Why purge valve above boiler? Pumping Away.

Hi everyone!

Learning more about pumping away techniques and @DanHolohan writings and examples.

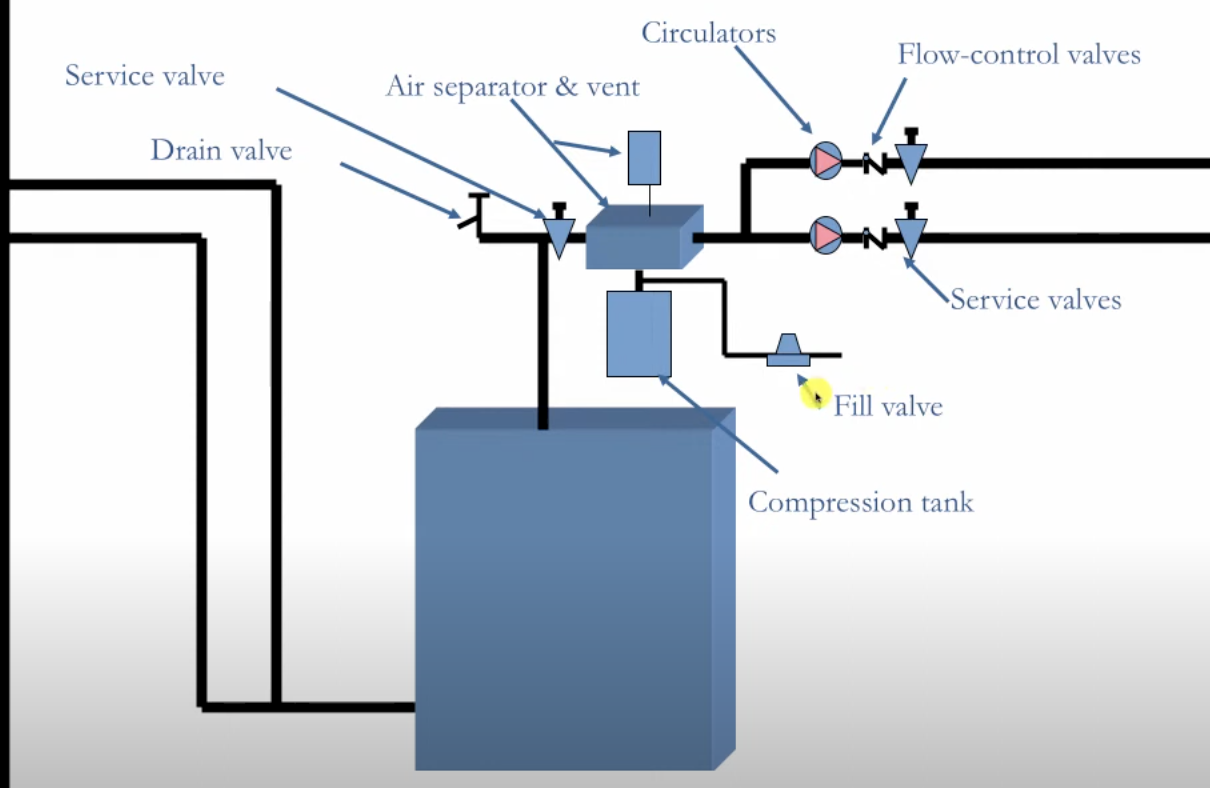

In one of this videos, he explains a simple way to purge the air from a single, hydronic boiler using a drain valve that is located on the supply directly out of the boiler. Curious why is specific location is chosen. Why not on the return side of the boiler?

I'm assuming this is so any air that may be in the boiler is also purged?

Thanks for any help!

Comments

-

you turn off the “service” valve , open the fast fill function

So water can only go around thru the system, it pushes air as it goes, up through the boiler to the “drain” valve purge point

With this method everything including the boiler gets purged from one point

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream3 -

The PRV enters the PONPC on the supply manifold when pumping away. Typically, the purge station(s) are on the return loop(s). If you follow the path of the water while purging, you'll see you never purge the boiler itself if set up that way. With a purge station as shown, you purge THROUGH the boiler.

Drop the pressure before isolating. Having the boiler not protected by the extrol will blow the relief valve otherwise.

1 -

Thank you, @hot_rod ! Is the circulator on or off during the process?

0 -

Thank you @HVACNUT ! Am I dropping the pressure at the boiler fill PRV to something less than the expansion tank pressure (15psi) or simply monitoring the pressure to not exceed the boiler PRV 30psi because I’ve isolated the expansion tank?

0 -

Keep the pressure below 28 psi when purging.

Or use a Caleffi 573, which is a high flow, fast fill valve, always. If you want to end up at 12 psi, set it at 12. It will flow about 5 gpm as it fills. No levers, screws, hoops to adjust, no worry about over-pressurizing.

I keep the circ off while purging, dirt and air will be passing through.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Thanks @hot_rod ! Currently the boiler has a Taco 3450. Would this be a suitable part for the job? Or is the 573 a better bet?

0 -

-

-

Very simply...its the last spot before the unwanted air gets out in to the system. Mad Dog

1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements