BACKFLOW PREVENTER ON HYDRONIC BOILER, NOT SURE IF THIS IS FAILING OR NOT

Hey Everyone,

Was working on getting my boilers cleaned up and ready for the coming cold months. Last year I replaced the expansion tank on my hydronic boiler as it was leaking and not holding pressure. Then Id say the last month or so of last heating season, I started noticing water had come out of the pressure relief valve. So I checked the expansion tank and it was reading 12 PSI, so no issue there. Ran the boiler for 2 heating cycles and the boiler pressure never went over 14 or 15 PSI, so that checked out ok, and never saw the pressure relief valve open up. At that point, winter was over and I just decided ill figure out in the fall, and here we are. The last few days I have fired it up and ran a couple heating cycles, pressures in the expansion tank and boiler were exactly as state above. However I noticed a tiny leak coming from the vent tube off the pressure relief valve. So that indicated to me that the water I was seeing on the floor (albeit it appeared to be a lot), might have just been a week long slow drip in between me coming down and checking on things. So I took off the relief vale and it was pretty gunked up, so I just ordered a new one. Then today, I was working on swapping the new one on and noticed another leak, this time coming from the Backflow preventer. The vent tubes for the backflow and pressure relief valves are basically right next to each other so you would have no idea which one was leaking if you weren't looking at it. So I started playing around to see if this was just runoff water in the system bleeding out, or if the preventer was bad. I took a short video and included the YouTube link below for easy reference and explanation.

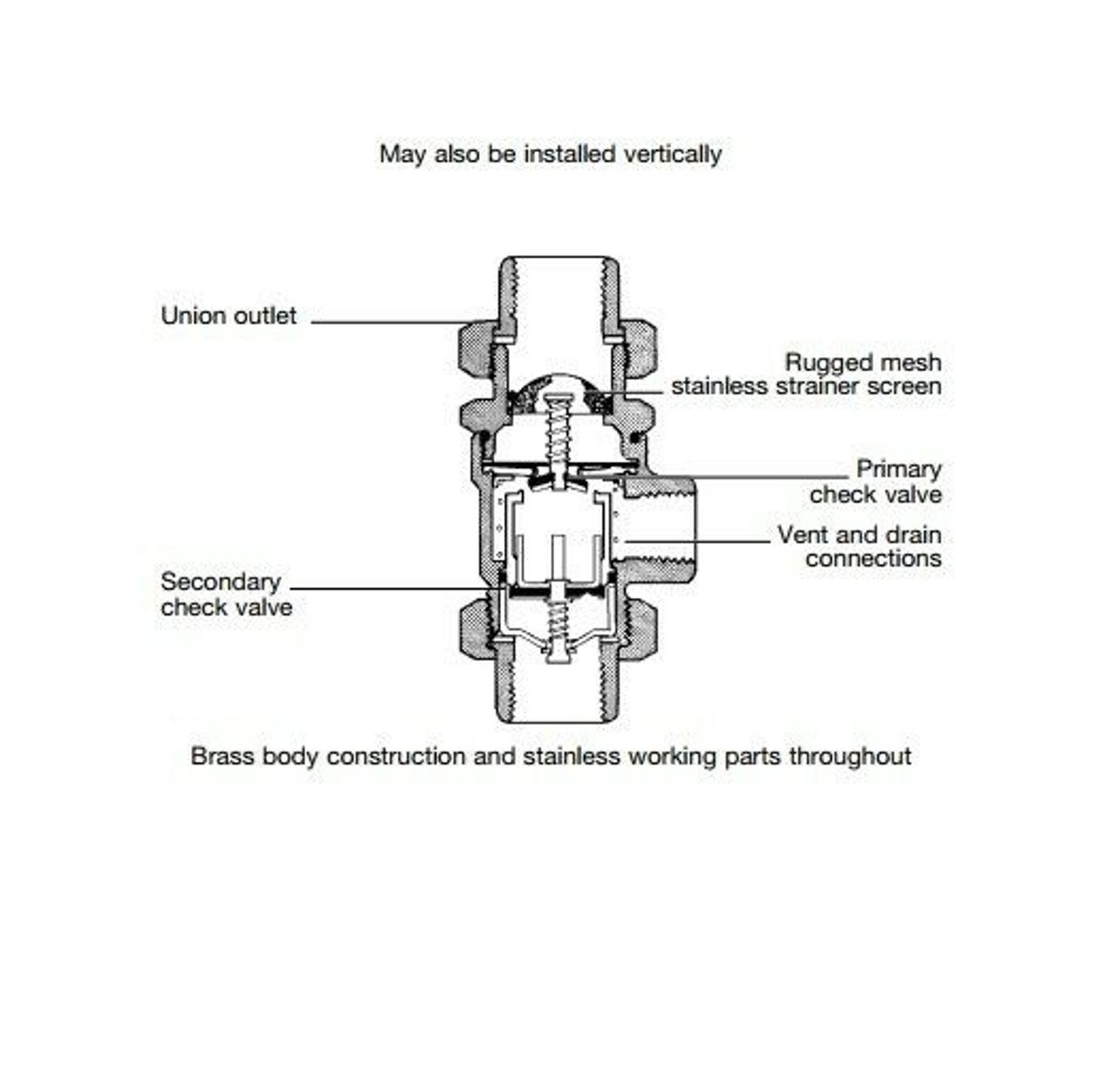

Mainly, I'm just trying to figure if the backflow preventer is bad. However, I'm also just curious on how these dual check valve preventers work. In the video, as far as I can surmise, the leak is coming from the inlet side, which means the main shutoff valve isn't fully sealing when closed. But what I'm really curious about is why the backflow preventer would allow a small amount of water at basically no PSI to pass through the inlet check valve and out the vent, then STOP leaking immediately after I open the main inlet valve and pressurize the line. I have included a diagram for the exact backflow valve that I have, been staring at it for a while and cant totally figure it out. Do the primary and secondary check valves move in tandem or are they independent?

Youtube link

Comments

-

3 things happen inside that type of check , 3 different springs, snd tensions. incoming water pressure first slides a spool closing off the vent port, this is the weakest spring, next the inlet check is opened, next spring tension, then the second check

If water drips out the port while pressure is on, probably debris in the spool seat

The black shows where seals are located in this cutaway, notice the 3 springs

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

AH thank you so much! So in my situation, it leaks out of the vent when i have NO water pressure. So if I turn off the main valve leading into the boiler BEFORE the check valve, and bleed all the pressure out of the line, before and after the check valve, I end up with a small leak coming out of the vent line. This leak is coming from the main valve. There's about 4 feet of line between the inlet side of the check valve and the main shutoff, so initially I just figured it was residual water in that line that would drain out and the leak would stop after a minute or two, but it kept going and filled a one gallon bucket. The boiler itself is fully drained, and I have the shutoffs closed on both the inlet and return sides of the zone valves so I don't have any water coming back down from the system. So the only place it could be coming from is the main shutoff, so it must be 99% closed, but not 100%. No big deal there, easy fix. But I'm just puzzled as to why that tiny bit of water would leak out of the vent.

Based on your description and the diagram, if the first thing that happens is incoming water pressure slides the spool to close off the vent port, then that should mean the vent port in its static state is open when there's no pressure, correct? If so, then I guess a tiny leak that has basically zero pressure wouldn't be enough to slide the spool and close the vent port, therefore would just end up leaking out of the vent. But as soon as I add pressure, the spool closes and no more leak.

If that's correct, then I guess the check valve is operating fine, just need to fix or replace the main valve so that it fully closes and eliminate the small leak leading into the check valve and ultimately out of the vent port.

Thoughts on this???

0 -

somewhat unrelated but when you check the expansion tank pressure are you taking it off the system and then checking the air side or leaving it hooked to the boiler system while you check the air side?

0 -

leaving it hooked to the system when testing

0 -

If the main shutoff up stream is not sealing 100% and there is not enough flow or pressure to slide the spool over the vent, AND something is stuck in the first check, then you would see a drip coming out the vent. It's actually doing it's job protecting the system against a failed check.

Rust, sand, teflon tape, etc in a check valve can cause a check to not seal.

Generally there is a small strainer in those small dual checks, but it does not catch all the small particles.

They are fairly simple to disassemble and check/ clean, to large nuts remove all the guts.

However if it is old, 10 years or more the o-rings and seals could be deteriorated or nicked. Time to replace it, it is an inexpensive safety device that protects you homes water supply.

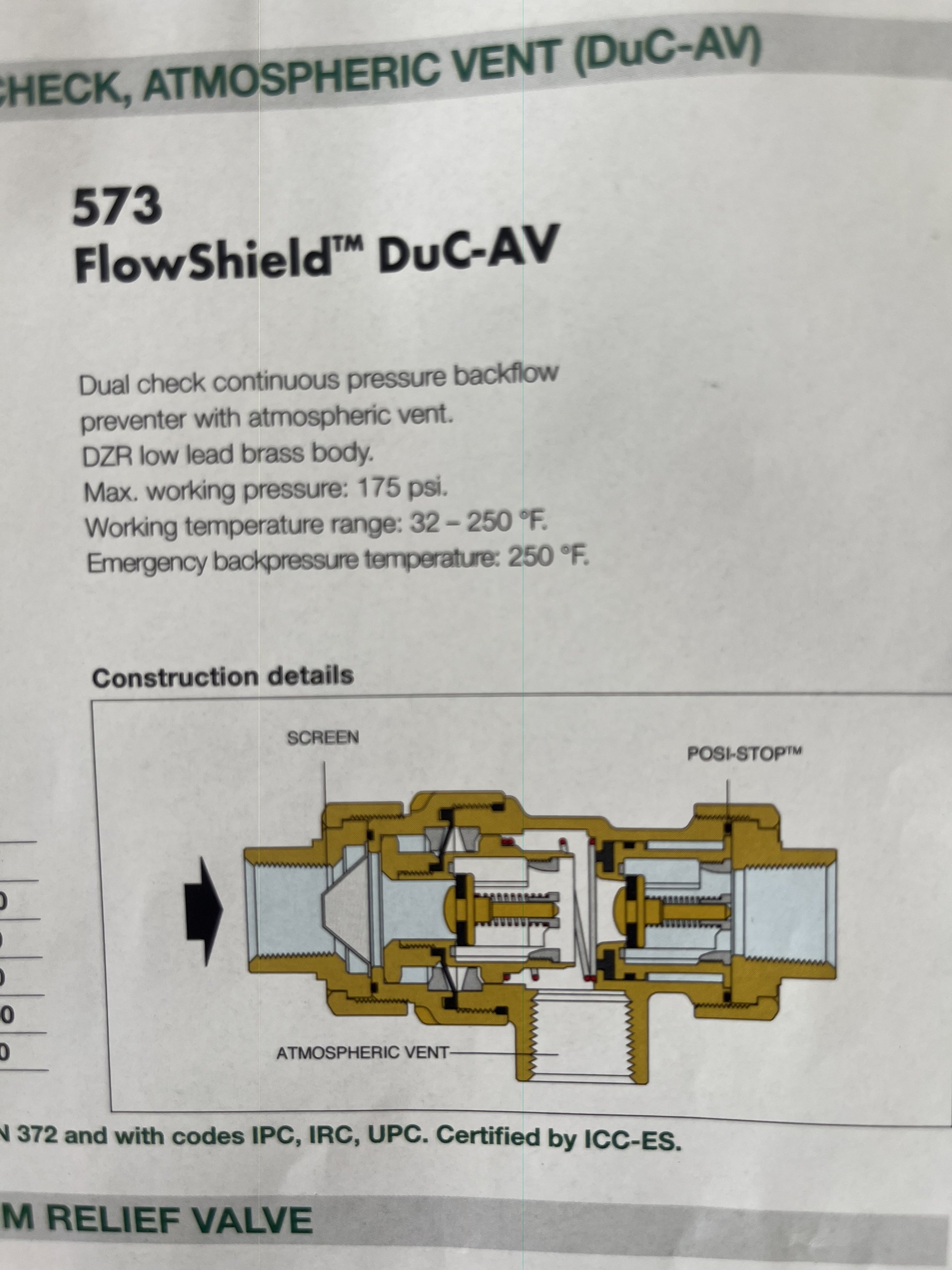

Do you have a backflow on your water main into the home? That protects the city water and users from getting your water back :). The BFD on the boiler protects the water inside your home. Pretty much all plbg codes require both protection, appliances and entire building main.

Many jurisdictions are now requiring an RPZ type dual check on boiler feeds, a higher hazard listed valve, since they don't know if any chemicals may be in the boiler water. Those will require a yearly inspection by a licensed backflow technicians however.

Another option is to disconnect from the water line and add a fill tank, like an Axiom.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Got it thank you for confirming! Its most likely over 10 years old so I will just go ahead and replace it along with replacing the main valve. No backflow on the water main, but it is on my list of things to get done before the end of the year. Thank you again for the help!

0 -

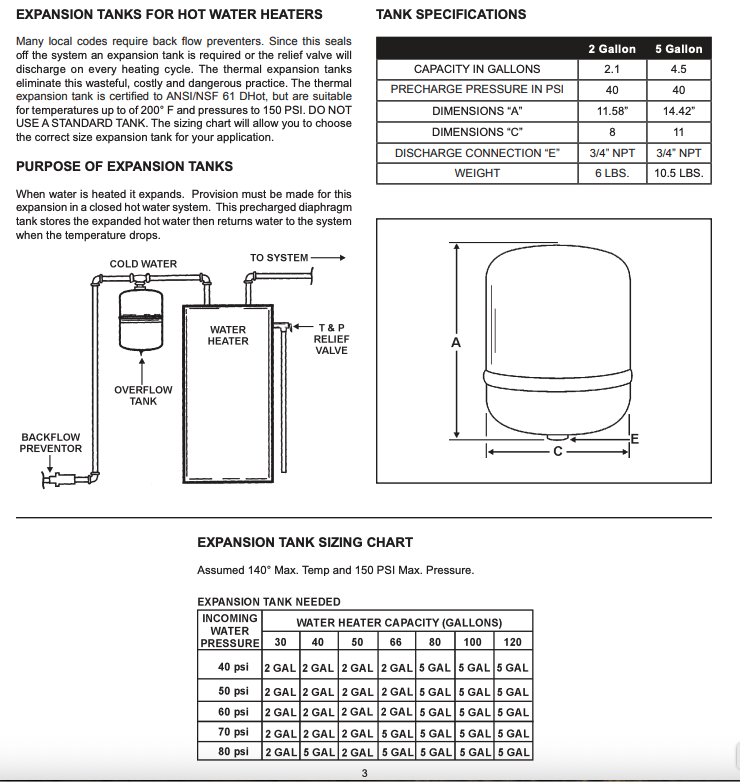

If/ when you put a BFD on the main, you need a thermal expansion tank at the water heater.

Example from State Water Heater

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

got it, will do! Thanks again!

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements