Replacing steel pigtail with brass - parts selection

Hi folks,

When I moved in to my current house in fall last year I promptly had the [1 pipe steam] boiler system inspected and serviced. When the technician took off the pigtail, the elbow and nipple connecting it to the boiler was pretty well clogged up with rust, and he said it probably was never serviced (i.e. in the 10 years since it was installed). I discovered, from later finding the plumbers who the previous owner used, it likely was serviced probably 2 years prior.

Fast forward to now, where I realize all connections between the boiler and pressuretrol (including pigtail) are steel instead of brass, which I understand is not ideal. I just took it all apart to inspect, and found plenty of gunk at the elbow and nipple again (not quite as bad as what was found last year). I did notice a few instances of the boiler shutting off before the heating cycle was done, then promptly restarting, at the end of last season which I presume is related to the pigtail being clogged.

So I figure I should replace it all with brass fittings instead of steel. That would include a 4" nipple, elbow, 3/4 to 1/4 bushing, pigtail, and union - to do it one for one.

Looking at supplyhouse.com there are a few brand selections. Can anyone tell me if there is something I should look for or avoid for these brass parts?

In particular, I see a 1/4" straight brass pigtail for $9 : https://www.supplyhouse.com/Wal-rich-1706006-1-4-Straight-Brass-Pigtail

Or "straight brass steam gauge siphon loop" for $35.

https://www.supplyhouse.com/Apollo-Valves-2740101-1-4-Steam-Gauge-Siphon-Loop-180

Or, another 1/4" pigtail for $11 https://www.supplyhouse.com/OMI-Parts-PIGTBRS-1-4-Straight-Brass-Pigtail

Which should I go with?

Most of the other parts (nipples, bushings, etc) seem to be predominantly from Bluefin brand.

Another opinions welcome too, regarding others ways to redo it. i.e. eliminate the elbow and use a 90deg pigtail? Still though, whats the difference between the Apollo, Wal-rich, and OMI pigtails, and do I need to care?

Thanks,

Jeff

Comments

-

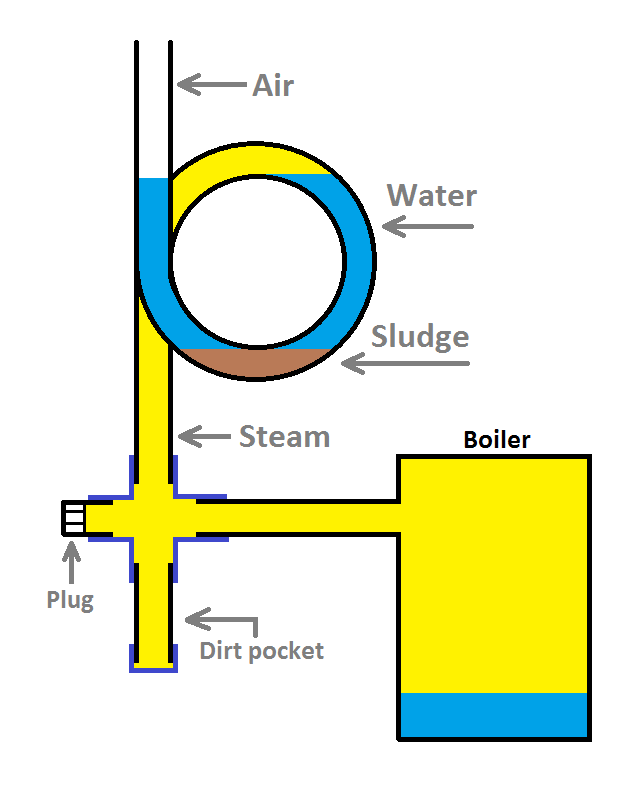

You can make a trap out of brass tees and nipples and plugs and you can just remove the plugs and flush it without having to take it apart.

0 -

The short cycling is likely the boiler being way oversized or the venting being poor, not the pigtail being nearly clogged.

the pigtail being clear is critical to safety but it probably isn't the cause of your short cycling.

i'm more concerned about why it is full of rust again so soon.

the different pigtails are likely similar parts with very different prices.

0 -

I was led to believe (from this forum and we got steam book) that the pigtail and connecting parts being made of steel was likely to cause problems with it clogging to due to rust. Unless that looks like more rust than one would expect from just that?

There was one point last where I noticed white smoke from the chimney and had the boiler checked for leaks/cracks by way of filling it. It turned out to be fine, and was just due to being an exceptionally cold day. I can imagine now that could have deposited some crud in the nipple to the pigtail.

It still sounds like its a good idea to replace the steel parts with brass though, and I'm curious if there is anything to watch out for regarding the brass parts selection.

0 -

some stuff has much poorer tolerances in the threads than others although what is made now might almost all be poor.

steel does rust and clog itself over time but all that crud doesn't look like it formed from that 3/4" nipple and ell in one season, that came from inside the boiler and/or the system. some flushing of the boiler and returns might be called for.

0 -

Brass can still plug up, it just takes longer. Is your water clean ?

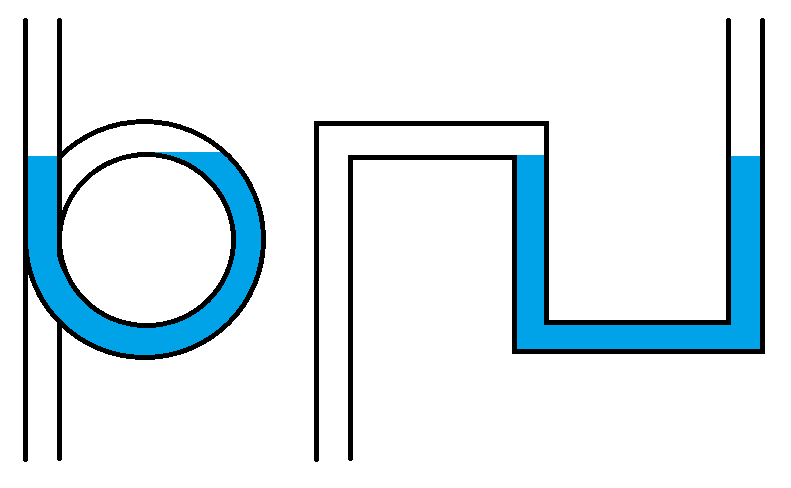

I would replace that elbow with a cross and make a dirt pocket and have a plug to clean out the horizontal pipe to the boiler. Might as well make needed maintenance easier. You could scrap the pigtail and make the water trap out of larger piping, if the needed elbows are tees or crosses with plugs easier to clean out.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Ok. The dirt trap idea is interesting - I may do that in addition to replacing it all with brass. Any reason not to replace the nipple and everything else with brass?

The boiler was drained/flushed at the start of season last year, and again (not as thoroughly) mid season when I went paranoid and thought I had another problem. The first time the tech said he was "skimming" it, although as I now think I understand, skimming really refers to skimming contaminants from the top as its boiling, and not simply draining from the bottom of the boiler…

In neither case was the wet return flushed - I have been wondering is that specifically is something I should do (either myself or request technician do it).

0 -

Yes, all brass, the only down side I know of is it will cost more.

When Skimming it should not be boiling.

The cleaner the water the better off you are. Not all wet returns are set up for flushing out, but they should be.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

most of the muck forms in the wet returns. make sure it isn't losing much water. probably around a gallon a month is normal through evaporation and venting. more than that indicates a leak somewhere. are the wet returns above the floor? they frequently rust out and leak. if they are below the floor it can go unnoticed.

0 -

Here is an example of a water trap built up with nipples and lots of plugs for cleaning. In this case the long horizontal pipe fills with water providing the water trap protection. For some reason your boiler seems to like to fill up that pipe in a short about of time. Brass may slow it down but the buildup in your picture seems excessive for that amount of time. Maybe (historically) they only serviced the pigtail and not the larger pipe going into the boiler. If it keeps loading up the pipes maybe a different tapping on the boiler would work out better.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Thanks folks.

Yes the wet return is accessible. Anything I should do before draining it? The system hasn't run since April probably - should I make it run for a cycle before draining?

0 -

you should flush it with a hose.

do you have wet returns or just that piece of return below the water line at the boiler?

0 -

If those are the only two spigots in the return system there is no good way to flush that short wet return on the left hand side other than firing the boiler and let the condensate drain out of the Left valve pictured. Better than nothing. Probably better done during the heating session.

You could connect a hose to the Left valve pictured and drain out the right valve but the excess water will mostly just go into the boiler.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Yes, those are the only two spigots. And yes, just that one return below the water line.

There is a main vent at the end of the main before it drops down to the return. I suppose I could remove the vent and flow water in via a hose there if that would be worth it.

The other thing I could think of is, once draining it, I could flow in just enough water from the feed to fill the wet return, then drain it again. Could maybe do a few iterations of that. You can see the copper line feed on the right, then it runs under the drain on the right at bottom of the boiler to connect to the riser of the return line.

0 -

Yes you can, I did something similar. When I replaced my main vent I built out the 3/4" pipe and added valves to isolate the main vent during a flush and also added a hose bibb (actually just a thread adapter), so I can flush out the 60 ish feet of wet return just by connecting a garden hose and opening one valve and closing the other.

I have not yet modified the Hartford loop end so the sludge from flushing can't get pushed into the boiler. So far I have no drains like you do. Adding the wet return drain at the boiler end will either be a Spring project or a replace the almost 100 year old wet return project.

The wet return in your system since it is very short and only 10 years old may not be too bad, but preventative maintenance is good too. Kind of like keeping that Pressuretrol pipe clear.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

The near boiler piping is presumably about 10 years old when previous owners had the oil system replaced with gas. The rest of the piping (mains, runs to radiators) I assume could be about 100 years old.

0 -

Pipes that carry predominantly steam, and are not flooded 100% of the time don't rust much. I think you will find most of the rust in a system is the boiler and the wet returns.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

unless the boiler is throwing a lot of water in the mains or a previous boiler was. that could have got in the boiler when it was flooded to test for leaks if they filled the mains too. could be the ci in the boiler if it is losing a lot of water as well. i don't see that essentially return header making much rust.

0 -

Thanks for the input.

I don't believe I have any issues losing water. I did have an issue with main vent failing (wasn't shutting) at one point, but fixed that pretty quickly.

I'm not sure exactly how I would evaluate if the boiler was throwing lots of water in to the main. I get some creaking from pipes expanding I believe, but little to no water hammer if I recall correctly (will find out again within a month probably…)

The headers directly connected to the boiler are not insulated until it gets to the basement ceiling and begins the horizontal run. I realize that is not ideal, but haven't been convinced there would be any real return on investment to improve that.

The other less than ideal thing is that the main run through about half the basement is uninsulated, (comprising of maybe 1/3 of the main) - presumably as a way of providing heat to the finished half of the basement.

0 -

Your water looks clean and I don't see any contamination at the top at the water line. During steaming if the water line in the sight glass changes levels violently or even disappears the boiler could be throwing water up in to the mains. Otherwise it is all about the header and associated piping acting as a water / steam separator.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

This is what I ended up doing:

Left the original nipple in the boil, then replaced everything else with brass and made a dirt pocket as mentioned above.

Haven't turned the system on yet. Waiting for a cooler morning perhaps.

I also got some 8-way boiler treatment to try out. Any advice on using that? (how much? Should I drain the boiler once first then add 8-way?)

0 -

Looks good, now you can inspect the horizontal part with a flashlight. The horizontal part could have been brass too.

I'd fix this too when you get a chance.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Yeah… the new brass pigtail is a bit longer so the existing flex conduit isn't quite long enough. If I don't encounter any problems when turning it on, then I suppose I'll look in to replacing it with a slightly longer run of conduit.

I did get a brass nipple to replace the part going in to the boiler. I just ended up being wary of messing with that in case the existing piece is rusted in there really well and prone to breaking off.

0 -

I understand. And if it proves it may be beneficial it always can be changed at a later date like after a heating season and not going into one.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements