Boiler plumbing questions

New here and new to hydronic heating. I have an Energy King 35ekb wood boiler that I am installing in my house that has no existing hydronic infrastructure. Planning on using cast iron radiators with trvs. Also want to use a plate exchanger for domestic water. Can I use a groundfouse Alpha circulator as my only circulator or do I need primary boiler circulator with secondary circulators for my heat and domestic? Not planning on storage atm .

Comments

-

-

If you do not mind listening to someone who burned wood and coal in a hand fed unit for 33 years I want to help you.

Piping your system as am overhead/top fed gravity hot water heating system with an open to air expansion tank is simpler to do and eliminates the need for circulators.

The top fed/overhead gravity hot water heating system ELIMINATES BLEEDING RADIATORS OR HOT WATER BASEBOARD heating methods. It also allows you to use 170-180 degree water to heat you home slowly and evenly as all the hot water reaches the radiators from the top and the cooler return water returns to a common return header pipe that is plumbed into the boiler sump.

The overhead method fills the system with water from the top down and the hot water riser that delivers the hot water to the top floor allows any air bubbles to quickly dissolve into the open to air expansion tank.

The overhead/top fed heating method eliminates the need for an expansion tank as the system pressure is allowed to rise and enter into the open to air expansion tank and the pressure/vapors exit the vent pipe through the roof or to the drop pipe that drains back into a floor drain or a laundry sink.

The drain pipe also allows the end use to fill the open to air expansion tank with make up water by simply using a ball valve plumbed into the riser to fill it with make up water and the drain pipe will show you when it is filled.

The 35EKB has 35 gallons of water and uses a 2 inch steam chest tapping if the cool water return tapping on the side of the boiler it will allow the riser and return pipes to rise closely to the ceiling of the basement to allow the simplest piping to the radiators using a common return header hung in the ceiling joists.

You will have a massive amount of thermal mass in the 2 inch piping, the cast iron radiators, the open to air expansion tank and the total water volume of the system.

The ability to provide slow even heat will warm your home no matter the weather as the boiler is operating using the high limit and low limit temperatures set on the triple aquastat in the basement.

NOW as psb75 has stated you need hot water storage being a buffer tank to extend your burn times and increase your available thermal mass; hot water storage is just like money in the bank except the bank is the thermal mass bank.

There are water heating calculators available from the web that you can download and type in all the numbers you have to see how much hot water you will need to heat and how long it will take to heat it.

The basic key to using wood for hot water heating is this:

Splitting your firewood into the smallest piece provides you with the greatest amount of firewood to heat your hot water in the shortest time.

Using coal grates and Anthracite or Sub Bituminous coal will provide you with more heat for extended periods which reduces the number of times you have to load the boiler. Using coal and wood with coal grates would also make heating your home easier with an overhead gravity heating system that will also heat your domestic hot water.

The 35EKB

1 -

-

The worse condition to run a solid fueled boiler is short cycle conditions. These are inevitable unless you have a full load always on the boiler. Their sales slick cautions against that. Any idea what your heat load is for the home?

Usually a manufacturer will show some piping options in he manual??

https://www.energyking.com/manual/energyking-furnace-user-manual.pdf

I had a similar boiler that I heated with. I started with a 160, then 300 and ended up with a 500 gallon buffer tank, an old repurposed LP tank.

Only then was it completely manageable.

Dry wood is a must, no green wood or garbage.

Some piping ideas here.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

I am aware of the shortfalls of no storage, currently working at digging out my basement so there is no room for it and there isn't funds available to purchase a pre-made solution or time to build it myself. Will be utilizing a dump zone.

0 -

@psb75 my question was do I have to run a primary / secondary circulators or could I feed the heating zones and the plate exchanger with an Alpha? Is the head pressure through a plate exchanger to much different than a heat zone to treat it like another zone? I will be feeding the radiators with 1/2 pex. 1200 sqft house so the runs to the radiators are not going to be extremely long.

0 -

Hello Bob,

Appendix B on page 39 shows an example plumbing diagram.

The cool water return location is on the side of the boiler in one model (but not the unit he has) and it is parallel to the hot water tapping on the steam chest creating perfect water flow for an overhead gravity hot water system.

Having a cool water storage tank in the basement piped into the side tapping would allow the system to have a huge water buffer that would easily work well with an overhead hot water heating system as the return header in the basement ceiling would allow for a simple install where the returns from each radiator would tee into the main return header that would return the cooler return water to the two 1 1/4"return tapping's simply by the weight of the water passing out of the radiators and into the horizontal storage tank or multiple tanks hung between the ceiling joists OR using a larger buffer tank where the return header would be piped into the base of the tank and the return water would be taken off the top of the tank using the two 1 1/4" tapping's on the boiler as it is warmer and would flow to the boiler sump by convection and it would continue to let the water flow through the boiler and to the hot water riser delivering the hot water to the top floor open to air expansion tank or a an expansion tank piped to deliver over flow to a basement drain or laundry sink.

0 -

@leonz how do you zone a gravity system?

0 -

@hot_rod I do not have a specific heat loss calculation the house it is a log house with little insulation there is lean to additions front and rear with unknown insulation.

0 -

no need for PS with that boiler pipe the radiators with an Alpha

Either a separate zone valve for the plate hx or a second pump

With a good size hx, pressure drop is small

Most combi boilers use small 4 or 5 by 8 plates

If you look online 5x12 are the most common and priced right 8 or 10 plates is plenty

If you read that Idronics we suggest D I mp handle a full fire box of fuel, same with the power outage dump zone

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

@hot_rod thanks for the information, So the zone valve on the heat exchanger would be activated by a flow meter? Or can I have the plate exchanger have constant flow or will that not work for an Alpha set up for trvs? In other words could i ballance it with the other zones or would it get priority flow causing no flow to heat zones? Sorry if I'm being dense 😃

0 -

Hello Forge_fixer88,

The entire home is one zone, all you would need to do is close the valve on the radiator in the room you want to cool down, the diverter tees in each radiator deliver hot water from the overhead header pipe and you can open and close the valves on each radiator if you want to do that. With your home as you describe it I doubt you will want to zone it in any case as the entire home will be heated slowly and evenly by the simple use of convection moving the hot water slowly through the basement and then to the top floor without circulators.

0 -

So I can be clear in my understanding of what @Forge _Fixer88 is attempting to do here. There is a log cabin with some additions that may not be logs but possibly uninsulated frame walls (or possibly uninsulated log walls. I have seen both). There is no heating system at all yet, but there is electricity available. Fixer wants to use repurposed cast iron radiators with TRVs to control the heat in the rooms. There will be no other fossil fuel or electric boiler system, Only the solid fuel boiler. And he is starting from scratch. Does that about sum it up?

My thoughts on this:

In the later 1800s and early 1900s this is what we did as an industry. We took homes without heating systems and installed them using solid fuel boilers and cast iron radiators with no other existing heaters or systems in place.

All the literature on solid fuel boilers is written to install them next to the existing boiler as an alternative heat source, not the primary heat source.

Fixer needs to look at the installation instructions that the Dead Men used (all the plumbers and pipe fitters before us) to install those old boilers and design the heating system according to those manuals that you might find in the here.

There were no TRVs back then, there were no circulators back then, they were not designed using a buffer tank, there was a wife that kept the home fires burning just right while the husband was out working the fields or earning a living or bringing home the bacon so to speak. Once you use @leonz's idea and learn to stoke the fire properly, you will then know how to keep from overheating and under-firing based on the weather of the day. Wouldn’t it be great to find some great-grandmom’s daily diary of how she fed the coal boiler? Times, temperatures, pressure, amount of coal and damper settings

But that would only work on that home, your home will need its own diary.

Regarding the DHW heat exchanger, That would be nice to have for winter use of hot water, but how do you heat the DHW in the summer when you don't need the heat? You are going to need something to heat water in the summer. Back in the 1800s indoor plumbing was not in everyones home and the cooking stove would be the place you got your summer hot water from.

Just some random thoughts.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

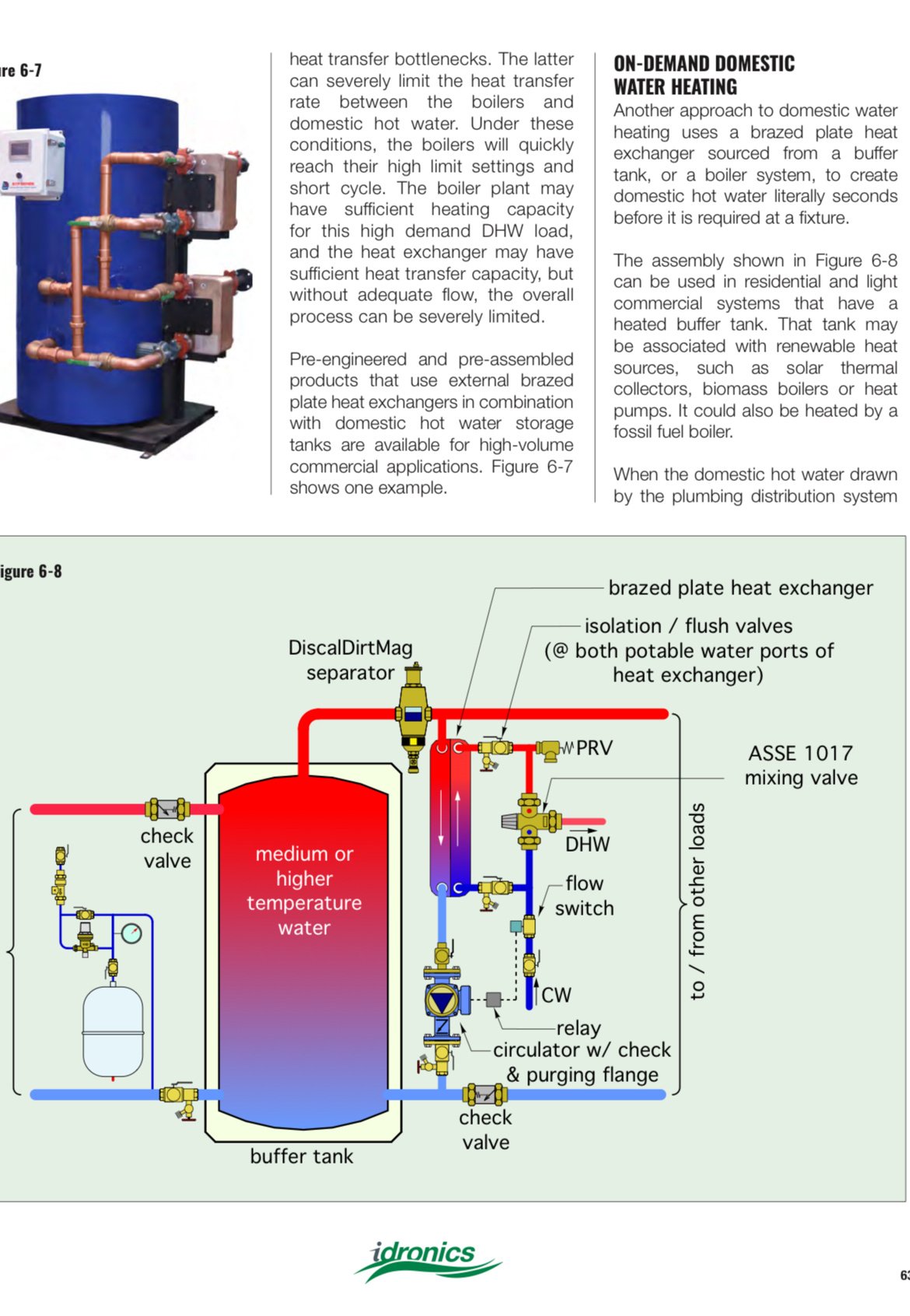

here is the common way to use a hx for dhw

A small flow switch on the cold feed turn on the pump or zone valve

Sika and Harwill are two brands I have used. Trigger point at .35 gpm flow

Of course the boiler will need to be maintained hot all the time. With a solid fuel boiler you cannot wait 20-30 minutes to fire it

You can generate 120f hot water with boiler temperatures around 140f. Even lower if you up size the hx

Generally a small electric tank is used in summer months i had solar thermal heating that 500 gallon tank so 90% of the year wood or solar worked

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

@hot_rod I have an electric water heater, the existing heat was an old yukon energy forced air wood furnace.

1 -

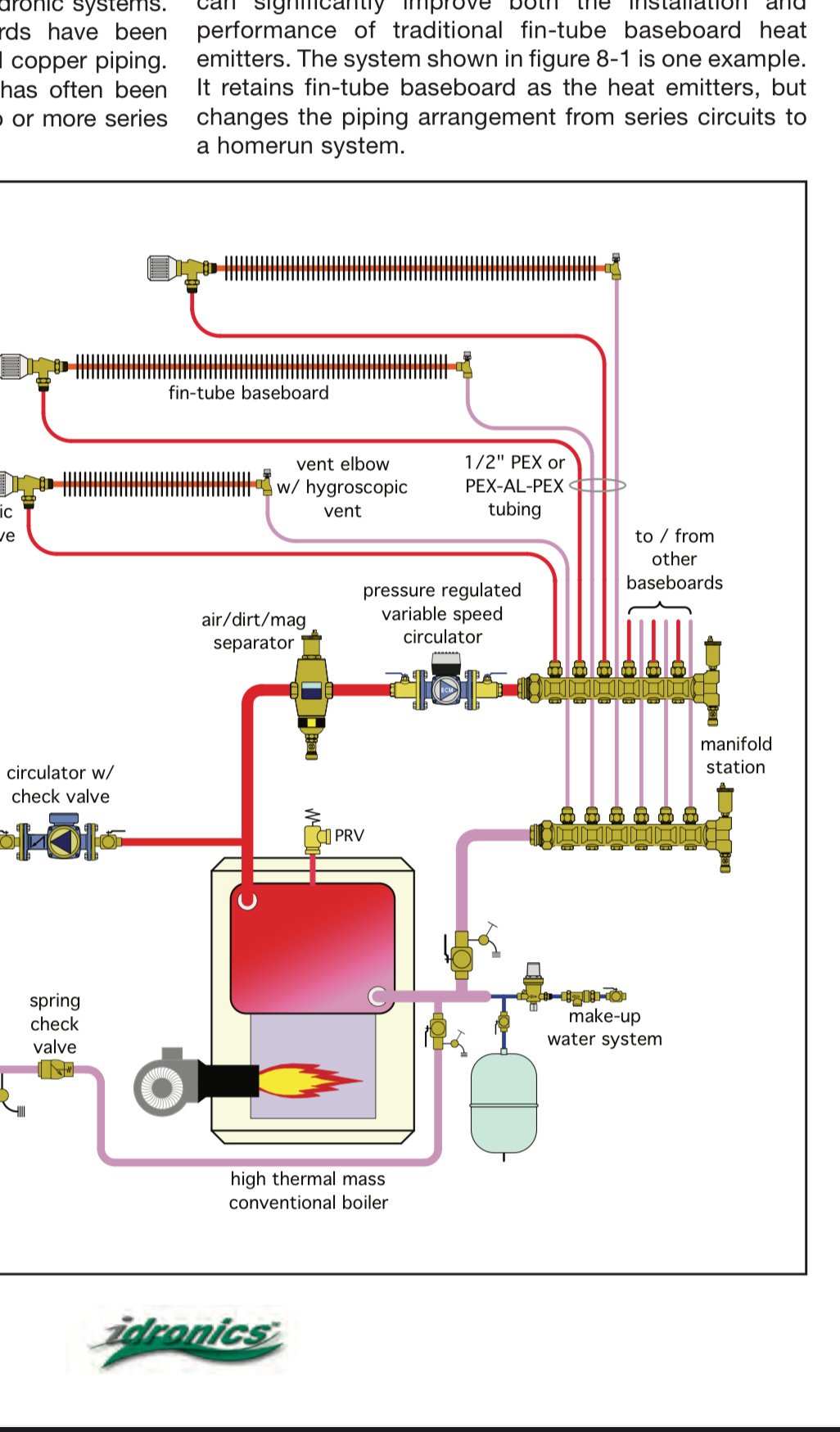

I would suggest a home run system with 1/2” pex to every radiator. It could be zoned with TRVs or with electric actuators. This is in the realm of most DIYers

An example with fin tube

The plate HX just after the pump before the manifolds

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

That was my plan to run home runs to the radiators.

0 -

The issue with the use of pex will be the heat and the 2 inch riser. If you still want to use pex and circulators you should consider creating a 2 inch riser and header pipe and running it from one end to the other of the basement and then installing tees or crosses to feed the hot water to the radiators with a common return header with Tees for the cooler return water and then splitting it into 2 drop pipes to meet the boiler sump tapping's.

With your open construction you have the opportunity to install an overhead gravity hot water system eliminating a lot of extra work and having slow even heat no matter the weather at a lower temperature.

Please go to the Heating Help Bookstore and purchase a copy of CLASSIC HYDRONICS and a copy of HOW COME and you will be very happy you did as they show how a bottom fed or top fed/overhead hot water heating system works and works well using simple convection to move the hot water for you.

Your boilers design allows you to install both the hot water riser and the cool water return piping next to each other which will allow fast delivery of hot water to the radiators to heat your home and return the cooler return water back to the 2 tapping's in the boiler sump to be reheated. The weight of the water is going to be your friend as it has mass and when heated greater thermal mass and it is lighter in weight allowing it to move more quickly by convection.

0 -

I'm not sure how many folks have the ability or $$ to run 2" piping throughout their homes. I'm guessing in the $5- 6.00 per foot for schedule 40 steel pipe. Plus insulation?

In log homes it may not be easy to hide or cover large piping.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Hello Bob,

My only thought throughout this was the simplicity of the overhead gravity hot water heating method and how little messing with an overhead system requires=none, no bleeding, no slugs of air to deal with, no bladder tank to create the point of pressure change, no circulators, no bypass valves, balanced even heating because the flow of hot water and return of cool water is continuous back to the 2 return tapping's in the base of the pressure vessel, low operating pressure in the entire system, water flow to each radiator can be throttled with ball valves as the water bypasses the radiator and flows to the one below it before it flows back to the boiler sump, very long system lifespan etc.

The higher initial cost of installation is simply an expense but the benefits of the overhead hot water heating method allow for fast installation in this case and properly installed with cleaned threaded pipe ends, fittings that have been washed with dawn dish soap before the tap or die is run in or over them and connections made with pipe dope or tape one thread back from the end of the male thread help assure there are no problems.

With a single 2 inch riser and two 1 1/4" return tapping's I see an opportunity to add hot water storage in an insulated tank in his basement or lean too.

The option of using 2 inch pipe for the single hot water riser to the open to air storage tank and 1 1/4" drop piping to the radiators and to the return headers saves money too.

0 -

@leonz I don't think I want a gravity system I think trvs will give the control I want in each room. My wife and I cannot sleep if our room gets to hot so I'd prefer a system that can react to different heat demands.

0 -

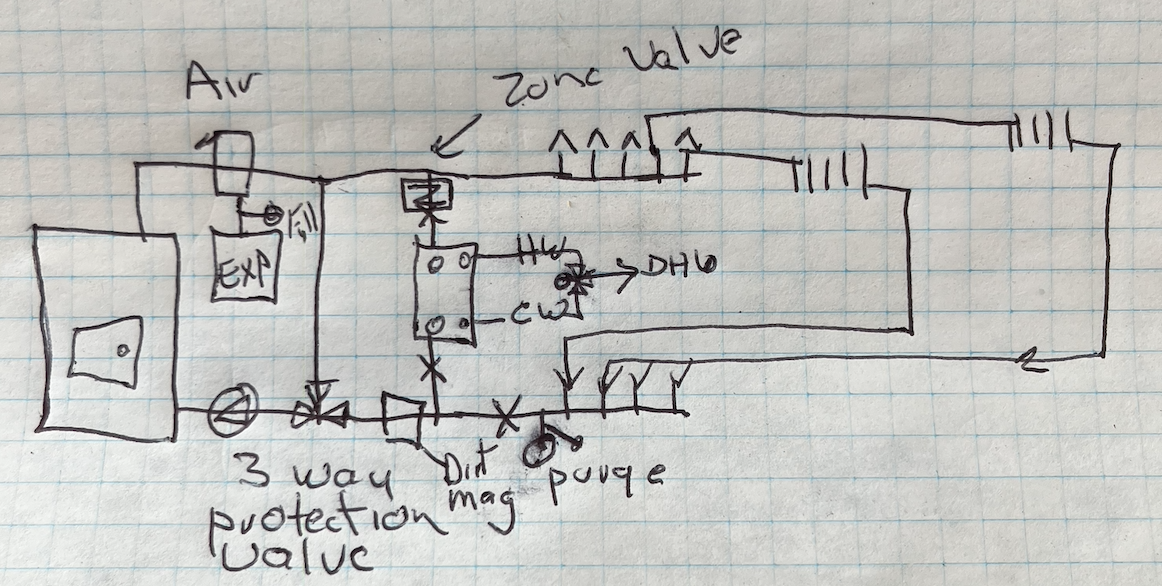

The piping could look something like this. A single delta P circulator, zone valve for DHW hx, manifold distribution. Trvs on radiators.

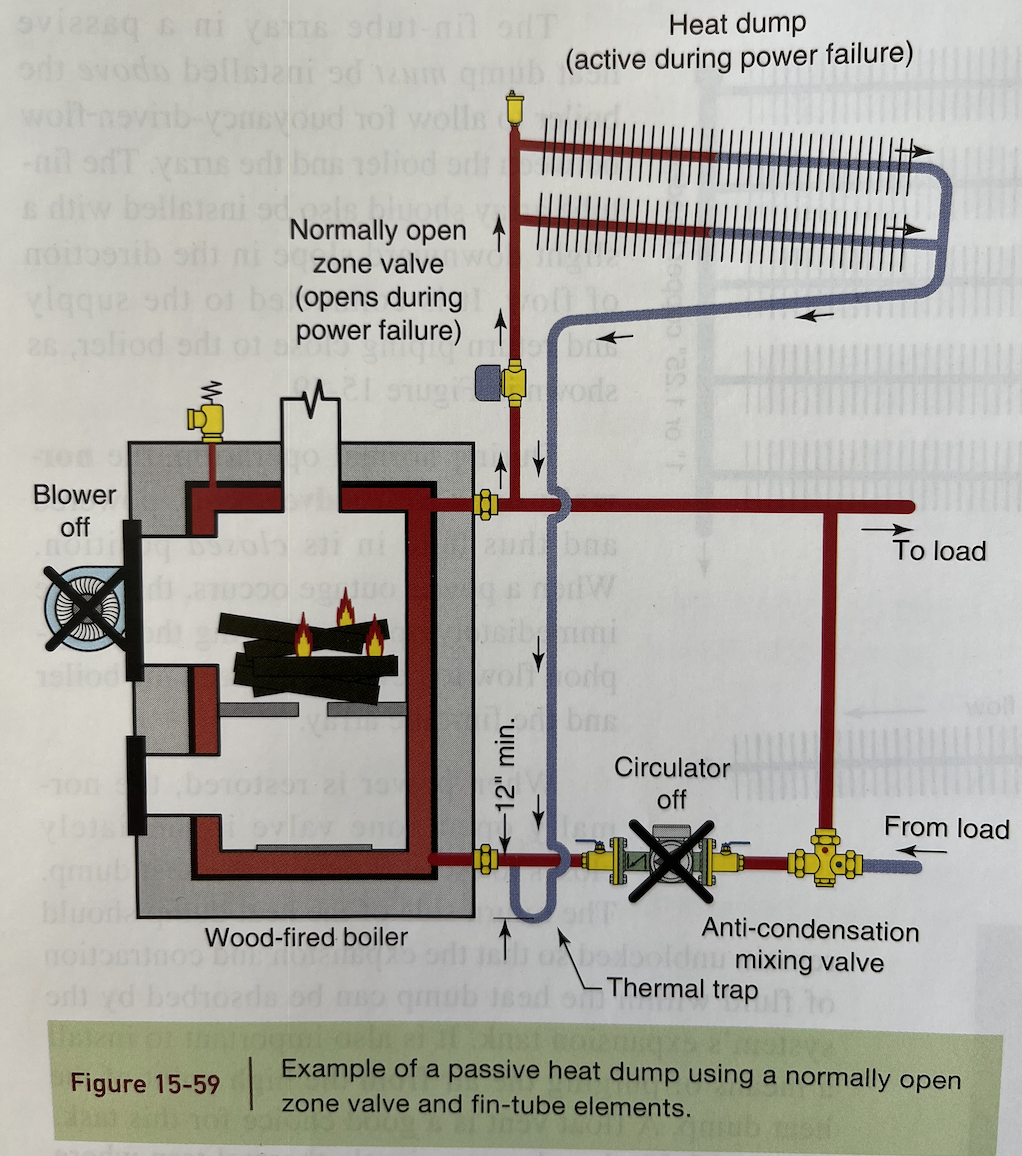

A dump zone with a N.O. zone valve could be added. Some large diameter fin tube works well for a power outage gravity dump. Or a IPS to run the pump for maybe 4 hours.

But again, your boiler will need to be maintained "hot" you would not have an end switch or TRV call on the boiler start cycle.

From my experience a system with little to no buffer will need pretty consistent attention, adjusting the fire size to the heat load to minimize dumping heat that you just created :)

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I am going from memory here,

Just remember that you will not have slow even heating if you do that.

You can always run your wood boiler at summer temperatures and throttle the flow with a ball valve to a room and do the practically the same thing as a trv using a monoflow tee and a ball valve. The excess hot water will bypass the radiator and drop back to the basement if you have the drop pipe connected to one side of the radiator rather than bottom to bottom.

0 -

@hot_rod Thanks for your input, can I tie in another heat source with that piping arrangement? If my plate exchanger is on the input side of my water heater am I going to want it zoned or have a constant flow to it?

0 -

Like another backup boiler? If so pipe it off to the left of that drawing, parallel with the first. One, either or, or both boilers could run, depending on control logic.

An idea of what you are trying to accomplish would help determine best piping options, and control logic

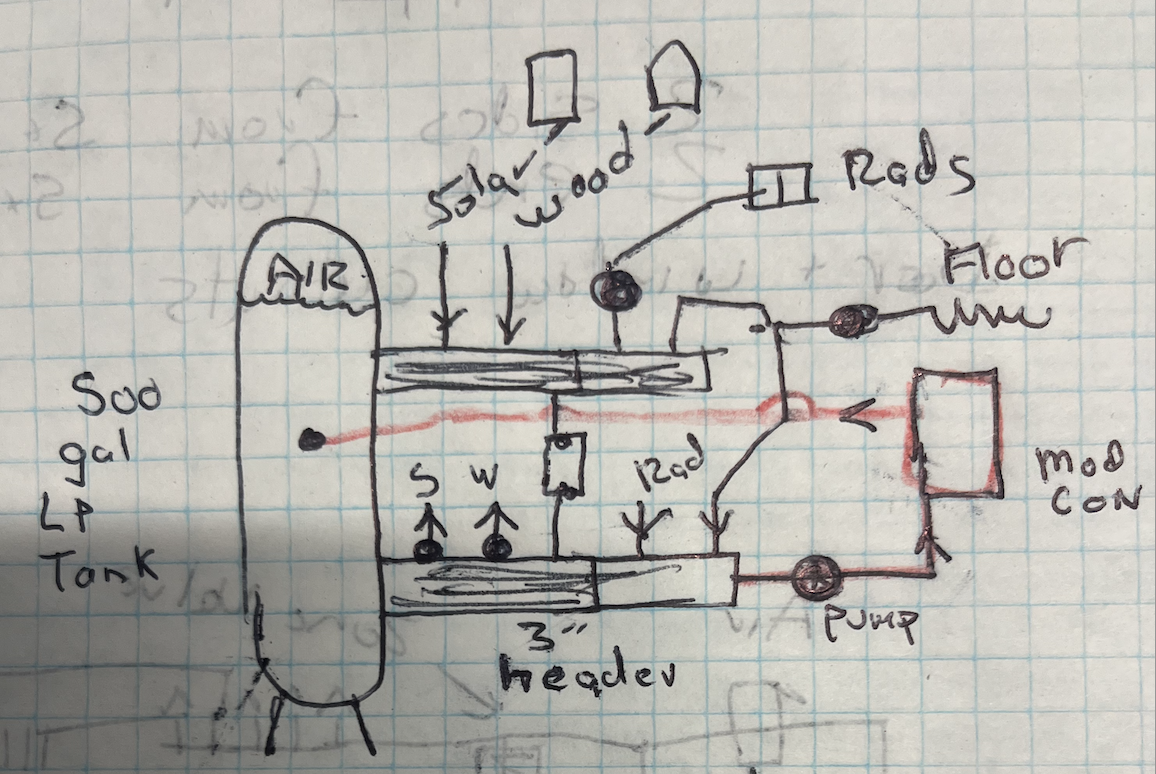

My shop system had a wood fired boiler, a large solar thermal array and an LP backup boiler. The LP would only kick in it the tank dropped to a low temperature. I had a solar controller with 3 outputs that controlled the whole enchilada.

It had several zones of low temperature radiant, a few old cast radiators as high temperature, and the plate HX for DHW

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

My end goal is a wood boiler supplying heat and dhw with some type of fossil fuel backup. I want to plumb it in such a way that I can add storage in the future and is not impossible to convert to fossil fuel only. Will parallel piping keel from sending heat up the unused heat sources chimney.

0 -

Parallel piping shown on the cover of Idronics #10. Flow only goes through either boiler when it is running, so no flow through a boiler that is off. There are two check valves also one in the pump, one on return so no gravity flow if the boiler is mounted above as shown.

Piping depends a bit on the type of boiler and buffer size.

IF you end up with a mod con for backup, and a large tank over 150 gallon, then I would pipe the mod con to the tank so it only heats the top portion, just enough for the DHW production.

Since a mod con can modulate, no need to always heat that large tank.

Here is how I piped my buffer. Notice (red line) the mod con pulls from the bottom but supplies near the top. The on/off sensor for the mod con was at the top 1/3 of the tank to accomplish this.

The top 12" or so of the 500 gallon tank was the air space, this was both for expansion and for the drainback solar. So everything sees the same water, tank, boilers, solar. Plain well water in the entire system.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Stopping heat loss will require you to seal the flue pipe of the unused boilerwith either a cap or plug and plug the unused flue to this and use rtv sealant to seal it.

If you pipe it exactly as is described on page 39 of the EKB35 manual you will be able to do this and add hot water storage as long as you can pipe the storage in series with the boilers.

if you excavate enough room in the basement you could buy a very a large hot water storage tank with multiple copper coils in it that would be connected to both boilers to suck all the heat out of the boiler water and store it.

0 -

Am I completely off my rocker to use a propane tank style water heater as a backup?

I understand the lack of efficiency and not being able to run as high as temperatures. Simply looking for something that can keep the house from freezing if I'm away for a weekend.

0 -

Typical residential water heaters are in the 30- 40,000 input btu/hr range. So not much horsepower from one of those. It could be enough to keep pipes from freezing, but not much heating on a cold day.

High output tanks run up around 75,000, commercial tanks 500.000 or more.

The only ways to know for sure would be a heat load number for the space, or trial and error.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements