Deviating from specification on head position.

Technician question:

One thing that is missing in the various oil burner tuning documentation, videos etc, that I have found, is the head position adjustment other than the obvious, adjust it to OEM specs.

What symptoms lead you to think you should adjust the head position away from specs? and any tips, processes, insight, on this would be appreciated.

This question is coming from several experiences. most recently I serviced a Buderus G115/4 boiler with a Carlin burner that was running rough and the sight glass was completely blacked out. Not a terrible amount of soot but dirty. The head bar was missing, and the hole was covered with foil tape. I found the head bar under the boiler. Upon cleaning the flue/HX/burner then replacing the filter and strainer I found the wrong nozzle in place. there were no notes on the boiler from the previous tech. I figured the tech didn't have the right nozzle and that required him to tweak the head position.

I replaced the head bar, marking the previous position, just in case, installed the spec nozzle and started from scratch. the burn was noisy and I could not reduce the smoke without the burner going off on safety. I had a bar kit and basically matched the old position and was able to get a smooth run smooth with reasonable numbers but did not leave felling like a pro. I don't like that.

Comments

-

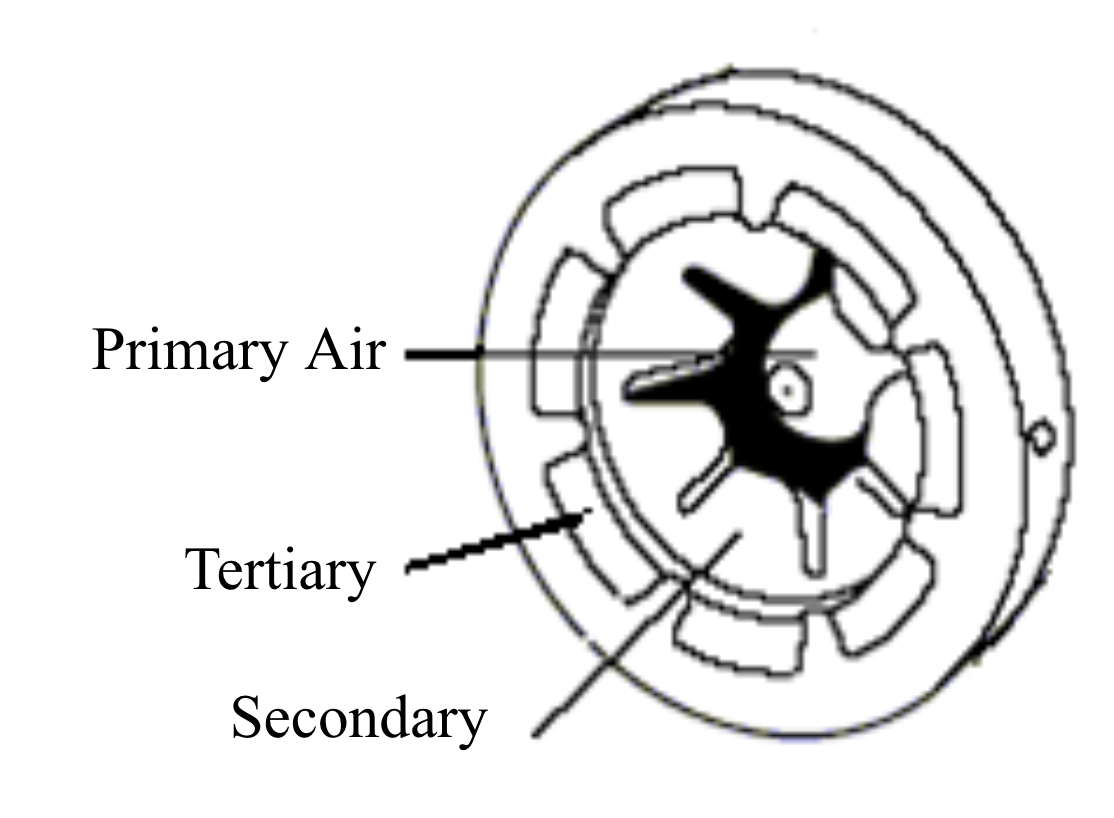

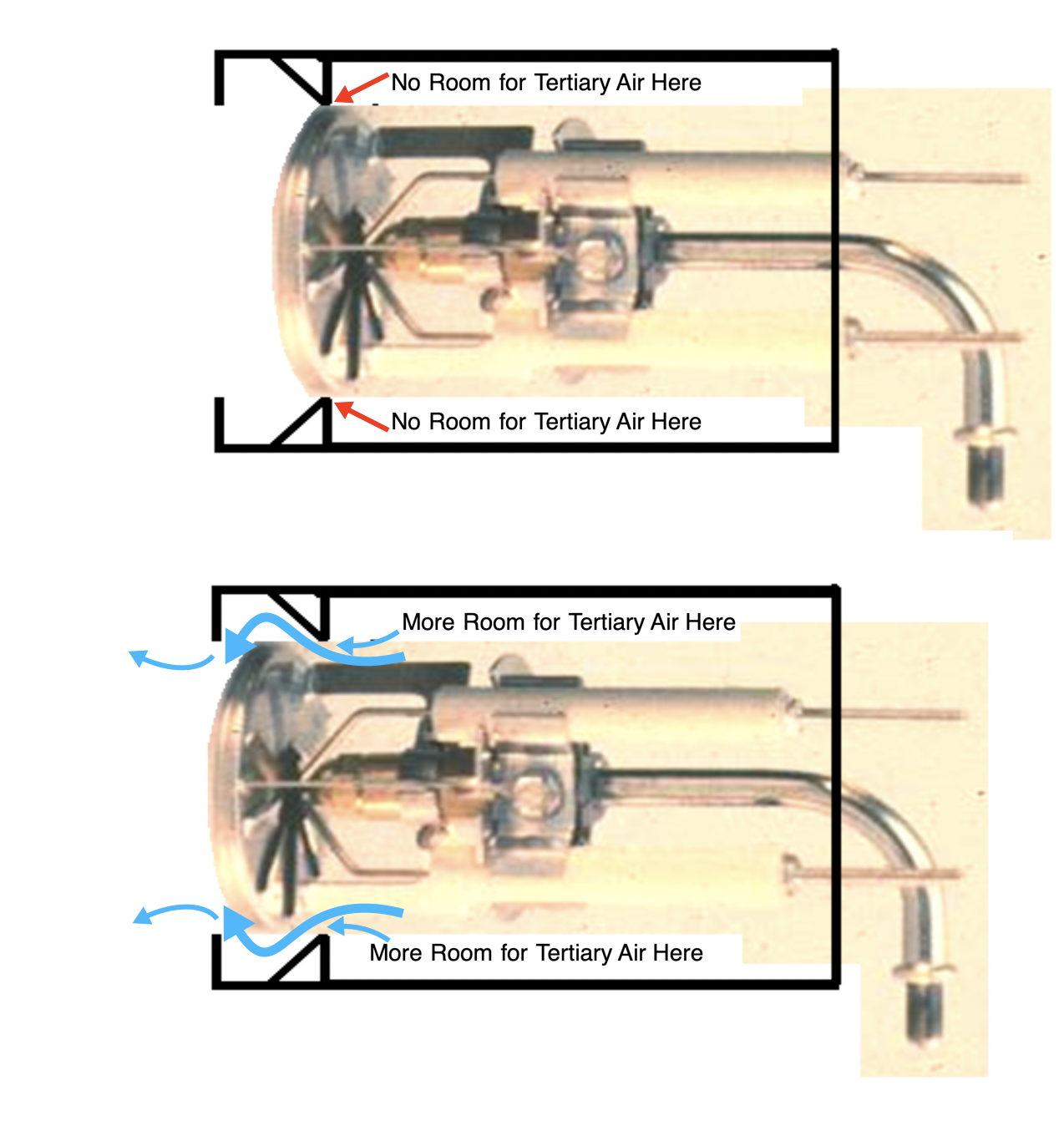

The retention head position on any oil burner that uses the retention head that attaches to the nozzle assembly like the Carlin CRD and the EZ burners do are made adjustable so you can add additional air for combustion when the primary air (the air that flows through the center 5/8" to 3/4" circle where the oil spray enters the combustion chamber) and secondary air (the slots in the retention head) are insufficient for complete combustion. That third air adjustment that makes the opening between the edge of the retention ring and the air tube opening, is there so more air or less air can get to the flame as needed.

Looking at the fixed head flame retention heads like the ones found on the Beckett AF and AFG burners will indicate clearly that the larger the opening around the outside of the circumference of the flame retention ring (like the F12 thru the F30 end cones) are designed for larger firing rates while the narrower circumference openings (like the F0 thru F6 end cones) are for the lower firing rates.

These adjustable head burners allow you to shape the fire from a narrow long flame to a fatter short flame with a little tweaking. That adjustment is not available when you use a fixed head burner without replacing the end cone from a F3 to an F6 and you know that isn't going to happen in the field on any regular basis. Changing that third air adjustment by moving the nozzle in and out while the burner is operating can give you real time visual and audible feedback to get the quiet operation that your customer require.

Move the nozzle closer the the chamber gives you a larger tertiary opening that may quiet down the flame. After locking that down you can then reduce the air gate opening to compensate for the additional air. When you get that zero smoke spot test, and the combustion numbers look good, you can leave feeling good about your adjustment that is not exactly on the OEM starting position numbers that are published in the manual.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

2 -

On a fixed head like most Becketts, you pretty much can't do anything except that in some cases different size heads may be used with the same nozzle as the firing rate for the heads overlaps.

On a Carling most heads are adjustable. Start with the MFG recommended settings but do not be afraid to deviate if it doesn't work.

On a Carlin moving the head changes the static pressure the burner fan works against. Moving the head changes this pressure higher or lower and also changes the air flow through the burner and changes the flame retention.

In general, pulling the head back will give a more intense flame, maybe noisier, maybe a shorter flame. Moving the head foreword will make the flame less intense and quieter and maybe longer.

2 -

^^^Exactly that ^^^

Interesting story: During the second oil crisis (First 1974 Second 1978) I was a full time oil burner service technician at the F P Young Co. in Philadelphia during the Carter administration. Following the Nixon administration the Department of Energy was formed in 1977 in order to study ways to conserve energy. Frank Young was very interested in all that was going on in the government regulations that were being imposed on fuel oil dealers and got involved with different committees in order to be the voice of the fuel oil retailer.

As part of the way F P Young Co. did business with their customers we had a program where we would evaluate the old coal conversion boilers and furnaces to determine if there was any way that our customers could reduce their fuel usage. I know this sounds counterproductive, but having a customer that burns less oil made for a happy customer and also kept those customers from converting to Natural Gas. "Less fuel oil sold is better than no fuel oil sold".

Since we were already in the business of selling more efficient oil burners to reduce our customers fuel oil consumption, the F P Young Co. had something that the government was interested in offering to ALL the fuel dealers. Modernize the old boilers and furnaces and retain customers, and that will reduce the US dependence on foreign oil. As part of that program the F P Young Co hosted a government committee that was composed of some top engineers in the business, to witness an actual “Modernization” of a coal converted boiler with a 1940s oil burner. All the engineers were contributing to the specifications for the actual job (that usually took 4 hours) in order to get detailed notes on the specifications to make the old converted coal boiler to operate in the 80% Combustion Efficiency range. It was approaching the 8 hour mark, The manufacturer's specifications in the I/O manual on how to adjust the burner were not producing the expected results. The F P Young technician who was actually doing all the work under the guidance of the committee of engineers was interested in going home as it was at the end of his work day.

Bob was his name and I recall this story; where he was just about at the end of his patience for this “installation by committee” and told all the PhD and Masters degree heads to step aside and learn something. This Vietnam veteran who had a high school diploma and was just a blue collar working stiff needed to show all the brainiacs “how it is done in the real world.” and took over the Carlin burner adjustments. His experience of doing over 200 different modernizations in his time with the company allowed him to use the best nozzle, oil pressure, and burner air adjustments that made the burner operate quiet, zero smoke and about 81% combustion efficiency. And one of those adjustments was to move the nozzle assembly 2 notched foreword of the factory specified setting for the firing rate being used.

That was back when we were all using wet bottle kits for checking Carbon-dioxide percentage and a stack thermometer for the temperature and a slide rule calculator to look up the combustion efficiency. I do recall that there was one “Lynn Analyzer” that plugged into a 110 V. outlet to electronically tell you the stack temperature and the oxygen content in real time as the adjustments were made. The first electronic combustion analyzer all the way back in the 1970s WOW!

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

2 -

-

Back in the 70s and 80s I had Carlin factory tech out to two different jobs we had problems with that both had interesting fixes.

The first one was an old lady with a 400N2R (the old lady was noise sensitive hence the slow speed burner) which was a slow speed Flame Retention burner that had been newly installed 3 years prior and ran fine with no issues.

After 3 years it was building carbon on the chamber floor. This burner had been gone through by me trying to fix the problem and everything was set up properly. It was installed with a 70 degree nozzle and we tried a 60 degree to narrow the fire with no improvement and still made carbon on the floor.

Carlin came out and tried a few things then we put an 80-degree nozzle in it and that was the fix. When I asked him why he shrugged his shoulders and said "I don't know, different oil maybe but the 80 degree nozzle fits the flame pattern of this burner in this boiler better"

So, I learned an important lesson. Mfg. specs are a starting point and don't work on every job.

If you bury your nose in the book and insist on the factory specs on all jobs you will fail once in a while.

The second job was a new boiler for the National Guard Base. A Weil McLain factory package with a Carlin 200CRD (I think). This one had poor combustion even when set to factory specs.

I don't remember what the fix on this one was, but I think it was a nozzle change as well.

1 -

Realy good dope as allways!!! thanks you!

So, if I understand correctly, if you move the nozzle assy on a fix head configuration, you will be tweaking just the primary air that flows around the nozzle. Is there ever a benefit to that?

0 -

"If you bury your nose in the book and insist on the factory specs on all jobs you will fail once in a while."

Very good advice!

0 -

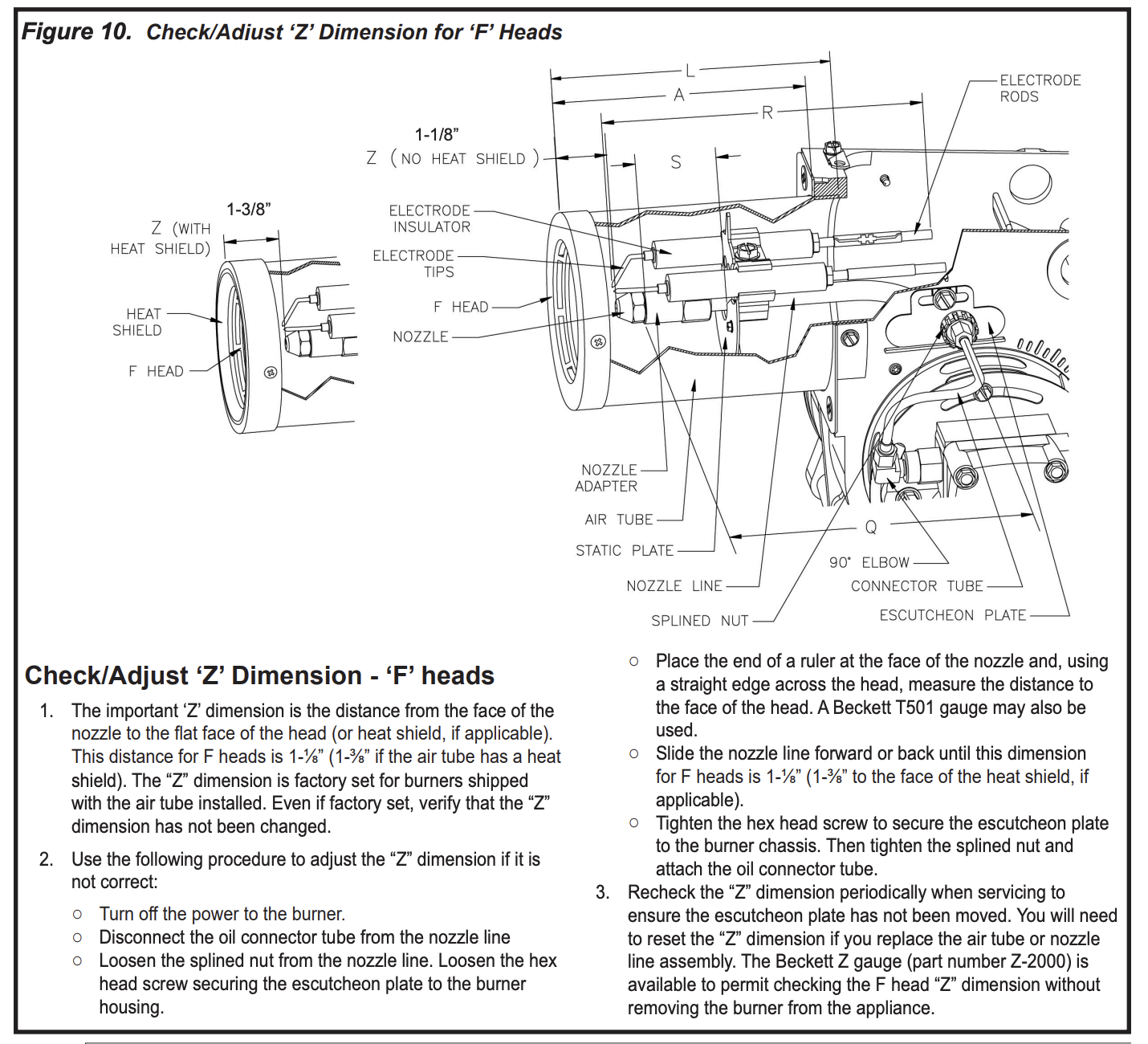

NO. !!! NO !!! NO. !!!

moving the nozzle in relation to the fixed head will only mess up the dimensions that pertain to the spray pattern with the retention ring. That is not an adjustable dimension. On the Beckett AF and AFG fixed head burners that is called dimension Z and that is always 1-1/8" with F head end cone. Sometimes there is a 1/4" heat shield on some burners that don't allow for easy measurement of the Z dimension in relation to that part of the F Head so there is a 1-3/8" specification to the end of the shield.

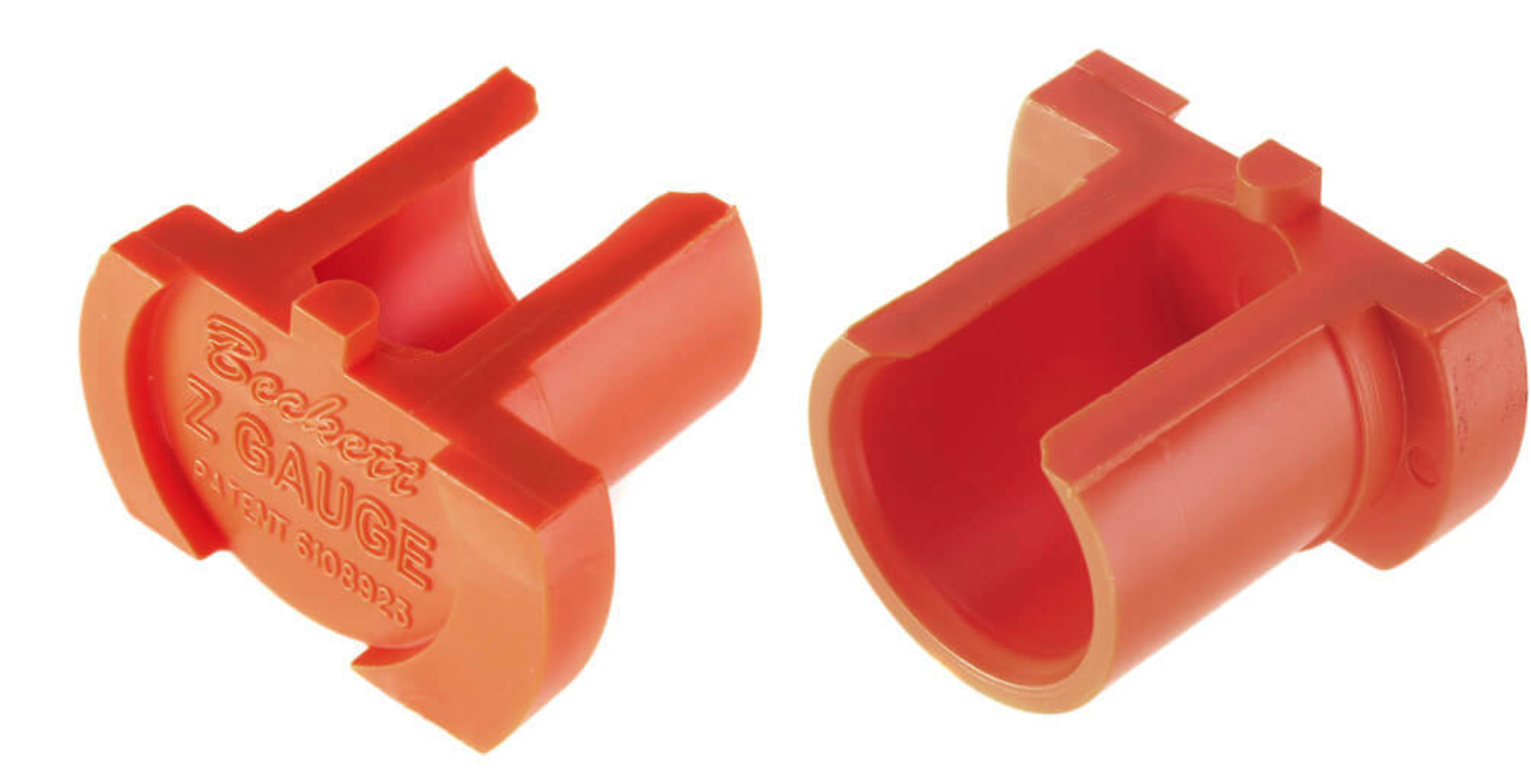

There is actually a gauge that you can use to set the Z dimension when the burner is already mounted and it would be a hassle to remove the burner to measure from the end of the F heat ro the face of the nozzle orifice. This is the Beckett Z gauge

It measures the Z dimension from the back of the end cone so the nozzle is in the perfect position in relation to the flame retention head.

Other burner manufacturers use a fixed head end cone like the Aero oil burner found on some oil fired water heaters and the Ducane furnace also had a fixed head oil burner with the same brand name (but I think is was built by Wayne oil burner folks. You must follow the manufacturers specification for that dimension on any fixed head burner.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

As @EdTheHeaterMan said

Do not move a nozzle assembly on a fixed head burner. That one must be set to the factory spec. Adjustable head burners like Carlin can be adjusted within reason.

1 -

-

I wont!

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements