What size pex tubing do you recommend?

This fall I will be tearing out the concrete for 3 car wash bays and redoing the radiant floor heat lines with O2 barrier PEX. The old concrete is falling apart and needs to all be replaced.

What size pex would be best? I was thinking to do 1/2 ID but also know that 5/8th inch pex delivers more BTUs efficiently.

Each bay is 33 feet by 18 feet. There are 2 bays west of the boiler room and one bay to the right of the boiler room.

This is just a snow melt system. I'm leaning towards doing 6 inch on center spacing but also considering doing 9 inch spacing.

Thank you for all the help!

Comments

-

-

Tube diameter has little to no effect on BTU output per SQ FT if properly installed. 1/2" is cheapest and easiest, and with only ~1800SF, 5 loops per bay at 250ft each w/ 6" OC is going to be more than adequate. There is absolutely no reason to run larger diameter, and anything wider than 6" OC would be a mistake.

0 -

So, each bay is 600 square feet x 125 BTU/square foot = 75,000 BTU. And you think that would work with ½" PEX?

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0 -

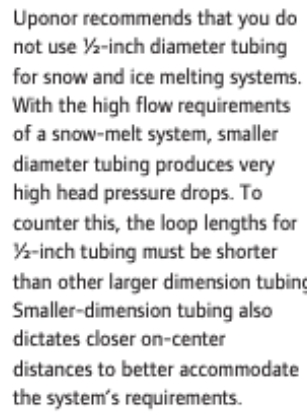

You need to move a lot of BTUs of cold glycol in a SIM. Uponor suggest 5/8 or larger tube. 1/2 maybe for some stair treads where loop lengths are very short, you need a tight spacing.

Assuming the bays are covered you are designing more of an ice removal or anti-icing protection system, no real snow load to speak of.

So the tube and spacing as well as loop length dictates and SWT/ gpm dictates how many BTUs you deliver.

All the info about SIM design here.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

125 BTU/SF is more than double what's needed to prevent ice buildup inside a wash bay (I own a 2 bay car wash and have installed radiant floors in roughly 20 others as well). With that said, yes; 1/2" would easily cover 125 BTU/SF. Tubing diameter matters not; tubing quantity is what makes the difference. 1/2" at 9" OC will put out roughly the same amount of BTU as 3/4" at 9" OC, the only benefit to larger diameter is slightly longer loops.

0 -

What delta do you design at?

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0 -

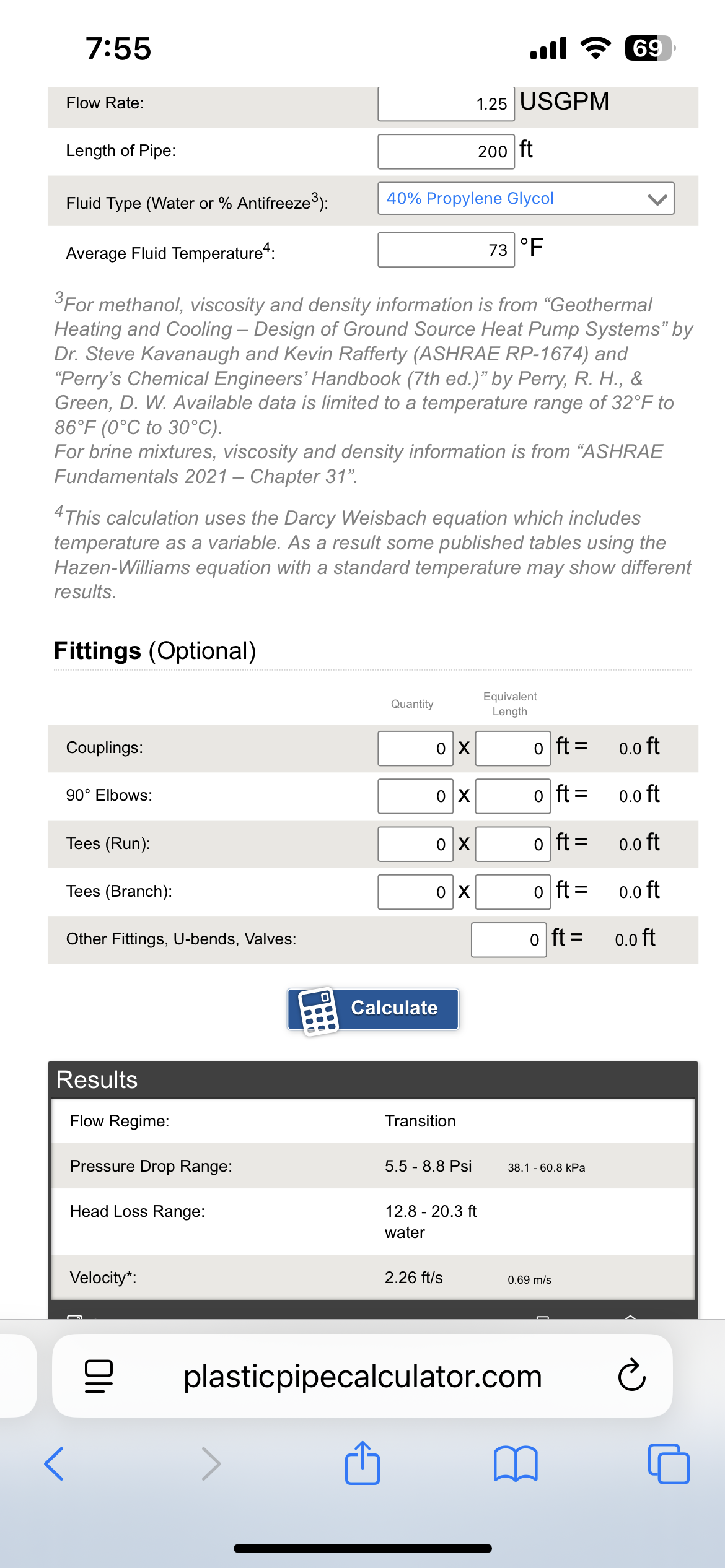

1.25 gpm, 200’, 1/2” loop with 40% PG around 20’ head

300’ of 3/4 is about 1/2 that at 2 gpm

pex manufacturers will do a design for you based on your location and needsBob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

With a cold start SIM system, a 20* delta is largely ridiculous to get any amount of BTU output regardless of tube size. Space heating, sure- but a cold start snowmelt will almost never hold a 20* delta while also doing its job properly. 50+* is not uncommon and there is absolutely no downfall to doing that, quite the opposite in fact. Maximized BTU output with minimized upfront cost and the highest possible efficiency, all great things.

With that said, car wash systems typically don't need more than about 40-50 BTU/SF to keep the pads clear unless they never close the doors. Any respectable car wash closes down at about 0*, so my suggestion of 1/2" at 250ft is only a 15* delta at .8 GPM per loop, yielding 50 BTU/SF. This is not rocket science, guys.

0 -

Thanks for your patience in dumbing it down for us addled brainers, @GroundUp.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab1 -

As I'm sure you are aware, tube diameter is not really relative to BTU output. A 1/2" tube at 100* will put out an almost identical amount of BTU to 3/4" at that same 100* in the same slab. 1/2" tubing at 6" spacing will put out considerably more BTU than 3/4" at 9" spacing, assuming the same temperatures which obviously vary by flow rate. Pressure drop in 250ft of 1/2" at .8 GPM is about the same as 375ft of 3/4" at 2 GPM so while there is potential to carry more BTU with the same pressure drop and fewer loops, larger diameter tubing does nothing for actual BTU output after the dust is settled if spacing and delta are equal. I would personally rather fight 1/2" at 6" spacing than 3/4" at 9" spacing, but maybe that's just me.

Now if it's a large space like a 5000 SQ FT driveway with a 150 BTU/SF load, I'm all aboard the 3/4" train. In the case of a car wash however, there is not a chance I'm wrestling 3/4" when 1/2" is better from all aspects.

0 -

Missing from this discussion is an accurate load. Is it 50 or 150 btu/ sq ft?

50 btu/‘ is a leaky or uninsulated home in New England🧐

A hand wash bay without any doors, a wind tunnel, probably 100 btu or more.

Location and typical winter temperatures goes into a design

Large pex allows more gpm.= more btus transferred. That is why pex comes in multiple sizes

You get one chance to get the tube right. Compromise and go with 5/8

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

Yes, we would obviously need more details if it's not a regular car wash bay that gets shut down at a given temp, but that does not negate the fact that larger diameter tubing does not equal more BTU output per square foot. 1/2" at 6" spacing offers more BTU output capacity than 3/4" at 9" spacing, no matter how you slice it.

0 -

in that size bay, call it 600 sq ft

3 - 300’ loops of 3/4, 9”oc $450

6 - 200’ loop of 1/2, 12” oc $360

using BlueFin heat pex online prices

The 1/2 will take 6 port manifolds m, more connections, more ties and more install tie labor

So $$ wise the 3/4 may be cheaper to have installed

2 gpm in the 3/4 and 1 gpm in 1/2 is a wash on pump head, 12’ at 30% PG

The output of a sq ft of concrete is based in its surface temperature. The 3/4” can move twice the flow to warm that sq ft.

So knowing the btu load is important in the decision making

If the 1/2 under performs you don’t have much wiggle room other then over-pumping the tube. A high head circ and excessive flow velocity for a small improvement

If the $$ is the same, or less, then 3/4 makes the most sense

Since the load at this point is a WAG, 3/4 give you more performance potential

Few if any radiant pros are unable to handle a 9” 3/4 pex/ slab install install. It is easiest in warm weather😎

Insulate under the new pour for faster recovery and lower operating cost

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

You're comparing apples to oranges, Bob. 6" spacing WILL allow more BTU output per SQ FT than 9" spacing. Period. Tubing diameter is irrelevant for the sake of this discussion. On that note, I'm not sure which Bluefin tubing you're looking at, but 1200LF of 1/2" at Supplyhouse is $280 not $360. 6 loops of 1/2" would be considerably less labor than 3 loops of 3/4". I will wholeheartedly agree that 1/2" is not the answer for every application and have mentioned that several times now, but having done this very task many times in one of the coldest areas of North America on top of personally owning a car wash which this post is specifically geared toward, I will say one more time that 1/2" at 6" spacing is the most feasible option here. It's cheaper, easier, and will outperform 3/4" at 9" spacing all the way around. The bays (2) in my personal self-serve wash are 14x42 and utilize 5 loops of 1/2" at 6" OC, 250ft each, with a 4ft heated entry/exit pad. Mine is automated (as most are, at least in my area) to shut down when outdoor temp falls below 0*, and the pump will not start until the door is closed when it's below 32*. We've had a few automation failures over the years where the doors don't close, or those fun days when it goes from 40* to 0* in 2 hours during a blizzard, and not once in 6 winters now has there been any ice accumulation. I run this on a basic Tekmar 519 stat with the floor sensor set to 50*, with an 80k Lochinvar Noble (so roughly 60 BTU/SF max capacity) set to 90* using P/S piping, and very seldom does it see high fire.

0 -

@hot_rod @GroundUp thank you for taking the time to help on this project. I really appreciate it.

Some more information: This is in Michigan with an average winter temperature in the 20s. Each bay is enclosed by 3 walls with the 4th being the opening to the bay. There is no door, it is constantly open to the elements on the opening to each bay.There is a roof to prevent most of the snow from entering the bay but some does blow inside with the wind. Also each car that uses the bay blows off piles of snow that needs to be melted from the floor heat.

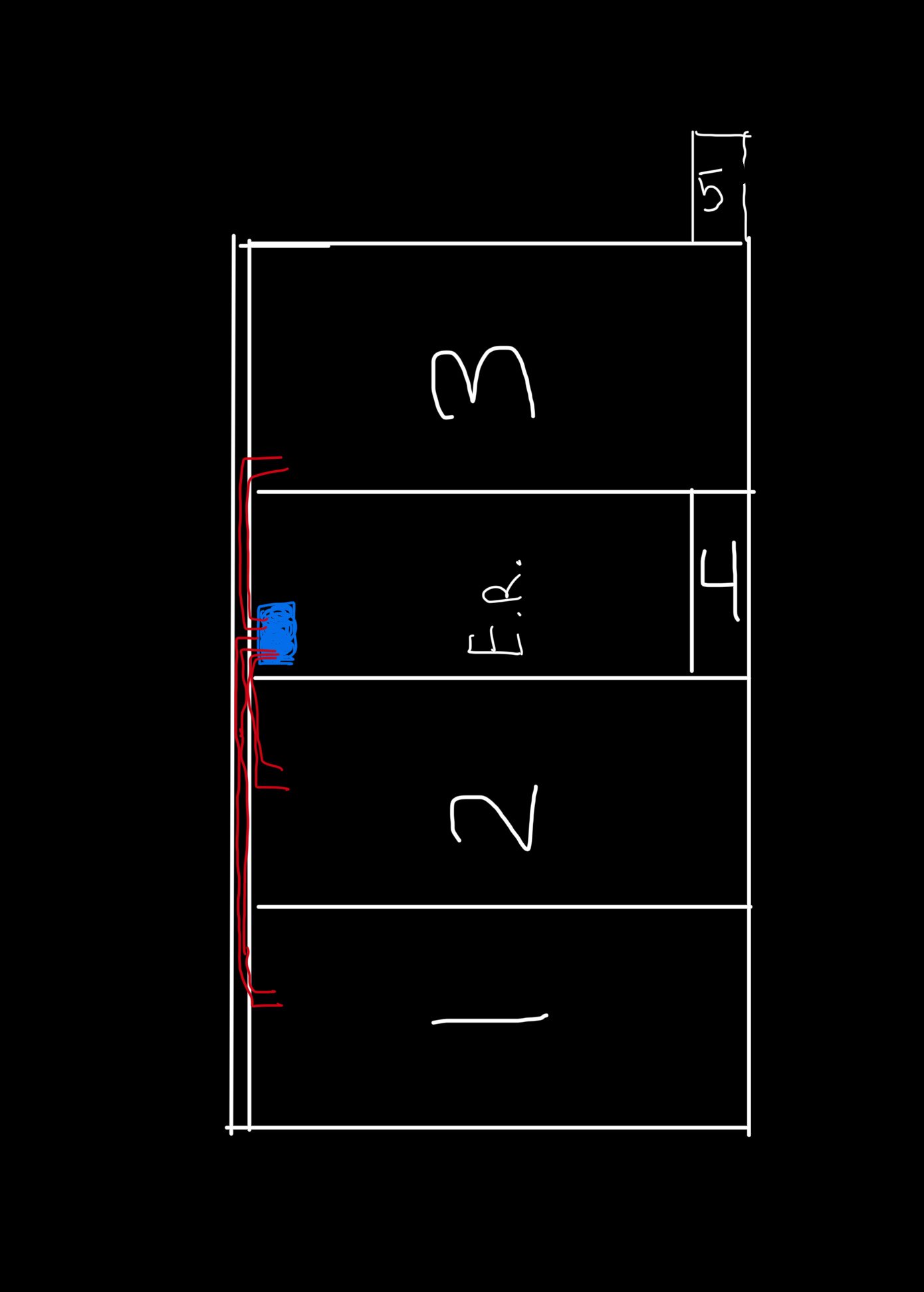

We will be pouring a 6 inch pad with R10 insulation at the bottom of the slab.Below is a picture of the layout with the bays labeled 1, 2, and 3. Areas 4 and 5 are where customers can walk to for vending items and will be heated as well. The label of E.R. Is the equipment room in the center of the building.

I have colored in the blue area for where I would like to put the boiler. The red lines and where the pex will be running out to the bays. There are paver stones in that small gap leading to each bay that I can remove to lay down the pex and make the runs into each bay.

Total is 1900 square feet.Currently I'm torn as do either 1/2, 5/8 or 3/4 pex. And then depending on the size whether to do 6 inch or 9 inch spacing.

0 -

You could contact any of the tube manufacturers or reps or most wholesales for a design, if you want another opinion. They do this all day for a living.

I think @GGross covers michigan as a supplier with hydronic experience. Buy from him if he does a free design😏

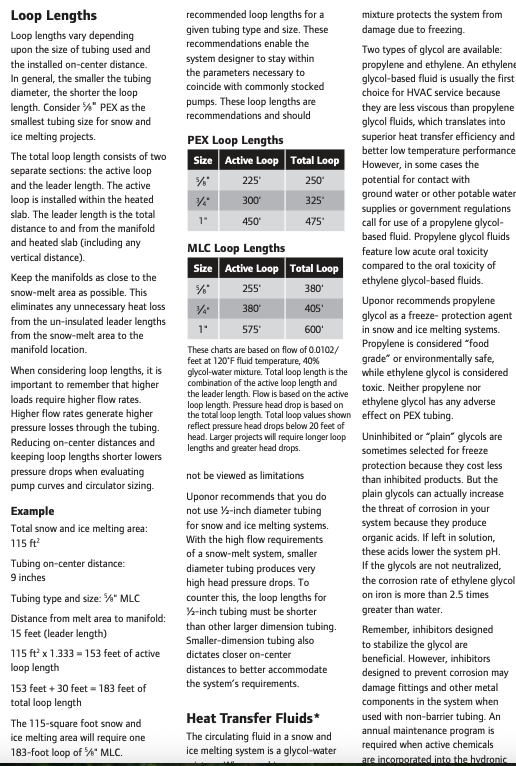

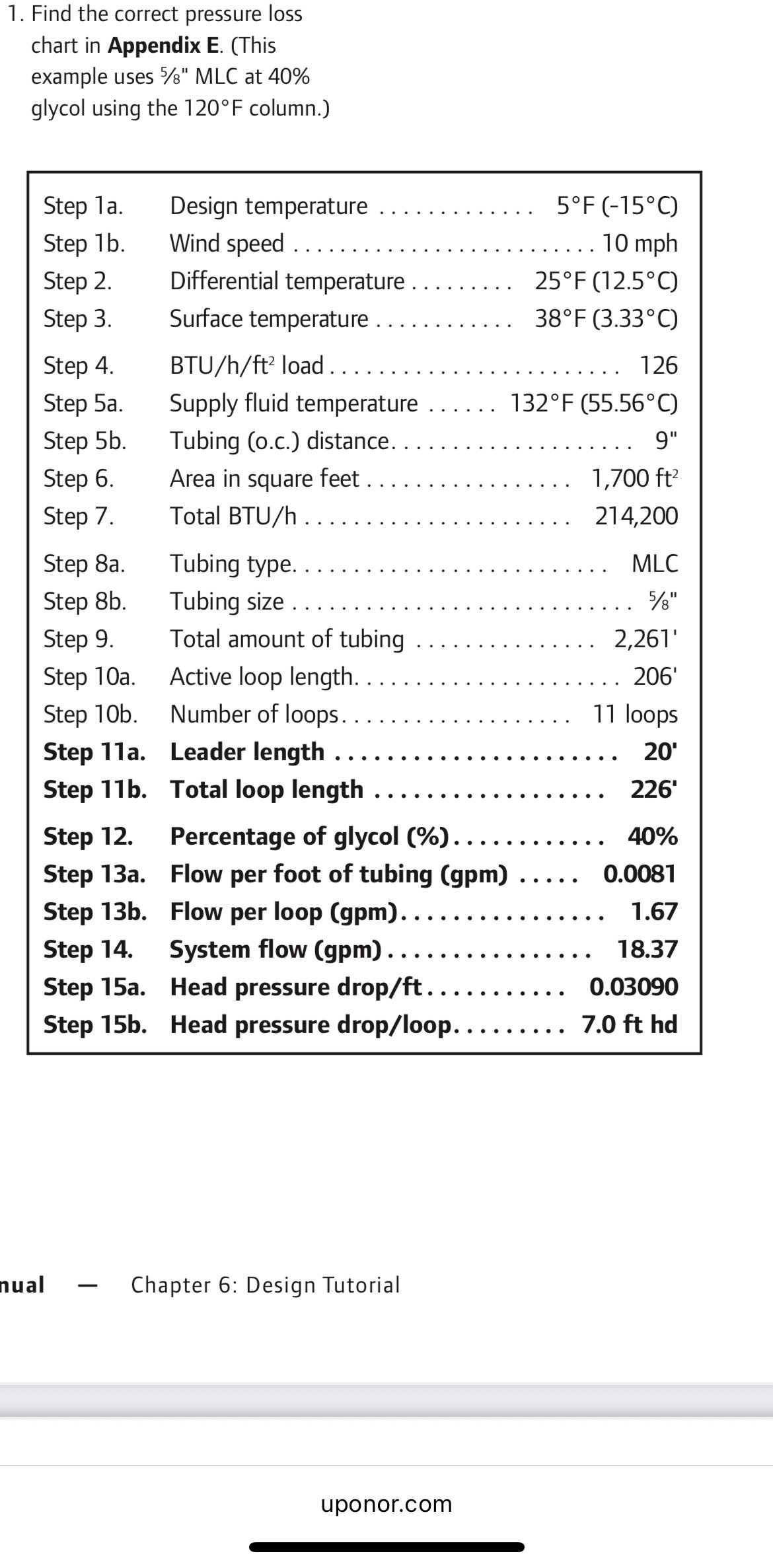

Here is a design from that Uponor design SIM (snow ice melt) book that is fairly close, for an example.

You have a bit more square footage so call it a 240,000 load

126 btu/ ft at a 5 degree design, 5/8 tube, 9” oc

I think something like 2700’ of 5/8, 12 loops at 225’ Bay 1 will take more leader length, bay 2 hardly any. A loop layout design will show this

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Once again, 6" spacing will always have the ability to put out more BTU than 9" spacing. Personally, I wouldn't even consider 9" for a SIM system. Given the lack of doors, I think you might be unpleasantly surprised with the fuel usage for this system, but I would still lean toward 1/2" or possibly 5/8" tubing. There is absolutely no reason to wrestle 3/4" in such a small area, and 6" spacing is all but impossible. At least 5/8" you can still catch 6" spacing if you're careful.

0 -

I assume liability, slip and fall, is a concern so you want an ice free bay. Why else spend this kind of installation and operation $$?

My suggestion is to design for 125 BTU/ sq ft. You can always run the system at a lower delivery rate. But if you under design or install inadequate btu delivery, not much can fix that

So agree on a potential load 237,000 btu/ hr.?

A modulating condensing boiler will adjust based on the changing load. On milder days it will ramp back its output. It will run mid to high 90% at these operating conditions

Now that 237k load needs to be divided by the loops and the btu they can carry

12- 1/2” loops need 1.6 gpm per loop to move 237K. Agsin using the PPI calculator

With 40% glycol at 60f, in a 200’ loops that will take an expensive high head circ. This is one reason that SIM generally uses larger tube, minimize the pressure drop that the cold glycol penalizes the flow.

The pump cost difference alone will offset the tube cost difference.

The longer loops help with coverage also as you burn up loop length traveling from manifold to bay. A 200’ 1/2” loops will not get you as much coverage you end up with 24 runs clustered at the manifold. The loopCAD will show this congestion

Search around, all the major tube manufacturers have some design examples online

The non biased PPI, has a easy simple SIM calculator also, link below

An example of their design attached, again with 3/4” at 8” oc

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

@hot_rod in what world does SIM need a 20* delta? Twelve 1/2" loops at .8 GPM with a 50* delta is 240k. I'm not here to argue or complain, but let's be realistic here. 130* SWT w/ 80* RWT is still going to melt the same amount of snow as 100-80 with a 2.5x flow rate. If I'm not mistaken, I believe I've seen you mention more than once the superior European method of a high delta system. We've adopted 20* as a baseline (mostly because it's easy to calculate), but from a practicality perspective, it serves no purpose in a snowmelt system.

1 -

And I'm not arguing that a piece of concrete will melt snow or ice regardless of the size of, or spacing of, tubing in it.

I agree with that and have for years promoted tight 6" spacing, 10- 15 ∆ in residential heating, specifically for comfort, quick ramp, and lowest SWT. I don't see these 6" tube spacing numbers numbers being critical for SIM design.

My point is larger tube give you more BTU capacity, longer loop length, less pump power requirement. I doubt many are barefooted in carwash bays in the winter??

All I suggest is the OP read some of the attached info I present.

I suspect the screenshots I offered throughout this post were generated in SIM software from Uponor, PPI, Rehau, others.

There is no specific way SIM HAS to be done. But there are industry guidelines based on hundreds of systems that perform to expectations.

The tube size recommendations, the 25-30 delta, tube spacing, loop length, SWT, flow rate, etc, etc all come from the manufacturers design example. These are not numbers I'm pulling from thin air.

When you have a load calc done by one of the reps or manufacturers, and sign off on the assumption doc., they guarantee the system will perform as designed.

If someone designs for a 25- 30 and only attains a 50∆, they missed something. A 50∆ in a 200' loop seems awful high?

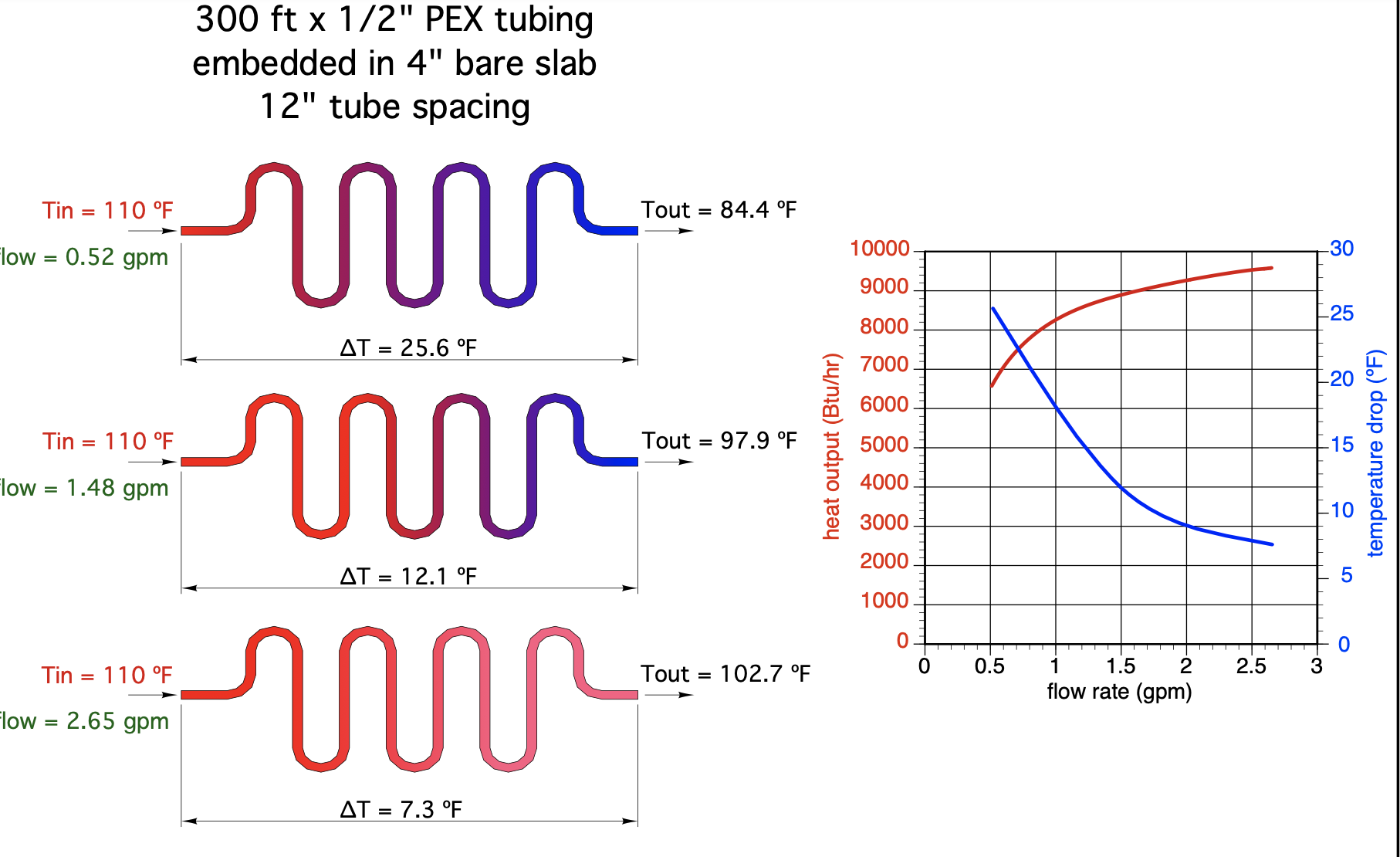

While running tighter delta increases the slab btu output a 20∆ probably isn't juice worth the squeeze for melting snow, considering the pumping power required to get there. An example attached of 3 different ∆Ts and their output change. Same SWT in all cases. I'm seeing a specific pattern from the 3 or so examples I have shown which is 5/8 or 3/4 tube size, 25- 30 delta.

( a heat transfer demo example, not intended for a SIM design) Tighter ∆ obtained by higher flow rate= higher BTU output in the loop and section of slab it is in. You would see the same variance if you plotted a 20, 30 and 50∆ for a SIM example. Which is why I suspect the industry looks at 25- 30 ∆ in SIM designs, reasonable output, reasonable pump requirement. Which is mentioned in all the manufacturers guidelines.

Pinning down the BTU required for the OP specific job is best accomplished by the industry guidelines, in my opinion.

I did check around some carwash forms and found even wilder suggestions of 100,000 btu/hr/ bay!?

Although in the OP case the 125 btu/ hr I suggested comes out to 75,000 BTU/hr. per bay. A bit shy of what the owner/ operators on those forums suggest.

Granted these attached designs are snowmelt, the concept of melting snow or warming a slab to melt ice, and turn to liquid, or keep the floor ice free, maybe even dry after evaporation, within the same temperature ∆ would be similar in my mind. At days end we are trying to keep the slab surface around 38°F at a specific OAT.

Digging deeper at all the manufacturers sites may turn up a 3 walled carwash specific design. My money suggests they would be 100 btu/ft or higher designs.

Don't shoot the messenger, I'm just parroting readily available, industry accepted numbers and suggestions.

I suppose 1/4 copper tube loops 25' long at 2" OC could be made to work also😉

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements