Frozen EVAP coil

4 ton Trane RTU. I replaced the compressor, TXV, drier few weeks ago. Performed pressure test and pulled good vacuum. Charged per the unit tag. Unit ran fine.

Yesterday service call- evap coil frozen. Thawed it overnight. It's cooling. R-410a.

110/262. My sub cooling is 12.5F. I have 20F across the EVAP coil. 54F discharge air into the space. Clean filter and good airflow. Only thing that concerns me is the low side pressure. My EVAP coil temp is 36F. I'm afraid it will freeze up again. But I'm reluctant to add gas as I charged the exact amount. I've checked the setpoints and schedule on the thermostat and it looks good.

Any idea?

Garrett, Georgia.

Comments

-

TESP

Static Pressure?

0 -

I don't know what the static pressure is. I notice the EVAP coil is dirty in spots. Can that coil spray be used on micro channel coils?

0 -

You need Static pressure readings.

As far as cleaners check with the manufacture. Most do not allow cleaning chemicals.

Why is the coil dirty?

0 -

What size TXV is in the unit and what was the outdoor temp the night it froze the evap?

Low outdoor temps can cause underfeeding.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

I'm not sure what the night temp was because they said it had been warm in the office for awhile. But night temps have been in the 60s this week.

I got sent on another call so fingers crossed it will be ok. Pressures were 115/325 when I was leaving and it's maintaining setpoint. Time will tell if it freezes again. If I get time I'll try to get the static pressure readings. It's an ECM motor and it's wired to the High terminal.

0 -

Not sure of the TXV size but I installed the same valve as the original. It's the valve Trane supply gave me

0 -

One other thing on this unit- I replaced the condenser fan motor recently also.

0 -

When I replaced the TXV I mounted the bulb in the same position as the old bulb. It was on a vertical part of the suction. Does that matter? Or should it be on the horizontal in the 10 o'clock position?

0 -

pressures without temperatures are worthless. We need super heat and sub cooling numbers

0 -

Super heat 15F

sub cool 12.5F

0 -

If accurate its airflow related.

0 -

pecmsg- I think you may be correct. I now recall issues in the winter on this unit. Furnace was locking out on high temp which I suspected was airflow related.

0 -

Thanks guys for the input. I'll check it again on my next visit.

0 -

Possible causes IMHO

- Low air flow, maybe dirty coil

- Some people bury the thermostat set point. Anything below 70 could cause a problem. Normal cooling temps are 74-76. If they set stat low it may be ok during the day but at night if temps drop condensing temp drops and evap temps follow.

- Blocked returns or supplies

- You can put the evap bulb on the vertical if I recall correctly the bulb must be pointed down with capillary on top but horizontal is better.

0 -

Hi Ed,

the setpoint is set at 73F during the day and 76F at night. It's possible of course that they left it set too low one night. The EVAP coil cleaning is my next step. I have checked for any closed dampers or insulation blocking airflow but didn't find any.

0 -

-

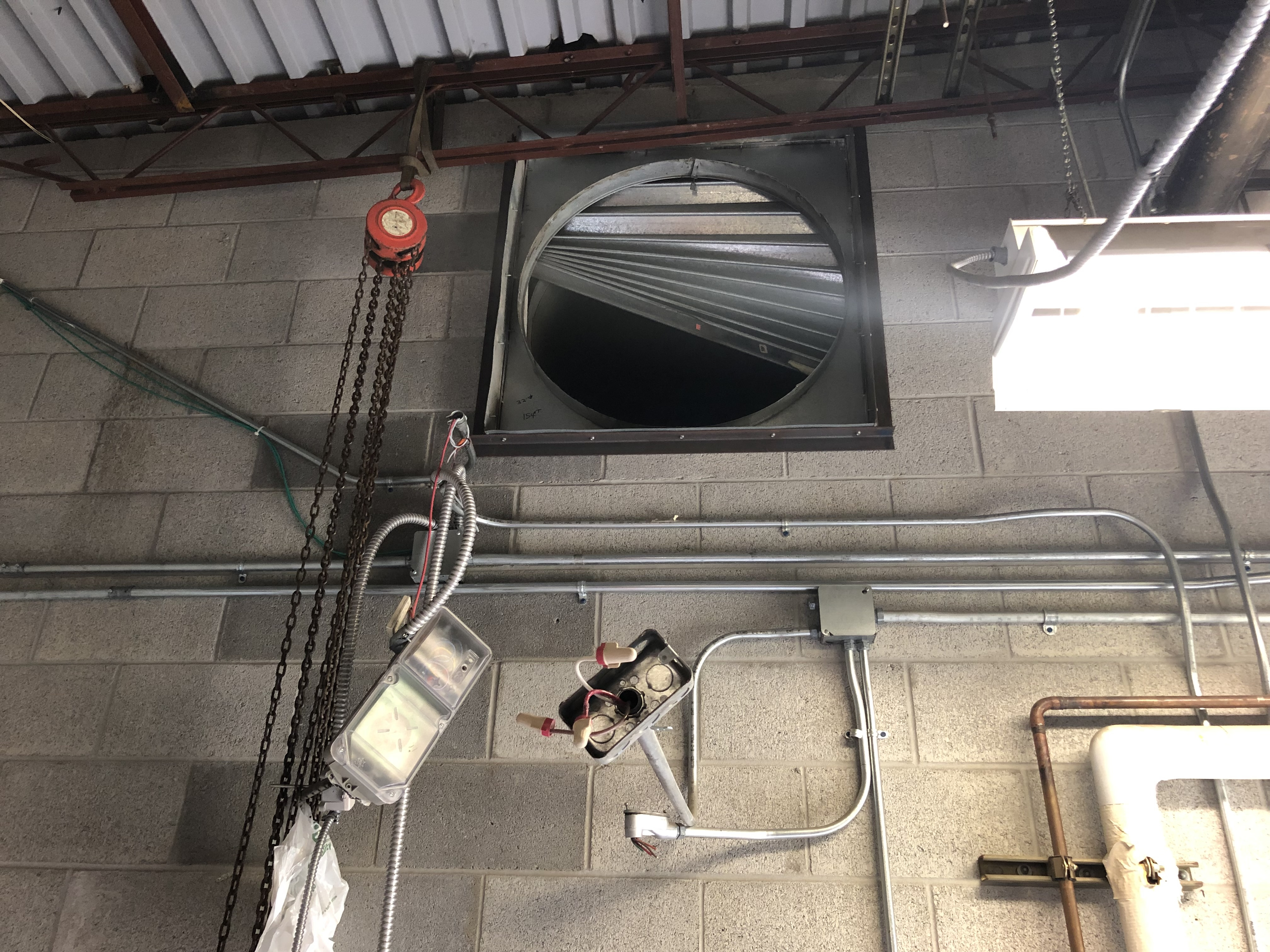

If you’ve verified airflow at all the registers it probably isn’t an issue, but fire dampers are worth checking if there are any. We found this one during a DOAS unit change.

0 -

Is the return ducted to the space being cooled, or is it an open plenum?

0 -

Why does the coil require cleaning is the big question. That's not normal. That indicates poor air filtration, dirty ductwork, possibly high static pressure. Why has so many parts been replaced on this system? It sounds like the parts cannot has been fired at it but it still doesn't work.

In order to effectively help you we need static pressure measurements, saturation temperature measurements, indoor wet bulb, outdoor dry bulb temperature measurements. You know, the information a professional relies upon to diagnose a system properly. There's no reason so many parts should have been replaced and you still have a problem.

2

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements