Disconnection of indirect water heater from tankless coil of Slant Fin steam boiler

The indirect water heater is connected to the tankless coil of Slant Fin Liberty 30 steam boiler, as shown in the picture. I am going to remove the indirect water heater and put in a stand alone water heater.

The installation manual shows the tankless in relation to its inlet and outlet. Thus, draining water from the indirect’s coil cannot remove the water below the inlet/outlet level of the tankless coil. If the two vertical pipes are cut a couple of inches above the inlet/outlet and capped, whether partially filled water inside the tankless coil would be ok when the boiler is in operation?

How would you disconnect the indirect from the boiler?

Thank you very much.

Jack

Comments

-

If the two copper pipes in your picture are going into a tankless coil in the boiler (looks like they do) just cut them off. no need to cap them unless the tankless coil has a leak in it.

In fact if the coil does not leak you do not want to cap those connections as the coil could build up pressure inside it.

To be sure can you post pictures of the indirect and the piping between the indirect and the boiler?

?

0 -

@JDE said: "How would you disconnect the indirect from the boiler?"

Answer: Sawzall.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Now when you are finished using the Sawzall, you don't want to cap/plug the coil openings, or only one of the pipe connections can be capped/plugged. If you cap/plug both openings, you will produce a closed pressure vessel inside of the boiler. When the boiler makes steam and that closed pressure vessel has some leftover water in there, you may find that water will expand into steam at some point creating an over pressure situation that could cause those caps or plugs to blow off under excessive pressure. That can be quite dangerous, so leave at least one side of the tankless coil open to the atmosphere.

If you find that the other opening starts to leak boiler water on a regular basis, that would indicate you have a hole in the coil. Said hole is allowing boiler water or steam to pass thru to the tankless coil. At that point you can cap the other opening because the tankless coil is no longer a closed vessel and is connected to the boiler system and the boiler's relief valve.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

EBEBRATT-Ed and EdTheHeaterMan:

I am grateful to you for your help. I will follow your instructions: no capping.

The picture of indirect piping.

Jack

0 -

I am just wondering why the change from indirect to stand alone?

- Insufficient hot water?

- Leaking tank?

- Leaking tankless coil?

- Cost to operate?

If the burner is set up properly the boiler can actually get cold while the water in the indirect stays hot for many hours if there is no hot water demand. If you burner is not wired that way, then you are spending too much on DHW by keeping the boiler hot all summer long.

The lowest cost standalone water heater is electric but it is also the highest cost to operate in most areas of the country.

IIf you are using a fossil fuel water heater, then they are more expensive to insstall however less costly to operate. I find that connecting a stand alone fossil fuel tank to a chimney to vent the exhaust fumes also lets heated water in the tank out the vent pipe during standby. It has been said that a water heater is only used for about 2 hours a day. That means there are 22 hours on non-use stand by time. In that stand by time you may notice the water heater burner operate every 3 to 4 hours to recover from the standby loss.

Properly connected, the burner on the indirect will only operate once every 16 to 20 hours during that same 22 hour stand by time. That is because the indirect tank is not connected to an exhaust vent so the heat stays in the tank longer.

So I ask again: "What is the reason for the change?"

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

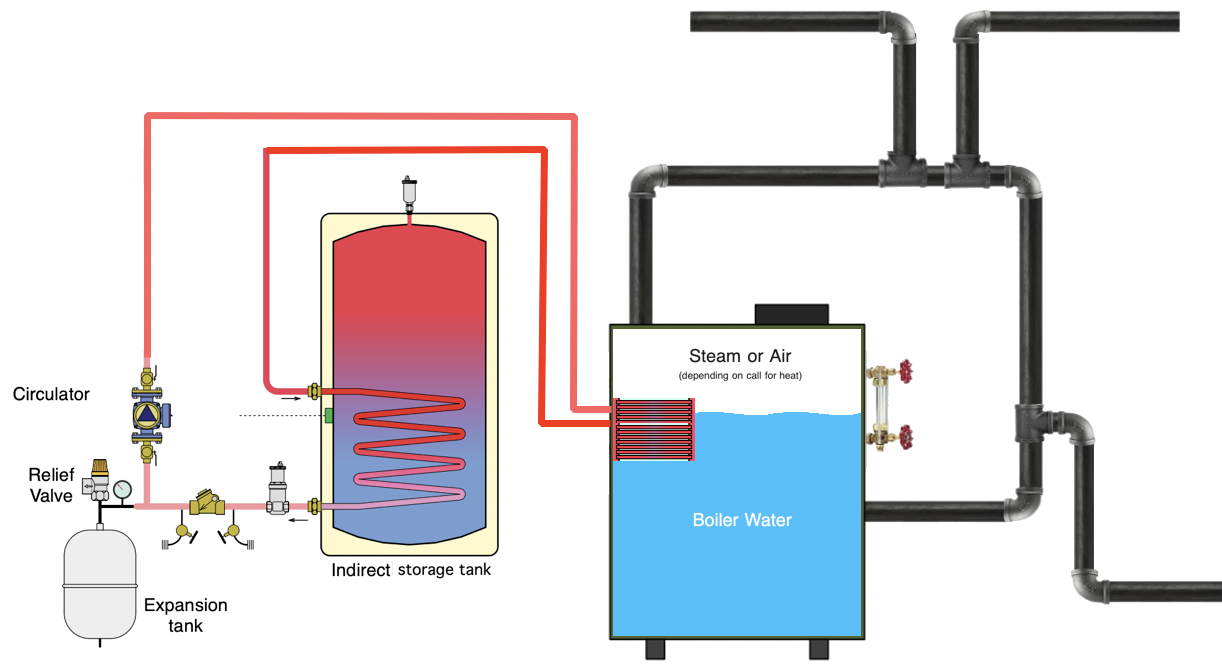

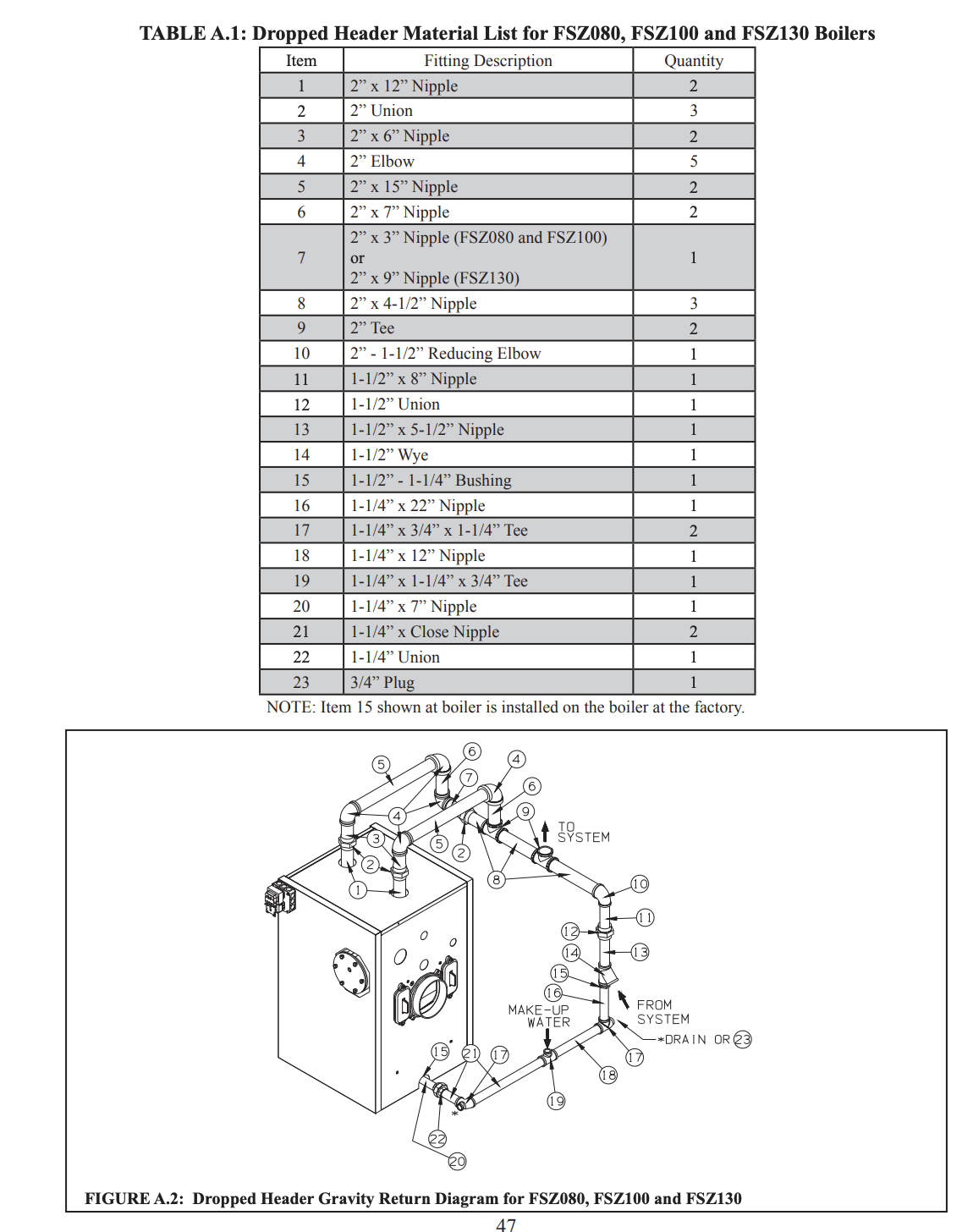

Looking at your piping… I don't see a circulator pump on the boiler water piping from the boiler to the indirect. Without a circulator to pump the hot water in the tankless coil, to the coil in the indirect, the recover rate for heating the indirect must be very slow. Here is a diagram of how you should pipe the tankless coil to the indirect. Missing many of those parts will cause poor performance of the water heater.

It may be less expensive to get a circulator, relay, expansion tank, and relief valve, so the indirect can operate at full potential. It would be a shame to discard a perfectly good water heater with years of life left, just because some uninformed handyman installed the water heater wrong.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

What water is in the HX loop? It looks like a Taco 006, so is it domestic pressure in the loop, and the tank? Or is it set up like a one zone boiler at 12 psi?

0 -

EdTheHeaterMan:

It is leaking.

The reason to put in a stand alone water heater is the age of the steam boiler (installed in 1996). My initial plan was to replace the current Liberty steam boiler with an Intrepid one (both are basically the same made by Slant Fin), along with a new indirect water heater, with correct installation. But yesterday I found Slant Fin closed down in 2022.

Now, I am in a hurry to install a gas fired water heater, while learn other manufactures’ steam boilers.

Thank you very much again for your help in this matter.

Jack

0 -

HVACNUT:

Yes, it is Taco 006, but I don’t remember what exactly follows, probably “-BT4”. The max pressure is 120 psi and the set up 10 times lower at 12 psi, if I remember correctly. Now, everything associated with the indirect water heater is gone. Tomorrow, a new gas fired water heater will arrive.

Thank you very much for your help in this matter.

Jack

0 -

Good Eye @HVACNUT. i didn't see that 006 in the shadow connected to the tank. i believe that is potable water pressure in the tankless coil because there is no sign of an expansion tank… unless it is out of the frame of the photo.

@JDE. You will want to look into Crown by Velocity Boiler works. The folks there are great to work with and you can get them thru Johnstone supply of you have one near you. There are other distributers also. The best thing about Crown Boiler is thay have the near boiler piping kit with all the nipples and fittings to get the installer to install the boiler correctly.

If your installer has the ability to read and follow the diagram, you will have a properly installed steam boiler.

I have installed many Crown boilers in my time on this earth. Great folks to work with. Customer support is the best.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

@EdTheHeaterMan said

"If your installer has the ability to read and follow the diagram, you will have a properly installed steam boiler."

Quite the optimist today😊😊😊😊

1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements