Thermal break for new radiant heat slab in older attached garage?

Hi all, long time lurker first time poster here.

In the process of redoing the floor in my attached garage. Located in northern MN and the long exterior wall of the garage faces south (overhead door faces west)

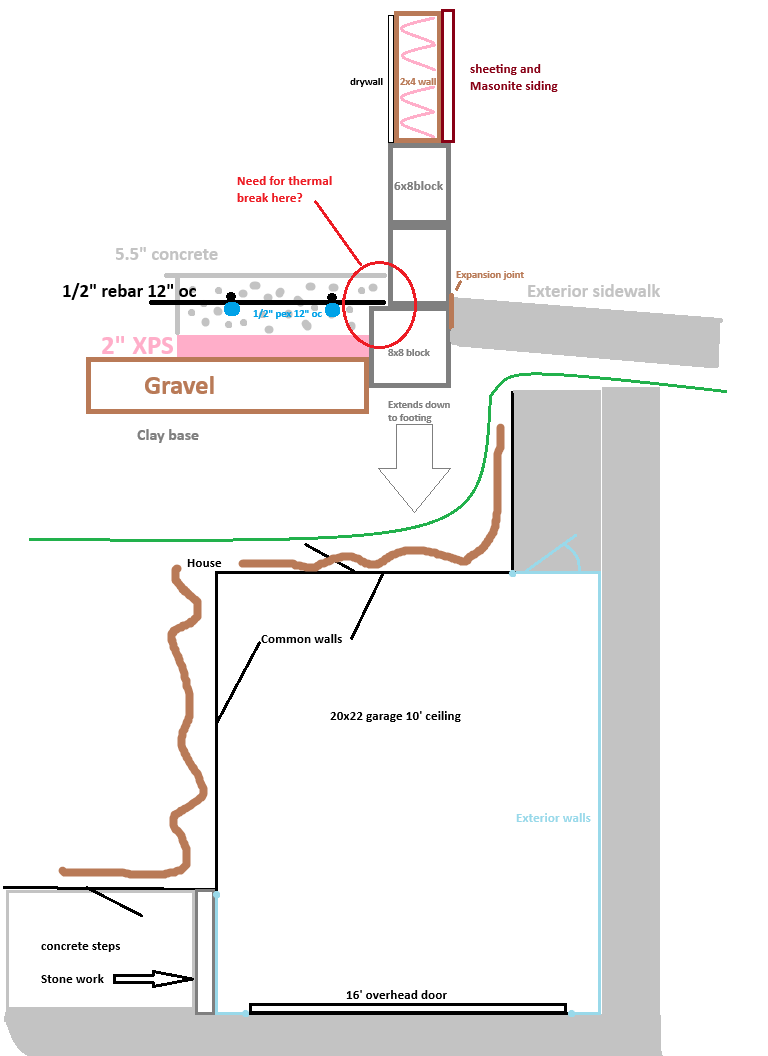

The picture shows what my plan is so far, but I am trying to figure out if I "need" a thermal break here? Ideally yes, the heated slab is uncoupled from the uninsulated block. But trying to figure out a good method that will both uncouple them and still allow the footing to support the slab has me stumped.

Planning on running 2 loops of pex, first run along the north wall and under the overhead door, second long the east to the south both filling in back to the NE.

Is leaving that point coupled going to effect the heat through the rest of the floor to the point that it is a MUST DO. ? Am I going to loose a lot of heat at this point? I am okay with some loss as it's only the garage and I plan on keeping it around 50* floor temp so the vehicle melt off, the floor will dry (there will be a drain) and my garage door won't freeze down every morning it's below 0 (which can be a lot for us up here)

I have also considered insulating the exterior of the block wall from the siding down 4', but can't go much more than 1/2" foam before I would be sticking out to far and would need to address the siding (also a consideration, but that's a can of worms I don't feel like opening this fall). I have the sidewalk and pad ripped out and will be repouring those as well.

I want to get things right and get the best most cost effective thing I can do, but am I overthinking the details?

Comments

-

That is a tricky connection to detail. Whatever you use with have an edge exposed. On my last shop I used 1" foam. But when I had a garage epoxy coating applied it started to eat into that foam.

On my current shop addition I use 1/2" treated plywood.

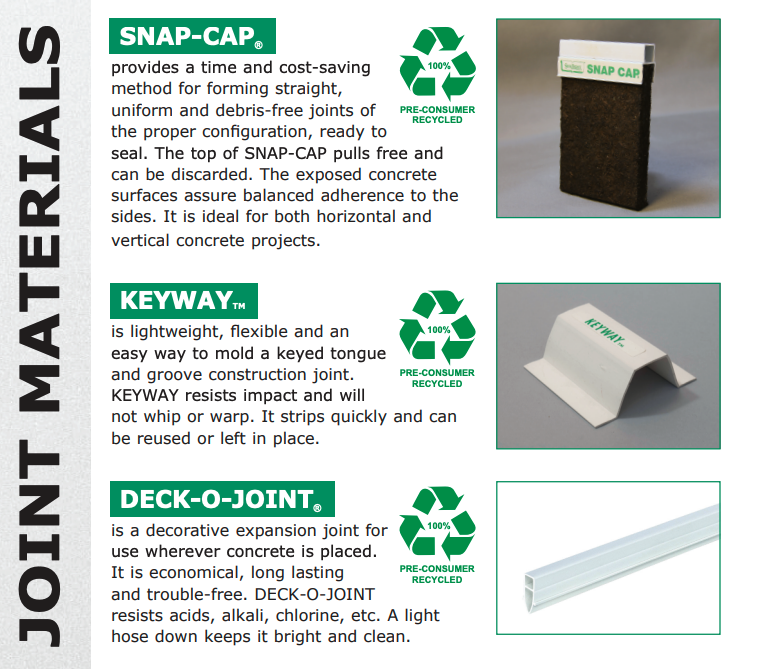

There are some expansion strips that you put an H shaped plastic cover over the edge. Then peel the top ant use poly urethane in the gap. I did that detail where the driveway concrete connects to the garage slab.

Here is the product I used

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Yes you need a thermal break.

BUT

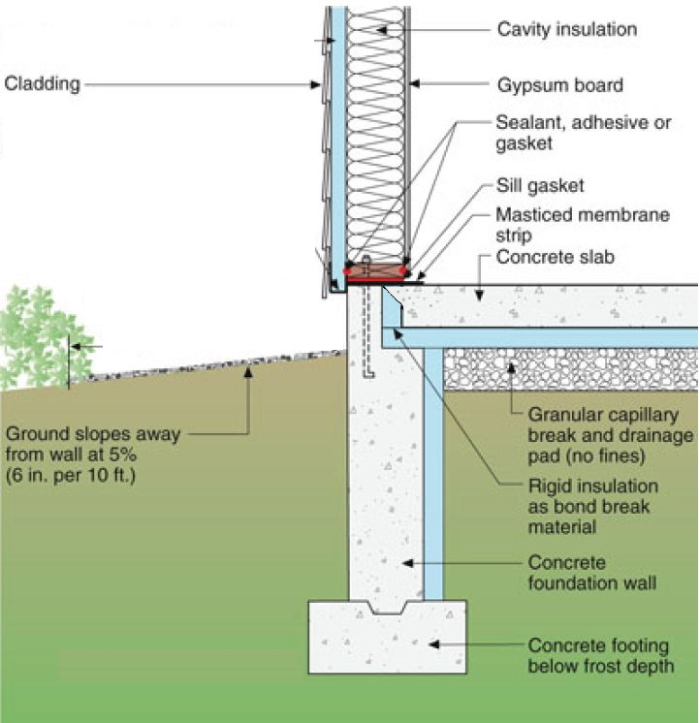

The foundation does not, or should not, support the slab. They need to be structurally decoupled from each other, or you will get serious cracking at the edge of the slab.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

Here is a shop addition I am working on. I've always tied the slab to the foundation wall with rebar, under the garage door. This keeps the frost from heaving the slab under the overhead door.

Around the other edges I used PT plywood for an expansion joint. A PT plywood strip above that is to pour an epoxy coating and lap it up the wall a few inches for a tight easy to clean connection. Also to keep water off the inside sheathing sheetrock or OSB.

I doubt you want an exposed foundation wall of block or concrete around the entire edge of the space?

I have seen tar paper used as a bond breaker when slabs are poured over foundations. I think Schlutter makes a more engineered cleavage membrane, used for tile work also.

Thermal break is important for radiant slab heat loss, and also expansion movement. If a radiant slab is poured with concrete foundation walls, the expansion can lead to what they call external restraint cracking. No room for the slab to expand as it is heated.

I think it is the compacted sub-grade that is supposed to support the slab, not the foundation walls.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

This is an option on how you can handle the slab edge without having exposed insulation. The overall goal is to have the slab FULLY wrapped in rigid on all sides. For the door opening, you can put a piece of pressure tread lumber or composite deck board on edge under your door as thermal break. Concrete is a great conductor of heat, so anywhere your slab touches cold concrete/dirt you will loose a surprising amount of heat.

0 -

2" XPS around the entire perimeter of the slab, and keep the tubing in a minimum of 24" from the edge at the overhead doors (6-12" on the other 3 sides). Believe it or not, heating that "tongue" outside the overhead door is going to make the door freeze down worse than they already are. As a fellow Minnesotan, I made that mistake with my own shop and fight it every winter when it snows below zero. The footing does not need to support the slab at the house side, it should float everywhere besides the wall where the overhead doors are located.

0 -

Another insulation detail, however that beveled concrete edge will absolutely crack where it thins out. I did that detail only once.

Still another option is insulate the outside of the wall and use a flashing detail at the top edge of the foundation foam. Here is a Z flashing I made to cover the top edge of the foam.

Spray foam is also used around and under radiant around here.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements