Steam device to be identified

Hello.

I'm working in Paris, France. There, we have few old steam central heating system still working in some old housing building.

Few people here know well about these systems.

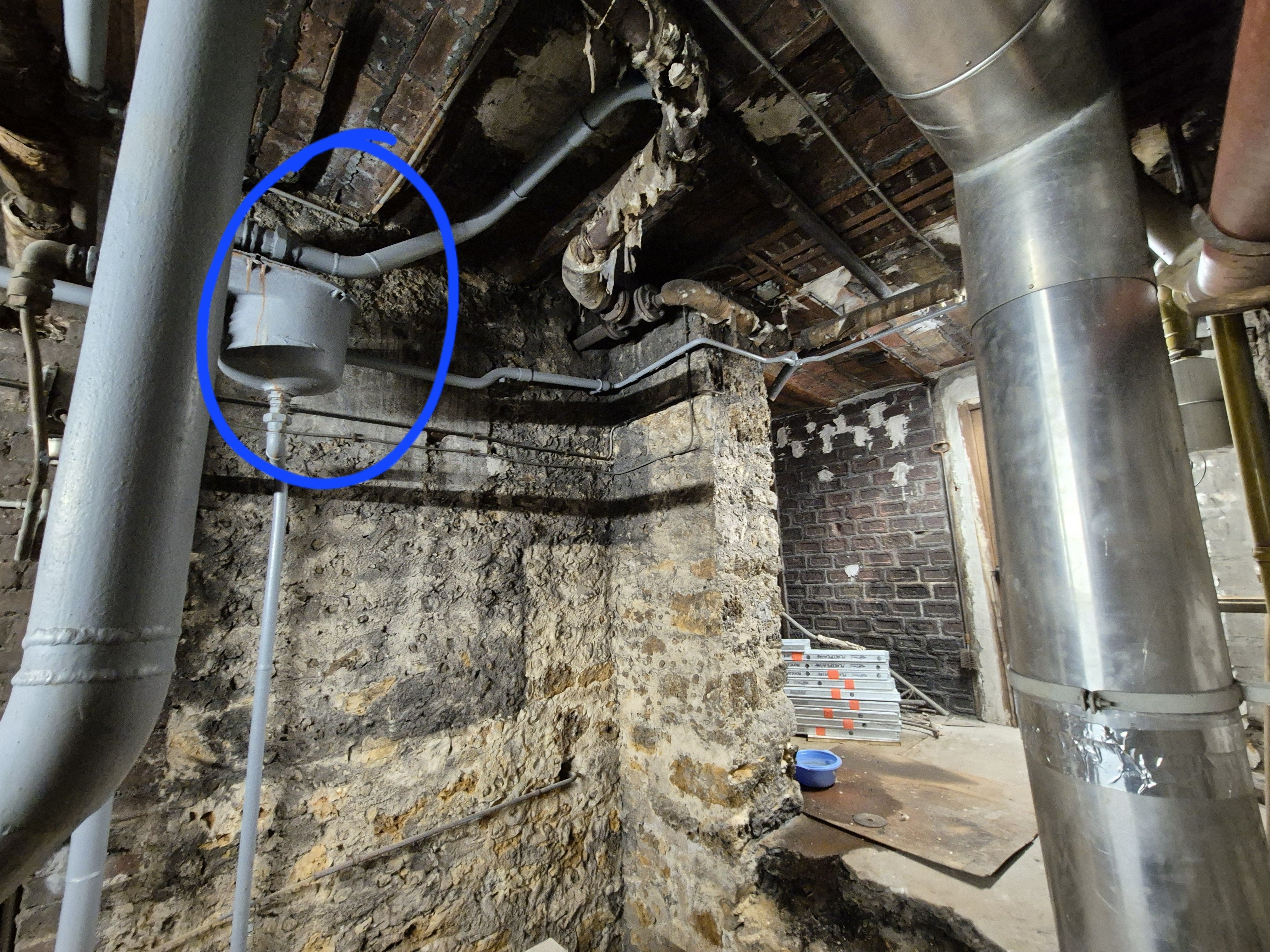

Would you be able to identify the device that is surrounded in the enclosed picture?

When the maintener increases the steam pressure, the steam goes out of this device from the top connection as if it was a kind of safety valve but it does really not look like the one I am used to see. Is it one?

FYI decades ago, it was a coal boiler.

I apologise for my weak English.

Jérémie

Comments

-

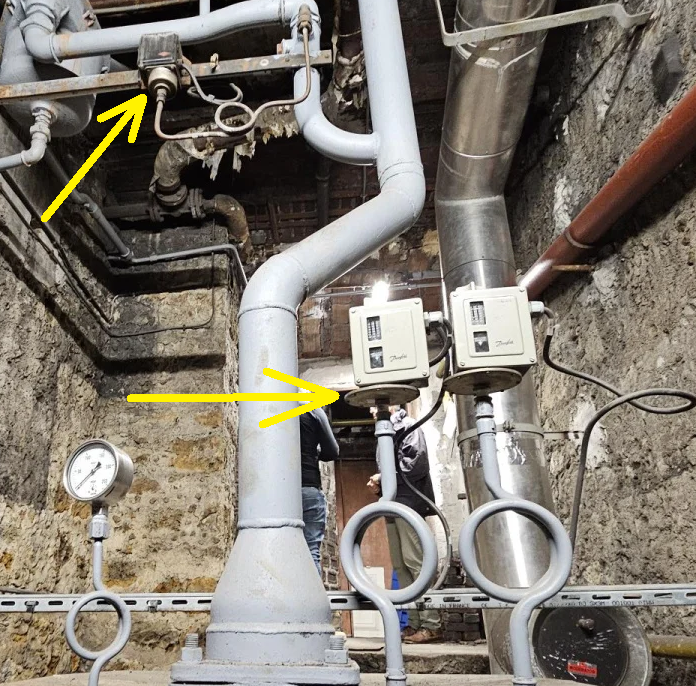

it is all the same yet all different. Everything is the same controls we have on US boilers but it is all a different design and manufacturer. It looks like the low water cutout is a Mcdonnell Miller low water cut out that we use in the US.

Unless there is something special about European boilers that can separate the steam and water, the near boiler piping is very wrong.

I assume that this is a 2 pipe steam system, each radiator has a supply and a return, not a single pipe where steam enters and condensate exits through the same pipe at the bottom of the radiator.

I think that is some sort of "boiler return trap". If the pressure in the steam supply main gets too high in comparison to the return for the water to be able to return to the boiler, it allows some steam in to the condensate return to equalize the pressure and allow the water to return to the boiler.

You would have to find the European @DanHolohan to figure out exactly what that device is.

4 -

@jeje59350 , welcome to HeatingHelp. It looks like I'm going to have to visit Paris at some point.

A "boiler return trap" is basically a pressure-powered pump that comes into play if the steam pressure gets too high for condensate (water) to return to the boiler by gravity. These were pretty common in the States, and were used mostly on Vapor systems, which were 2-pipe steam systems that ran with a maximum pressure of 8 ounces (roughly 40 millibars) or so.

Where does that pipe go that comes down from the bottom of the device? Does it connect to the return line? Are there any check (one-way) valves in the piping under the device?

Also, you might be interested in this article:

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting3 -

My guess is the item in question is an " Inverted Bucket trap" or something similar.

Typically you don't want to increase the steam pressure, you want to run it as low as possible, my boiler never exceeds 2 inches of Water Column or 0.005 bar or 0.5 kPa.

Yeah the LWCO (Low Water Cut Off) does look like a Mcdonnell Miller # 67, it does need to be flushed out often, Yellow handled valve.

Although typically not what we want to see around here, I bet the near boiler piping on the steam side works good considering the vertical height.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Interesting. The good old #67 lives on.

0 -

I like my M&M #67, probably over 50 years old.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

Thank you all for your comments on that Topic.

It is indeed a two pipe steam system (i've never seen a single pipe system in France).I'm visiting the building again on next monday. I'll take all the pictures i can in the boiler room and of the radiators. Let me know if some specific pictures can help understand the way the system is designed.

I'll try to draw a sketch of the architecture of the steam piping in the boiler room and outside.

If i summarize, according to you it is most likely to be a boiler return trap (thishttps://www.youtube.com/watch?v=j9FfGBXxDVE&t=206s)

Just so you know, i think there are some major differences between the steam system in the US and the one i can see in Paris. For example :- I have never seen any kind of thermostatic steam trap on any radiator's return piping.

- Some radiators are equiped with air venting system but not all of them (maybe they were all equiped originally but not anymore).

I'll come back on monday with more information ;)

Jérémie

1 -

@jeje59350 , read the article I linked to above. I'll bet it explains much about that system.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

While we're waiting for updates- in the article it states "the Continental fitter uses as few fittings as possible, preferring to bend the pipe into the required shape". You can see this on some of the smaller pipes in the pics. I'd love to visit this basement!

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

Looks like mostly a welded system.

Wonder if they are still doing installations like that or have the MEGA and Pro Pess boys taken over?

0 -

the welded piping has to be later, from post wwii because electric resistance welding didn't really exist before that.

0 -

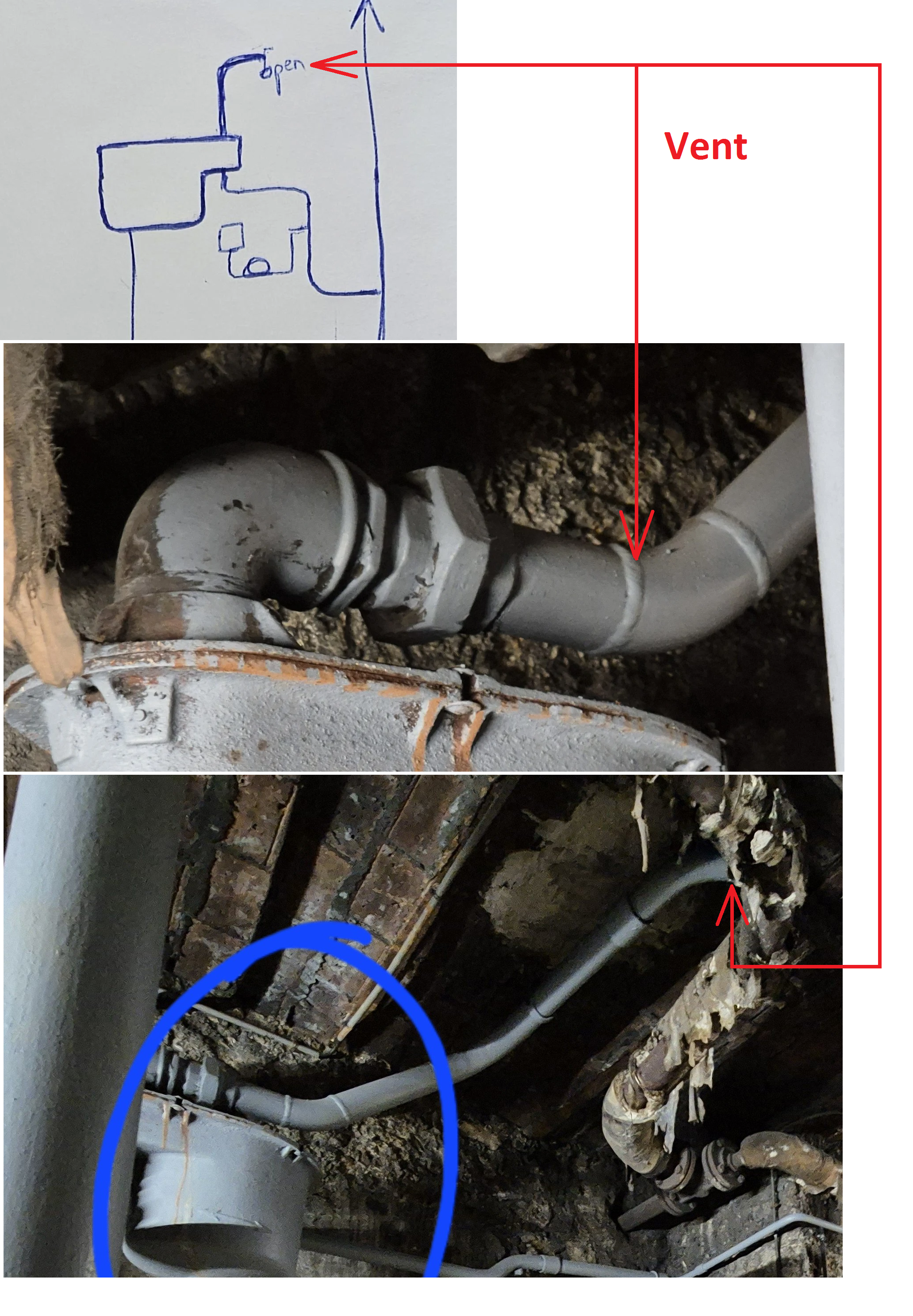

So, here are some additional pictures and a sketch of what i've seen.

About the context :

The building is from 1912. Originally it was a coal boiler.

They switch directly to gas boiler in the 70's.Originally They were heating Domestic Hot Water as well but the abandonned this system.

Originally (when it was coal) they had "open air" vents (i don't know what is the right word) directly on the outside of the building.Now, they have mechanic air vent (i don't know the proper english word) on the top of each steam column.

When they installed the mechanic air vents they had to increase a bit the vapor pressure to make it works well.

But the problem they have is mostly because they added a new network 70 years ago to heat the bedrooms and it doesn't heat instead they increase the pressure >40g/cm² (0.57 PSI approx). But from 0.5PSI this device is realising steam in the boiler room. It works well below this pressure.

About this devis, you can see how it is connected in my sketch.

The top of this device is just "open air" and that's where the steam comes out when the pressure is too high. Really looks like a safety valve..The bottom of this device is connected to the condensate return line.

There is no check valve or anything special on the return line. So it does not really look like a "boiler return trap".

I enclosed as well a picture of a radiator. Nothing special. As I said, in France we quite Never use steam trap on the condensate line of the radiators.

0 -

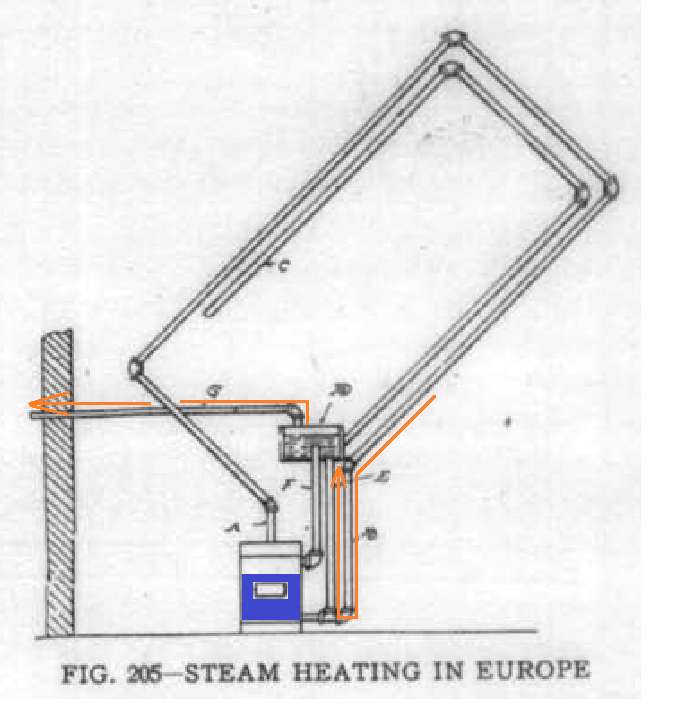

@jeje59350 , look at the article I linked to. In figure 205, a device is shown which appears to be similar in connection and purpose to yours. I therefore believe your device is a safety valve, especially since I do not see a safety valve on the boiler- at least not one that looks like those we use here.

Your photo 103123 shows a radiator that looks similar to the Rococo model that was made here up until 1920, by American Radiator Co. I believe American Radiator had a subsidiary in France then, and I'll look that up later. This would mean the radiator is probably original to the building.

Photo 103111 shows a device on the outlet of a radiator- what is it?

How does air get out of the system?

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting2 -

Photo 103111 shows what we call "té de réglage", that's basically just a balancing valve. We mostly use it with hot water heating system either to be able to isolate the radiator if it leaks or to limit the flow to do a rough balancing. Here, I guess it is simply to isolate the radiator if needed.

Yes indeed I've seen that fig 205 shows something quite similar. I must admit I did not fully understand the whole explanation about the regulating valve then.

And Yes the device somehow work as a safety valve but it do not understand why it is connected to the return line.

The underlying question is : can they remove it and replace it with a modern safety valve ? Or should they do something else to ensure any additional function that this device would eventually have ?

0 -

What is this tube, where does it go? Is it a vent for the radiator or is it part of an older pneumatic control system or what?

0 -

The regulating valve isn't that complicated. Basically, in a 2-pipe steam system there has to be a way to keep steam out of the dry (overhead) returns, which are only sized to carry returning condensate (water) and air. There are several methods, steam traps being one, but in a Tudor system the radiator valve contains a restriction, or orifice, that will only let a certain amount of steam enter the radiator at a certain design pressure. So, if the steam pressure is kept to that certain point, there will not be enough steam entering the radiator to fill it completely and enter the dry return. In the valves described, the installer sets the restrictor, and after that the owner cannot open the valve any further.

One of the nice things about this method is its lack of moving parts that will need servicing.

So, how does the air get out of this system? Basic principle is, steam will not go where there is air. In figure 205, a pipe leaves the "safety valve" and exhausts the air outside. Is it possible this system once had such an air pipe?

A couple other things to check:

1- blocked return line between the "safety valve" and the boiler, and

2- boiler pressure getting too high, which can force the returning water out the vent.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

Does the boiler have a modulating burner that maintains pressure or does it limit pressure with an on/off control (in the us that is called a vaporstat or pressuretrol depending on the pressure range)?

1/2 psi is typically about what pressure vapor systems operate at in the us, the orifices are sized to admit a small enough amount of steam to the radiators that it doesn't reach the returns.

0 -

@Steamhead It appears to vent the air out, it has to go through a bit of water at least the height of the boiler water, Figure 205. It makes it harder for the air to get back in resulting in a vacuum for faster steam propagation with the next cycle.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

Yes the tube is the way you drew it and it is indeed the radiator supply.

The burner is not modulating. It is on/off control thanks to the two white pressure switches on the bottom of the picture. One is for starting the boiler when the pressure gets too low, the other one is for stopping the boiler when it reaches the pressure setpoint.

The black pressure switch on the top is a security "high pressure" switch.0 -

Thanks for the explanation on the regulating valve. Very clear. I did not understand it was to be mounted on the radiators. Then ok we don't have this device here.

0 -

You might actually have it- depends on what's inside the radiator valves.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements