Repiping monoflo returns, how does this look?

Finally got around to replacing bad gate valves that isolate two monoflo returns to allow individual purging.

I have minimal experience, does this look like a decent way to do it to make it easier changing those valves in the future or should i keep it as it was? Open to suggestions.

Biggest problem is that the slopes on return marked RED and the return marked YELLOW are different, no easy fix for that without additional fittings which aren't good for monoflo. Somehow they were able to connect everything though.

Comments

-

MonoFlo® systems are not a purgeable design. Each radiator must be vented individually. Purging implies that you are forcing water thru a loop to entrain the air and cause it to exit at a valve near the lower end of a system. This only works on a series loop. When there are tee fittings in the mix (like MonoFlo® tees) the water has two paths, and the water will take the path of least resistance, and the other path will stay air bound.

Can you explain to us what you are attempting to accomplish?

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

In theory you could do it with a big pump cart and big connections, but you won't get enough flow with a hose.

I would use ball valves for the replacement of those valves so you can balance the system with them. The gate valves I guess were just isolation valves.

You can use copper for the replacement, it doesn't have to be black iron, be a lot easier to do all those fittings in copper although black unions and nipples for the final connections to the system will be cheaper than copper unions.

0 -

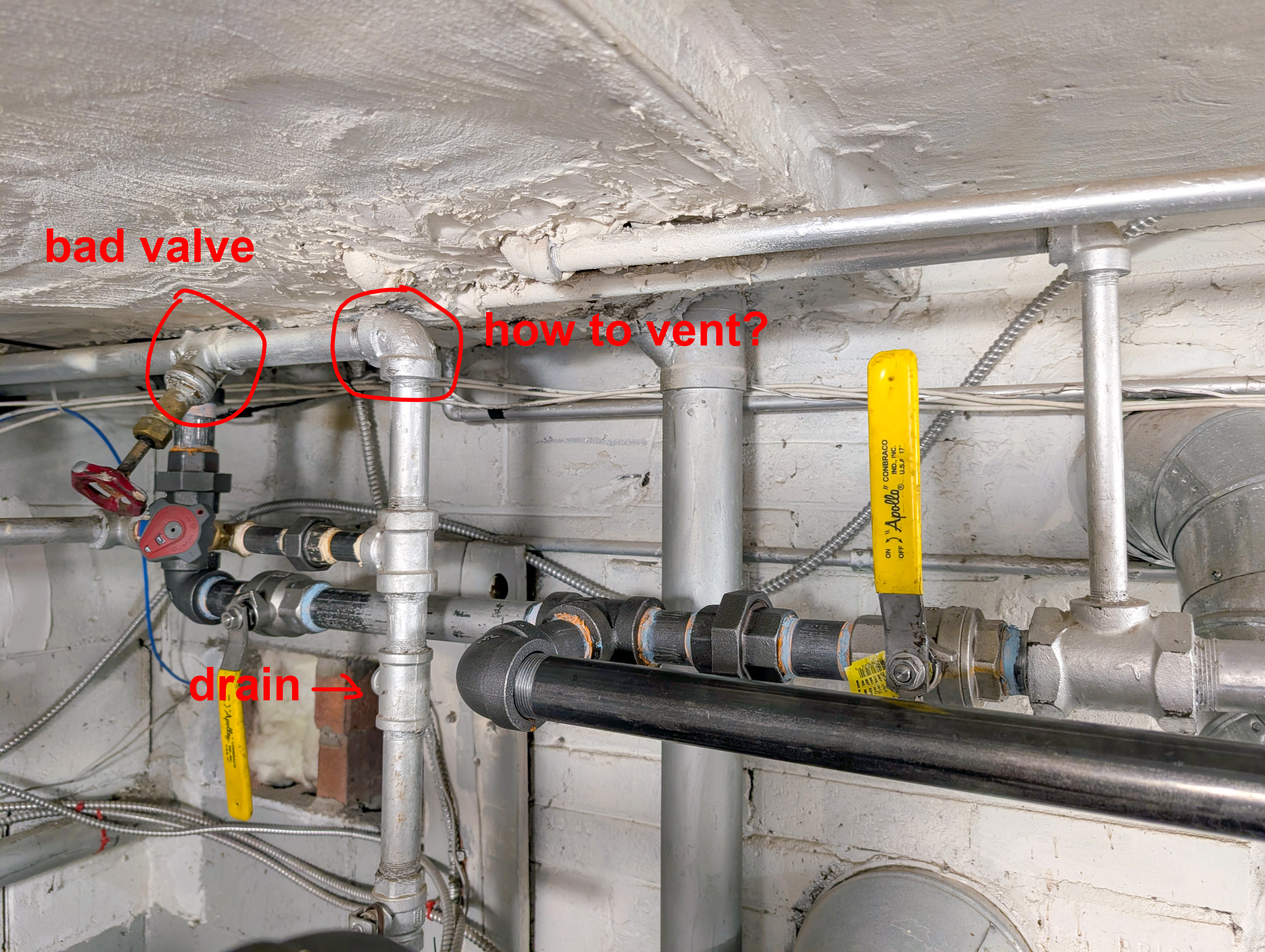

- Both of those (circled orange) gate valve are bad, one has a detached gate, both leaking from the stem.

- I didn't know monoflo cannot be purged but not surprised. However, it DOES work in practice to some extent with my 70psi city water supply, at least to get rid of some airlocks from the main in this system, and certainly to clear out some built up magnetite.

- The two returns are not 100% balanced, will tinker with it with new working valves.

So i want to replace the valves, and re pipe it in a way i can replace the valves in the future or just keep it the way it was if you guys think it was fine.

0 -

I am doing it with black steel. My hole place is schedule 80 iron. I can't solder larger copper well, and don't have a press tool. I do have a threader and a tristand.

Already took the old stuff off, it was seized completely, had to notch and cut off the valves.

Already got Apollo stainless ball valves for a great price.

Progress picture (just checking alignment using random parts)

0 -

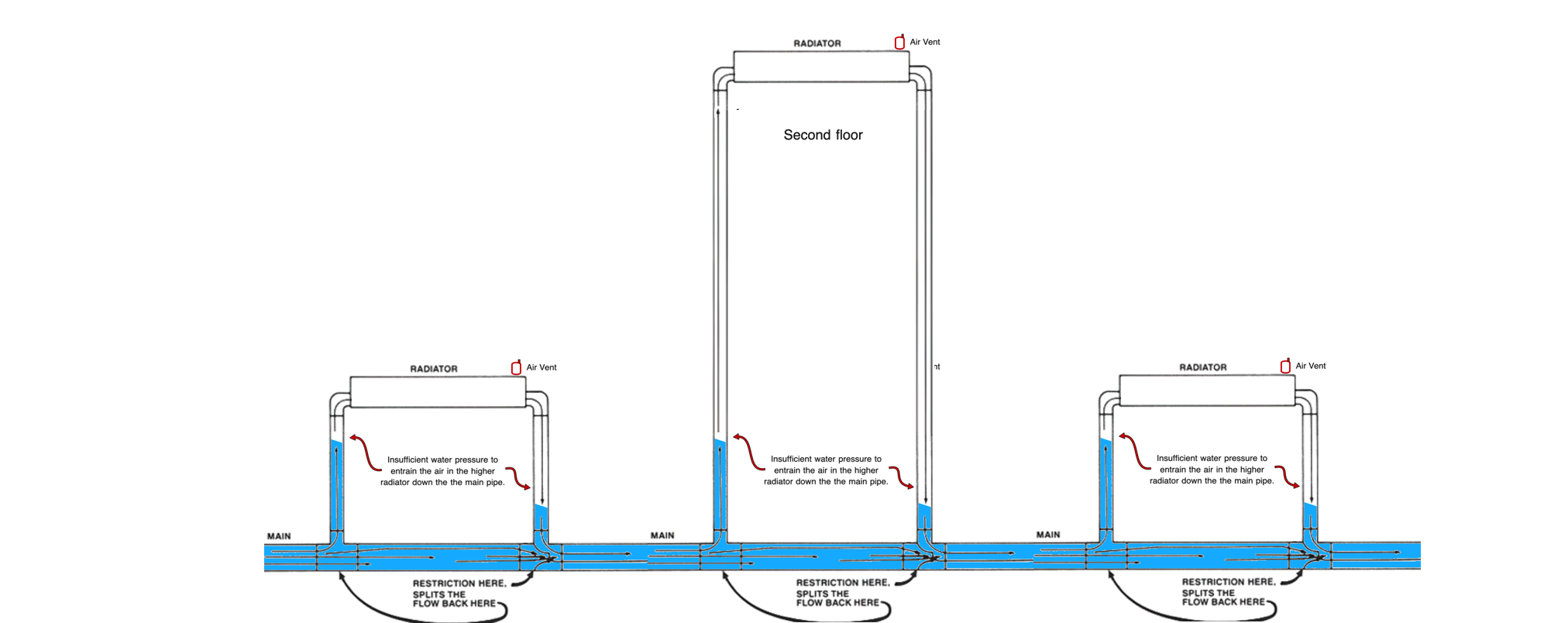

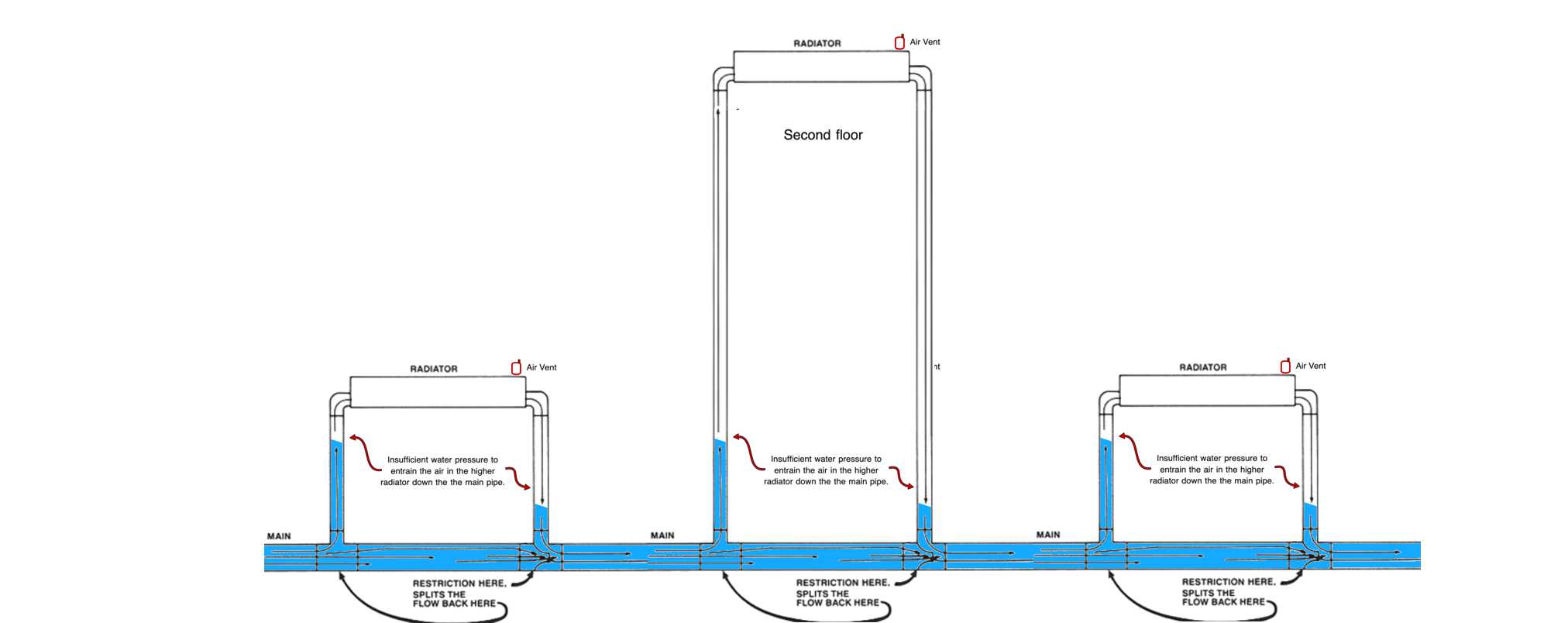

This is what purging might look like in your Monoflo® system:

You will be able to get air out of the main pipe however the risers, especially to the second floor,

will be impossible to PURGE…. they must be VENTED.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

Ball valves are a great choice for replacing those old gate valves. Remember to exercise them a few times a year to keep them usable in the future. If you are using them as balancing valves then mark the spot where the handle is after you get the system balanced. One should be 100% open and the other restricted (partially closed) at the point when both returns get hot water back from the supply within a few seconds of each other. It's not rocket surgery, so don't stress on geting it exact. 15 to 30 seconds from the time loop "A" returns hot from the time when loop "B" returns hot is good enough for government work. So it should be good enough for you.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Sounds good. Thanks!

I guess the piping layout looks fine since nobody commented with any suggestion there.

————————————————We'll see how the purging goes.

Most systems with water are under 30psi.

"Pumping away" supposedly pushes air into solution at less than 30psi.

My city pressure is 70psi.

- If i let the pressure build up to just under 30psi in the system, then purge a bit and repeat, why wouldn't the air get mixed in with the water move along the system?

- Monoflo tees are about pressure drop, if there was only 1 monoflo radiator on the loop, even it it was 8ft above the main, on the top floor and this tiny loop (low pressure drop) system is purged at 70psi, wouldn't it push out the air from the one rad? Likewise, if there are 10 rads on a branch i wouldn't expect this kind of purging to do anything for the last few rads because the pressure would be too low by the time the water gets to them. That's why being able to isolate each return to pump more pressure into a branch seems like it would help.

Always eager to learn, please help me understand what i am missing.

0 -

the monoflo tee just partitions the pipe in to 2 sections, one connects to the main, one connects to the branch.

the dissolving and undissolving air won't work unless you can get enough air out of the emitter for water to flow through the emitter and you won't get that with the flow through a 3/4" garden hose or makeup water supply. you would need enough flow in both the main ad the branch to have enough flow exiting the emitters to pull the air down hill with it.

0 -

can we see a radiator, you sure there aren't vents ?

known to beat dead horses0 -

@sixplex said:"

- If i let the pressure build up to just under 30psi in the system, then purge a bit and repeat, why wouldn't the air get mixed in with the water move along the system?"

This is a point that @DanHolohan mentions in his story about how the book Pumping away came to be. Dan states that our work is dirty and we want to stay away from the clean white walls and white convector covers upstairs. By pumping away from the expansion tank and raising the pressure, and letting the pump run at the higher pressure to get more air dissolved in the water, you may be able to avoid going upstairs to vent convectors in a MonoFlo® system. My experience has been mixed. I needed to vent the convectors on systems that were not piped as instructed in the Pumping Away seminar I attended, and the book I purchased. But when it is piped just as Dan explained, the system purged the air itself over a 24 to 48 hour period of constant pump operation and cycling the burner only on the thermostat. It only worked on a single floor system. If the radiator risers went to the second floor, I needed to vent the radiator.

You need to understand that when purging, you are causing the air bubbles to be pushed by the velocity of the water through the pipes in order to force the air bubbles to flow downward against the force of gravity. When using Pumping away to remove air, the air actually gets dissolved in the water due to the higher pressure and lower temperature of the water. This is Boyle's Law of dissolved gasses. Think of it like relative humidity in reverse. The air molecules actually dissolve in the water, just like water vapor is dissolved in the air all around us. Temperature and pressure make the amount of air that water can hold change. Just like temperature and pressure change the amount of water vapor the air can hold. That water is invisible until the temperature drops below the due point and we can see the water vapor as fog. You can see the water but you can't fill a glass of water with it. It just floats there as micro droplets of water.

The air in the water when pumping away gets absorbed in the radiators and then when the boiler heats the water and the pump inlet’s low pressure acts on that water, the air leave the hot water as micro bubbles. (fog in reverse) But that air will just get redissolved again, unless you have some way to separate those micro bubbles from the water before they get to the pump and get pushed back into the higher pressure of the discharge side of the pump. That is what the different air scoops and air separators do. This process is using the physics of water to remove the air and it is not instant. Purging and venting is instant. It may take several hours or several days depending on the flow rate and the amount of air you are trying to remove using the pumping away idea. I can guarantee you, the you will need to vent any radiator that has very long risers from the basement to an upper floor. Pumping away will take too long to do this center radiator on the second floor.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

If a cold system is pressurized to 30psi, would the air dissolve into water or not?

0 -

The way you drew it is fine. I would put a vent at the end of each monoflow return before the ball valve (vent upstream). You will be able to get the air out of the main. Then venting up at the radiation will be less

0 -

project is coming along.

a gate on one of the old valves was completely gone, felt great removing that valve.

want to do a bit more work on the return feeding basement rads,

a valve there is also bad and it really needs a vent at the end of the run, but no way to add it, because if the ceiling.

anyone has any ideas how to do it?

a horizontally oriented hygroscopic vent would fit, but not sure if it would be effective enough that way.

0 -

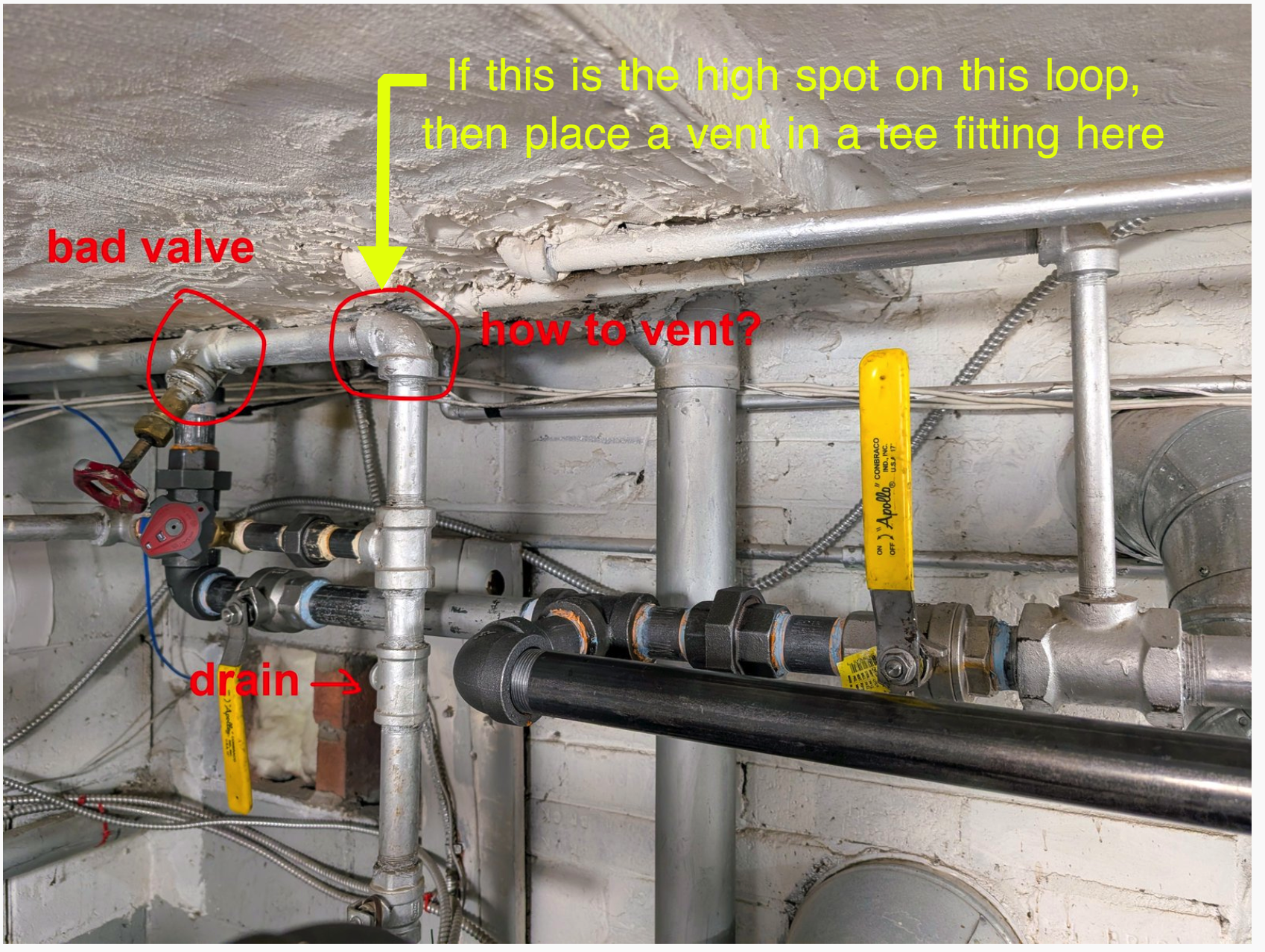

Use a tee and a manual vent or boiler drain. Are all the emitters on that section below the main or does it go down before it goes up to emitters? If you put in purge valves you can purge the main. you'll still have to manually vent each emitter but you should be ale to purge he air out of the main to deal with thing like offsets that go up then back down and things like that.

It is common to solve the problem of the stem breaking in a gate valve by opening it up and removing the gate.

0 -

That return only serves emitters that are below it.

Anytime the system is drained and refilled that line is air locked, purging it through the drain shown on the picture pushes the air out.

Should I not even bother with a manual vent if I have to do it manually anyway?

0 -

You mentioned that this is a high spot on the loop and all the radiators fed by this pipe are on the basement floor. You need to get the air out initially so place an air vent in a tee fitting that you install while you have everything is apart to replace the valve.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements