Navien NHB-80H control panel/menu ?

I had a NHB-80H installed 2-3 weeks ago. It has just fired up for use/heating. The install & user's manual lists four temperatures for display but does not define them. They are:

6. Supply Temp, 7. Return Temp, 8. Sys Supply Temp, 9. Sys Return Temp.

What is the difference between 6 & 7 vs. 8 & 9 ??

Comments

-

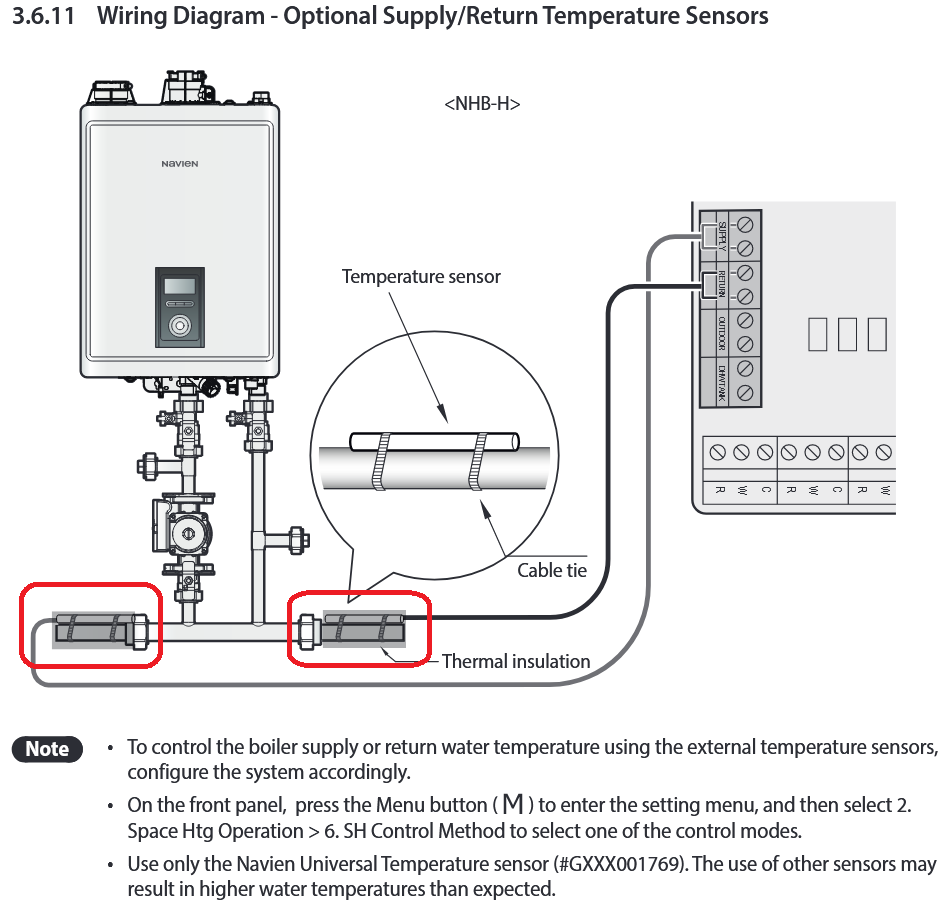

if you use an optional sensor on the system side, it reads the supply and returns This may differ from the boiler supply and return depending in how it is piped

Section 11 does a good job explaining parameters. There is a lot to know about the numerous settings and how to apply them

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

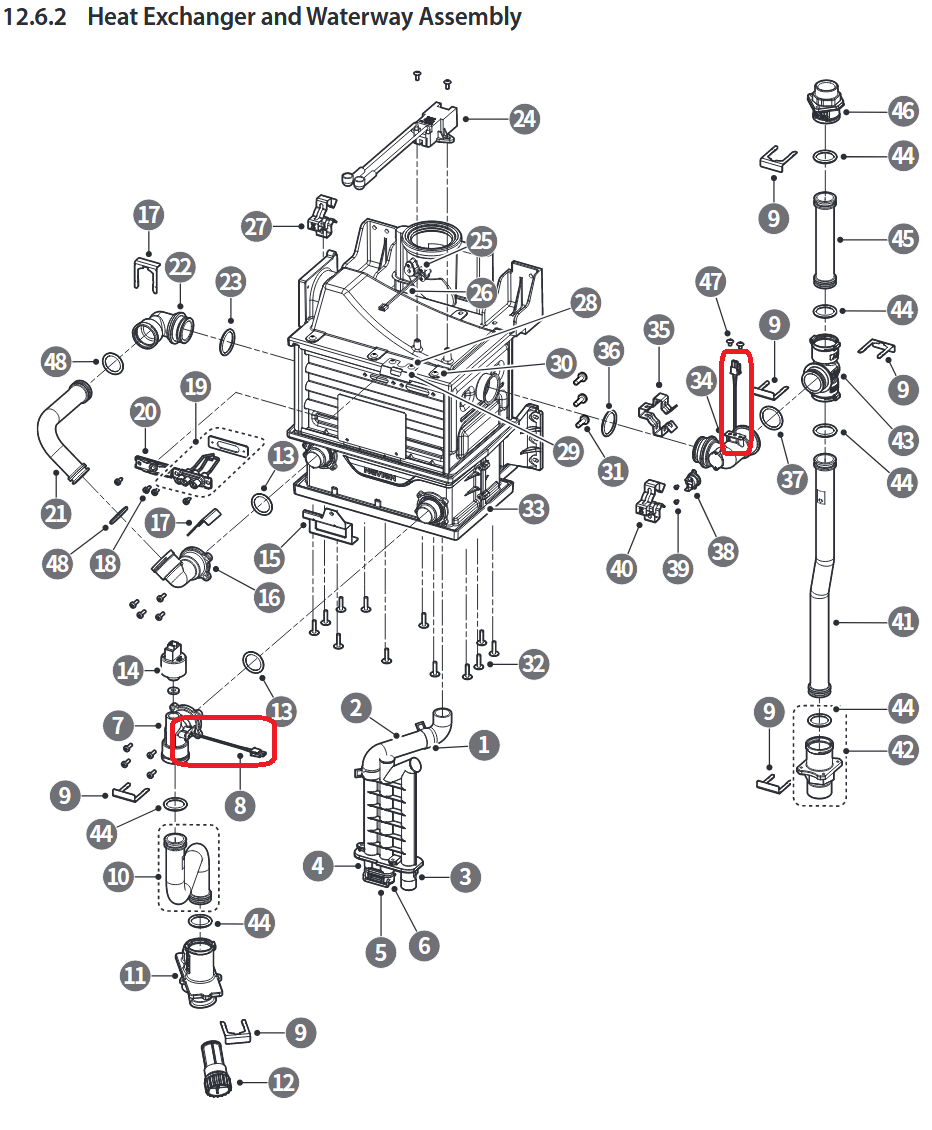

I think you will find 6. Supply Temp, 7. Return Temp, are inside the boiler's jacket and

8. Sys Supply Temp, 9. Sys Return Temp. when used are on the external pipes.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

hot_rod….I disagree, section 11 sucks about "explaining the parameters." Yes, there a lot to know about settings and how to apply them. I trusted my installer. BUT I don't see any baseboard temp near the 180F boiler set point. Baseboard is about 161F. That's why I am "nosing around" now before it gets COLD.

109A-5…I never would have thought to look at the "parts diagram" to understand the vocabulary used. The "note" on fig 3.6.11 tells me where to look next…THANKS.

0 -

"

hot_rod….I disagree, section 11 sucks about "explaining the parameters." Yes, there a lot to know about settings and how to apply them. I trusted my installer. BUT I don't see any baseboard temp near the 180F boiler set point. Baseboard is about 161F. That's why I am "nosing around" now before it gets COLD. "

are you, you are running outdoor setback ? do you have an outdoor temp reading?

if so, it may be restricting your 180* setpoint,

post a picture of the boiler and all the pipes around it, all in one shot,

known to beat dead horses0 -

neilc…no outdoor temp sensor.

photo attached. ignore dark copper pipes (vertical to ceiling) far left. they go to baseboard fins

in garage (shut off). supply/return also on far left, but go into slab floor>thu foundation>crawl space.

0 -

That looks like direct to load (there is no extra pump elsewhere). The most likely culprit for the temp loss is you are loosing heat into the slab. Concrete is a great conductor of heat and so is the dirt under it. Depending on how long that bare copper run through the concrete it is, you are loosing some real BUTs there.

The other thing that really irks me is the lack of outdoor sensor. A modcon running at fixed 180F output does not condense at all, you are giving up about 10% of free efficiency most of the heating season just because the installer didn't care to install the outdoor sensor and set a reset curve.

The high temp also means your unit will cycle more and no condensate means more buildup on the heat exchanger.

Installing the sensor (which was included for free with the unit) is one of those things that there is pretty much no drawback to out. You use less gas and the unit lasts longer.

0 -

KAOS…"direct to load"…yes. there is no hydraulic separation. installer said no need in simple, one loop sys. Various mfg manuals agree (sort of).

concrete: I figure vertical is 8" and horizontal thru foundation is12-18". Then there is ~22' horizontal in crawl space to come up into first baseboard.

outdoor sensor: installer may have omitted cuz I wanted all efforts to go toward getting HOT water (160-170) into baseboard. Last winter never got above 146 (measured by oven thermo) at baseboard inlet. Of course, the exisiting Riannai (DHW used for heat only) was 12 yrs old and dying. House never got above 67 during coldest weeks and we have a mild climate.

Would you bother to insulate the 22' run in crawl space?

0 -

R U getting 180 out of the boiler on that gage?

yeah, insulate the 20 feet in the crawlspace, and anywhere else you don't want to leak your heat away,

how cold does it get where you are?

crawlspace addition? how's the building envelope? run the bath and kitchen exhaust fans, clothes dryer also, now walk around barefoot on a cold morning and feel for drafts coming in under the walls, around all doors and windows(trim to walls, and top and bottom also), electric and switch boxes, seal up those drafts,

known to beat dead horses0 -

Personally, if a customer asked "all efforts to go toward getting HOT water (160-170)" hydraulic separation would have been my first requirement for this boiler…. That heat exchanger has an excessive pressure drop, its the same style thats in a tankless water heater, tiny little passageways, meant for higher pressure DHW systems…. Think about it for a minute, if I can heat my house with 180 on the coldest day of the year, then I can heat with lower temperatures every single other day of the year, ODR isn't the blockade to your comfort, flowrate might be though… I suppose at this point we don't really know IF there even is a problem yet correct? You may be reading a lower value at your baseboards because with the system set to a higher than necessary setpoint the system never needs to reach a "high temp" average water temperature to end a call for heat with mild weather conditions. (if flowrate is an issue that also adds to it of course)

to determine where you are at right now, the easiest way would be to record a few values

boiler setpoint temp.

supply temp

return temp.

these supply/return temps need to be taken when the system is in steady state operation to be helpful, we want to see the steady state delta T (temperature differential)

preferably with a temp gauge that isn't inside the boiler. though you could measure with your thermometer just keep in mind the actual temp is probably different than what you record, the delta T should be somewhat close if you measure with the same device for supply and return. Some oven thermometers are not very accurate though so I might check on that first!

0 -

neilc…the gauge reads 170 when SH temp on panel is 180. our worst winter is about 1-2 weeks of 20 during nite, maybe 18. Can't find anyone who wants 2hr job to insulate 20' tube. I've been down there, but takes me 15 mins to crawl back/forth…I'm 80+

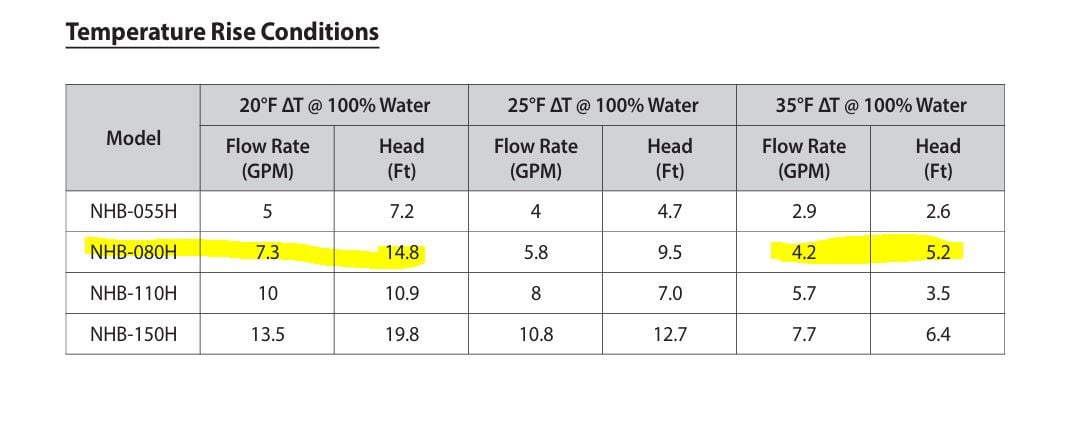

GGross…pressure drop in whole sys is ~12-14 feet. I get this from pump curve at 4 GPM which is what control panel calcs. Correct, don't know for sure if there will be a prob. But doesn't the boiler work to achieve its output set point with the lowest gas flow/firing rate? And right now it takes about 1 hr operation to get near 180.

I have temp inside boiler (I assume w thermisters/couple), outside boiler, 1 ft away thermisters, outside boiler w manual gauge. But at baseboard is just my oven therm.

0 -

your pressure drop is also dependent on the flow rate, less flow, lower drop. to get the full output of that boiler you need 7.3GPM which puts the pressure drop through the heat exchanger alone at 14.8'H add your estimated system drop (14' - 4.2 from heat exch estimated!) and you get an approximate 24' head at 7.3GPM

Though that number could be slightly higher as our flowrates will also increase! and we are working from a calculated pressure drop based on a pump curve, there is a little fudge factor in there of course. but I would want a more exact number before replacing for a larger pump

Without primary secondary piping you need a pump capable of 7.3GPM at just under 25' H to get full output. so if your system struggles to heat this year that would be why. if it heats fine then you know your heat load somewhere closer 40k btu/hr max

this is all based on an assumption that your measured flowrate of 4GPM is accurate! and for reference a wider passage boiler might 1-4' pressure drop for the same 7.3GPM, this is why p/s piping is important with condensing boilers, most especially ones with very restrictive heat exchangers

fyi if you type @ and then a username it sends little notification to that user like this @dpenny

0 -

@GGross THX for continuing this chat. Currently TACO 0011 is set at mid-speed, and boiler shows 4 GMP. I will set at high and see what flow I get. Currently boiler capacity # varies between 39% and maybe 50-60%. So you are saying that if I up the flow, this capacity # will increase, and likely temp at baseboard input.

I'll be away for 6 days and not able to respond during that time.

0 -

More than likely yes! if the boiler is reading a flowrate out then it no doubt has a flow sensor, it very likely limits the fire rate based on the flow it reads, this would all add up that your boiler is calling for 180, but never reaches it! In mild weather I would expect a boiler to reach its setpoint temp pretty quickly. Without outdoor reset its just targeting the setpoint, and I can't speak for the manufacturers specific programming but typically when there is no ODR installed on a mod/con the boiler will try to get to setpoint ASAP (barring any safeties like flow sensors! and burner programming) and then modulate down to maintain that setpoint.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements