Post for feedback

Hello all,

I am new to the mod con, combi world. I moved from an area that had fuel oil only so this is my first go at installing these new units.

I have a before and after picture here of a Navien that I replaced with a Lochinvar.

I'm looking for feedback on if I accomplished the goal of primary secondary. The Lochinvar has an internal system pump so the boiler loop is the primary.

I got the idea for the "moose antler" installation from either a Taco after dark or coffee with Caleffi webinar where it was suggested.

I made the primary and manifold piping 1-1/4" because the boiler is 199,000 BTU.

I have more of these installs lined up so please let me know what I can do better. Thanks!

Comments

-

Why would the water flow out through the system instead of through that bypass?

0 -

-

Very clean install, easy to service. I find manifolds add a lot of value and save significant install time. If you need more flow than the typical ones, Watts has high flow series that will do 4GPM per port.

Besides the correct hydraulic circuit, the other important bit is the setup and configuration. Is the outdoor sensor installed? A reasonable reset curve to match emitters? Space heat limit set to a reasonable value above expected space heat load? These bits are just as important as it will effect the actual efficiency of the unit and how much it will cycle. Short cycling is the silent killer of modcons. Also a bit of education of the home owner to understand that with outdoor reset recovery will be slower so they have to change the programming on their thermostat.

One small improvement with any combi or tankless unit. A small 5 gallon plug in tank with 3/4" ports on the outlet of the unit will eliminate any wait time without having to keep the boiler running by enabling combi pre-heat.

0 -

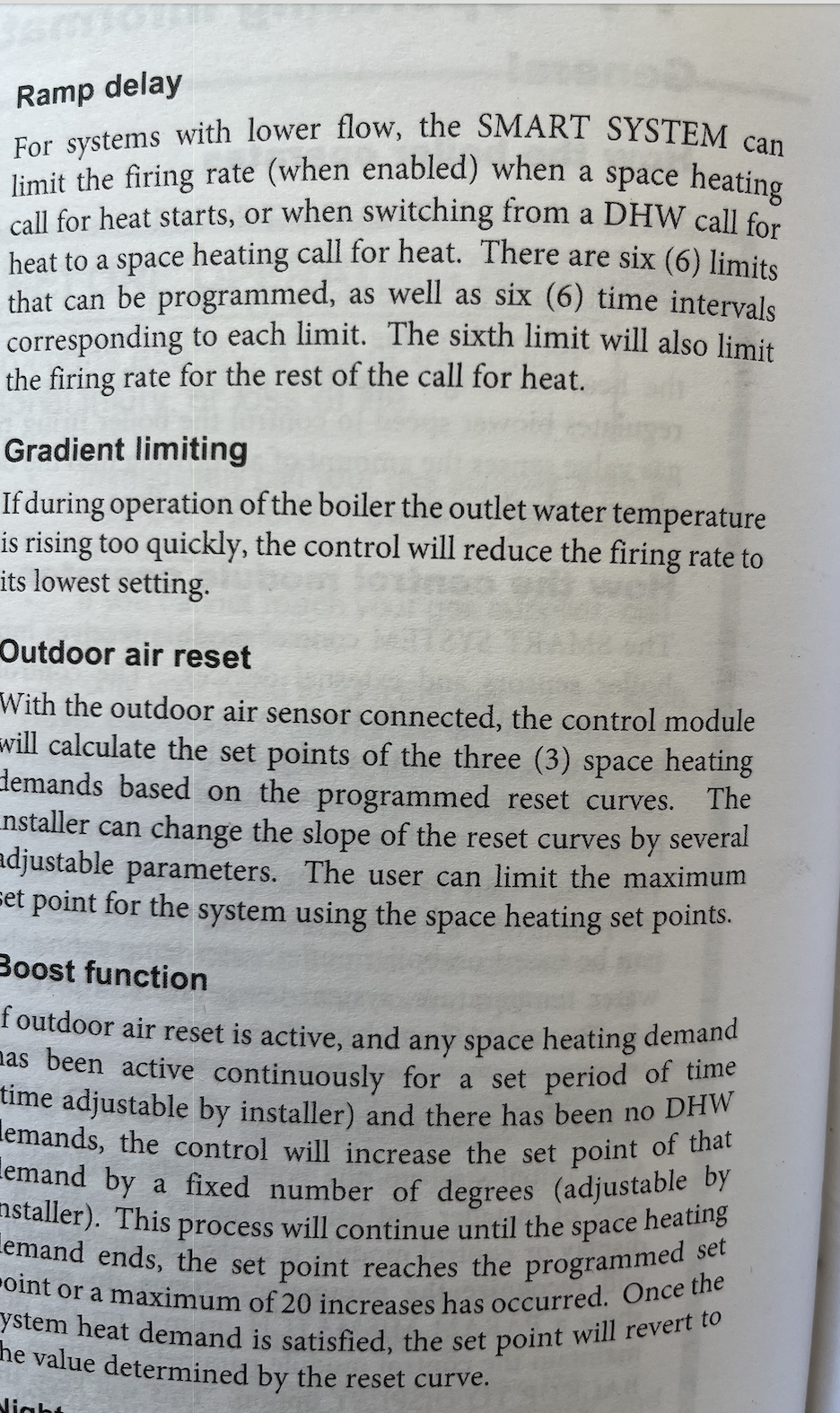

I have that boiler, I think the boost function over rides the ODR, so recovery should be adequate

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thank you! I'll fix that tomorrow

0 -

I am working on learning the right way to set the inputs. So far using Lochinvar U videos. There are three zones of baseboards and I have a 140° target system temp running right now. I am not happy with the ∆T, it's only 5-10° lower on the return temp. The Taco 0015e3 is set on medium speed, I'm thinking about going to the low speed. I don't suppose anyone uses a circuit setter residentially, right? I'm a former commercial and industrial and I'm learning what's common and available residentially as I go. Thanks for the help!

The outdoor reset is installed, on the North wall of the home.

0 -

When installing these, one thing to do is allow as much room as possible for serviceability. All too often these things get crammed into tight spaces.

0 -

This falls into the category of the benefits outweigh the risk of a callback. Especially with series fintubes, higher delta T will reduce output on the last emitter, nobody likes cold rooms. Higher delta T with modcons is your friend in most other cases though.

140F is a good target if you can get away with it. If the previous setup was ok at 140F, or the owner is the type that can adjust it if needed, otherwise set a bit higher to avoid callback.

Even going as far as checking delta T is more than most residential techs will do, typically pumps are installed and set to max.

1 -

.Not to worry about that ∆. The delta is always moving a bit until you reach thermal equilibrium. The point when temperature has stabilized, not increasing or decreasing across the loop. At that point you should be at design ∆. Probably most systems never are, as @Kaos suggested. It is rare that an installer checks these numbers. It could take hours, days, for a large concrete slab to reach thermal equilibrium on cold start up.

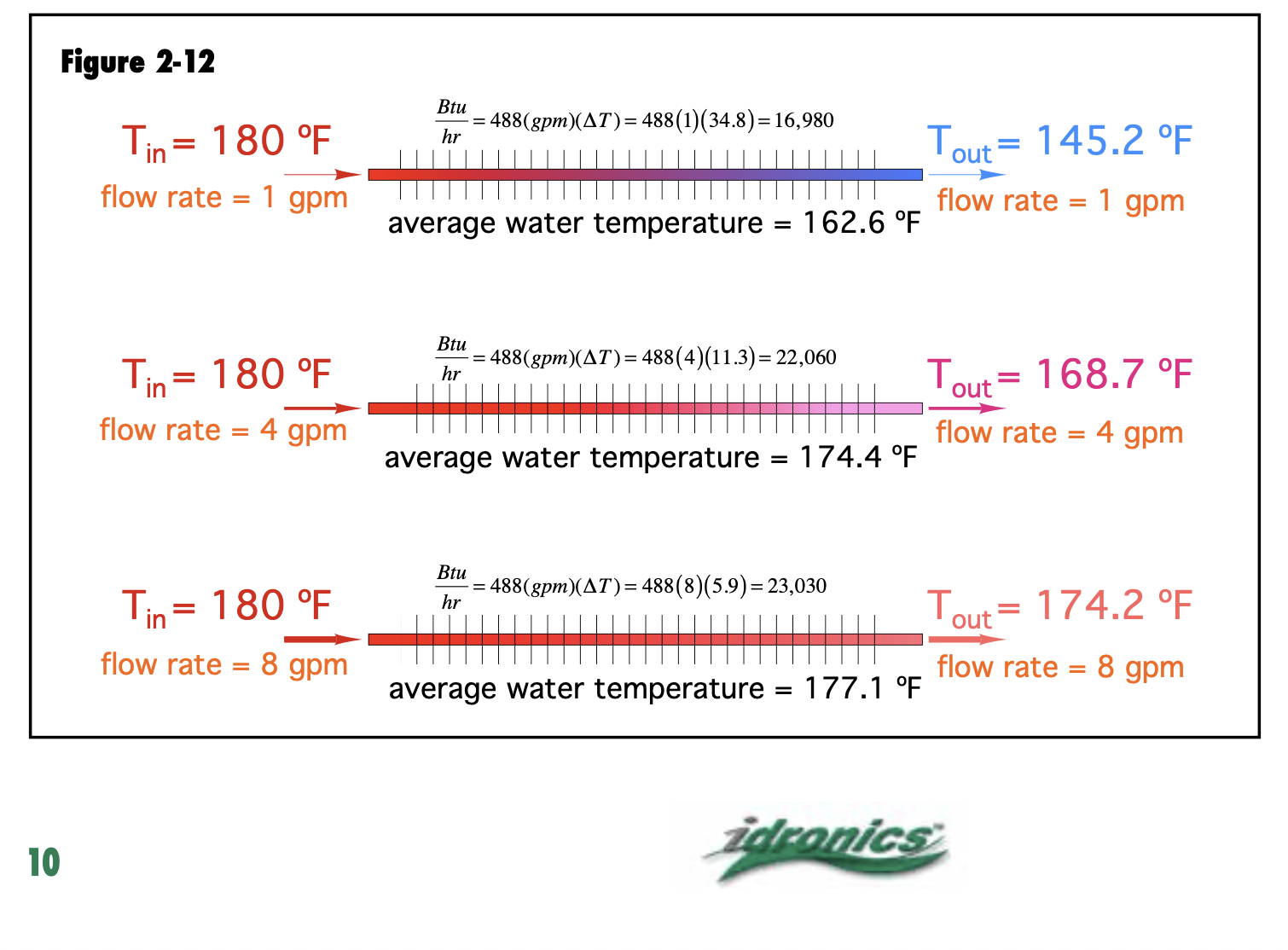

Lower delta= higher heat transfer rates. It does cost a small bit more pumping, and you want to stay below 5 fps velocity to keep things quiet.

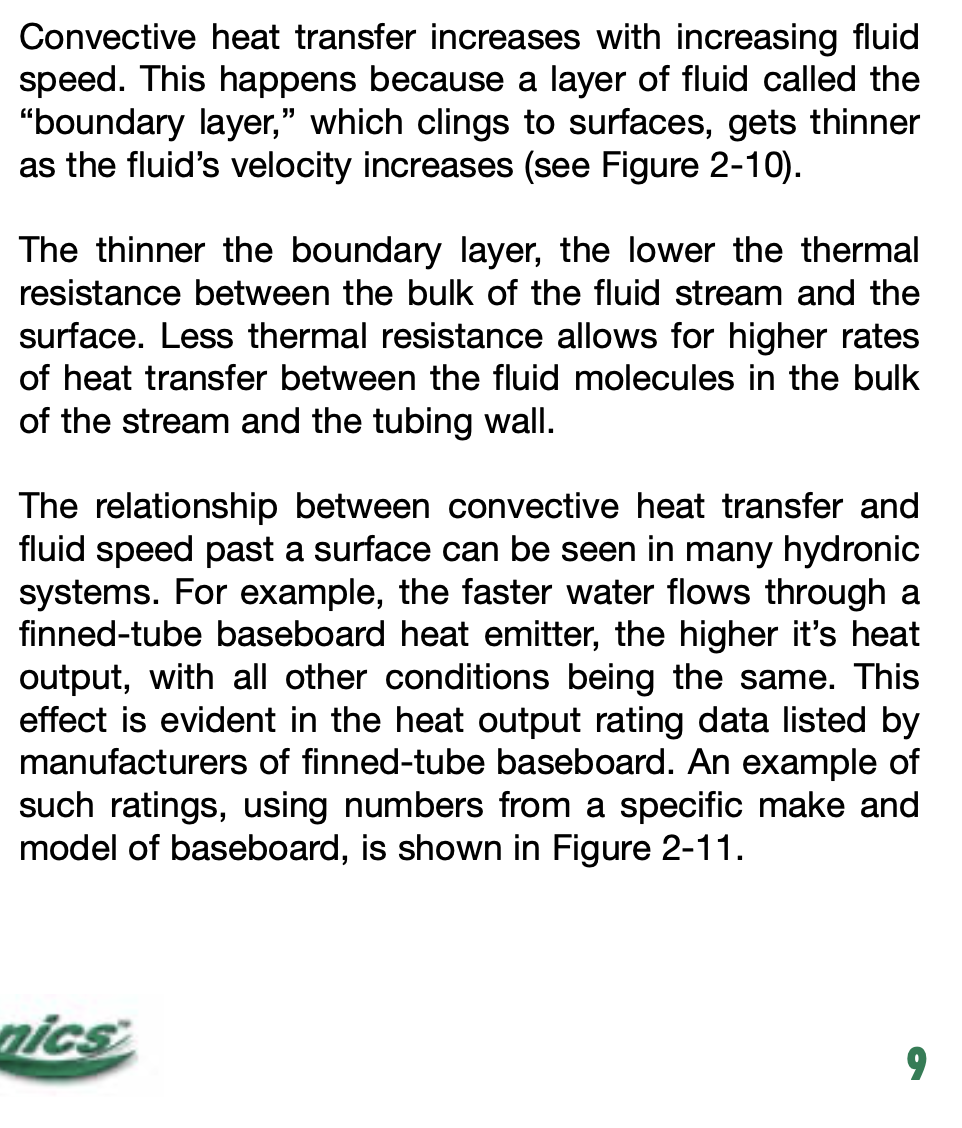

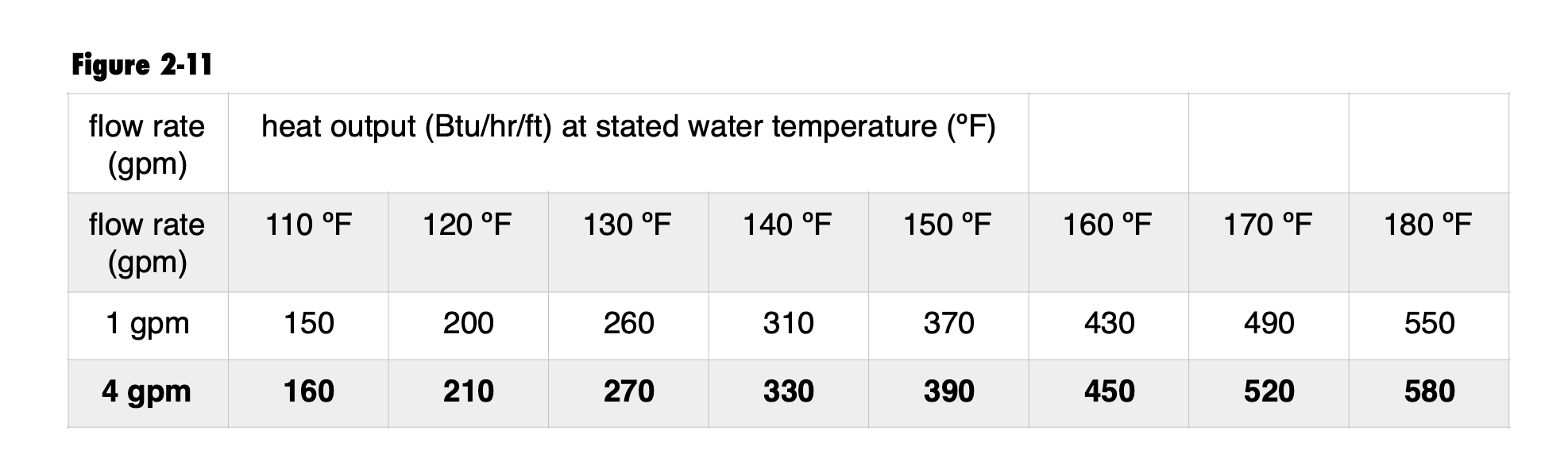

Here is the rational for the increased output:

You would need to get up around 8 gpm in 3/4 M copper to exceed 5 fps

Idronics 23 is a good read for understanding heat transfer in Hydronic systems

Lots or residential insyallers that want to know or check flow rates install Quicksetters as you do not need a $3000.00 B&G delta P meter to read them :)

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

You're measuring the delta t on the individual zones, not the boiler or supply and return mains, right?

0 -

Thank you very much for the feedback, fellas.

I have a Knight boiler as my next job. I'm leaning towards the floor model because there will be an indirect water heater so I'll need to build a platform anyway.

@hot_rod I will read that issue of idronics, thanks for the knowledge! I am trying to remember where I read about the 1-1/4" vs 1" primary loops and at what BTU you see better performance... Perhaps in one of Dan Holohan's books. That's very interesting information about the boundary layer, I'm interested to learn more

@Kaos That is very helpful input! In one of the Lochinvar U videos, the trainer was talking about setting the parameters in the programming to essentially get rid of the warm weather shutdown giving the homeowner control of the boiler via the thermostat. I hadn't really thought about how coaching them to adjust the ODR parameters to bump up the target temp would save me the hassle of a call back. Luckily we're not too cold outside yet so I have some time to learn the system so I can then try to teach it to them.

0 -

-

I've used all; these functions on my Knight. It takes some trial and error to get it set exactly to your application. I really like this control.

Properly dialed in you can get close to continuous firing, a very efficient operating mode.

The ramp delay takes some practice, don't get too aggressive or you delay heat.

I know the boost overides the ODR, but not sure if it over rides the ramp delay?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

I would be careful with telling owners to mess with boiler settings, I know of only a handfull of people that should. Set the reset target to what the system used to run at before and call it a day. If the fuel is expensive like propane and the owner wants to get that couple percent extra efficiency out of the system, they can pay for half a day during a cold snap to watch paint dry while dialing the settings in.

I would be careful with those advanced settings @hot_rod linked to. The one that is worth while to set up is the boost function, the rest I would leave alone.

There is also no drawback to setting the fire rate limit to match radiation as @mattmia2 suggested.

0 -

If you do choose to adjust parameters and get balled up, one quick button push resets everything to factory default settings

The factory defaults are listed in every parameter adjusting menu in the manual

On the back page I make notes of all the settings I change and the numbers

There are tutorials at the Lochinvar site and plenty of installer you tube demos

https://lochinvaru.com/videotutorials/models-kh-055-285/Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I think it looks great. The only thing I would have tried to do if I had the time would have been to paint the wall behind the piping. Love Lochinvar though.

Rick

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements