Any pointers when doing a homerun type system?

So i've decided to do base board heat in a small 950 sq ft floor on the first floor (no basement) I figured running each base board off of a uponor manifold. Is this wise? and what to watch out for when using a homerun type system. I was going to run everything in PEX A oxygen barrier, i figured without doing the math. ( which I'm doing now) to run each loop in 3/4 pex unless i can get away with 1/2 to each individual baseboard , the runs won't bet 35' ish feet long . Doing the heatloss calcs now and then figuring out how to go about from there. Just need pointers on homerun type systems . THanks

Comments

-

You can definitely run ½" PEX to each BB unless the BB longer than 30' which I doubt you have there. PEX A, yes, good. Insulate those runs with insulation that has at least 3/4" wall thickness. Use a good manifold like Roth, Uponor or Rehau that has flow gauges and shutoffs.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab1 -

@Alan (California Radiant) Forbes IDK what happened with all those blank comments… computer is on the fritz.. So your saying, in add foam insulation ? any examples what to use? also what if the runs go over 30' ? go to 3/4? only one loop that might be over probably 45 also when figuring that length the 30' is that the return and supply side added together or?

0 -

Do you want to zone individual rooms? It doesn’t seem like you would have many fin tube emitters in that sized space

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@hot_rod The first floor would all be one zone, that would be something that would be figured down the road due to $. I have a total of 68' for Base Board for the total job based on the room to room heatloss at 85 degree DTD.

So I was talking to the homeowner, and our question is… If I do baseboard heat with the homerun style. IF we could run the piping from the emitters to the homerun manifold through the slab to make the job easier and quicker and IF we do that what do we have to do to make sure the piping is safe in the slab? How deep? How to insulate? Maximum length of pipe? Thank you again @hot_rod

0 -

@hot_rod The homeowner owns a masonry company and said he could cut the floor and fill it back in. WE think this is the cleanest most effective way to run the piping instead of tearing out 50% of the sheetrock

0 -

-

@EBEBRATT-Ed Any type of other prep work for the pipe beside getting insulated PEX? how far down to go with the pex? and what kind of mix to use any special concrete? and what type of insulated PEX would you recommend ? I'm definitely going with PEX A with oxygen barrier but any make you suggest? Thanks again @EBEBRATT-Ed you have helped me TREMENDOUSLY in the past

0 -

Rehau, Uponor, Mr. PEX are all good PEX A brands. Make sure you buy the oxygen barrier kind.

All your runs can be ½” PEX. When I said no more than 30’, I meant BB length as ½” will comfortably supply 30’ of BB - 15,000 BTU’s.

If you have to bury the insulated PEX, get it deep enough so that the concrete won’t crack or even better, install it below the concrete in the gravel.

When you purchase the tubing, it comes bare and you add the insulation. I use the foam kind - polyolefin.8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab1 -

A series loop with less than 75 feet of element is within reason. That would make for a lot less concrete cutting. Placing any tubing in the concrete with 3/4" pipe insulation will retain heat in the piping so only the elements are heating the room. If you were to cut channels in each room to a home run location, you might as well just do a radiant floor heat system. (that was a joke). It will be easy to service and purge air from the system with only one series loop. Or perhaps 2 series loops with a common return from the farthest point.

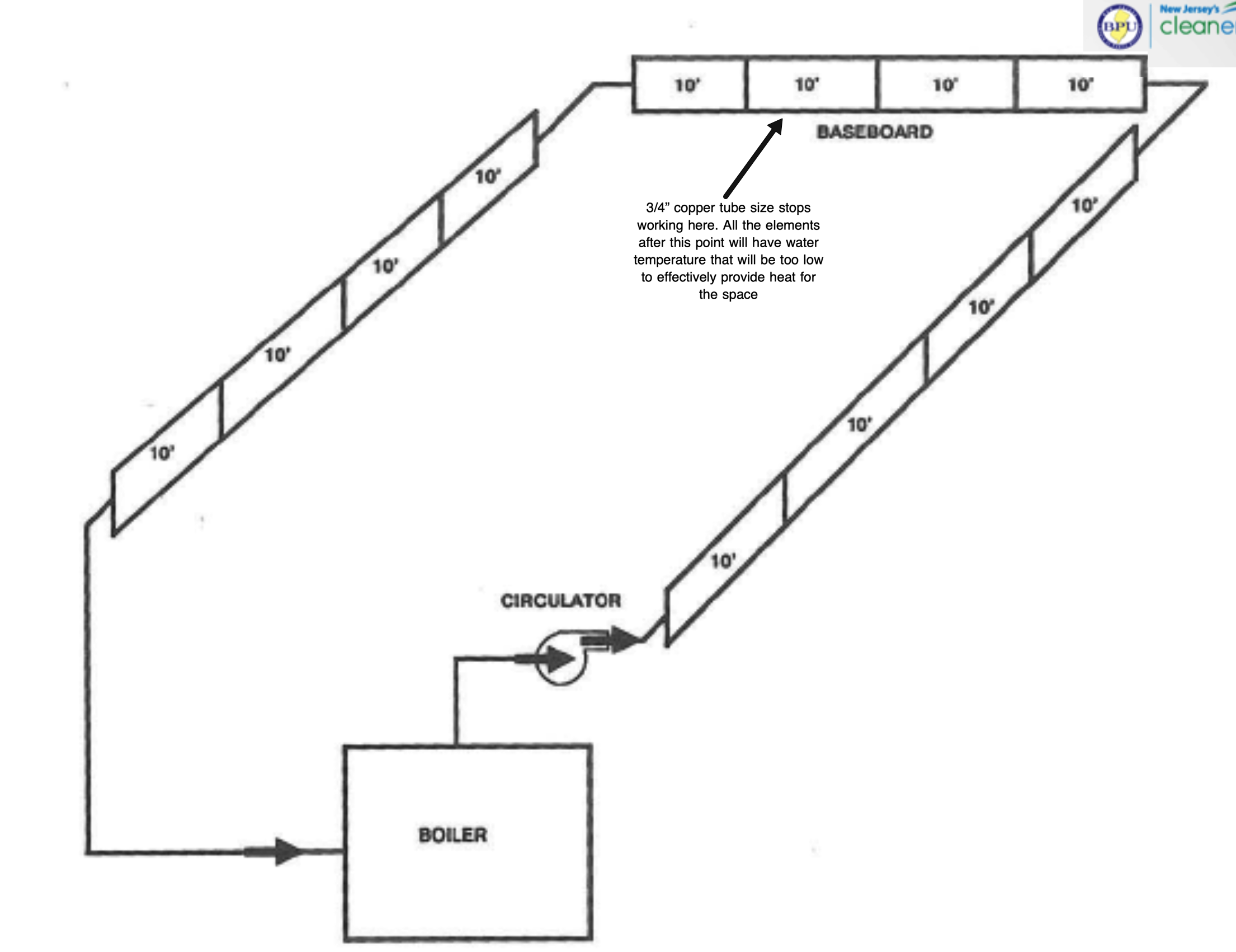

This is a slide that I used to teach Hydronics for the Eastern Heating Cooling Council.

It illustrates that running 120 feet of 3/4" baseboard in a series loop will not work past about 78 feet. So the service call might be not enough heat in the last three rooms on the system but the rest of the house is just fine. This call will happen only on the coldest days of the winter. The milder days will eventually get heat form that poor piping design.

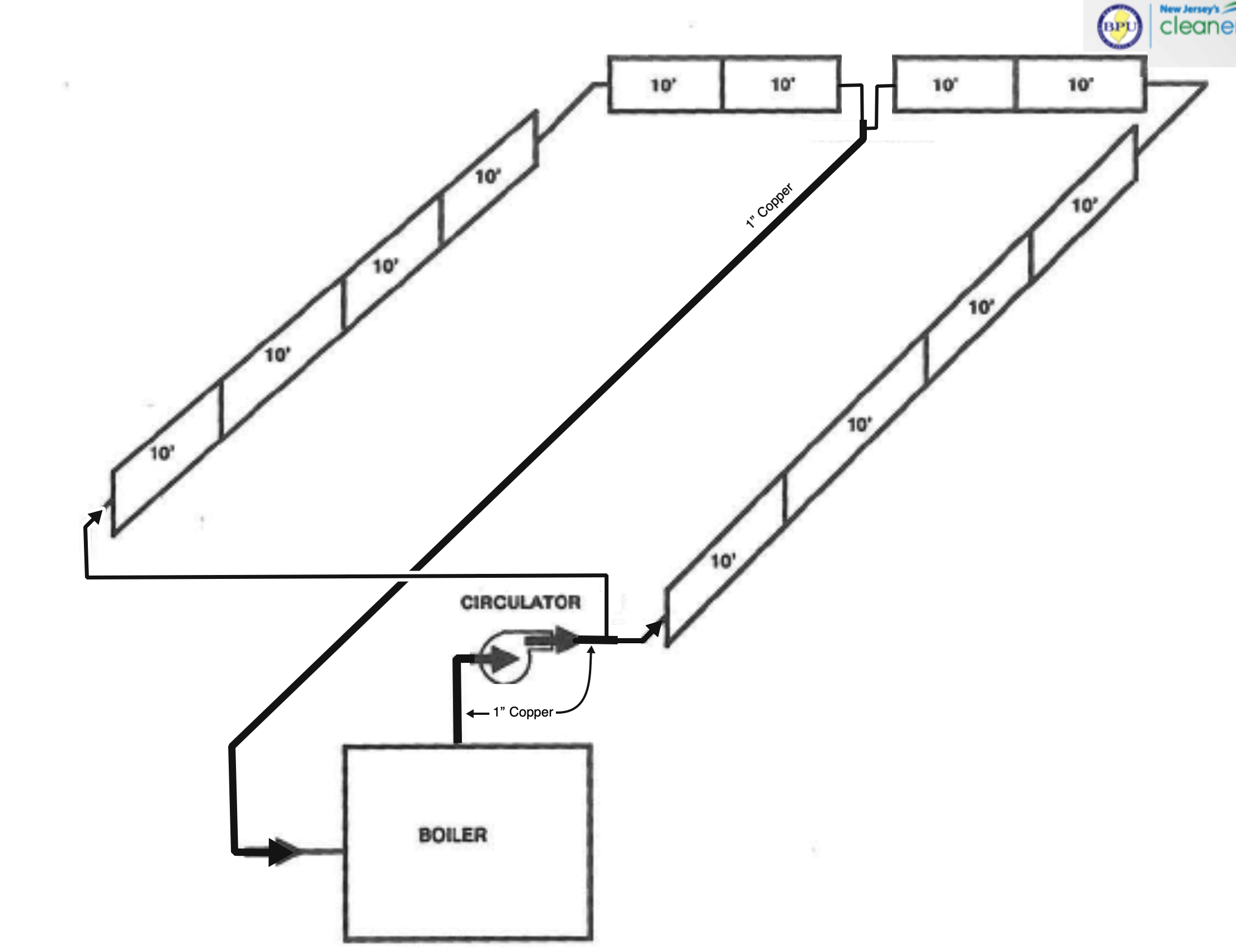

This next slide shows how to fix the problem without a major repiping of the entire system. Take the radiators that are connected to the return and place them on the supply side of the boiler. Increase the common pipe from the boiler to the circulator to 1" and use a 1x3/4x3/4 tee fitting to connect both loops to the supply. Take the mid point of the system so that there are about 60 feet on each loop and run a common 1" return back to the boiler.

I actually did this for a customer that called me up for a price on a new boiler because the old boiler was "too small". Three other contractors bid on the replacement boiler without thinking about the fact that a new boiler with this top illustration's piping arrangement would not solve the problem. For less that 10% of the cost of a new boiler I was able to solve the "too Small" bpoiler preoblem by increasing the pipe size and splitting the series loop into two series loops.

Since you are designing this from the beginning you can design a series loop that will work with no problem. Making a home run system for 7 to 10 radiators is really overkill unless you are placing a thermostat in each room. I do not recommend that! Two series loops maximum on this job is recommended. 3/4" supply and return is all you need for 68 feet of element And if you are operating this from a single boiler for each unit, you will need the smallest boiler you can get. They will all be too big becauseno one makes a boiler that small.

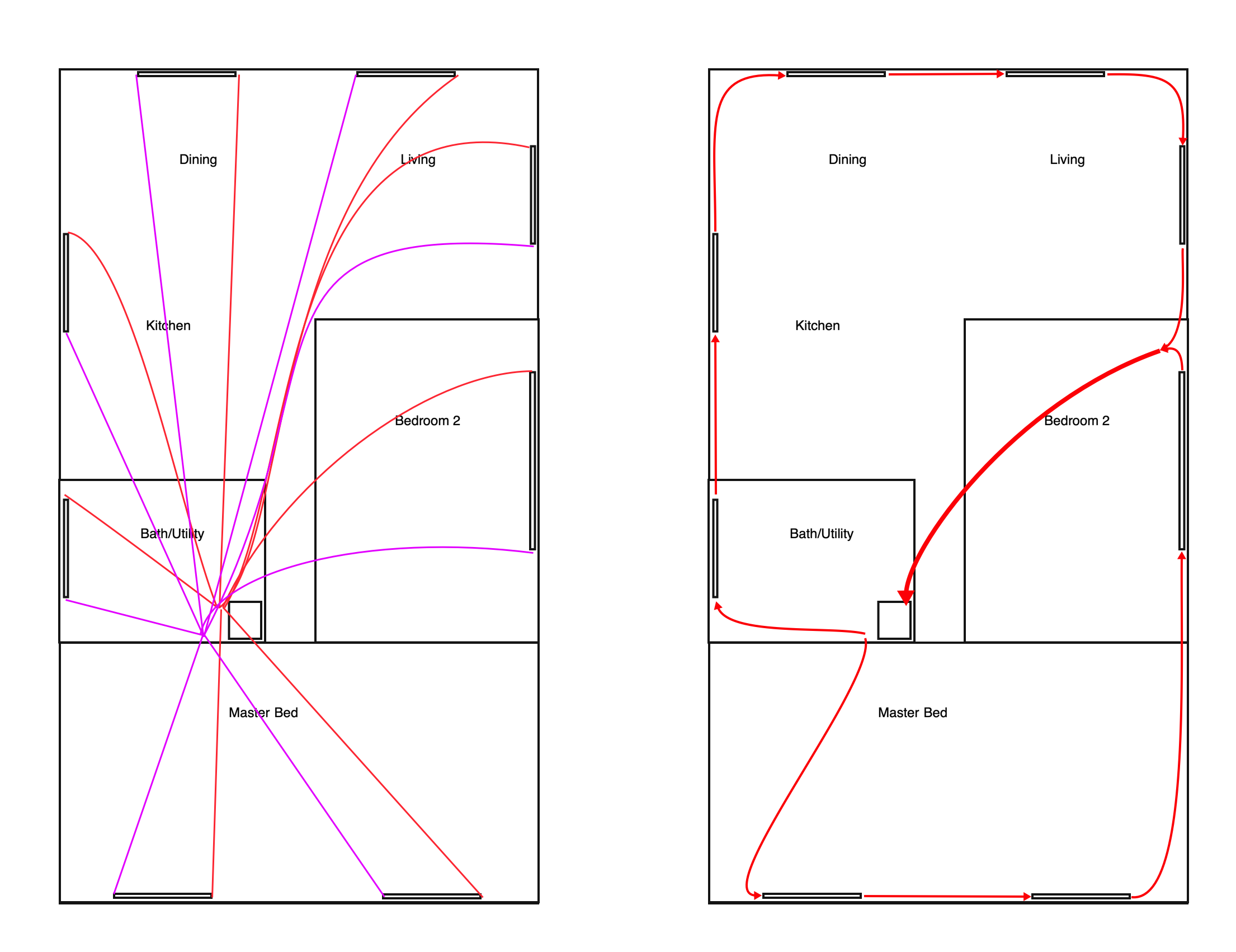

If you are operating one boiler for the entire building and this is just one of the apartment units then you can run 3/4" from the manifold location back to the central boiler room. Just look at this mockup of a 950 sq ft two bedroom layout with 8 baseboard radiator units. there is a lot of cutting needed for the home run system even if you can get a lot of them to a central "shared" trench for a part of the distance from each radiator to the manifold location.

There is a lot less concrete cutting with the series loop design.

Hope this helps.

Mr. Ed

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

-

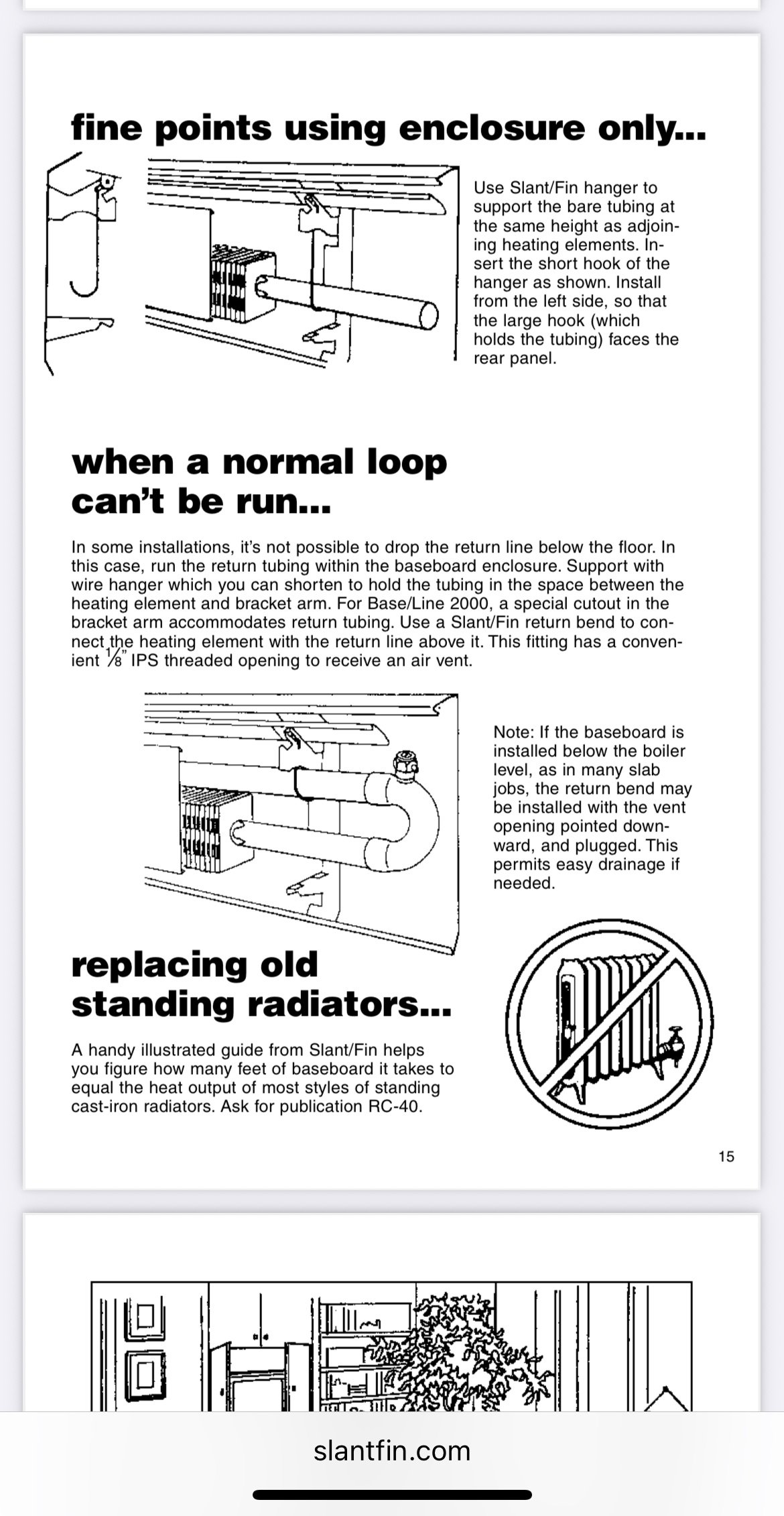

@EdTheHeaterMan I have seen contractors run the supply on one side of a baseboard and then on the opposite side use a 90 and a street 90 and bring the pipe back over the top of the fin tube hidden inside of the baseboard cabinet so both pipes come out on one end? My only question to that is how well does it put out heat piped like that due to the air gap needed for convection. And Thank you for the diagram and your time

0 -

I was just going to suggest that. This will save a lot of cutting. Some profiles even have a chase for the return pipe. The pipe is typically against the back side where the louvers cover it anyways so won't effect output. Adding a vent/bleed elbow on the return will make it much easier to get the air out.

1 -

the Viega FostaPex in straight 20’ lengths was good tube for running inside the fin tube enclosure.

The return tube can also run below the fin if you make some hanger wires.

Regular pex or pert in straight lengths will work but needs more supports and expands/ contracts more.

Look for a brand of tube with the outer UV layer

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Installing a U turn at the end of the baseboard to loop the return back to the same side as the supply has no adverse effect on performance. That will reduce the amount of trenches needed by half. I would not use PEX for that return because it will want to flop around inside the enclosure, but that's just me. I want to look inside the louver and see a straight piece of pipe. If your return pipe is below the element, then that may cause some air flow blockage especially when the carpet installers redesign your heating system by blocking the bottom air inlet with extra padding and thick plush carpet. I have told 3 different customers that the carpet is blocking the air flow. This is usually on the coldest days in the winter when you need the radiator to perform at its best. A radiator that is blocked will offer partial heating capacity, and in the mild weather all you need is partial capacity. You only need full capacity when it is the coldest outside.

One customer called me in 1989 and I told them about the problem and charged them for a service call minimum charge. Three years later the temperature dropped unusually low again and that same customer called again. I found that the carpet was still blocking the bottom opening. I charged them again the minimum service call fee and told them again to have the carpet removed or raise the radiators. 4 years later they called me again. When I pulled up in front of the house I could not believe that the same people were calling on the coldest day again for not enough heat. I changed the minimum charge for the diagnosis and I charged them for adjusting the aquastat high limit from 180° to 210° so the blocked radiator would put out more heat. I also quoted a permanent fix for the problem of a couple thousand dollars to return and raise the baseboard radiators up the watt 2 inches to allow for the air flow required. They never called for the radiator adjustment job, but I’m sure that the fuel usage increased. I doubt that they even noticed. Some folks just don't get it.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

the SlantFin brand had the carrier brackets designed to leave room for the tube up top

I imagine other brands did too,

Depending on the load you may get away with 1/2”

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@hot_rod @EBEBRATT-Ed @EdTheHeaterMan @Alan (California Radiant) Forbes @Kaos

You guys are the best, I cannot say how much I appreciate you guys. Your time and care is outstanding thank you. My customer will have heat this season at a reasonable price, I did not want to take this job on without the input of you gentleman. Thank you 1000x over again

1 -

Sterling also ran the return over the top of the element with little U shaped wire hangers.

To avoid any issues I would pipe the return with 1 street elbow and 1 regular elbow (so it lines up correctly) and pipe it in copper to the other end where both supply and return connect to the pex. No drooping pex or hanger issues.

3 -

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

@Alan (California Radiant) Forbes So.. Burying I was going to buy pre-insulated pex a and I was thinking about sheeting it with something with enough room for expansion. This is in Wisconsin.. what do you think?

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements