Delay of boiler firing?

There an easy way to delay the start fire cycle of a mod/con combi when thermostat calls for heat?

I need the pumps to come on for maybe 15-30? seconds to circulate the loop, as there's a heat exchanger and likely already hot water from an outdoor boiler... so the gas "backup" boiler wouldn't need to fire.

Comments

-

-

30 secs is a lot.

3-5 sounds more reasonable0 -

-

-

Yes but hooked to what?

0 -

Thermostat goes to a control, that sends signal to secondary looppump and the boiler. Boiler has primary loop pump integrated, like most little combi boilers I think.

0 -

Not doing this would constantly short cycle the boiler I'd imagine..

Boiler needs to be kept in the loop as a backup. It doesn't see hot water after 15 seconds, it fires.

0 -

-

Why does the gas boiler need to have a call for heat at all if the outdoor wood boiler is already firing? Are you firing the wood boiler without dissipating the heat somewhere? Your query seems to assume that there is a thermostat that is calling for heat on a zone (or the entire system) indicating that the call for heat is somehow off at times. Now that begs the question that you have a hand fired boiler that is generating heat with a circulator pump to a HX that is somehow off. That wood boiler will then be generating heat with no way to get rid of that heat. That sounds wasteful to fuel a hand fired boiler and not use that heat that is generated by the fuel.

I would propose that you learn to feed the wood boiler in such a way where any heat generated will be put into the home or the zone as it is generated. That way you will have a hotter home and adapt the amount of fuel you feed to the wood boiler based on how much or how little the home or zone overheats. That is how the folks used hand fired boilers in their basements before oil heat and gas heat became the norm. After 1920 you might live in a home where the winter indoor temperature was 85° inside with the windows open. (read about the Spanish Flu and how it affected heating system design) Even before that in the 1800s coal fired boilers in homes were hand fired and the only regulator was the dampers that controlled how much air flowed thru the coal fire, and how much coal you shoveled into the fire box.

However if there is a system that is hand fired, and you are using that heat elsewhere, and you want to draw some extra heat to heat a zone based on a thermostatic input from that room, there can be a circuit that can be designed to accommodate the room temperature thermostat calling for a circulator to operate to draw heat from the Wood Stove and preventing the gas from firing on the boiler if there is already enough heat available from the boiler even though it may take some time to reach the rooms.

If there is a need to have one thermostat in that room, then I can design a logical set of relays and temperature sensors to accomplish your needs. Please explain what components are in the system and how they are interconnected with the piping from the wood boiler, to the pumps, and the heat exchanger, and any other system accessories. For example: is the wood boiler’s heat being used any place other than the home or zone you want to heat in the original query, or is the wood boiler only to heat that zone or home?

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

The Outdoor boiler is a used oil boiler, not wood, but same setup as far as the piping.

It's outside in a connex. 1 thermostat controls everything. It's a wifi unit with multiple area sensors.

0 -

-

@nate379 this is what I do here! Just ask anybody!

The outside boiler being a waste oil boiler is a whole different thing. That outside boiler needs a control to turn it on, and that can be done with controls that start with the room thermostat. I assumed that the outside boiler would be what one of my former customers was using. I have also worked on waste oil boilers that were installed inside the commercial building. I can understand why you may not want something like that installed inside your home. And your waste oil storage is also something I would not want inside my home. This makes a lot more sense now.

With this info and the fact that waste oil burning can sometimes be problematic in extreme cold weather, I would love to help you design a control system that will do just what you need. Can I trouble you for the model number of the waste oil boiler/system?

With that info, I can do some logic that might work like this

- Call for heat from the room thermostat

- Primary heat source = waste oil boiler

- Gas boiler will stay off for at least the time it takes to fire up the oil boiler and get heat to the radiators (and/or the domestic hot water tank if you have one.)

- After a sufficient amount of time has passed, if the oil boiler does not heat the home, the gas boiler will be added to the heating system to generate whatever heat can not be completed by the oil boiler.

- When operating on gas heat only, the delays can be manually disabled with a Gas/Oil switch.

- Maybe even have a way to stage both heaters when it becomes apparent that the oil boiler will not operate as a result of a flame failure in order to make the gas boiler the primary source until the oil boiler failure is resolved.

With that model number from the oil boiler and the model number info about the ModCon Gas boiler the control system will be easy to design.

Also what is the thermostat brand and model number?

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

…unless you meant "second hand #2 heating oil boiler", or "previously owned", or a "regular oil boiler that was used in a different location".

I may have jumped to a conclusion about your term: USED OIL boiler and you really ment …used OIL BOILER. Either way, that control system is still easy to design. What is the oil boiler make and model number?

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I usually put a strap-on aquastat on the outdoor boiler supply line and use it to interrupt the call to the gas boiler. As long as it senses that the outdoor boiler is hot, the gas won't fire. You may need a switching relay as well if you don't already have one- the gas boiler would not run the pump(s) without a thermostat call.

3 -

The oil boiler isn't setup yet, I'm planning and parts gathering still.

I planned to leave the boiler constantly on.. aka a warm boiler. It's an old cast iron design and oil is essentially free, so no reason for a cold start setup.

The thermostat at the shop would just energize the pumps (will have a primary/secondary loop) at the oil boiler which will feed heated water to the shop, and tie into the existing heat system through a heat exchanger.

Another option would be just to run the oil boiler pumps 24x7, but that's uneeded wear and cost...something around $15 a month in power.

0 -

Honeywell T9

Vesta VRC gas boiler. I think 80 or 100k BTU. I'm out at work so can't check until the end of the month.

Burnham oil boiler

0 -

-

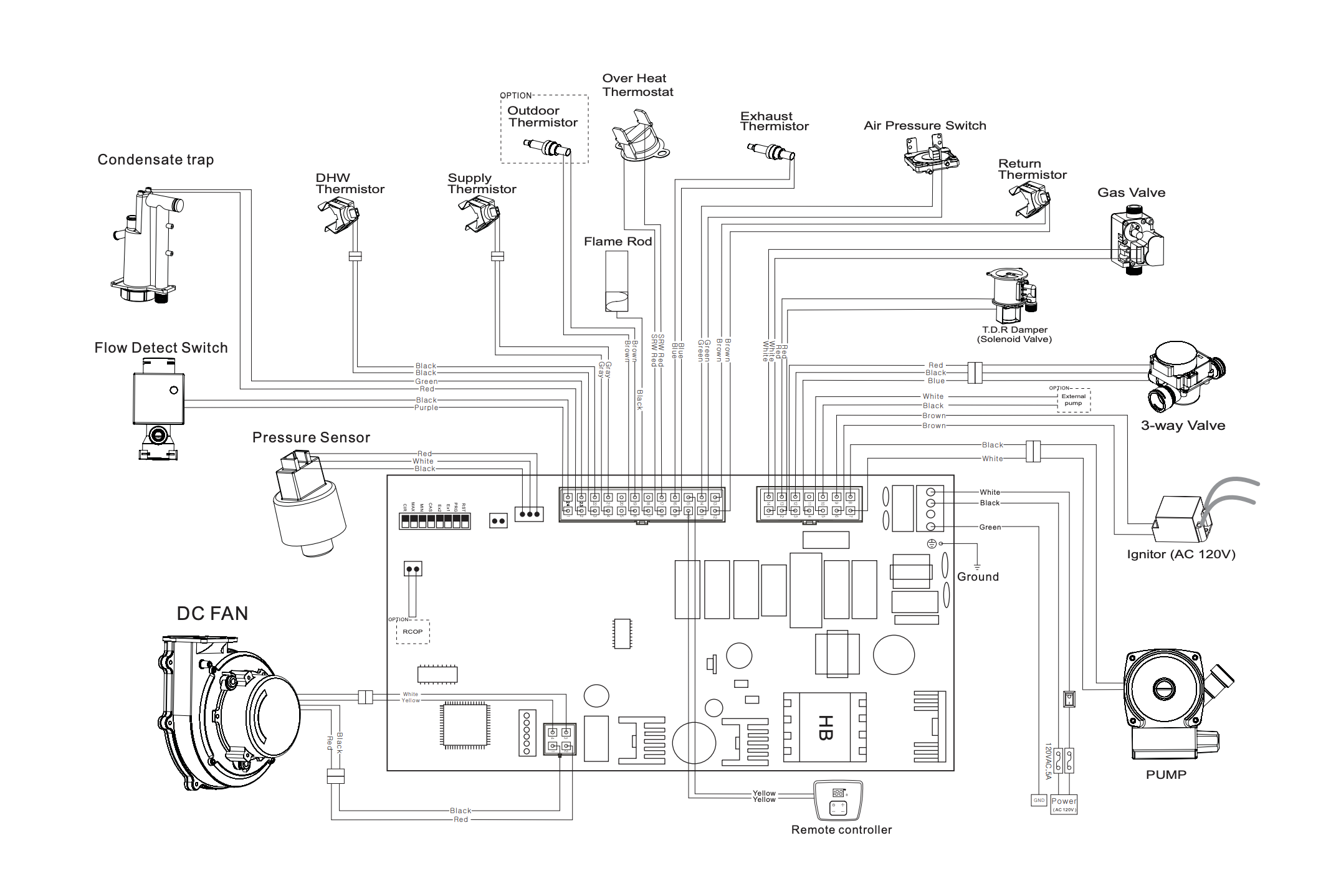

Without the actual model numbers of your actual equipment, i have used some generic wiring devices to illustrate what I believe you have existing, although I do not know what is making the oil boiler call for heat to operate the burner and circulator pump.

A WiFi thermostat is operating a typical ModCon-Combi boiler's Central Heat (CH) circulator pump and the gas burner. It was installed as the manufacturer recommended. After that system was installed and operating properly, there was an auxiliary outdoor oil fired boiler added with a heat exchanger so that the antifreeze water and the indoor CH system water were separate systems.

I do not know what might make the call for heat to the oil fired boiler might be since the room thermostat is operating the CH by way of the Combi boiler. That is why there is a question mark (?) on the diagram where the oil burner control thermostat is supposed to be connected.

If you can provide the model number of your Oil boiler, your Combi boiler, and your thermostat, I can draw you a diagram of the best way to operate your system.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Honeywell T9 thermostat

Vesta VRC80 or VRC100 combi gas boiler

Becket AFG oil burner.

Oil boiler is not commanded on by anything affecting the gas boiler. Just runs on an aquastat that keeps the water between 160 and 180. IE not a cold start.

Oil boiler pumps commanded by the thermostat. Either I'll do a 24v signal to a pump control in the connex or 120v off the pump control in the shop.

1 -

I looked at the VESTA Combi Boiler instructions. It appears that there is no room thermostat with the standard wiring of this boiler. Since you indicated that you have a Honeywell WiFi thermostat, I was interested to know where it is connected to, on your boiler.

Also, does the oil boiler have a control that a thermostat might be connected to that also operates the circulator pump? Perhaps a Honeywell L8148 aquastat. If not then how does the burner know when to stop operating at 160°, and how does the circulator know when to move the water from the boiler to the heat exchanger? Is the oil boiler circulator always operating constantly?

A cold start oil boiler will use less fuel, or perhaps one that is set at 80° and a call for heat will ramp it up to 160° will keep the boiler warm on the off cycle but not use as much fuel.

I believe that the Beckett AFG burner is equipped with a primary control that has a manual reset button for flame failure. That control may have a thermostat terminals labeled T T. Those are not the thermostat terminals I would like to use. I would like to use the thermostat connection that will operate both the burner and the circulator pump.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

There's a relay box the thermostat controls, ill have to look next week when I'm home to see how it ties to the boiler.

The oil boiler has an aquastat/boiler control. Fuel usage is a non issue, as I have more used oil than I can use. Plus it going cold could be well below room temp cold. It'll have antifreeze in it, but no sense not just letting it stay at ~170* all winter. The fuel use vs cold start is minimal. Plus cold start isn't ideal for a cast iron boiler anyhow.

0 -

-

@nate379… I understand completely about using the boiler to maintain temperature. Cold starting a boiler is not that hard on cast iron. It is done all the time. My son's home is set up with a cast iron boiler on cold start, and that boiler is over 30 years old with many more years of life. but your boiler outside may be a good idea to maintain some temperature when it is really cold outside.

I also understand unlimited fuel supply. I had an oil change/car wash client that had 1000 gallons of storage and about ten 55 gallon drums of waste oil, and still needed to pay someone to remove waste oil at the end of the summer. I suggested that he operate the waste oil boiler on snow melt if he needed to make more room for waste oil.

I have an idea that may work for you. Since the heat exchanger and the combi are in the same system, you will want to have that one thermostat operate both boilers, with the free oil as priority and the gas boiler as a backup. I don't believe the time delay is the way to go. I think a staging control is a better idea. But having 2 WiFi thermostats may be a good option too.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

-

The Idea of using the Oil Boiler to maintain a 160°F temperature and also operate the oil boiler circulator to keep the heat exchanger charged with 160° water will use more fuel but that seems to not be an issue. The only cost is the time it takes to do the transferring of the oil to a tank that you can use. I might set up a 275 gallon so you don't need to deal with totes every week or so. Spend a short day filling that tank so you have several weeks of uninterrupted fuel usage. The other cost is the electric needed to operate the burner and circulator pump. Not a lot of cost there either. I'm sure you already have that part figured out.

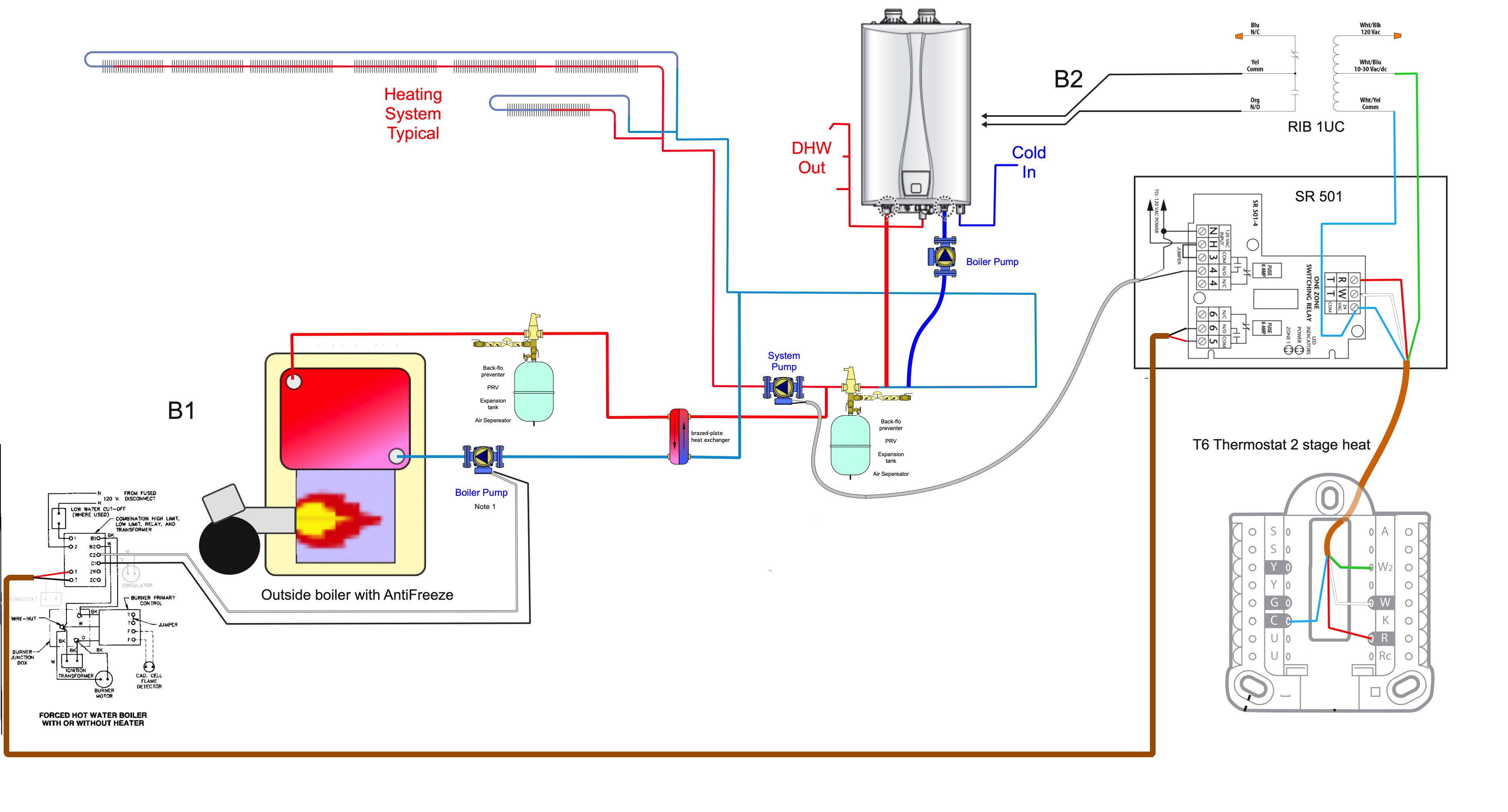

If your T6 is a two stage thermostat, then you may have almost everything you need. You will just need to add a RIB U1C relay. The relay that the thermostat is currently connected to might be a Taco SR501. If it is a different one that is OK too. I'll substitute the one you have when you get back and let me know the part number.

the RIB relay will act as the stage 2 thermostat relay to operate the gas boiler and the Taco SR 501 will act as the first stage relay to operate the system pump and the oil fired boiler.

If this wiring arrangement turns your oil boiler into a cold start boiler then we will need to add an aquastat to maintain boiler temperature If you want to do that. If your boiler already has a low limit feature, then that control will maintain a minimum boiler temperature that you can set at 120° to 140° without the circulator operating. You can then operate the boiler by the thermostat with a high limit of 170° to 180° when the circulator to the HX is operating.

This is the wiring diagram that I might recommend. I'm not to sure about how your piping is connected, but you should have a system circ pump, and a boiler pump for each boiler. You may even have another pump from the oil boiler HX to the system, and I can make that circ pump operate with the oil fired boiler if needed.

If your actual controls are different, I can re-do the diagram with your AS BUILT specifications.

The Sequence of Operation will be on a call for heat from thermostat stage 1, the oil boiler (boiler #1) will fire from the low limit base temperature of 120° and be allowed to get as hot as 170° before the high limit cuts off the burner. The call for heat from stage 1 will also operate the #1 boiler circulator pump and the system pump until the call for heat is satisfied (Even if the boiler is off by the high limit). If for some reason the oil boiler fails to maintain the room temperature for any reason the second stage of the thermostat will kick in and the gas boiler will automatically heat the system and the #2 boiler circulator and system circulator will operate to heat the home.

This is a better way to operate your system using staging and if you already have the proper parts, you may just need the inexpensive relay to complete the job.

Looking forward to finding out what controls and relays you already have.

Mr. ED

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I'll share photos when I get home next week.

Want to keep oil boiler fired as the lost heat off it will keep the connex warm.

May end up putting a heater in there, but I'm thinking just the heat off the boiler and piping will be enough.

Oil stays in the totes. 2 totes in the connex in a big catch pan. 1 being drawn from, the other warming up ready to go. Just forklift them in.

0 -

The floor heat and combi already exist and currently are the heat setup.

The oil heat I'm adding. Currently planning and parts gathering.

Was to be done this year, but it'll be freeze up in another month and I've got other commitments, so likely next year.

0 -

So the piping between the HX and the existing system is still to be done?

There is someone here that can help with the best design for that. There is an issue of Idronics published by the Caleffi company that has a lot of information on outdoor boilers (mostly wood boilers) and how to connect them to an existing working heating system. If you can confirm that your system contains different types of heating emitters, like radiant floor heat, or baseboard, or convectors. Can you also take photos of the way the near boiler piping is connected, so we can be sure it is connected properly.

Here is the link to the info about how to connect an outdoor boiler using a heat exchanger.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Just is floor heat in a 30x42 building. Well, and hot water in the combi side for the sinks and shower. I'm leaving that gas only as it wouldn't pay out to add a boiler mate off the oil... several thousand in parts to save maybe $150 a year.

0 -

I'm not able to edit... this site is terrible to use on my phone! Wanted to add...

Gas boiler is a standard primary/secondary setup with the integrated boiler pump and a Grundfos 3 speed on the secondary.

No zones.

0 -

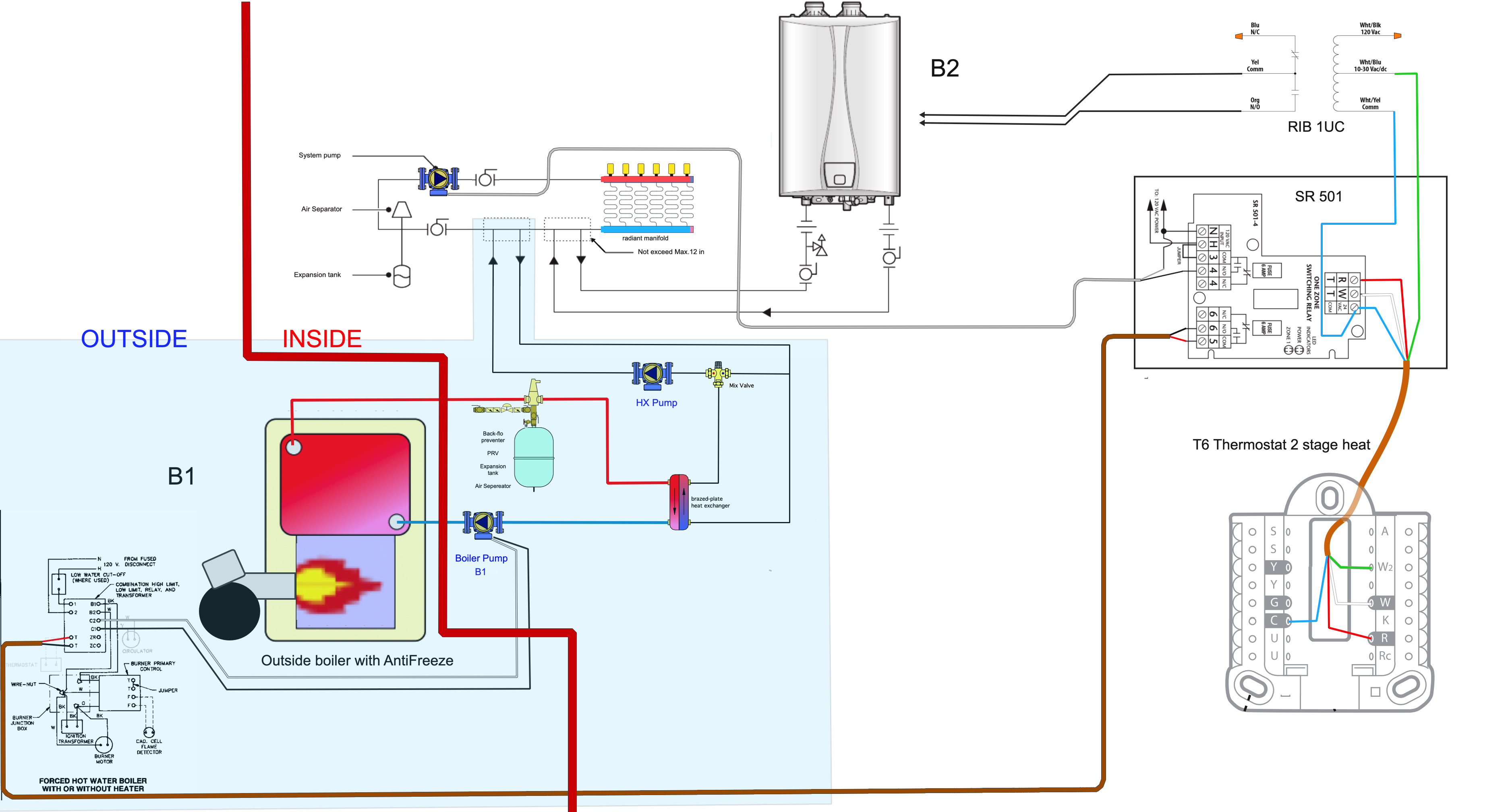

So you have a low temperature radiant floor system that is properly installed according to the VESTA manual. That should have a high temperature of about 120° to 125° to operate properly. The OIL boiler will operate at a minimum of 140° and stay at or above that temperature based on what control you have, because that is cast iron and you don't want to experience flue gas condensation on a regular basis. That makes sense. Now you need the HX to convert that 140° or higher temperature oil boiler water to 120° for the space heating part.

This is easy with a inexpensive mixing valve when it is time to connect the plumbing to the outdoor oil boiler & HX. The wiring will still be similar, you may need 2 circulator pumps to move the heat from the oil boiler to the HX and from the HX to the system. I'm going to suggest a piping arrangement but @hot_rod Bob Rohr is the expert on the piping side. He will keep in mind that your are not interested in adding expensive hydronic components. He can design the best piping connections.

Can you let us know what piping components you already have? The Boiler obviously, and perhaps the properly sized HX. Do you already have any circulators or mixing valves that you plan on using to connect the "free fuel" waste oil burning system to the radiant floor system. Also sizing is important. So the model number and size of the HX and any other hydronic accessories you have will be helpful.

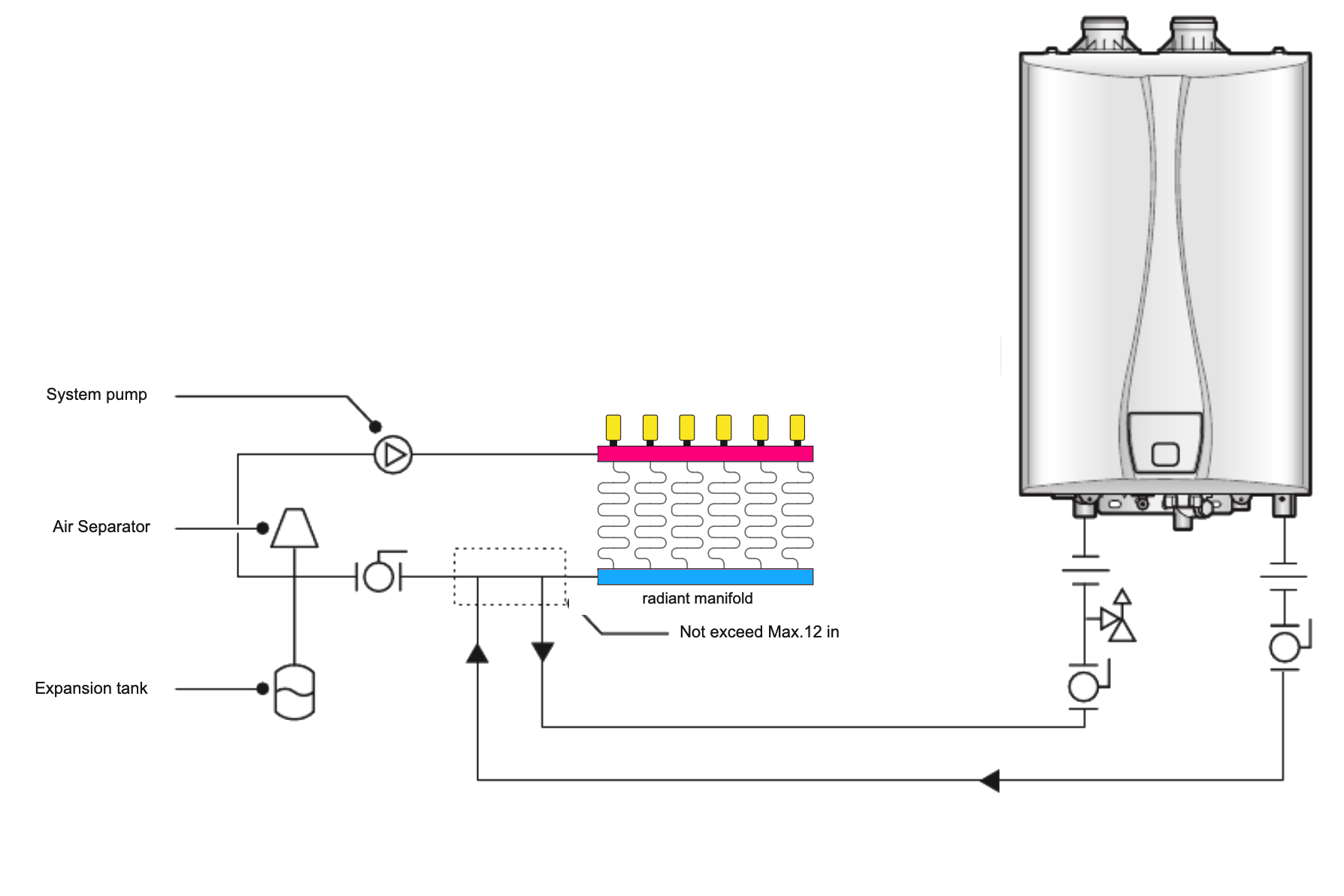

Here is a basic piping design that will get you where you want to be with the lowest cost components. Bob may have improvements. The wiring design still looks good for this arrangement. I just need to bring on the HX pump with the outdoor boiler call for heat. The outdoor boiler pump will operate whenever the oil boiler is firing so the water circulates to the HX which should be located inside the Vesta gas boiler room.

The blue shaded area is the oil boiler additional piping added to the Vesta boiler's I/O manual drawing for a one zone system …where I added the radiant heat emitters and removed the baseboard emitters.

EDIT: I might make a note here that both boilers will not run at the same time. This piping is for an either or scenario. The Gas boiler will come on when the oil boiler fails to operate by the second stage of the thermostat. That will usually be when you run out of fuel or if there is a flame failure condition with the outdoor waste oil boiler. The Combi boiler will operate as a backup. I would change the system connection for the HX if both boilers were designed to operate at the same time in order to maximize the output of both boilers.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Ed's diagram above is certainly an option, but is a bit more complex than it needs to be. The additional circulator and hydraulic separation for the HX really does not need to be there if manual bypass or backfeeding is desired. Also you wouldn't necessarily need a tank for DHW- a simple plate HX in the oil boiler loop would effectively do the same job as your combi is doing.

0 -

I have a circulator, I think a Taco 007 that's on the oil boiler. (The boiler is used and came with a few odds and ends)

Otherwise I haven't bought anything.

Was guessing a 5x12 30 or 40 plate heat exchanger would be fine, but I've spent hours researching and not gotten good info.

0 -

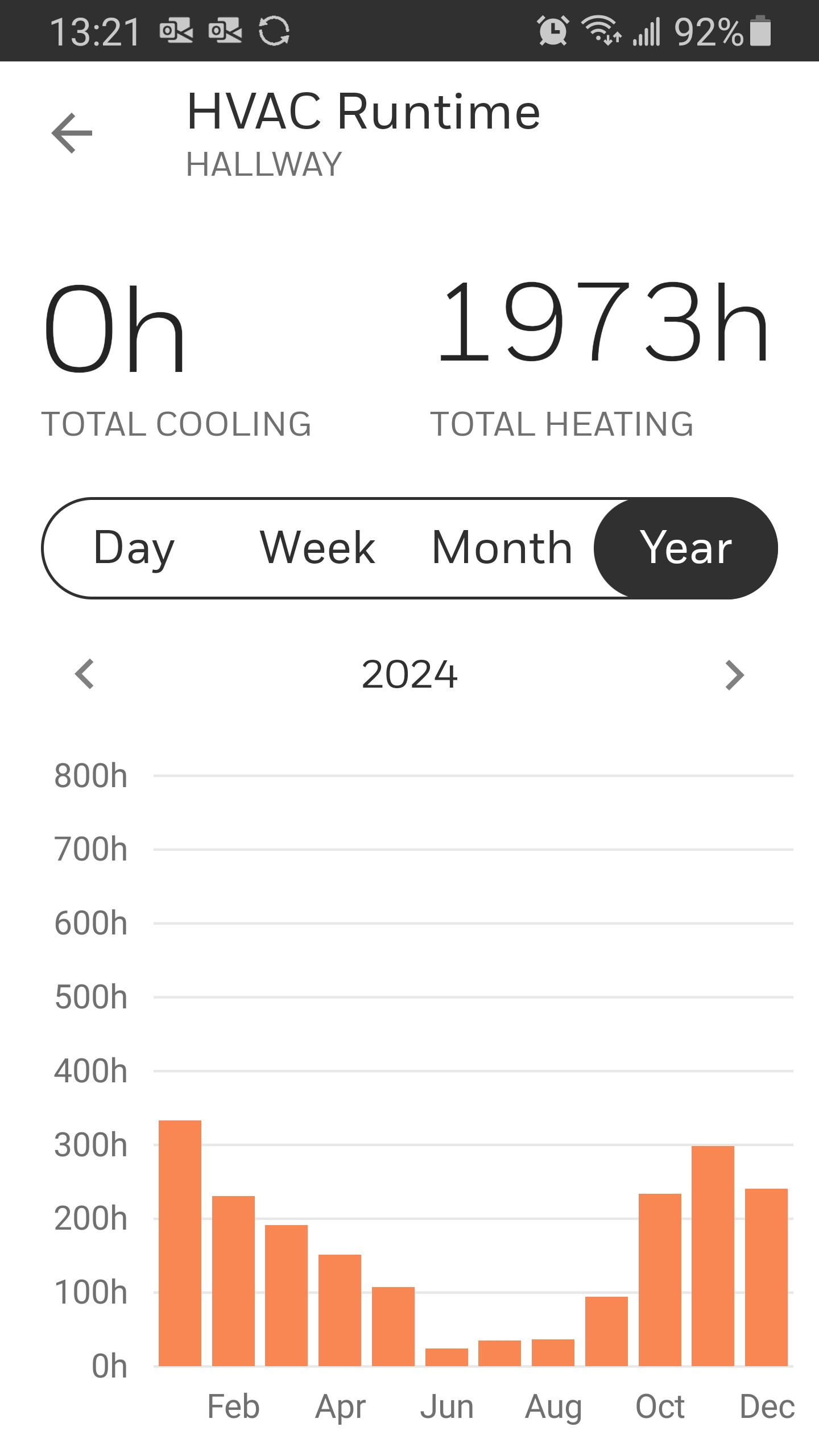

Current setup I run at 110* in the spring and fall and 130* in winter.

Building isn't insulated that great. Also the circulator has been running on low, I'm going to try kicking it up. My thought was slower flow equaled more time for the heat to go ino the slab, but it seems higher flow would mean hotter water getting to the slab and more BTU/hr available.

As is, I've not felt the system wasn't enough for keeping the place at 68*. Even though I'm sure it's not by the book, as the guy that built the place was a cheap hack.

0 -

Selecting a Flat Plat heat exchanger can be challenging. @hot_rod can usually help in this area. Knowing that the oil fired boiler will be producing a minimum of 140° with a high temperature of at least 160° is necessary in the calculation. The amount of heat needed to heat your space is also needed. Does your 80,000 BTU Vesta boiler have any problem heating the home when it is very cold outside? The flow rate through the HX on both sides are needed to exchange the proper amount of heat. Bob will have some questions for you when he checks in.

Bob may have a better design for connecting the HX to the existing boiler system. He needs to know that it is properly connected and designed. I would guess that the original installed used a piping design close to something like this.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Yes other than it's got no automatic air seperator. I have to use a pump and cycle water through a fill and purge port.

Originally it wasn't even a primary/secondary. but that boiler (Baxi) failed shortly before I bought the house.

I talked to the installer and he agreed it wasn't right. Because that was the only thing stopping the sale and the family was hurting for $$, they didn't argue over spending a bit more to make me happy.

0 -

-

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements