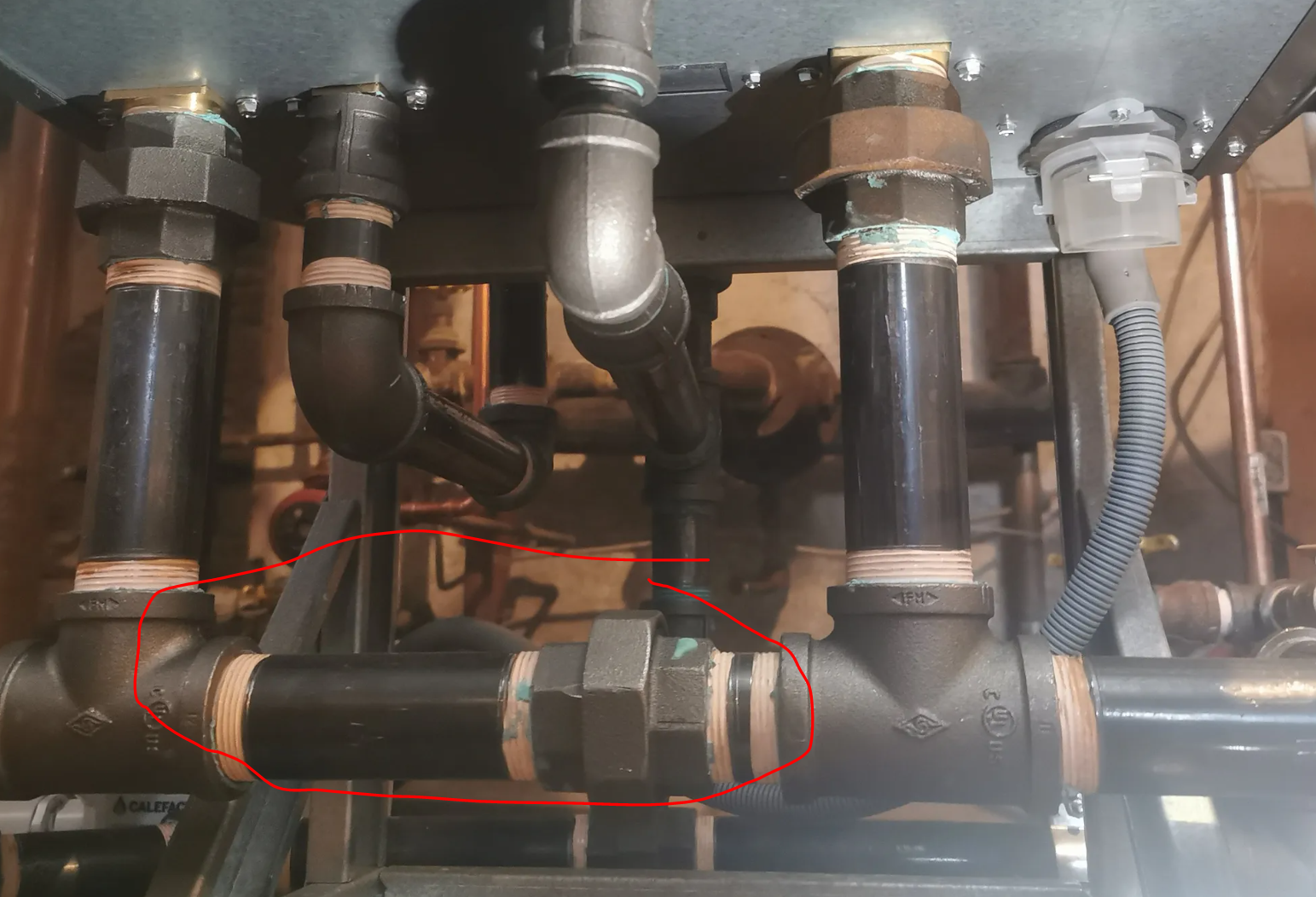

See how the very important closely spaced tees are missing? Also see how the circulators are on the return side of the system? There is also a lower cost air scoop that requires 18" of approach piping in order to be the most effective in air removal. There appears to be about 6" from the union fitting. So that sort of negates the efficiency of the air removal device. That 18" minimum is clearly in the Submittal and the installation instructions. Click here Submittal

That is just three of the many short cuts this contractor has used in order to do the least amount of work in order to get the big payment from the gas company.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Some additional information:

Pressure Reducing valve

(AKA Automatic Boiler feed). This valve takes the house water pressure of 40 to 70 PSI and reduces it to about 12 to 15 PSI. Lifting the flat handle (Red Arrow) will override the pressure reducing feature and allow full house water pressure into the boiler system. This is helpful when filling the system and air removal from the system.

Pressure Relief Valve

(AKA Relief valve) On your boiler it is preset at 30 PSI. If the water pressure exceeds 30 PSI the valve will open to relieve the excess pressure

Circulator

Your boiler systems have a variety of circulator pumps. they are designed to move the water thru the closed system.

Back Flow Preventer

AKA BFP Prevents boiler water pressure from forcing any boiler water into your potable water system. This can happen if the house water is turned off for service or some other reason and the boiler pressure is higher thatn the house water pressure. This BFP removes that possibility.

By the way, your BFP needs a safety tube added to the outlet just like your pressure relief valve

Manual gas Shut off. (Outside the boiler)

I believe you know what this is now!

Automatic gas control valve (Inside the boiler)

On some heating systems this valve is equipped with an on off switch or a manual valve for shutting off the gas during a service visit. this is not for homeowner use. Your particular valve does not have any manual on and off means

Tradicator

(AKA Boiler gauge)

Lets you know the boiler water pressure and temperature.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

Wow, this is beyond what I expected. You're saying I won't be able to troubleshoot this, no matter how much time, effort, and research I put into it, because they've installed it wrong.

So my next steps are to a) contact the heating company and say "your guys installed it wrong, they need to come back and do it over"? I almost guarantee the company owner is going to refuse. Even after reading your critique, I barely know what to say to him about why it's installed wrong, so he'll just shut me down. I'll read it several more times after I'm more awake, and probably spend significant time in the basement studying the setup while looking at your diagrams. But I still doubt I'll be able to express it effectively to the owner of the heating company.

At that point, b), contact NTI to get them to pressure the heating company? What if NTI isn't interested?0 -

I think it is piped properly. Closed space T under the boiler:

The installer didn't do themselves a favor with the spaghetti piping plus it is highly unprofessional to leave a setup without check you get heat on all zones.

My hat off to @EdTheHeaterMan for tracing any of the pipes as I couldn't when I looked at this.

I've had issues with triticators clogging on gravity feed conversions. The sludge in the old pipes clogs the gauge and gets stuck. A dirt filter would have been a good idea. Obviously you are getting pressure to the boiler as the relief valve vented (these are set to 30PSI).

You need the boiler tech back and they need to make sure you have heat on all zones before they leave. This is not something the owner expected to figure out. That is part of their job when doing this kind of work. If they have to replace any of the existing pumps, that would be extra work and cost, but if the pumps are fine, getting it all working is part of the job.

Also make sure there is an outdoor sensor installed and a base reset curve configured in the boiler. Without that, you are giving something like 10% of free efficiency up.

1 -

Thanks @Kaos. I did not see that picture. Wow what a difficult way to do the near boiler piping. There are no service valves or purge valves with that black pipe and fittings. So the boiler may be properly piped after all @sjh. I thought I looked at every picture and did not see the Tee fittings that @Kaos just showed in the above picture.

The installers still did not move the circulator pumps to the supply side just after the expansion tank and air scoop as recommended by NTI in the instruction manual. With that new information this is your as built system.

I am only guessing at the circulator location for zone 3 and 4. and there may or may not be flow control valves or Internal Flo Check (IFC) devices on the circulators. in either case if there is no flow control or FloCheck in the other zones 3 and 4 then you will get reverse flow in those zones when zone 1 or 2 calls for heat ans zone 3 and 4 are not calling for heat. That is certainly not a good thing.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I don't have names or numbers for the zones other than which apartment they're supposed to be connected to. 'Zone 1, Zone 2,' I don't call them that, they're not labelled as such, and in a couple of cases I'm not entirely sure which rads/baseboards are on which and which pipes are connected to which.

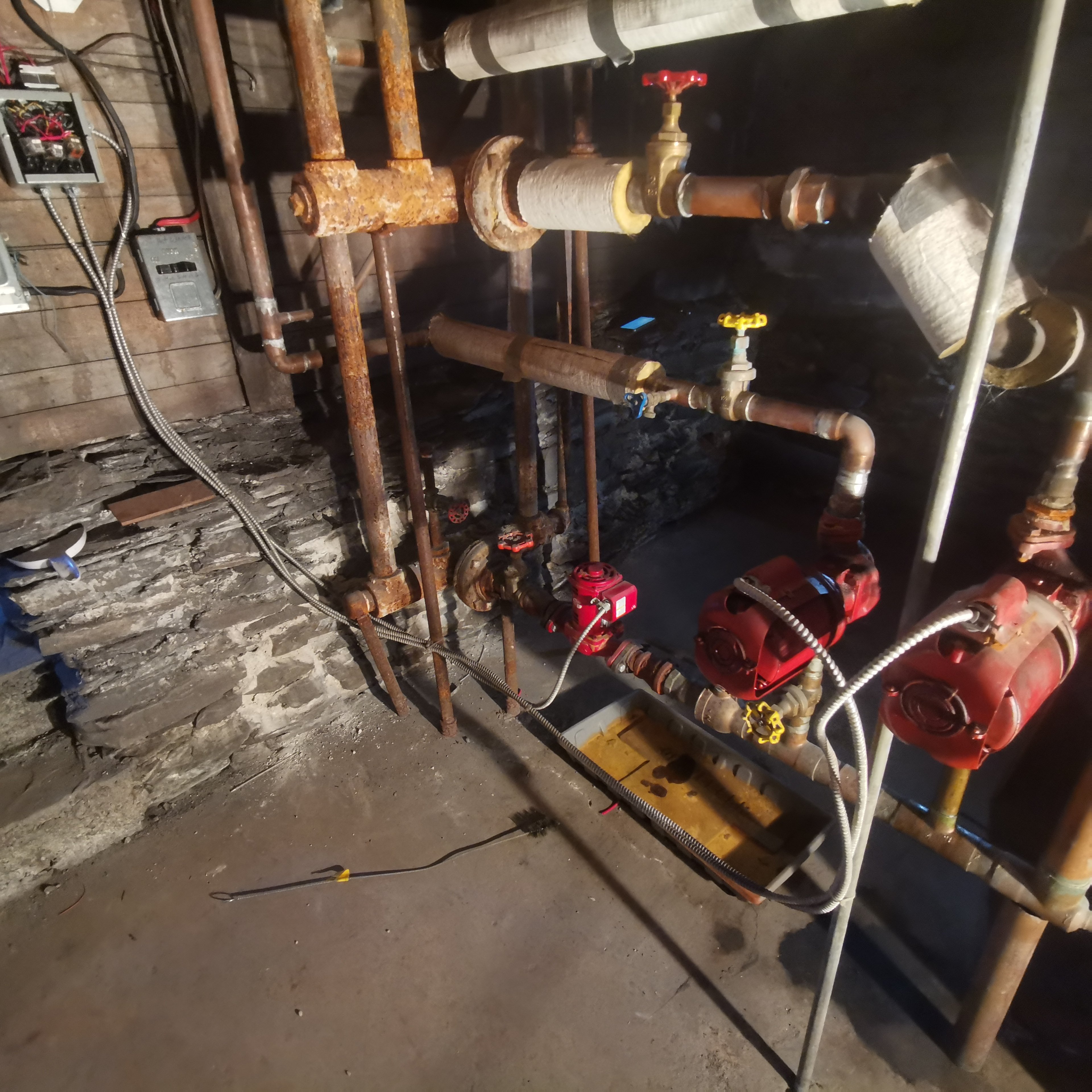

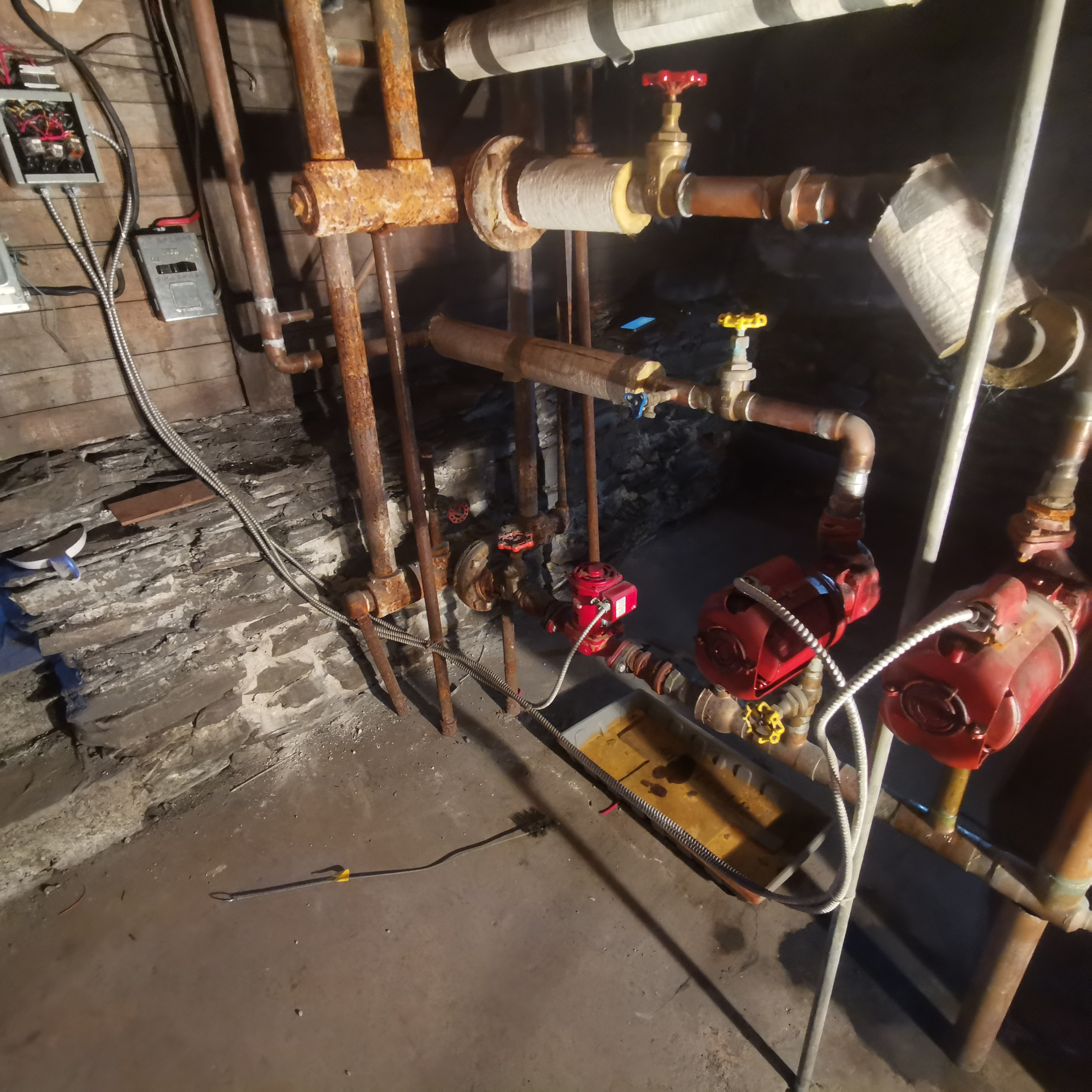

You know there's another section in the basement with additional circulators and infrastructure, right? It's not just that main boiler room. There's the other boiler room, which I posted photos from a few days ago:Your guess is as good as mine whether there are 'internal flo check' devices anywhere. I have no idea.

0 -

You still have leverage if you owe $4000.00. That always gets the attention of the boss when you ask a question about how things work and will be willing to wait for the explanation in order to produce that payment. If you are not satisfied as to the answers, you can always ask the installing company to tell you things like why the circulators were installed on the return when they are clearly shown on the supply in the manual. Just because they serviced it for all those years when they were on the return of the Weil McLain boiler does not mean that they can not be installed on the supply now.

And not for nothing… You did ask about that before they started the job. Nothing was resolved at that time when it would have been easy to make that change. Now that it is done and it is more involved to make that change, is not your fault.

Regarding the other circulators in the basement. I was wondering about them…. Are they connected to a different heating system that is controlled by the other switch?

I kind of remember that you may have mentioned that you have two boilers serving a total of 8 zones. Four zones on each boiler.

And not knowing what zone is what can make solving problems more difficult. You may want to take the time to find out that information before it gets too cold. You do it by turning off the heat at both main switches one mild night before you go to bed. In the morning all the zones will be cold. Now go and turn all the thermostats to the lowest setting before you turn the boiler switch 1 back on (leave switch 2 off for now. You will want to disable the outdoor reset feature on the boiler if it is active now. That way you will get the hottest water from the boiler in order to get the fastest response for your testing.

Then turn up one thermostat to 85° and see what radiators get hot. Call that zone 1A if it is controlled by switch 1. See what circulator pump is running. See what flow control valve is hot on both sides. See what return pipe gets hot after 10 or 15 minutes. Place a tag with a #1 on everything that gets hot when that apartment thermostat gets turn up to 85°. NOW, turn that thermostat for zone #1 down to 55° and move on to another thermostat. If nothing gets hot then that must be on switch #2 so move on to another thermostat.

When you get to the next thermostat that produces heat from switch #1, call that zone 1B and see what pump operates and what radiators get hot and what return pipe gets hot after the that zone calls for heat for 10 to 15 minutes.

Follow that procedure for every thermostat and every zone. Once you are completed, move on the switch #2 and do the same thing again. Once you are completely finished, you will want to make sure that every radiator in the building has a tag on them so you know that the radiator works when there is a call for heat. If there is a radiator that does not get hot by the time you are finished with the test, you can ask the contractor why there is a problem with that radiator. But for now you can't be sure if there is even a problem if you don't know how your building is supposed to work.

It is amazing what holding $4000.00 can get done when you have that leverage.

You can even give the contractor $2000.00 in good faith after they help you with understanding the system and call in a credit card payment to them for the balance once you have digested all that information. Then you can come here and let us know how things turned out and we will be happy to guide you if there are any other issues before you send in the last $2000.00.

Just some random thoughts.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

When you are all finished you should be able to have a chart or a spread sheet the has all the pertinant information.

- Switch #1 controls: Boiler #1 NTI model FTVN-199 Serial # XYZ 0000-00

- Hot water tank Model ABC 40 Serial # ABC 0000-0000

- Zone 1A for apartment (first floor north) with 4 radiators and a B&G 100 circulator

- Zone 1B for apartment (first floor west) with 5 radiators and a B&G 100 circulator

- Zone 1C for apartment (second fl north) with 4 radiators and a Grundfos UPS15-58

- Zone 1C For apartment (second fl west) with 5 radiators and a B&G NRF-2

- Switch #2 controls: Boiler #2 Weil McLain CGi 4 Serial number CP 0000000

- Zone 2A for apartment (first floor south) with 4 radiators and a B&G 100 circulator

- Zone 2B for apartment (first floor east) with 5 radiators and a B&G NRF-2 circulator

- Zone 2C for apartment (second fl south) with 4 radiators and a Grundfos UPS15-58

- Zone 2D For apartment (second fl east) with 5 radiators and a B&G 100.

(info in italics is not accurate and is for demonstration purposes only)

You can even keep a log of the repairs and the dates that parts were changed along with the paper copy of the receipt. You can also keep the instructions of every part replaced with the date it was replaced. That will come in handy if you find that the same part is bad and needs to be replaces within the warranty period of the part. For example if you decide to use a Taco 007 to replace one of your circulator pumps, it would be good to know that Taco has a 3 year warranty on their circulator pumps from the date of manufacturer. So some 2 year old pump may still be under warranty down the road. Good record keeping can save on repair costs in the future.

Keep all the instruction manuals in a lock box near the boiler for easy access to the service technicians in the future.

Another good thing is to have the wiring diagrams of all the controls and how they connect to each other. sometimes that will save time on a service call where there is no heat to one of the zones and you find that it is an electric control that is the problem and you don't need to spend hours bleeding radiators to get air out when it is not an air problem to begin with!!!

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

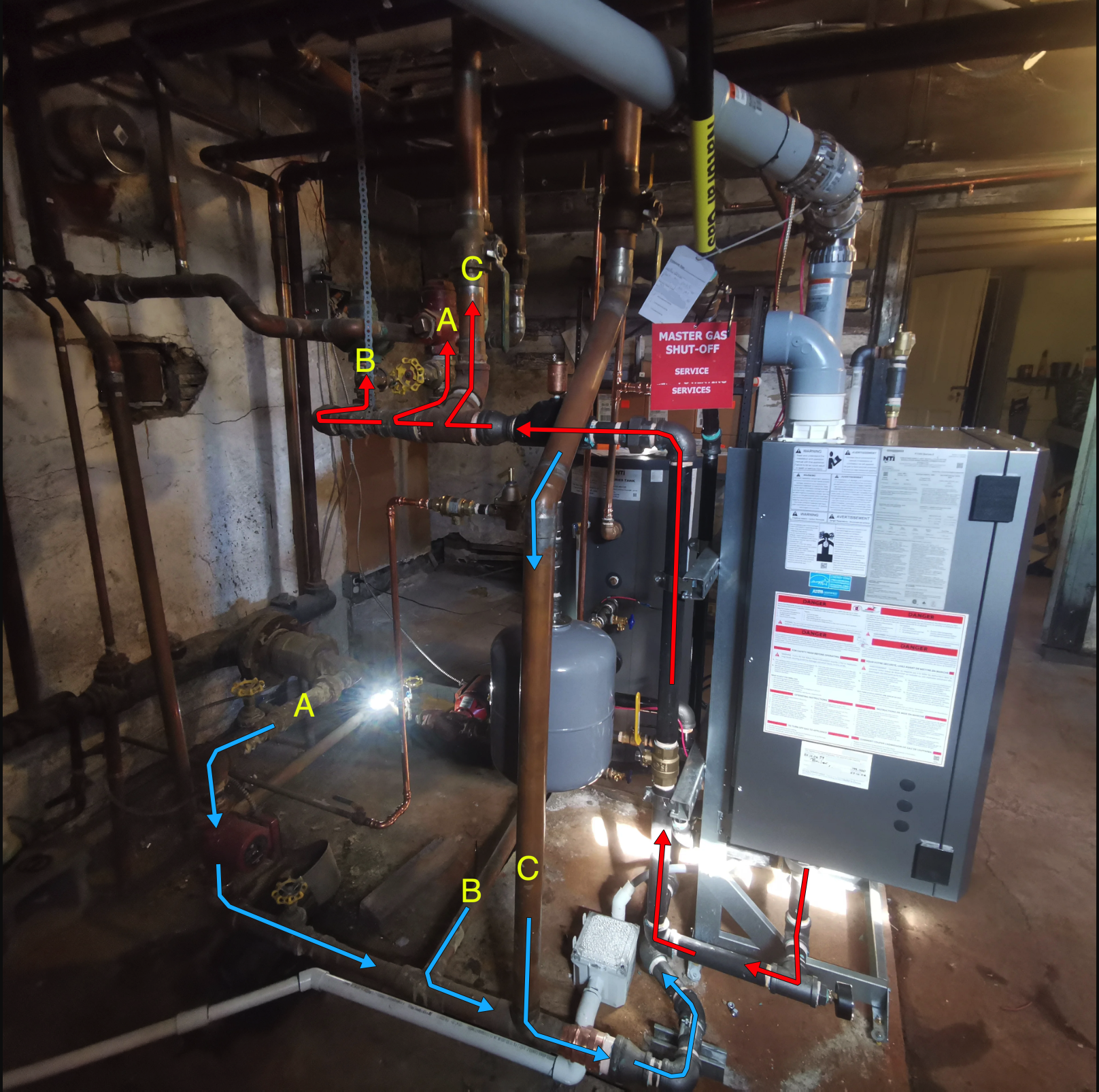

I never said there's 2 boilers, but there are 2 areas which are 'boiler rooms'. There's always been one boiler. The main room has the boiler. The other boiler room has 3 circulator pumps and a lot of pipes. I've posted several photos of each room. Here's the main boiler room which contains the boiler:

This is the secondary boiler room:

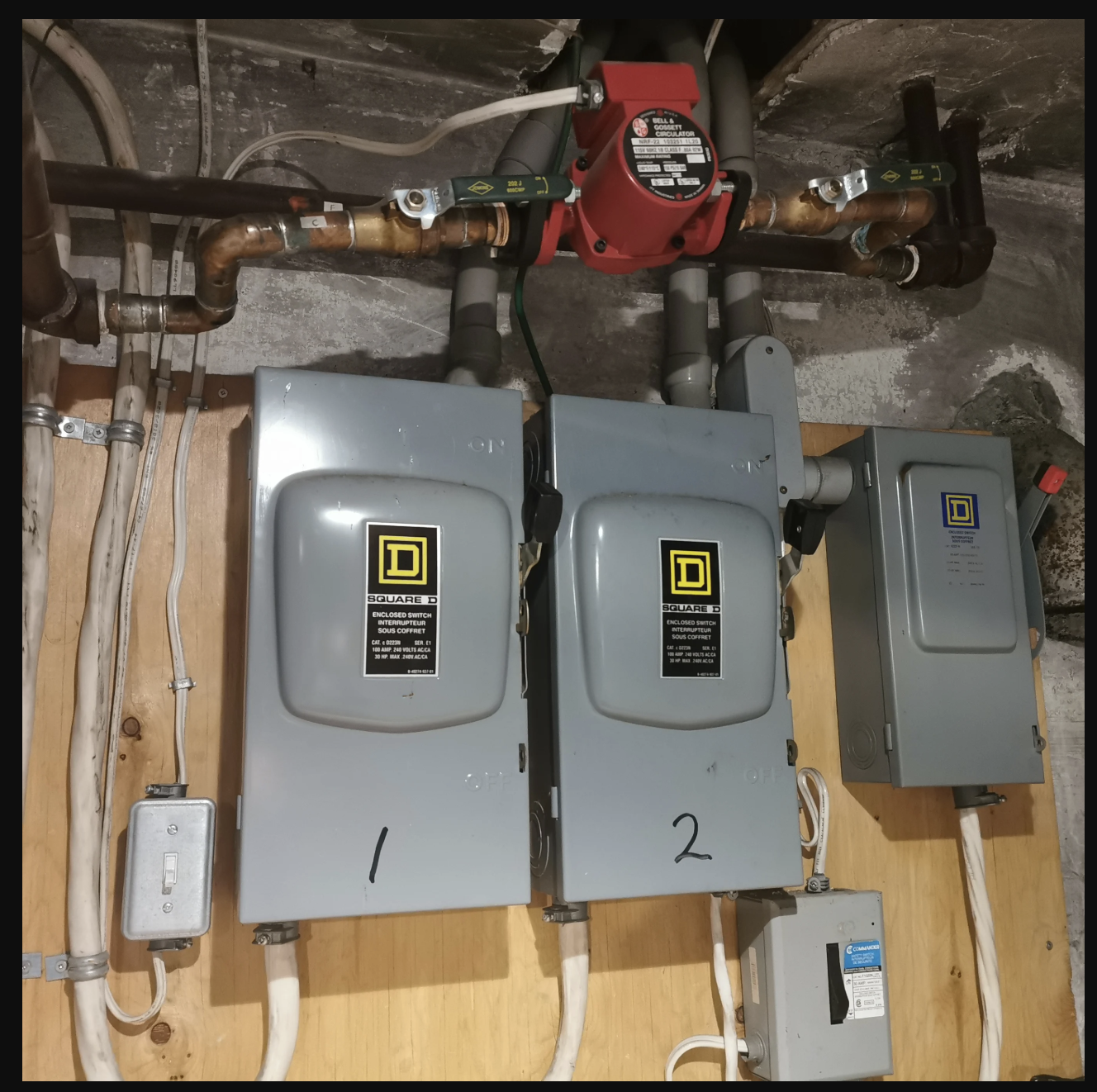

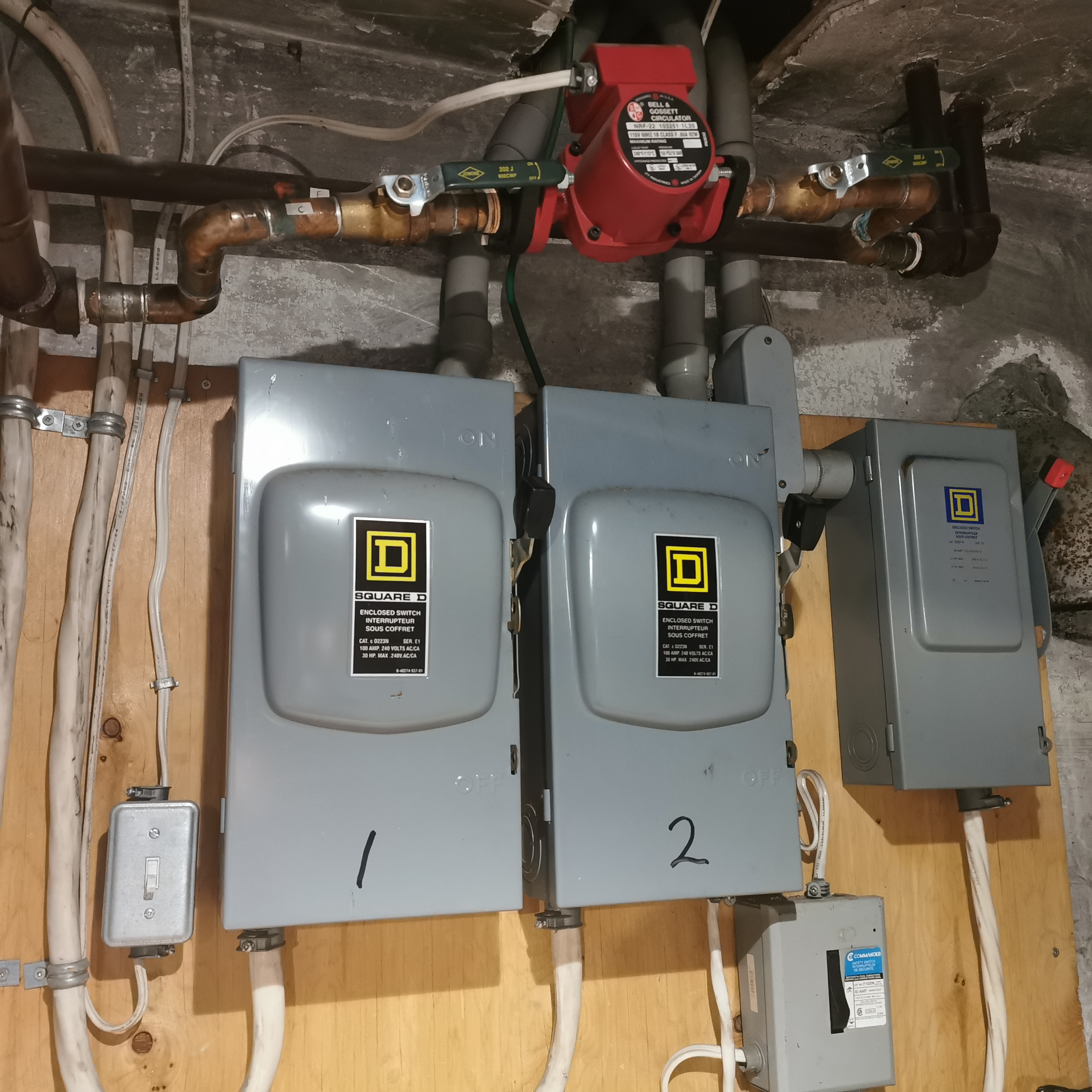

And there's also an electrical panel room that has the circulator pump with its own separate switch that my original thread last month was about:

That B&G circulator above the electric panels is the only one that has its very own switch. The other 5 circulators don't have their own switches. They're either controlled by the main switch for the boiler, or the other main switch in the other boiler room. So I have attempted to isolate which one controls what, over the years, but it's still not entirely clear to me. I even labelled some of the pipes themselves once, to help me remember which one goes where.

When I can't get anything working at all, it's difficult to use process of elimination to determine which circulator pump is for which apartment, much less which subzone in the apartments. I think there's 5 zones in total, but I don't know for sure.

If everything ever works in here again (it used to), I would then be able to systematically go through turning switches off and labelling everything like you've suggested. I believe there's only 3 switches in total to cover all the circulators like in your example.

But there's no other heating system, at least none that I'm aware of, that has any circulators on a separate system. They're all on the same system, as far as I know, and I've never seen any other boiler anywhere in here other than this new NTI gas boiler and the the Weil McClean oil boiler they just removed.

*************

I guess I need to plan out a call to the heating company owner, with a list of things to say. I'm not optimistic about doing that. You say I have leverage, but I don't really. It's too late. I have to pay them or I don't get the rebate. I have to pay them or the whole deal falls through and I'm on the hook for the full installation. When they first came to me with this offer, last year, I initially rejected it, to their disbelief. The gas company sales rep said nobody had ever rejected their 'free' gas line and boiler installation before. But then I got swamped with the other areas of the renovation, and got rid of my electrician after he started acting weird when I said it was time for him to get ready to install the heat pumps he had been preaching to me about for years - once it became time to pick out the heat pumps and order them, he got cold feet. He changed his tune to "heat pumps are no good - lemme just install electric baseboards all over your house - no maintenance!" But I know electric baseboards are the most expensive way to heat, and as proof I got killed on electric bills last winter because of having to heat the house with the few electric baseboards he had already installed. Just 3 baseboards, heating only one small corner of the house, + 4 space heaters heating strategic areas of the house to prevent pipes from freezing and that sort of thing, and for heating my apartment, cost MORE than heating the entire house with oil used to when I had oil heat. Imagine if the whole house was electric heat, even with efficient heat pumps, and I was keeping the whole house at room temperature or near that. So I got rid of him, and decided it would be easier to just leave the house on the same heating system it already had in place, instead of installing baseboards everywhere, and punching a bunch of holes in the side of the building and adding all this new infrastructure for electric heat pumps, which meant having the oil boiler replaced with a gas boiler. I thought if I gave up and went with the gas offer I'd have more time for the other areas of the reno. Now it turns out that that's not the case and I was going to be drowning in problems regardless of which choice I made.0 -

What is the deadline for the rebate? October 17? You have leverage. Some Leverage anyway.

To know how many zones you have all you need to do is to count the thermostats. Is the boiler operating now? If not… then you don't pay, take them take you to court, no judge will make you pay for a heater that does not work. Document everything. every phone call should be followed up by an email that confirms what was said on the phone. "This email is to confirm that on the telephone you said that this, that ,and the other thing… If you understood it incorrectly please make a clarification" and the email reply will be a document that has a date on it.

Any rules that apply to a rebate or a grant with deadlined must include that the system is operating properly. if the system can not be proven to operate properly, then you don't pay anything at all. You get a lawyer.

Questions that need answers when they come for the final payment.

- Why were the circulator pumps not moved to the supply side of the system as instructed in the manufacturer's instructions.

- Will you guarantee the system will operate trouble free when the circulators are on the return?

- How do you expect the air control device to operate properly when it is not installed as instructed by the manufacturer of the device? (Namely the minimum 18" approach piping)

- How ofter should I expect. to need to have air removed from the system based on this improper design of the piping and air elimination device(s)? If it is more that once than it is not an acceptable design for your system. If it is more than once a year, then it is a really bad design.

- How long will you stand behind your workmanship. The boiler has a lifetime warranty in a residential home and a 10 year warranty in a commercial property. since this is a commercial property, I assume that the heat exchanger will have a 10 year warranty from the date of job completion (you should go online and register this NTI boiler at the end of next month to get the 10 year warranty to last as long as possible)

- If they believe their product is that durable that they can offer a lifetime warranty to single family homeowners and a 10 year warranty to me, How good is your workmanship that you will offer me a warranty on the labor and workmanship you performed in my boiler room or at the successful completion of the job where air scoop is installed properly and the circulators are proven to be installed in an acceptable manor. If your warranty is only one year, then I want the one year to start at the end of the month after the circulator and air scoop issue is resolved so I have a couple of days to test drive the new boiler. You can do that for me, Can't you?

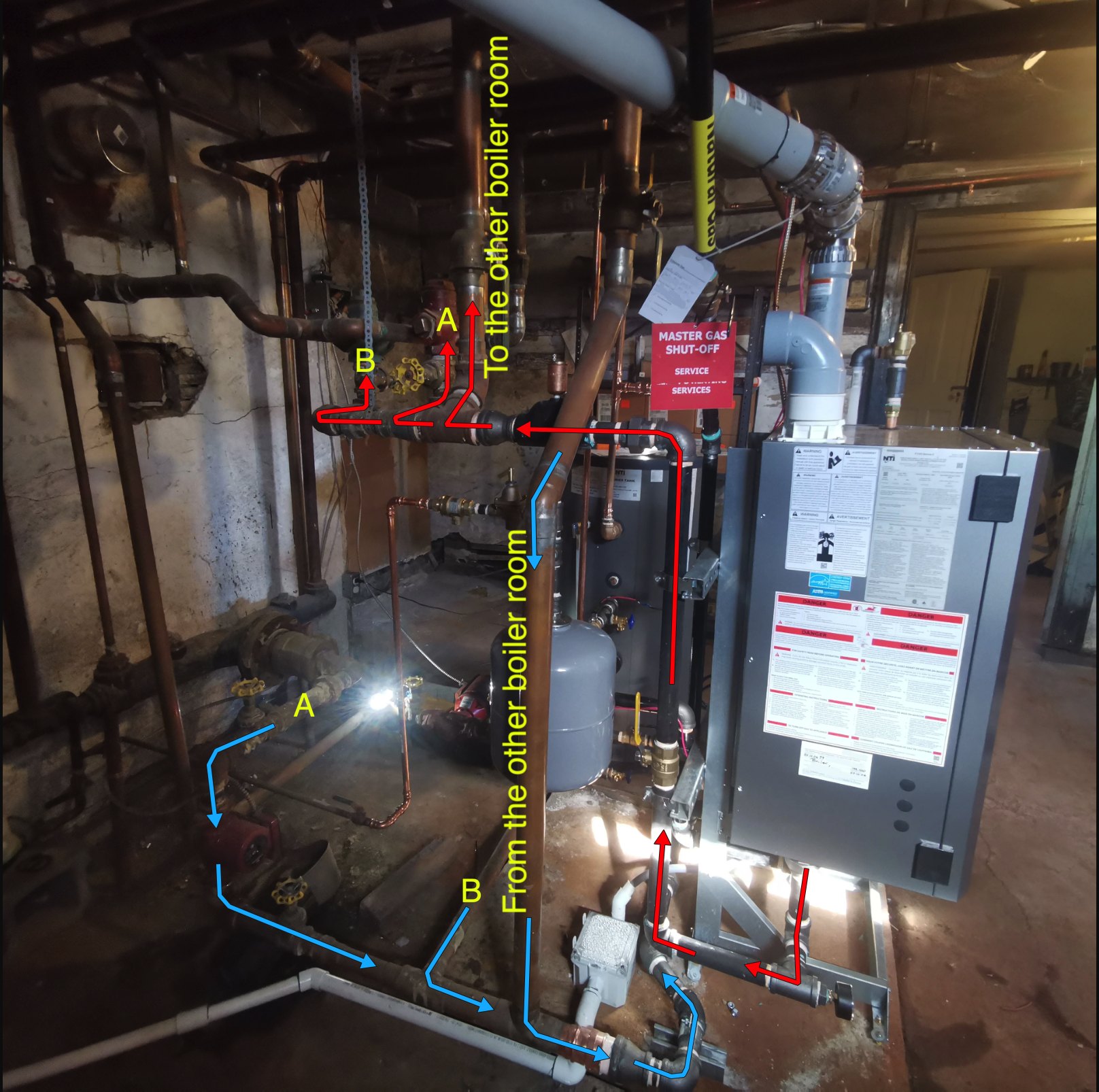

Finally I believe that your system as installed has more that one zone that are connected to what I called Zone C in my diagram. That piping must go to the other boiler room and get divided up with tee fittings that have additional flow control valves and the other circulators.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I'm not sure what you're asking. The valve whose lever I lifted to add pressure to what I thought was a boiler with no pressure is called a pressure reducing valve, yes or no? Or is it called a pressure reducing fill valve? Do I have both of these things, or are they the same thing and there is only one of them?

"Can you post a wider shot of that valve you opened…" I have, it's in this one: .The pressure reducing valve is smack dab in the middle of this photo, and the handwheel that I discovered was closed, so I opened it by turning it counter clockwise, is along the path of those blue 'A' arrows.

0 -

when you lift it, it manually feeds water. With the lever down it’s automatic to whatever it’s set for.

0 -

I just saw a notice that you mentioned me ins a post at 6:39 this evening. When I look at that post it was edited at 8:27 so I dont know what you said. but I'm glad to help if I can

I see a previous comment about the automatic boiler feed being called a Pressure Reducing Valve (PRV) which is sometimes confused with a Pressure Relief Valve (PRV).

Since there is often confusion on this topic with Professionals I like to make this information clear as mud whenever I can… I jusr saw you sent me a PM.

BRB.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

See if there's a pressure gauge inside the boiler that's working.

The gauge showing zero seems stuck. Tap it lightly with a wrench.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0 -

No gauge in the boiler. That is the one provided by NTI. There are digital readouts of all the parameters but that does not qualify as the gauge required by code. So, you get that piece of junk to pass inspection. I don't believe it is necessary if you know how to work the menu of the control. But not all customers are that well versed in reading the 100+ page manual to get to the menu that tells you the way to get that info. the pressure reading from the electronic menu may not stay there and drop to a default menu after several minutes of no input to the control. The age of modern computers that make out life easier. Don't you love the 21st Century?

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

that is the age of spending as little as possible on the display.

in the use a tridicator with only Fahrenheit isn't unusual. that gauge isn't an ashcroft or dwyer but it isn't complete junk either. As someone else said, especially being down in that corner it is probably plugged with pipe dope or teflon tape.

0 -

I don't see any evidence of pipe dope or tape used on it - it just screws in. I'm sure you guys see more gauges/thermostats/tridicators than I ever have but I haven't seen anything else that only shows temp in F unless it's 80 years old, while this tridicator is brand new - it makes me suspect they're skimping and it could be poor quality. The previous Weil McClean oil boiler that was here's tridicator was displayed in both C and F and if I recall, PSI +kPa.

I moved my previous comment from yesterday evening to a PM with Ed for legal reasons, just in case.1 -

Oops. this is on the wrong discussion

You have 5 zones and it took me some time to understand that when you first posted back in October 2025. I needed to see the old system and the new system and with some comments from others I was able to see that the new boiler may not be pretty, however it is installed correctly.

At first I thought there were only 3 zones on one boiler and three zones on the other boiler, until you told me that there was only one boiler. Then I looked at all the photos as you posted them. In the new boiler photo above there are three pipes that leave the boiler room on the supply and three pipes that return to the boiler. Only two of the pipes have circulator pumps A and B zones. The third supply pipe leaves the boiler room and goes to feed three other zones in the other Pump Room. The second picture I have labeled the return to the boiler room and the three circulators that are connected to that Return pipe.

You already know that the pump is backwards because when it was installed in the vertical position, the zone worked. Now that the pump is turned in the horizontal configuration the zone that pump feeds is not getting heat. DUH! That is because there is a flow control valve that prevents the water from flowing in the wrong direction. Your pump is pumping in the wrong direction. Believe Me. Your pump is backwards.

Look at the blue arrows on the drawing The two B&G 100 pumps are pumping down and to the left then up the return pipe and back to the boiler room. The B&G 45 is pumping so the water wants to go the other way. At the other end of the radiators on the supply side there is a flow check that is stopping the flow. As it is supposed to.

Ask yourself “if the pump was pumping in one direction and everything was working and now that it is pumping the other way and things are not working what did I change to make this happen? Your answer should be the pump direction.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements