Small baseboard zones

hi guys, I’m dealing with a navien boiler with 2 smaller baseboard zones. One zone 35’ baseboard and a small k42 kickspace heater off monoflo tees. Another zone 32 feet with a smiths psu10 wall heater off monoflo tees.

The zones are each on their own 007E pump. Probably roughly 100’ of piping in each zone or less. Plus the baseboard. The navien boiler shows 5gpm of flow. The delta T is low. About 10-12 with both zones and with one zone half of that.

are the pumps overkill on the zones? Should the be on zone valves with one 007?

I was helping a friend cleaning the boiler and noticed this.

I’m a plumber with not a ton of heating experience.

Thanks guys

Comments

-

-

Just thought the delta T was low and gpm was high, although right now in MA it’s not that cold outside.

0 -

What is the boiler output? You need to know that to know how much flow you need.

0 -

74k Ibr rating 64k

Seems a little oversized but it does modulate down to 11k btu

0 -

how long did you run the system?

It needs to get to a steady state condition, then observe the temperatures, the delta t.

Steady state is when the s&r temperature has stabilized, not going up or down

Delta t will constantly change as the building load changes.

You design a system around a certain delta, but in reality it may never run at that exact number. Nor does it need to if it heats adequately and doesn’t cause short cycling, etc.

Low mass emitters and light heat load conditions, steady state condition could happen in minutes. A design day may take much longer, of course.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

ran until it was steady, had a 10 degree delta T Probly took 10 minutes and it was a warm day here in MA.

0 -

Ideally the boiler turndown would match the load of the smallest zone. So on a design day it would run continuously. But any day other than design you would expect some cycling.

If there was never a designed ∆T for the zones?? You would not know if 10 is the right number.

20° ∆ is a common design number for fin tube and radiators. Radiant floors 10- 15. Panel radiators can design around a 30- 35∆. Their is no exact delta required , it is the designers choice.

Balance valves are used on some projects if you want to dial in an exact operating condition. Balance valves are the fine tuning device, used to optimize a system. However rarely used on residential jobs :(

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Is 20 chosen as the delta t because it cancels out the 500 in the btu/flow/delta t equation?

btu/hr = 500 * delta t * gpm

if gpm = 20 then

btu/hr = 500 * 20 * gpm

or

btu/hr = 10,000 * gpm

or

gpm = (btu/hr) / 10,000

0 -

-

not sure what delta T it was designed for.

appreciate all the replies from everyone! I learn so much from this forum!0 -

I have never found any info on why 20 is used, @DanHolohan might know.

Most agree it is to make the math simple as you indicated.

Much of the rest of the world heats with panel rads, they tend to use 25- 40 ∆ in their design. Wider ∆ allows small 11 mm tube, for example, to be used for S&R piping

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

I don't know why 20 is used but I suspect not to overstress the boiler

Don't forget if you have a boiler with 100,000 output and it is rated at 100,000 with a 20 degree TD and the water comes back with a 15 degree TD you are technically overfiring

0 -

Do conventional boilers spec delta t? Mod Cons have some specs but I suspect that is to make sure there is adequate flow through the hx. I suppose water tube and to a lesser extent fire tube boilers in general would care about that.

0 -

what would you say an ideal flow would be through the hx? I know each system would be different. But a good starting point?

0 -

~1gpm /btu/hr

which i suppose simplifies to some number of gallons per btu…

0 -

What flow rate or delta did gravity systems operate around?

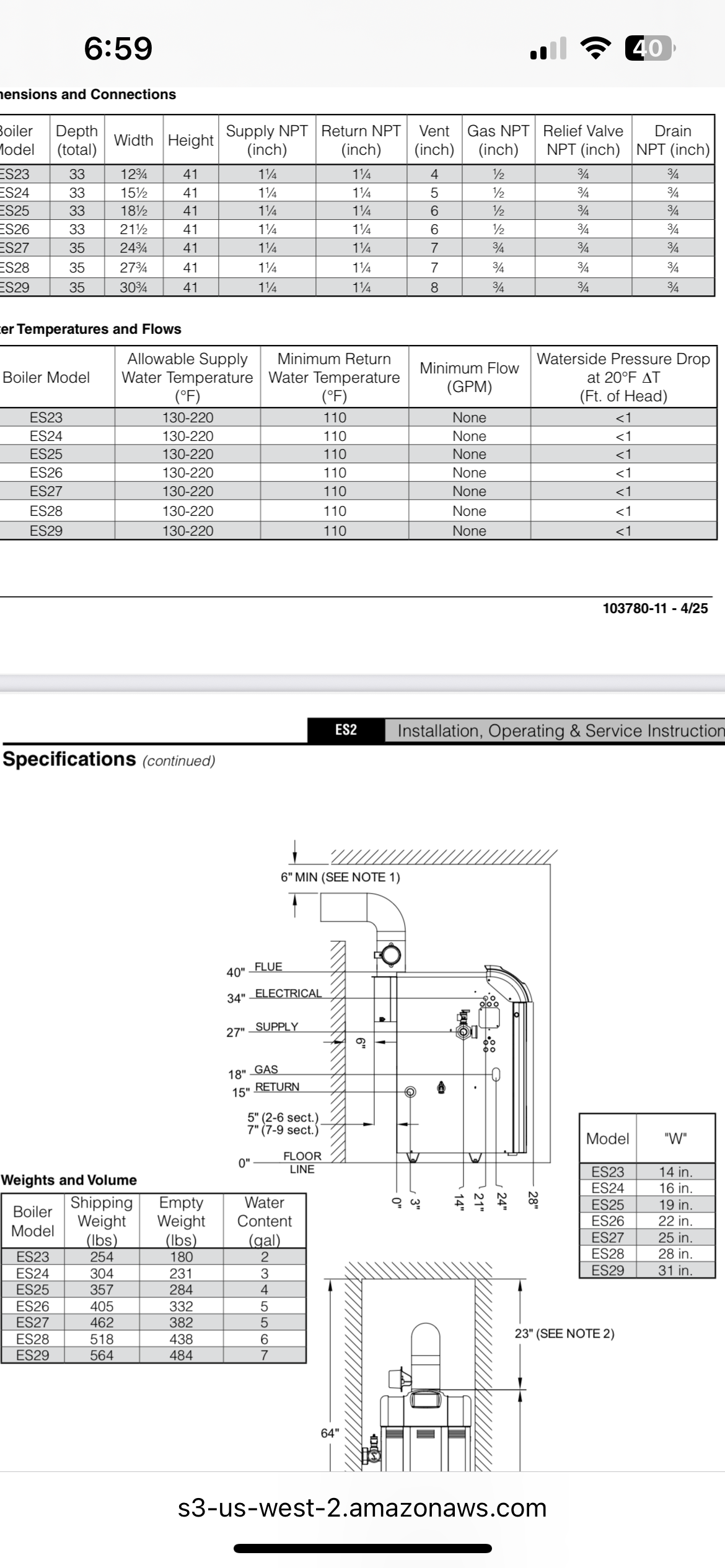

This US Boiler ES2 is a low water content, it indicates minimum flow as none?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements