Venting

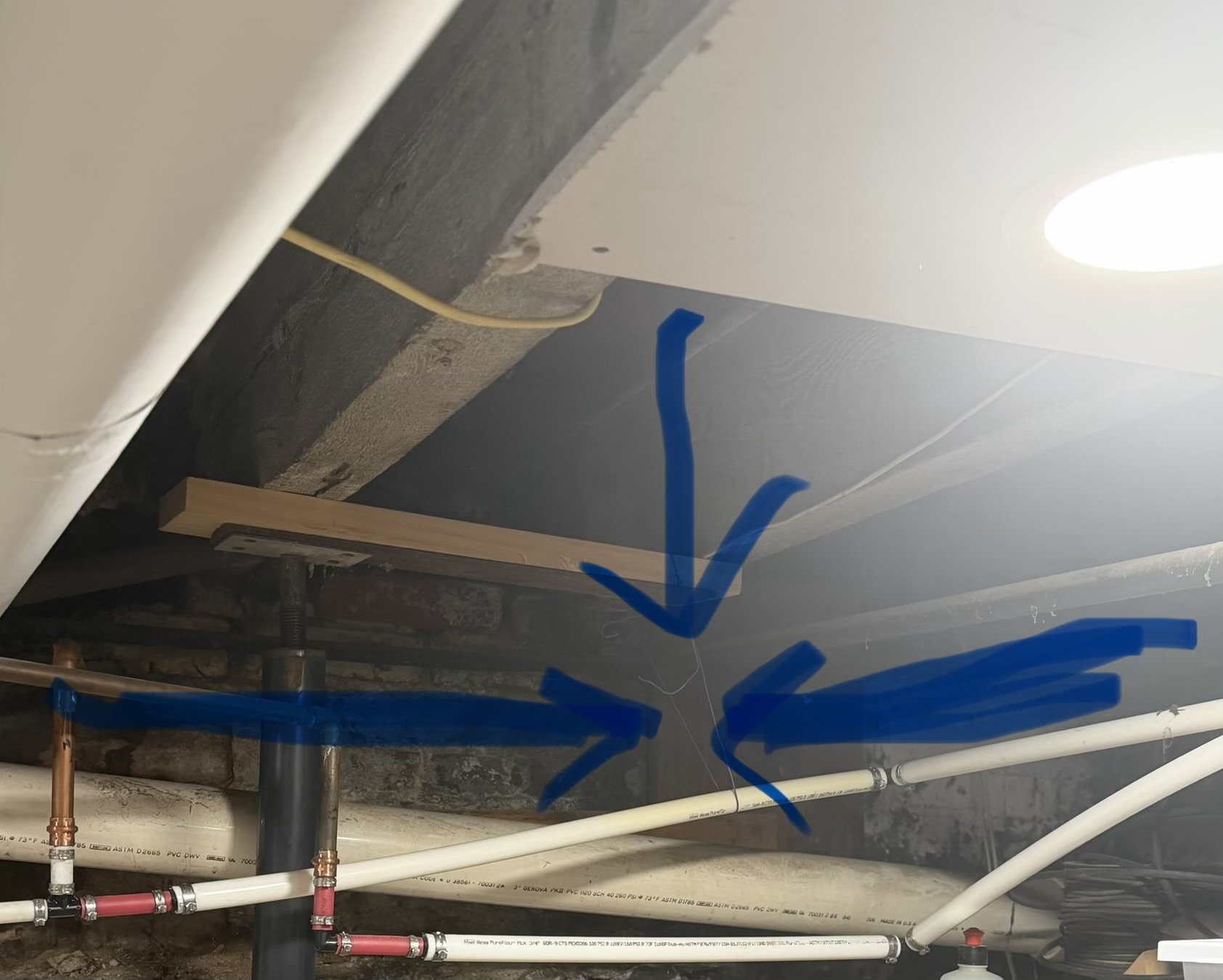

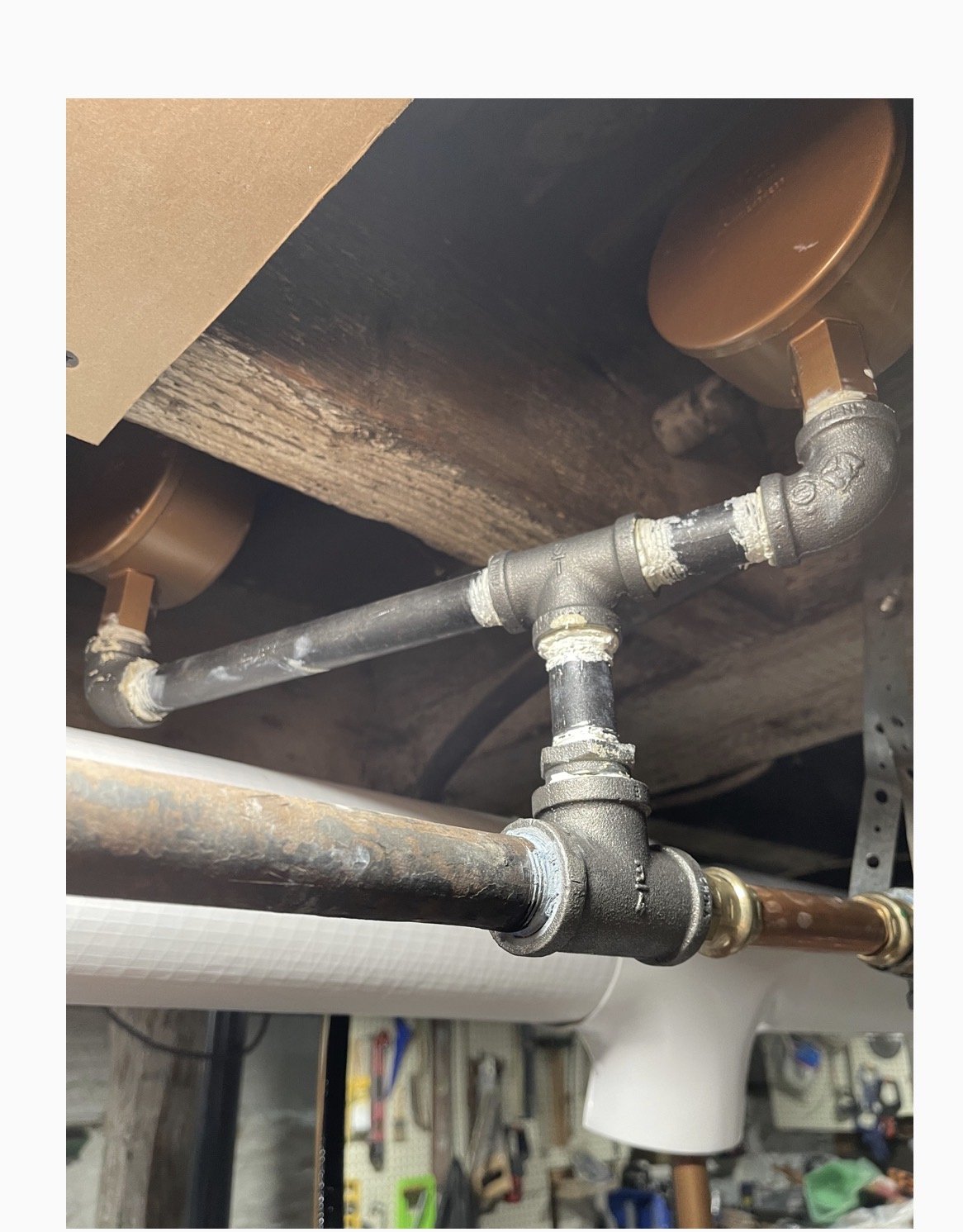

I had a bad install a few years ago that I still need to correct. But until I can get that done I need to vent my returns. The first picture is the returns from the second floor coming from the right. The other is from the living room. Should I put one gorton #2 on each pipe or two on the main after the upstairs dumps into it? The second and third pics are from the other side of the house. Second pic is the return coming from the upstairs and kitchen. The third pic is from the upstairs bathroom and dining room. The fourth pic is where they met then return to the furnace. Again should I put 1 vent on each of them returns?

Comments

-

This is a two pipe system? Radiators have a separate inlet and outlet and traps? If so, you can concentrate all the venting for the dry returns at the boiler, however, is convenient, before they join and drop to the wet return or boiler return.

And make that venting generous! You are venting all the radiators (and, in some systems, the steam mains as well!) through those vents.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

You may want to revisit that old post.

Is the situation still basically the same ? If so I think I would remove this wrong vent and put the Gorton #2 there. May help but it won't fix the other issues like the drips not being low enough. And you mentioned adding other Gorton vents, where are they ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I did put these two vents in place of that other one. But it’s directly above the furnace and I want to move them

0 -

Well you probably could put them any where along the return pipes. However they are usually found very close to the boiler. Pretty much where they already are.

" But it’s directly above the furnace and I want to move them " Curious, why do you want to move them ? Unless something else needs to occupy that space. I leave them right there. The system should vent just fine assuming the pipe pitch is correct and the issue below was corrected.

Was this drip corrected ? It should be a lot lower so steam can not sneak by and get to the vents trapping air in the system.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

that’s my next project! I’m going to lower the drips below the water line. I find the vents close because the heat from the returns heat them up before they can vent anything from the radiators. Once they cool down I can hear the air escaping from them. Other then the piping being wrong and I know in getting wet steam willdropping thedrips help that from happening?

0 -

If they (the vents) heat up fast, like way before the radiators are saturated hot with steam, the steam is probably sneaking through the drip (horizontal part that is too high) and getting to the vents, closing them. Moving the vents probably won't help much, steam travels fast. Say you move the vents, with steam traveling towards the vents a bit farther away from the boiler (lower pressure than the boiler) you still are trapping the air in the radiators. And some steam (more steam) is going the wrong way through the system, kind of a waste, and not pushing the air out of the radiators as it should.

I'd put my efforts into getting the drips as close to the floor as possible or at least as low as the wet return into the bottom of the boiler and add valve(s) to flush out the wet return part of the system. This should give the best return for the least work (as far as a properly working venting system).

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Not sure if it was previously mentioned in the other thread, this dimension should be as short as possible, it is not.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

As has been noted above, if the vents are closing on steam… on a dry return… you have some serious piping problems or bad traps allowing steam to get into the dry returns.

Until that is corrected, the system will never work right — regardless of where the vents are.

Steam should neve, ever get into the dry returns and get anywhere near those vents.

Don't shoot the messenger…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Looking at the pictures in the original post I don't think there are any traps, maybe orifices somewhere. Maybe originally this was not a steam system, not sure.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I don’t know the history of the system so it’s hard to say. I can say I have been told it’s a gravity system but again not sure. I have no traps on anything and I might have a few orifices in the originalhandles. The only vent I had was where I put the #2 vents at but that was just a turn valve I opened to bleed the air out. The one radiator as you saw has a bleeder which is the last radiator for the one side of the house. Trusts the return trusts coming out of the crawl space. Want to put traps on as well as new valves but money is the concern.

0 -

Jamie my near piping is horrible and need to get it redone but I’m sure it’s going to be a very expensive fix. I’m just trying to get better with what I have until I can get that done.

0 -

That's life! One step at a time…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Don't know how handy you are. I'd get a torch, solder, flux, tubing cutter, a few applicable wrenches, copper pipe and fittings and straighten out the Drips, wet return, Hartford loop myself. Many pipe sweating tips on Youtube.

Who added the two Gorton #2 vents that seemed to work out OK. You could redo the Drips, wet return, Hartford loop in black pipe if that is better for you but that may cost more in replacement pipe or reuse some of the copper.

I think that will give you the biggest performance gain and fuel conservation for the effort.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I’m going to start with the drips and get them dropped lower. If I have time I will add more vents to the other side of the basement. Just trying to figure out where to put them. Next summer I would like to mage the attempt at doing the near piping. Baby steps I think is the best option.

0 -

" If I have time I will add more vents to the other side of the basement. Just trying to figure out where to put them. "

Ultimately I think you will find more venting on that return pipe than what you already have is a waste of time and money. The object is to have the steam go only in correct direction through the system by venting the air out of the mains and then the radiators. Once enough venting exists more is a waste. I would think two Gorton #2 would be enough on the returns. If the steam is finding a shortcut to the present vents that is messing up the correct process.

An additional vent at the end of the mains or at least the longest main may help since you probably don't have crossover traps to aid in quick venting of the main. Venting the ends of the mains may help. However, I believe you stated you do not have access to the end of the mains. I suppose you could put a vent on the radiator supply pipe closest to the end of the main(s).

Another thing that makes your system awkward or dysfunctional is the lack of traps so steam can't go where is it not needed or wanted possibly trapping air in the system. Trapped air equals no heat when it is trapped in a radiator or prohibits steam form getting to a radiator.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I don't think it looks like a former gravity system… although that one radiator bleeder makes me wonder just a little bit…

My very first priority would be to get any drips firmly below the boiler water line and make sure that steam can't get into the dry return through any of the piping. If you are thinking this is a trapless system, next priority would be to get the pressure low and keep it that way — less than half a psig.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

That’s the biggest problem I have on the back side of the house is the last two radiators in the run don’t heat up as fast. I have had issues with trapped air as well. It’s been better with the new furnace but sometimes it could be better. That is the radiator with the bleeder. I can’t get to the main to do anything.

0 -

I have my pressure turned down the whole way which is .5 I would need to get a vapor stat to go lower.

0 -

Can you feel how far steam gets into that main? And how fast? And I assume there is a dry return from there? Does it get hot?

How are the pitches on the main and the return?

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Once it goes into the crawl space I don’t know much of what’s happening. I can feel the steam entering the radiator in the kitchen relatively fast once burner kicks on. But from that radiator to the one right above it which is the last radiator in that run seems to not heat as fast. The return for them is this pipe here. Should I put a vent on that pipe? The pitch on everything seems good from what I can see. I have one questionable pipe as far as return pitch but I have no issue with them two radiators.0 -

I assume it's the long straight pipe? Does it get warm or hot when the boiler is running? Which way does it pitch,, can it drain properly? How is it vented at present?

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

no it doesn’t get warm it’s pitched down coming out of that opening towards the furnace. No there is no vents on that pipe.

0 -

show where that dry return drops down to boiler or wet return(show from the Ceiling to the floor), probably need to fit a vent

known to beat dead horses0 -

" I can feel the steam entering the radiator in the kitchen relatively fast once burner kicks on. But from that radiator to the one right above it which is the last radiator in that run seems to not heat as fast. "

I'm thinking these radiators are essentially in parallel, with the one "right above" it not having its own supply from the main or an appropriately sized riser pipe with appropriate venting so the steam gets to both radiators at almost the same time.

Depending on the valve on the lower radiator maybe you can close it 90% to help balance that part of the system if needed once the drips are corrected.

If I understand correctly, the return pictured serves both radiators and I bet if you follow it (towards the boiler), it goes to the two Gorton #2 vents you have already installed.

Sadly this system as it appears is very atypical from normal. So I would 'repair' first what should give the most benefit. Which so far, as I can see from here, is the drips changed to go the floor or the bottom of the boiler (and the Hartford loop while you are there). Once that is done, reassess and move on if desired.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

@neilc hopefully these are what you were asking for.

0 -

@109A_5 as you can see in these pictures yes that pipe drops down into the same pipe as the gorton 2 vents.

0 -

Check all the pipe pitches to make sure that everything can drain. That long a straight pipe may have a drain only in the "middle" — and it may well have a flat slope, or possibly even a reverse slope… doesn't take much of a puddle hanging out somewhere to mess things up.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

@Jamie Hall I’ll check it out

0 -

2 thoughts,

1, that the vent heats up and closes before all returns are vented, follow the heat from the vent, back to from where it comes, and stop it there, if it's coming from what looks like multiple returns colliding, you need to separate the returns and drip them to the floor, with each drip having its own venting, or if from that high horizontal crossing drip at the boiler, well, same same, break the path and drip each to the floor, with venting,

2, the kitchen and the cold rad above, as @109a suggests them being parallel, the kitchen heats and vents to the return, trapping the upstairs on its own, add a kludge to your kludged system, try a vent on that upstairs rad,

known to beat dead horses0 -

Your Item 1 up there, @neilc , is quite correct — or would be, if this were a one pipe system. It's not. Those are dry returns, not steam main extensions (often incorrectly and confusingly called "dry returns")

Let me reiterate: On a two pipe steam system — whether normal pressure or vapour — the dry returns never, ever, see steam, and the vents on them never close.

Further, there's no need to separate them and drip them individually..

If you have steam in a dry return, moving vents is a bandaid. Find out how the steam is getting into the dry return (bad trap? water seal loop not deep enough (related problem: too much pressure))? In this instance, I'm deeply suspicious of a wet return which is set too high — too near the boiler water level.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

agree with you @Jamie Hall ,

I meant that steam is getting up to that vent, and it needs to be stopped from whence it comes, whether from returns, or up from the boiler return(s), trace the heat back to its source,

known to beat dead horses0 -

Well I made a video but it was too big to upload. My drips are getting hot from the mains first as the steam heads out. Then as the boiler runs the drip that comes down from the returns gets hot from boiler up to the returns which shuts the vents.

0 -

Recently someone made a video then compressed the file size by zipping it and posted the zipped file here and that worked. Normally a video is hosted on another site and the link to it is posted here.

" My drips are getting hot from the mains first as the steam heads out. "

As the steam heads out it should propagate through and heat the mains (only) first then go through the radiators and if any steam is left on the return side of the radiators (in your case, no radiator traps) should only propagate to the vents then the vents should close. Balancing the steam flow into the radiators may be critical in your case. So the steam can't go through a small radiator heating it up quickly than proceeding to the vents and closing them trapping air in the rest of the system.

The drips should not get steam hot since they only should have condensate in them since the water-seal at the bottom of the drips (each drip) inhibits the steam from entering the drips (no gas flow possible). That is why the water-seal on each drip is important to isolate the mains for proper vent operation.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I’ll try to make a shorter video maybe even several if needed. Once the steam starts the drips get hot to where you can’t touch them coming from the main. The pipe where the vents are heats up from the bottom up towards the vents then it will close the vents. Is this happening because I don’t have a water dam to keep it out?

0 -

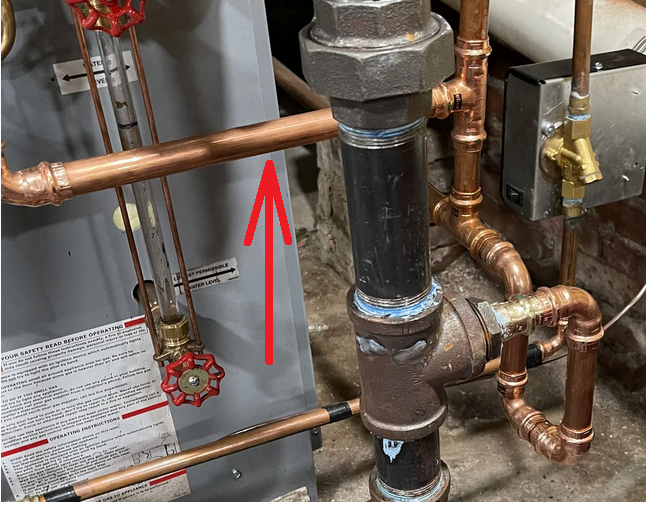

To refresh, can you take a picture like the one directly above but all the way down to the floor.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

0

-

Thanks but way too close, I can't get the big picture.

" To refresh, can you take a picture like the one directly above but all the way down to the floor. "

The whole view in one picture.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

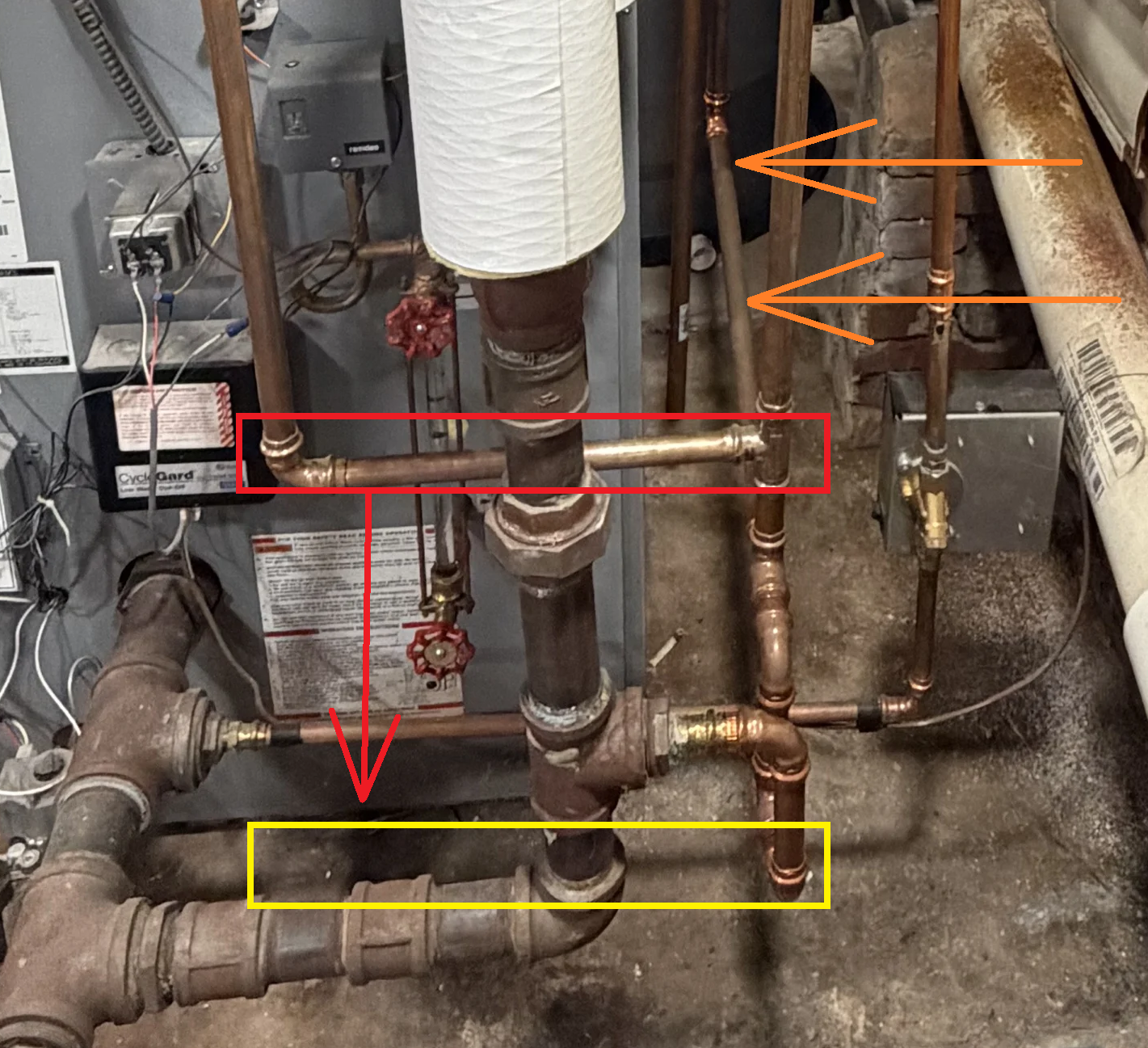

Here you go!

0 -

Oh OK, I thought something was changed, the bottom ends of all the Drips need to be well below the water line. Definitely the one in the Red box should be at the level of the Yellow box. I would also move the pipe at the tips of the Orange arrows down also. All join together below the water line then go to the Hartford loop. The water blocks the steam from moving where it should not be moving.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

that’s my project for next weekend I’m going to lower everything down almost to the floor. I was hoping to put more vents in but I’m not sure if I’ll get the chance til it gets to cold. The drips shouldn’t take too long so I’ll get that done and hope for the best.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements