Piping from scratch

Hi all. I have a job where the house froze over a couple years ago and blew out every cast iron radiator and majority of the piping. She wants to stick with a boiler system and replace all piping and get new cast iron radiators. Since we are starting from a blank canvas, I gave her the option of zoning the 1st and 2nd floor and she wants to go with that. The existing radiator total gave me about 90K btus. My question is what is the best way to pipe my supply and return mains? I spoke with US Boilers and they are recommending 2 1-1/4 supply mains for zone 1 and 2 with a pump on each and 1 1-1/4 return line. My thought was to hit the parameter as a loop and just 90 the end to pick up my last radiator on my supplies and the same with the return. It would be roughly 50' on each supply and return main so 150' total running all 3 lines together. We are sticking with a cast iron Burnham Series 3 Boiler. I have installed and serviced plenty of boilers over the last 25 years but never had to do a new repipe to this extent. Any help would be appreciated! Thanks

Comments

-

-

Do a heat loss calculation breaking it down by room and size your radiators that way. you may be able to use smaller mains once you size things to your actual load.

you can pipe it direct return as you describe, you can pipe it reverse return where the first emitter on the supply main is the last emitter on the return main, or you can home run small piping, usually pex, from each emitter to a manifold. On a small system like that they will all be about equal. Make sure you have a way to balance the system, either radiator valves or valves on the manifold if you pipe it home run. If you do the valving on the manifold right, home run will be easy to purge, direct or reverse return may not be able to get enough flow to purge the emitters and may require bleeding of each emitter.

your load will give you the flow you need in each emitter and branch and you can size the pipe and circulators or circulator and zone valves from that.

1 -

-

As long as you run a decent outdoor reset, there is no difference in comfort as the rads run at a near continuous temperature anyways.

@jamescast1983 I know saying it is blasphey on this forum, but if you are in a place with cooling, don't bother with rads. Install ducts and regular furnace+ac or heat pump. This the norm around me with older houses that are renovated. You can look at high velocity system which can be fished through existing wall.

2 -

-

Save yourself and the customer some $$. The old system was probably oversized. Have (or do) a heat loss calculation room x room.

Once you know the heat loss x room

- Pick the radiation that will heat the house at 180 deg water (you can go to a lower water temp with more radiation and save some fuel)

- determine the water flow in each zone (1 gpm will deliver 10,000 btu)

- Size the pipe by gpm 3/4=4gpm, 1" 8 gpm, 1 1/4 12gpm etc

- make piping layout and select circulators.

These are the basics. You can get in the weeds and design all kinds of systems.

2 -

I have been in your situation so I would recommend the following:

- Try to get your customer to agree to a less expensive radiator like euro panel radiators

- Once you have the radiators selected, do a room by room heat loss calculation and select the proper size radiator for each room.

- They will most likely be in the same location as the previous radiator but a little smaller

- Determine the riser and return pipe size for each radiator

- Since the old system was most likely gravity and the new system will be using a circulator the pipe sizes will be smaller

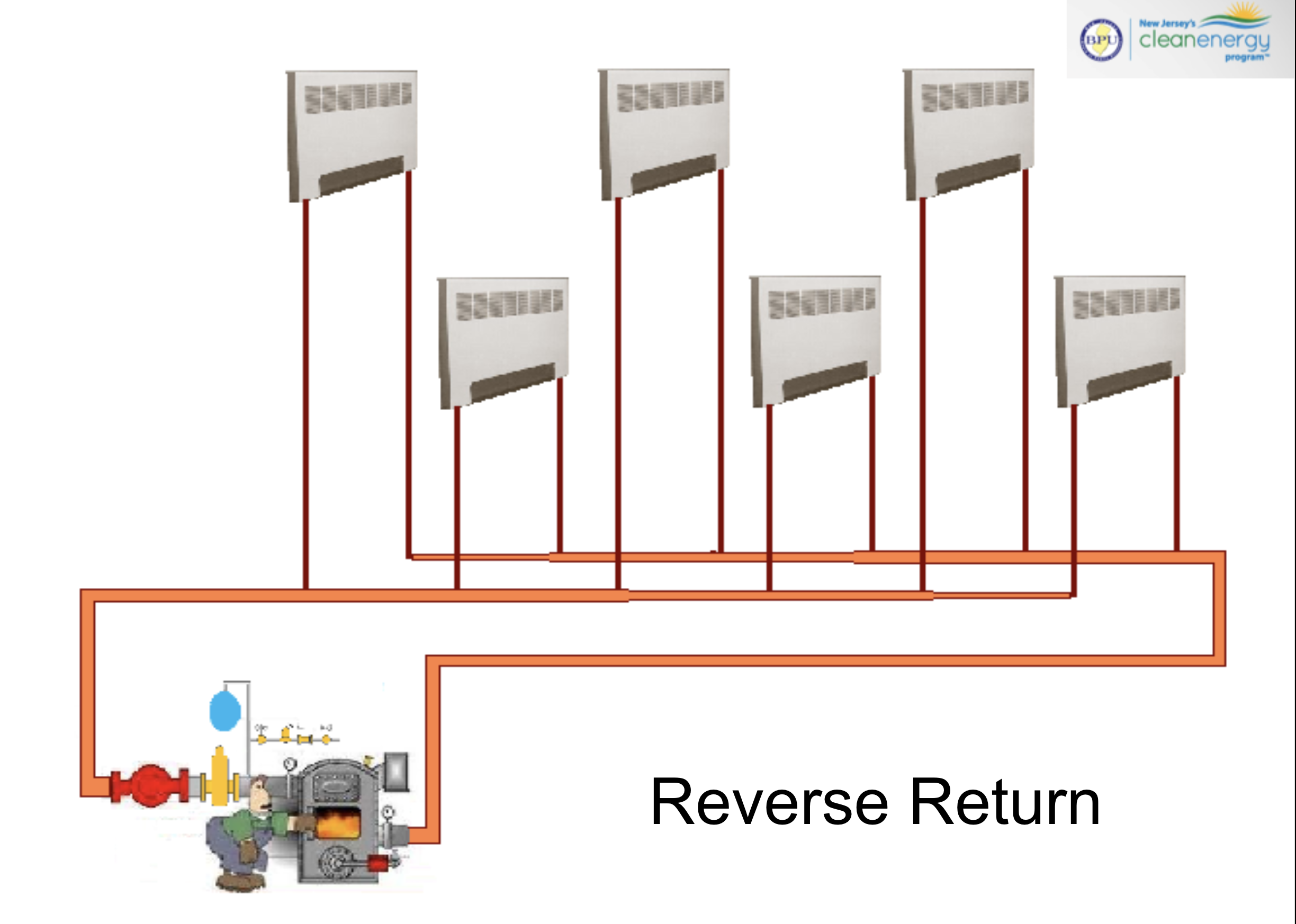

- The least amount of piping work will be to use a Reverse Return parallel design. That looks like this:

- You start at the boiler with 1” or 1¼” copper, depending BTU requirements of the zone.

- 1” piping will move 80,000 BTU of heat to the radiators.

- You can then select the pump required to move that much water thru the radiators.

- At some point you can use a common return for both zones and increase the shared piping as required

These steps will keep your cost down so you don't need to spend more $$$ on oversized pipes and extra pipe runs that will be doing the same job right next to each other. Example below:

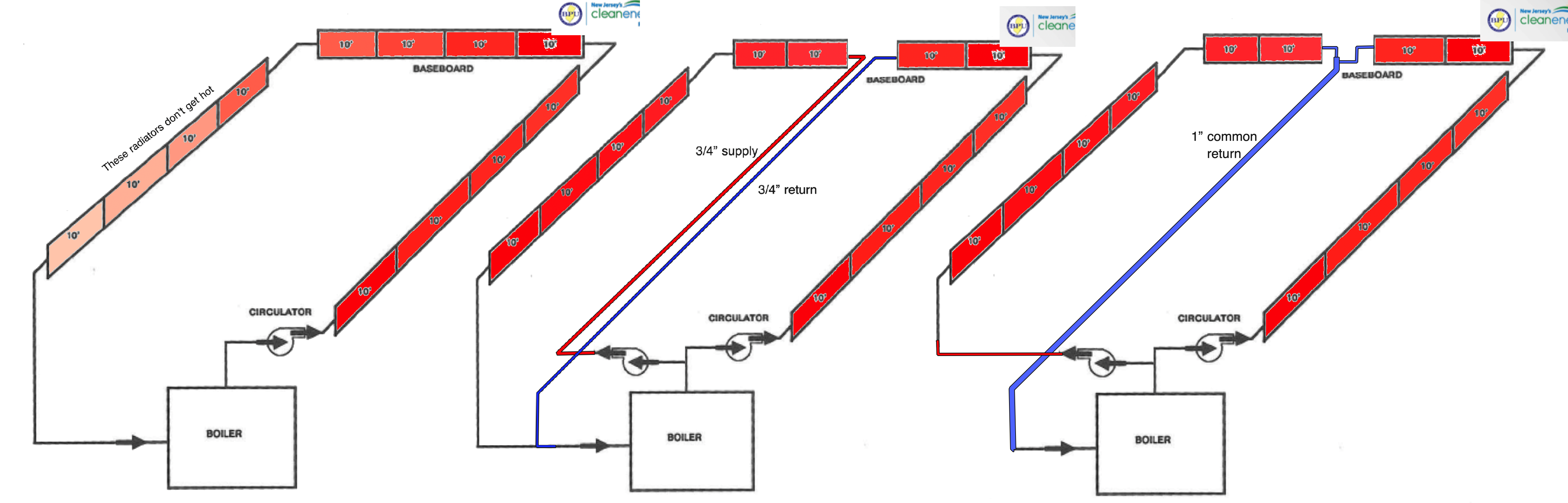

You can see in the first diagram on the left there is not enough heat in 3/4" copper to get all the baseboards hot

You can fix this with two zones as illustrated in the center diagram, with two sets of ¾” copper running the length of the house to accomplish this task.

The left diagram is a less labor and less material cost is illustrated by using a 1” copper shared return from the far side of the house.

PS: EDIT

I have actually done that job in Wildwood NJ many years ago. A nice elderly lady on a fixed incom asked several contractors for a price of a new boiler because the old boiler was not big enough to heat her home.

The replacement boiler prices she received were way out of her price range and the replacement boilers would not fix the problem anyway. I offered to put a 1" copper return pipe and common supply pipe from the center of a baseboard loop back to the boiler room for less that 15% of the price of the lowest boiler estimate. Took about 5 hours from start to finish and she had great heat in the entire house. No new boiler needed!

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

2 -

FInally I get to share my story on this topic. I had two jobs with frozen cast iron radiators. One was a church that many cast iron sections popped a crack in a non-leg section. As an apprentice I was taught to unbolt the rods connecting the sections, taking a tunnel bar, and a pick ax I broke loose the broken sections from their push nipples and rejoined the remaining sections. I added a little lamp wick on each nipple. Those few that had a leg section broke, if I was lucky i had another like it and married them. I think I only had to by two from the radiator scrap vendor to finish the job. All held up well.

Another job was an oil system whereby they ran out of oil since the oil delivery truck could not make it through the snow before they froze. I measured all the units and discovered I could replace all the radiators with convectors that would fit in between the floor Rad risers. "Most old systems are oversized anyway" and still be properly sized to heat the building. All done and it too worked well. This was done in the late 70's.

There are always other solutions, you just have to be smart and willing to find a better way, even if its outs🌡️de the box.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements