Debate me Bro-3/8 inch pex 150 foot lenths AOK for high delta T radiant

good case for high efficiency circulator but looks like an alpha could maintain 2 gpm at maybe 35 W on 4 legs as it can provide almost 20 feet of head at up to 4gpm. that would take care of what i'm looking for like 20000 btus with maybe 20 to 25 delta T. I feel like lower velocity high delta T is a good radiant fit if you arrange travel from outside of space to inside.

you get very little $ savings on the tubing albeit you are getting about 2/3 of the plastic–maybe cause they don't sell enough units of 3/8. you get more surface area to water volume with the 3/8 so that enhances btu transfer, at least to my simple mind, so if you don't mind high delta T why not? i guess if you could save 15 W an hour on the pump thats like 1/3 of a kwh per day so a dime maybe say the season is 180 days thats only $18 bucks.

i'm a big believer in how much easier it is to run and work with 3/8, esp. to make 180 degree turns on close (e.g. 4 inch) centers, obviously you have to be a little generous in the turns but more doable with 3/8 vs tough with 1/2.

willing to have someone tell me why they think this not a good idea. but who knows how well i will listen. :- )

brian

Comments

-

I'm having trouble trying to figure out what you are asking. If you're asking about the ability to maintain .5 GPM each in four 150ft loops of 3/8" PEX with an Alpha circ, then yes, not a problem.

0 -

What is the application? 20-25 ∆ is kinda wide for a residential home slab?

Back in the day 3/8 Heatway system designed around 200' loops. The rolls were 600' generally. And that tube wasn't as smooth inside, a bit more pressure drop.

3/8 is nice for 6" even 4" on center if you want to get an even more slab temperature consistency.

I'm doing a shop addition and was going to run 3/8, 4" on center to be kinder for the A2WHP, lowest possible SWT. But 3/8 barrier tube is not a commonly stocked item around here. I went with 1/2. 6" OC

\

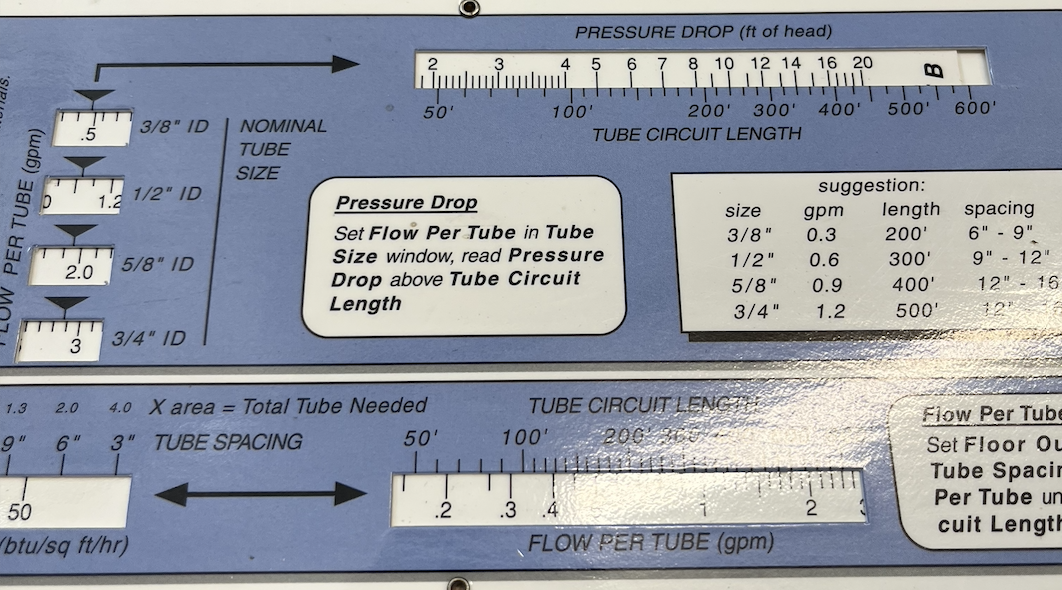

.5 gpm in a 150' loop of 3/8 = 6' head, on the RadPad

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Why is it that you believe 3/8" would have a high Delta T at such a short length would be my question ?

You didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38330 -

1/2" would give you more surface area. the slightly more mass and volume of water would be negligible in this case especially if you get your odr set up right and run it at close to a constant temp. You shuold be controlling it so that the water temp matches the heat loss and if you are adding say 5,000 btu/hr to 20 or 40 gallons of water, the heat added and lost is the same, you just get more transfer surface with 1/2" tubing.

0 -

All of my radiant projects that are underfloor are done in 3/8" pex. So much easier to run compared to 1/2".

Yes, your loop lengths will be shorter compared to 1/2" but your delta T should still be 10-15 degrees for the comfort factor and maintaining an even surface temp of the floors.

The average loop lengths from the manufacturers are based upon standard, safe circ selection without having to go to crazy high head circs.

But if you do the math, you can go past the recommended lengths, in my own house, I installed 3/8" underfloor (with and without plates) with 400' loops and a standard circ.

I used 1/2" for my slab for the same reasons, I wanted longer runs and less connections to a manifold and less actuators. I wanted to make sure each room I was installing tube in that it had one loop instead of two (easier all around)

Dave Holdorf

Technical Training Manager - East

Taco, Inc

1 -

@hot_rod haven't been offered one of those fancy slide rules at the caleffi booth (although I did win some prize there so I guess I can't complain!)

while I think it could handle 1 gpm in 150' leg of 3/8 i only need about the .5 you mention to deliver 20,000 btus in 4 legs. so the pressure drop is manageable. I have in mind precisely the approach you did, i.e. 3/8 on 4" spacing instead of 1/2" on 6".

3 passes of 3/8" actually provides more pipe surface area than 2 passes of 1/2". and I was thinking to myself that in a shop environment with the feed temps, i.e. high side of delta T, along the outside outside walls and the return winding toward the inside that an even higher delta T would be acceptable and this could favor even lower water temps and/or lower circulation rate.

there is less water volume to that surface area which suggested to me that for a given flow velocity you would get more transfer from water to pipe although given the conductivity of water maybe this isn't a choke point, not sure as to velocity. @Rich_49 , I kind of misstate what will go on at similar flow rate which would be higher velocity in smaller pipe but in going for higher delta T i'm thinking lower flow rate. that is the general approach i'm trying to take by which i meant the flow rate for 20 or 25 delta T is lower than for 10 or 15 delta T assuming the lower flow rate can still carry the required btus in total. but to flow a given volume per minute the velocity would be just a bit higher in 3 passes of 3/8 (.3 sq. inch cross section) to 2 passes of 1/2 (.36 inch cross section) so at the same flow rate the velocity would not be slower but for high delta T you can use lower velocity and I thought, instinctively, the additional surface area to water volume ratio would help with the heat transfer to pull that higher delta T. if there is anything I have observed about radiant floors it is that 6" spaced 1/2 pipe in a 4" slab you can readily identify the pipe location by feeling the floor so anything that makes the transfer to the entire floor more complete and even is better in terms of using the whole mass, albeit I mean even as between adjacent pipes more so than same floor temp at center of room as outside. From my seat of the pants engineering perspective getting more heat to more of the floor rather than warm spots where the pipe is would take better advantage of the radiant approach.

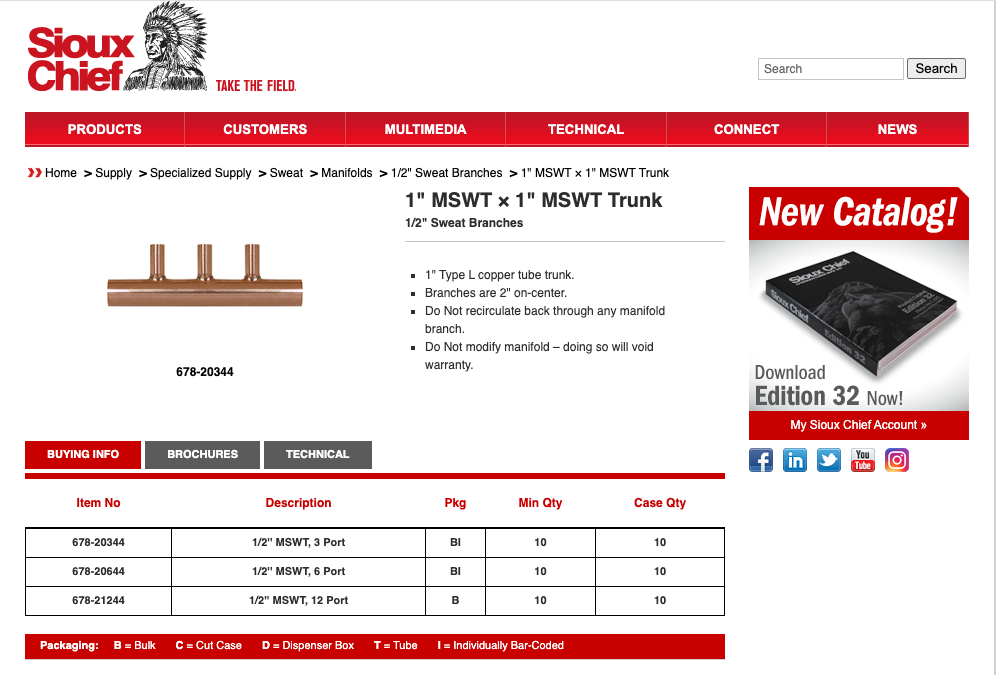

and the reason I titled this "debate me bro", homage to current events aside, is that the industry has pretty much rejected 3/8 in most applications which does as @hot_rod suggests make it hard to get, and i find it so much easier to work with but when the unit price of the 1/2" is virtually the same that means that the convenience I find in 3/8 is offset by 50% higher materials cost and the ease of running it is offset in labor if you are running more length. I use a lot of 3/8 in plumbing as well as radiant and I am continually dissappointed at how difficult it is to get fittings as well as tubing. you can get 3/8 adapters for manablock style and maybe i'm jsut going to have to stick to that although i like the sioux chief style copper manifolds which can't be had in 3/8 to my knowledge.If more people were using 3/8, I don't think it would be that much of a penalty. so i'm kind of using the occasion to jibe at the issue but also for folks to knock my seat of the pants engineering off its pedestal ;- ).

0 -

1/3 more length of tubing will have more surface area. 10x more tubing will have even more surface area. i was comparing equal lengths.

you could get the tool to punch and braze your own 3/8 manifolds.

0 -

@mattmia2 don't think I haven't thought about making the manifolds as you describe. so far i just bite the bullet and do a 6" piece of half inch to a 1/2x3/8 reducing fitting.

although i have to admit i used a manabloc for a water system recently where i could choose 1/2 or 3/8 outlets and i did like that. not sure what the oxygen permeation of that material would be and whether to worry about a small portion of a circuit being that way. although I often hit the used market for an old domestic hot water tank and separate the radiant water from the boiler and baseboard feeds anyway rather than a proportioning valve.absolutely understand that your comparison was equal lengths and I didn't initially specify clearly that i was thinking of more pipe. but as i mentioned that isn't more economical because even though the 3/8 pipe has 2/3 the plastic in it that the 1/2 does, it costs about the same unlike some products that commodities, e.g. spray foam insulation. if to get 4" costs you twice as much as to get 2". that also holds true for rubber roofing. twice the size is twice as much. but with pex 50% more plastic doesn't cost any more. I put that down to 3/8 being so obscure that stocking costs and number of units that move add to the price from manufacturing and all along the supply chain.

one more thing besides flammable refrigerants that i'm for and the industry, writ large, is more or less against ;- ).

0 -

@hot_rod haven't been offered one of those fancy slide rules at the caleffi booth (although I did win some prize there so I guess I can't complain!)

Just send Archie a fancy slide rule for his desk drawer. I'll pay the postage.

#archibald tuttle, #free stuff, #AHRExpo, #stuff I'll put in a junk drawer #stuff i'll never use, #L🤣LEdward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

It might be that the process to cross link the tube and to add the oxygen barrier are a significant part of the cost of manufacturing in 3/8" and 1/2" pex so the cost of the additional material doesn't affect the cost much.

0 -

-

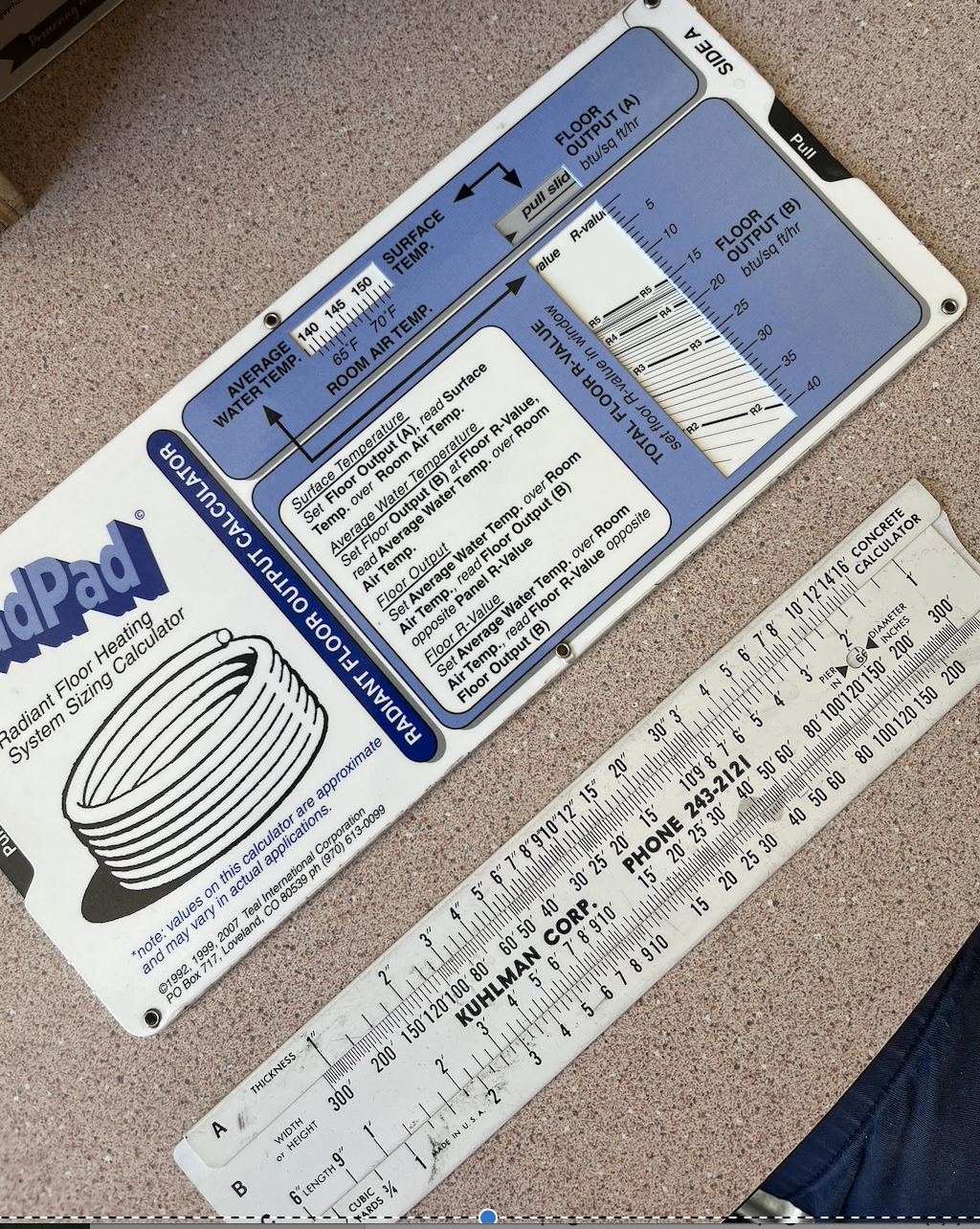

Two slide rules that I still use. I find them as fast as opening a software or app.

The Rad Pad developed by Larry Drake. 1992!!

A concrete calculator.

I do have an extra RadPad somewhere if @archibald tuttle wants it

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Yes , the industry has overlooked 3/8" . Mostly because training and teaching except for few resources are sorely lacking and the pool of "TRAINED" professionals suck at best .

The math is the math and math never lies , physics is physics and that also never lies . All one has to do is the math and a few decades of observation whilst realizing that you don't know what you don't know to become proficient .

I use a whole lotta 3/8" , even 5/16" in some instances , like bathrooms that have little tubing . I do this to keep a higher resistance so the circ/s do not become bullies and take authority of the whole system . Use your 3/8" , it is usually a better end result . Quit listening to the industry , it's full of guys whose paychecks are signed by entities with a conflict of interest in you doing a good job , they just wanna cover their **** .

You didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38330 -

fair question. dont have the tools on my cell but IIRC the pressure loss in 150' of 3/8 is still more than 300' of 1/2. so i was anticipating that i wouldnt amp up the circulator and the flow rate would be lower than target but i would be counting on high delta T to get the btus out and i have always 0referred that strategy even with 1/2 inch.

i can see from post below you share my affection dor 3/8. and they aint going broke selling it dor essentially the same price as 1/2.

and , to be fair, it is the pressure delivery at flow numbers on the plumbing side that warn folks off but i shower with 3/8 pex and im happy. i have to admit i chickened out running it on hot side to showers in 4 story building although i wanted to to cut the time to get hot to the shower head. if i would have had easier access to the chase i would have tried it .

so my occams razor take on the 'industry' is not even that they tell folks to do qhat is profitable to them but that they have given up on thinking about the best ways to so things and go the easy way for them. that includes the industry letting us down with regards to speaking out against bad regulation instead of just going along .

brian

1 -

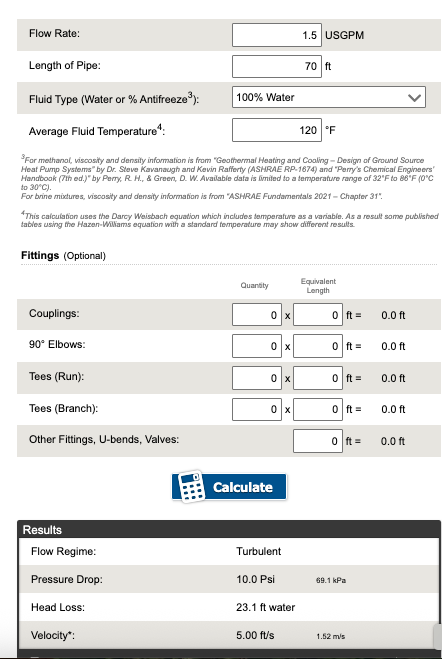

Of course the difference in a plumbing system is you could have 50, 60 even 80 psi to push the gpm.

As I recall 70' was the max. distance for 3/8 on a Manablock system

So a 1.5 gpm shower, full hot you have a 10 psi drop. If you start with 60 psi or more, that is not so noticeable.

If you have a well with a 20/ 40 pressure switch, recalculate.

With the free PPI calculator, 5 fps is acceptable for non continuous HW flow in pex.

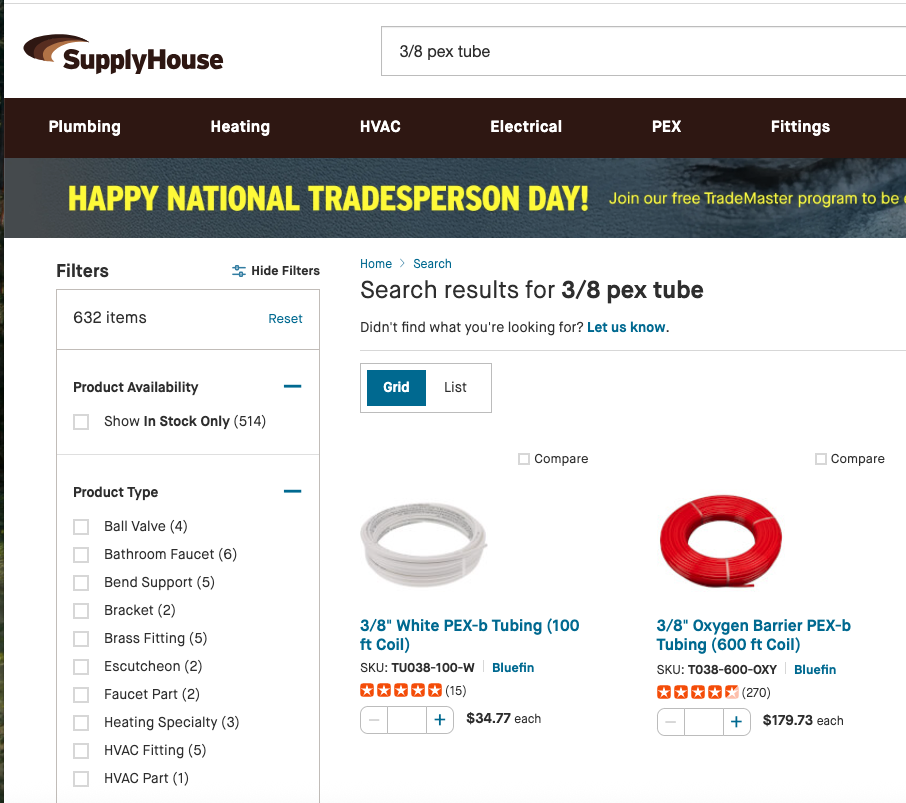

I'll bet SH could have 3/8 barrier pex at your door step in a day or so. I've used 3/8 in shower walls and concrete counter tops for tight spacing

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

The Levitt homes here on Long Island were 3/8" radiant system. Also the spaghetti convector system used 3/8" .

I like running 3/8" …. The only issue, which not a big deal are the adapters , it's the extra step . I have to admit I prefer to pull it out of the box :)

There was an error rendering this rich post.

0 -

"I have to admit I prefer to pull it out of the box"

do you mean grab the center of the coil and pull it sideways out while the bulk of the coil is retained by the box? that's heresy in my book, but could be a reason some people like 3/8 cause you could actually do it.

The other think I like about 3/8 is I could make my own floor panels from XPS with a 1/2" box core bit set 1/2" deep. one of my favored techniques when I don't have a lot of ceiling height to give up and i'm going over uninsulated concrete with no pipes in it. I bought some heavy foil that I press in and the 3/8 stays right in the groove.

and "spaghetti convector system"

was there a specific thing or was this just informal reference to the helterskelter appearance of pipes laid in before a pour?0 -

@hot_rod

is this PPI calculator on line tool. whats the URL.I like that it gives velocity. given the shorter length of tubing you might need a higher velocity to get the btus through 3/8 but I am willing to deal with a wider delta T spread so don't have to pump like crazy.

0 -

Plenty of good info on all types of plastic tube

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I am not sure if it were mentioned , You want to use an A Pex system with 3/8" system .

Yeah.. pull it from the middle. That lasts until it snaps back in :)

If its a big enough job , a despensor works well , I would look to rent one .

Hope this Helps

There was an error rendering this rich post.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements