Tankless coil feeding storage tank?

Just moved into a new place, and have a question about this setup. It looks they've got a coil feeding a storage tank, and my question is why? We had a tankless coil in my last house, and it provided limitless hot water, so I'm curious what the need for a tank is?

Thank you!

Comments

-

-

There is a sensor, it does not run all the time. But still, what is the purpose of a tank if you have a tankless coil capable of producing endless hot water?

0 -

It could have been installed as a just in case sort of thing, to make sure they always had a buffer. Or perhaps a previous resident did manage to exceed the capabilities of the boiler and so they needed a buffer for their hour long showers on the coldest of winters days.

0 -

Aquabooster is the name of your hot water system . It's a step up from just running a coil . The coil will deliver constant hot water if the flow rate though the coil is under a certain rate with the same incoming temperature of fresh water . The water that heats up the coil is also used for heating the home. Durning the winter the water enters the house is cooler and boiler water is sent out to heat the home . The tank will give you storage for good even temperature hot water and volume for a shower..

Hope this helps

There was an error rendering this rich post.

3 -

Some tankless coils are less efficient, depending on the water quality, the older they get. You may have a coil that needs a cleaning.

You may have a water heater was repurposed into a lower cost indirect water heater. Y have preached the benefits of indirect water heaters for years, here is one of my comments about the subject:

If you have a tankless coil and you do not use any DHW for 20 hours, the oil burner will still operate about every three to four hours for about 6 to 10 minutes in order to maintain a boiler temperature of 155° or more. That is because you have a vent connected to the boiler that allows lots of heat to go up the chimney. That is called standby loss. An indirect can save you on that standby loss because the boiler can get cold and the tank that is not connected to a vent can stay hot longer.

Indirects are more expensive than say an electric water heater or a storage tank like you have. Now I came across a customer that had a tankless coil that was abandoned in favor of a new electric water heater. They complained that ever since the plumber installed the electric water heater two years ago, their electric bill was outrageous. I suggested an indirect water heater would not use electricity and would offer abundant hot water, and use much less oil than the tankless coil did three years ago.

But what do we do with a perfectly good electric water heater? I converted the electric water heater into an indirect water by using the tankless coil inside the boiler. See the tank didn’t have the requisite heat exchanger, but the boiler did. So I piped the tankless coil to move heat from the boiler into the tank and left the hot and cold piping from the water heater alone. I disconnected the 220 VAC wires from the water heater and used the lower tank thermostat to operate the relay that powered the DHW circ and burner. This essentially made the electric water heater that was only 2 years old into an indirect. The electric bill went back to normal and the oil usage barely increased at all. Less than a hundred dollars worth of oil over the summer and they had plenty of hot water.

At the following year oil heat tune up they thanked me for all the savings. And doing the job so economically. I reminded them, in 10 years or so, when you need to replace the water heater, think about spending a little more for an indirect that has a 20 year or even a lifetime warranty.

I wonder if you have the same setup? If not, then perhaps you can get the boiler to be rewired so it does not need to maintain a minimum temperature and use the storage tank as an indirect water heater. Ask Me How?

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Thank you for the replies everyone.

Ed, with the electric-to-indirect conversion, did you just pipe the coil output to the cold input on the tank?

2nd question... Why does my tank only have 3 connections and not 4?

0 -

I have a 40 gallon electric Hot Water tank being supplied from a tankless coil in a Weil McLain WGTO4 boiler. There is a standard mixing valve of the hot water output of this tank. I connected an elapsed timer to the 220 VAC input to the tank to check how ofter the tank heaters ran and used electricity. I was pleasantly surprised that the tank heaters rarely turned on. The tankless coil in the boiler is supplying hot water (various temperatures) to the cold water inlet of the tank and the hot water outlet of the tank is controlled by the mixing valve. I am very happy with this setup; We now have a steady supply of hot water at a constant safe temperature. The original boiler piping only had a ball valve to mix the hot water from the coil and the valve was closed. So, you had a spurt of cold water in the shower followed by a spurt of scalding hot water from the coil and then cooler water until the boiler kicked in and raised the boiler temp to provide warmer hot water. And, we are now able to turn off the oil burner/boiler for 6 months of the year and use our HVAC heat pump for house heating in the Spring and Fall and the electric hot water tank for DHW.

1 -

-

I piped the from the tankless coil to the cold water inlet then from the drain valve port I put a brass Tee fitting so I could put the drain valve back and have a place to pipe to the circulator and from the circulator to the cold inlet of the tankless coil. That way the heat from the boiler entered at about 6" from the bottom and exited to the bottom drain valve opening. this put all the hot water at the bottom. That way gravity would do the job of letting the hot water rise to the top. I'm not sure that is the best way to pipe that design, but it worked for my customer.

The reason for only three tappings on your tank is that you have something we used to call a "range boiler". they would be piped to a coil that was installed in a coal furnace or coal steam boiler and would absorb heat from the coal then thermo-syphon to the tank. The center taping is for a control well in the event you might have a circulator pump moving the water.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

That’s not what this is.

0 -

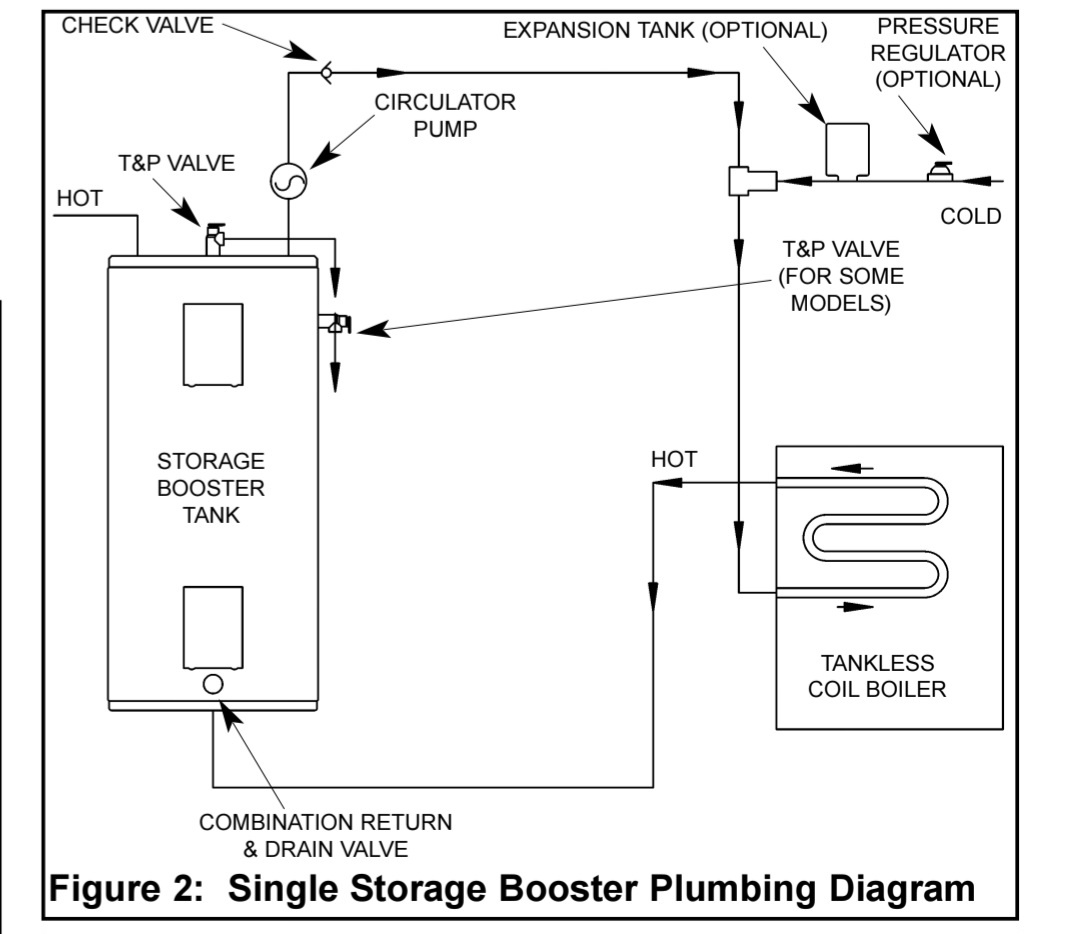

There are a few different way to pipe an aqua booster , with pros and cons .

Three pipes yes , the third ..(middle) pipe with the circulator, pumps out toward the coil and the return heated water is using the cold water pipe back to the tank. From what I can see…

I noticed an open flow valve tap . Throw a plug in the open tap for safety …

There was an error rendering this rich post.

1 -

-

EdTheHeaterMan,

in your piping from a Tankless coil to an Electric Hot Water Tank, do you need a check valve on the loop with the circulator to prevent cold water bypassing the Tankless coil or use a circulator with a built in check valve. Then is the boiler in a cold start mode controlled by the tank aquastat. Should the aquastat have a low temp cutoff for the circulator so you don't circulate until the boiler is hot. Thanks

0 -

A check valve is used to force water though the coil on a draw . Keeps the coil clean and adds more hot water . The draw back is the pressure drop .

There was an error rendering this rich post.

0 -

Yes, use a bronze or Stainless steel pump with a Internal Check Valve (IFC) or a separate check valve so water does not short circuit back to the hot outlet To the faucets.

Yes, the boiler then becomes a cold start boiler so you save fuel on standby loss.

While re-plumbing the DHW tank to the Coil, add some valves so you can do coil maintenance. there are valve kits for tankless gas wall hung water heaters. You can adapt one of those for the purpose of flushing your Tankless Coil. Tankless maintenance valve kit.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Thanks for all the replies!

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements